Preparation method for lubricating oil composition containing ionic liquid, modified nanometer copper powder and graphene

A technology of lubricating oil composition and nano copper powder, applied in lubricating composition, petroleum industry, additives and other directions, to achieve the effect of enhancing dispersion stability, solving dispersion difficulty and improving dispersion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

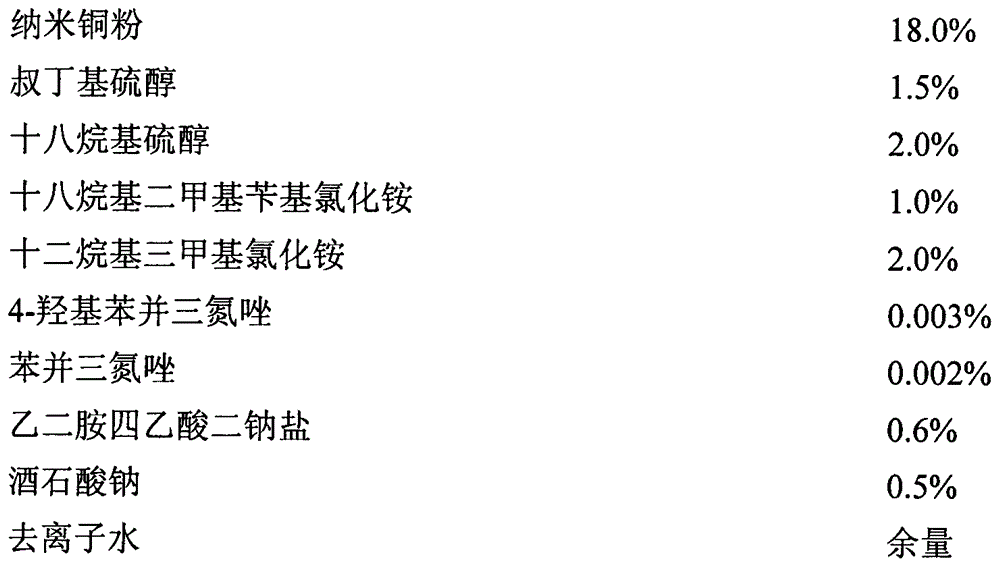

Embodiment 1

[0037] Preparation of modified nano-copper powder:

[0038]

[0039] According to the above mass percentage, tert-butyl mercaptan, octadecyl mercaptan, octadecyl dimethyl benzyl ammonium chloride, dodecyl trimethyl ammonium chloride, 4-hydroxybenzotrimethyl ammonium Azole, benzotriazole, disodium ethylenediaminetetraacetic acid and sodium tartrate were added to deionized water, stirred for 0.2h under the action of ultrasonic dispersion with a frequency of 20kHz and a power of 1kW, and then added nanometer copper powder, Further, under the ultrasonic dispersion with a frequency of 20kHz and a power of 1kW, it was stirred for 5.0h, and then the modified nano-copper powder was obtained through centrifugal separation, deionized water washing, centrifugal separation, vacuum drying, grinding and sieving process, and obtained The modified nano-copper powder is used for subsequent use;

[0040] Preparation of lubricating oil composition:

[0041]

[0042]

[0043] According...

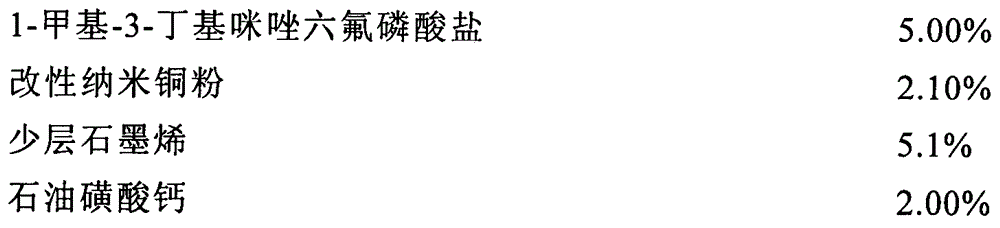

Embodiment 2

[0045] Preparation of modified nano-copper powder:

