High-volume high-strength nickel slag brick and its preparation method

A high-strength, high-volume technology, applied in the field of industrial solid waste recycling, can solve the problems of large strength differences, consumption of nickel slag, low strength of nickel slag bricks, etc., to reduce transportation, reduce energy consumption and production costs, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

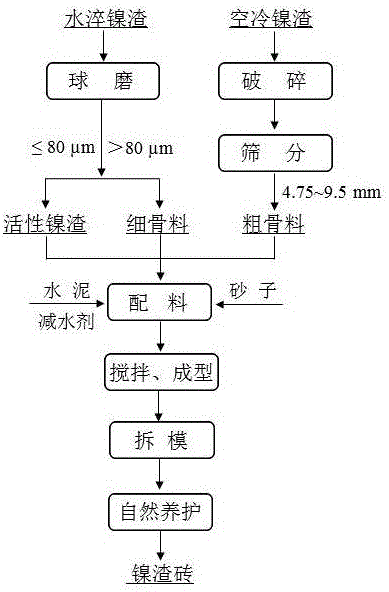

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: A kind of preparation method of the nickel slag brick of high strength with large dosage, is made by following steps:

[0040] Step 1) Put the water-quenched nickel slag produced after nickel extraction by pyrometallurgy into a ball mill for ball milling, control the mass ratio of nickel slag and balls to 1:1, and mill for 60 minutes;

[0041] Step 2) Put the air-cooled nickel slag produced after nickel extraction by pyrometallurgy into a jaw crusher for crushing, and vibrate the crushed air-cooled nickel slag through 4.75 mm and 9.5 mm sieves for 10 min;

[0042] Step 3) The mass parts of each component of the nickel slag brick are: 50 parts of water-quenched nickel slag, 25 parts of air-cooled nickel slag, 6 parts of sand, 9 parts of cement, the amount of water reducer is 0.08% of the cement mass, and 10 parts of water Specifically, 50 kg of water-quenched nickel slag, 25 kg of air-cooled nickel slag, 6 kg of sand, 9 kg of cement, 0.0072 kg of water redu...

Embodiment 2

[0044] Embodiment 2: A kind of preparation method of the nickel slag brick of high strength with large dosage, is made by following steps:

[0045] Step 1) Put the water-quenched nickel slag produced after nickel extraction by pyrometallurgy into a ball mill for ball milling, control the mass ratio of nickel slag and balls to 1:1, and mill for 15 minutes;

[0046] Step 2) Put the air-cooled nickel slag produced after nickel extraction by pyrometallurgy in a jaw crusher for crushing, and vibrate the crushed air-cooled nickel slag through 4.75 mm and 9.5 mm sieves for 1 min;

[0047]Step 3) The mass parts of each component of the nickel slag brick are: 55 parts of water-quenched nickel slag, 20 parts of air-cooled nickel slag, 6 parts of sand, 9 parts of cement, the amount of water reducing agent is 0.06% of the cement mass, and 9 parts of water ; Specifically, 55 kg of water-quenched nickel slag, 20 kg of air-cooled nickel slag, 6 kg of sand, 9 kg of cement, 0.0054 kg of water ...

Embodiment 3

[0049] Embodiment 3: a kind of preparation method of the nickel slag brick of high strength with large dosage, is made by following steps:

[0050] Step 1) Put the water-quenched nickel slag produced after nickel extraction by pyrometallurgy into a ball mill for ball milling, control the mass ratio of nickel slag and balls to 1:1, and mill for 30 minutes;

[0051] Step 2) Put the air-cooled nickel slag produced after nickel extraction by pyrometallurgy in a jaw crusher for crushing, and vibrate the crushed air-cooled nickel slag through 4.75 mm and 9.5 mm sieves for 7 min;

[0052] Step 3) The kilograms of each component of the nickel slag brick are: 60 kilograms of water-quenched nickel slag, 20 kilograms of air-cooled nickel slag, 5 kilograms of sand, 7 kilograms of cement, and the amount of water reducing agent is 0.04% of the cement mass, which is 0.0028 kilograms, 8 kg of water;

[0053] Weigh the required ball-milled water-quenched nickel slag, crushed and sieved air-co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com