System and method for centralized classification treatment of steel metallurgic dust mud

A technology for iron and steel metallurgy and dust sludge, which is applied in the field of comprehensive utilization and harmless treatment of solid waste in the metallurgical industry, can solve the problems of high investment and operation cost, inability to reuse the steelmaking system, high energy consumption, etc., so as to reduce the cost of ironmaking. and solid waste treatment costs, efficient recycling of resources, and low investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

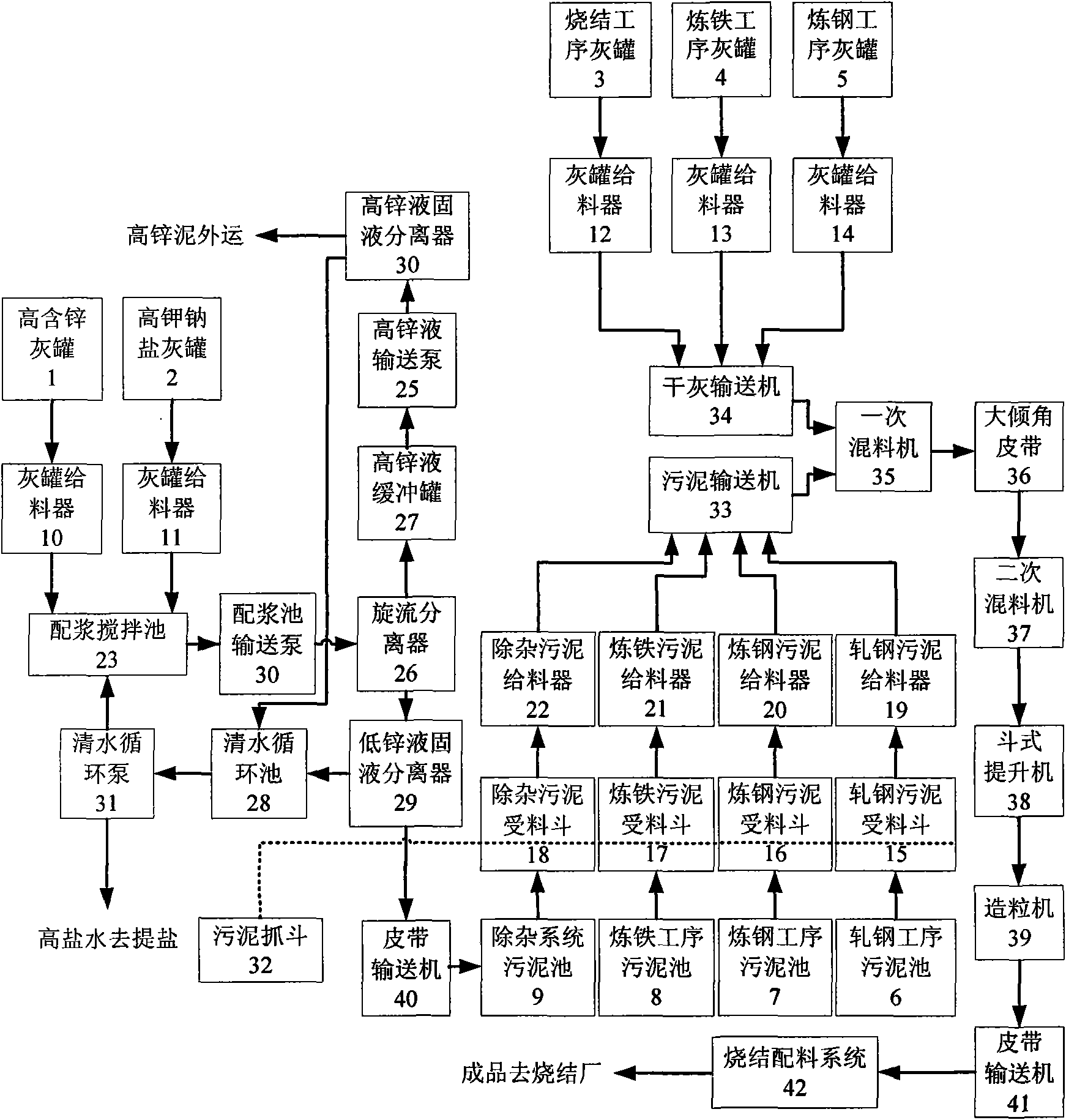

[0032] The realization steps of the present invention include:

[0033] 1. Unified classification and collection of iron-containing dust generated in the iron and steel metallurgical production process;

[0034] 2. Carry out integrated impurity removal treatment for the high-impurity materials in the dust;

[0035] 3. Mix and homogenize the low-impurity materials after removal of impurities with other dust and sludge in a certain proportion;

[0036] 4. The mixed materials are granulated to make sintered pellets, which are sent to the sintering batching system as raw materials.

[0037] The iron-containing dust and sludge include various iron-containing dust and sludge produced in the sintering and pelletizing process, the iron-making process, the steel-making process and the steel-rolling process.

[0038] The material with high impurity content refers to the material containing more than 2% zinc element and the material whose total content of potassium and sodium elements ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com