[0046]

[0047] According to the above mass percentage, n-butyl mercaptan, phenethyl mercaptan, dodecyltrimethylammonium bromide, tetradecyldimethylpyridinium bromide, hexadecyldimethylbenzyl Ammonium bromide, methyl benzotriazole, sodium citrate and potassium tartrate were added into deionized water, under the action of ultrasonic dispersion with a frequency of 28kHz and a power of 5kW, after stirring for 0.4h, nano-copper powder was added, further Under the ultrasonic dispersion with a frequency of 28kHz and a power of 5kW, stir for 3.0h, and then obtain modified nano-copper powder through centrifugal separation, deionized water washing, centrifugal separation, vacuum drying, grinding and sieving. Modified nano-copper powder for standby;

[0048] Preparation of lubricating oil composition:

[0049]

[0050]

[0051]According to the above mass percentage, 1-methyl-3-butylimidazolium tetrafluoroborate, modified na...

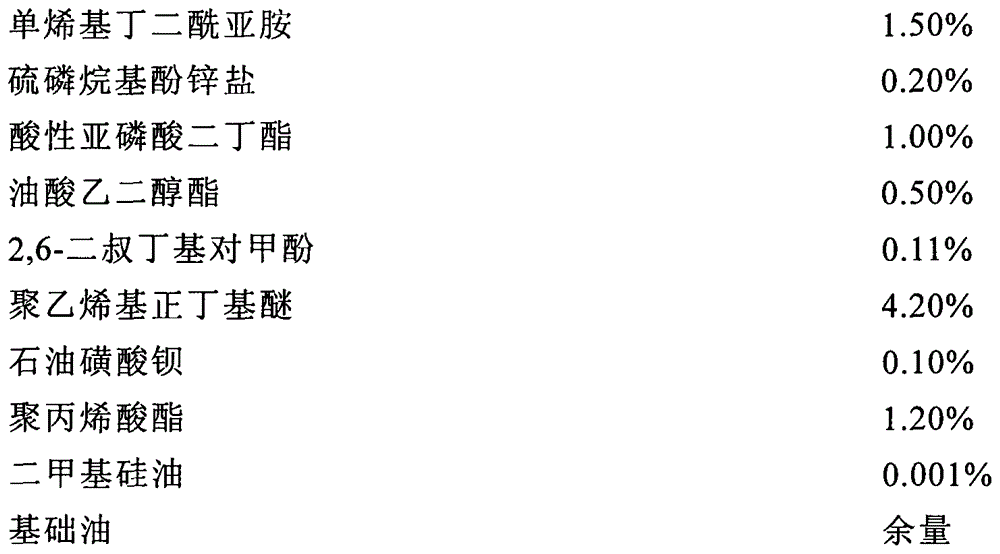

Embodiment 3

[0053] Preparation of modified nano-copper powder:

[0054]

[0055] According to the above mass percentage, n-dodecyl mercaptan, n-pentyl mercaptan, dodecyl dimethyl benzyl ammonium chloride, octadecyl trimethyl ammonium bromide, N-hydroxybenzo Add triazole, benzotriazole, disodium edetate and potassium citrate into deionized water, stir for 0.5h under ultrasonic dispersion with a frequency of 40kHz and a power of 10kW, and then add nano-copper powder, further stirred for 2.0h under the action of ultrasonic dispersion with a frequency of 40kHz and a power of 10kW, and then centrifuged, washed with deionized water, centrifuged, vacuum dried, ground and sieved to obtain modified nano-copper powder. The prepared modified nano-copper powder is standby;

[0056] Preparation of lubricating oil composition:

[0057]

[0058] According to the above mass percentages, N-butylpyridinium hexafluorophosphate, modified nano-copper powder, double-layer graphene, calcium alkyl salicy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com