Fatty boric acid phosphate ester and its preparation method and use of the ester to prepare micro-lubricating oil

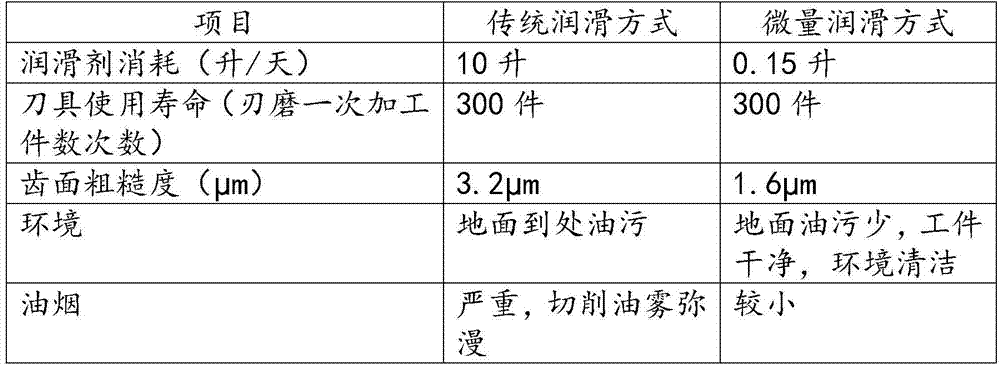

A boric acid phosphate fatty ester and lubricating oil technology, applied in the field of lubrication, can solve problems such as trouble adding water tanks, clogging of energy-saving nozzles, and abandonment by workers, and achieve the effects of good lubricating performance, good lubrication, and excellent anti-rust performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 85kg of oleyl alcohol, 8kg of phosphoric acid, and 7kg of boric acid and add them to the reaction kettle respectively, use nitrogen to convert the air in the reaction kettle, heat to 170°C, react for 10 hours, and remove part of the water generated by the reaction under reduced pressure, which is a kind of Fatty borate phosphate.

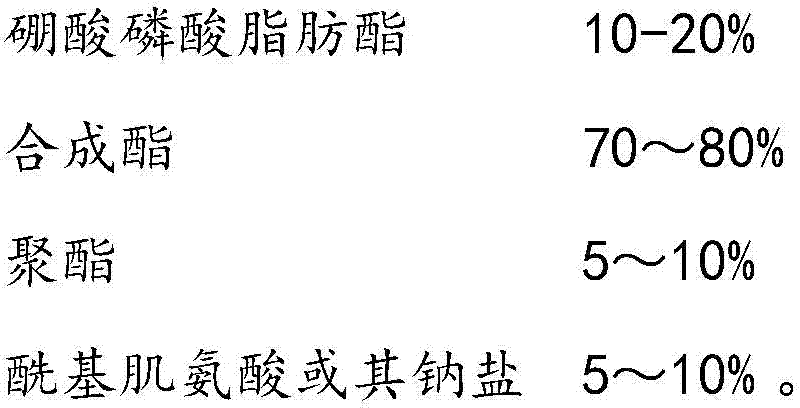

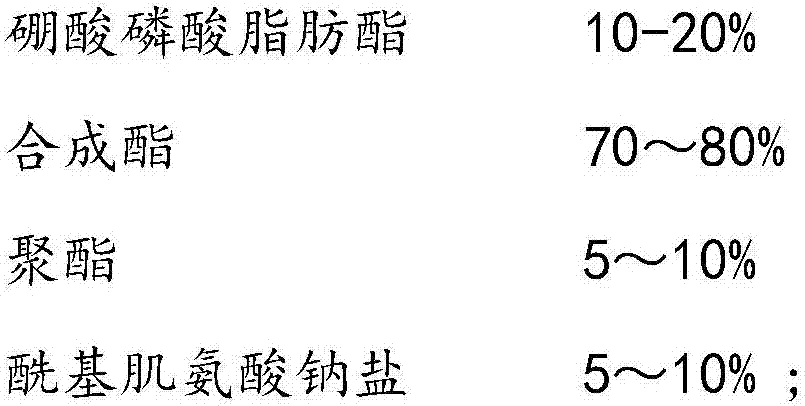

[0029] Weigh 15kg of boric acid phosphate fatty acid ester prepared above, 71kg of trimethylolpropane trioleate, 7kg of polyester (Priolube 3986), and 7kg of sodium lauroyl sarcosinate were added to a stirrer and stirred at a temperature of 50°C for about After 1 hour, when the sampling observation is completely transparent, it is a kind of micro-lubricating oil.

[0030] The trace lubricating oil prepared by the above method has the following physical and chemical indicators after testing:

[0031] project

basic data

experimental method

Exterior

yellow transparent

Kinematic visc...

Embodiment 2

[0035] Weigh 80kg of stearyl alcohol, 10kg of phosphoric acid, and 10kg of boric acid and add them to the reaction kettle respectively, convert the air in the reaction kettle with nitrogen, heat to 180°C, react for 8 hours, and remove part of the moisture generated by the reaction under reduced pressure, which is a A boric acid phosphate fatty acid ester.

[0036] Weigh 20kg of boric acid phosphate fatty acid ester prepared above, 70kg of glyceryl trioleate, 5kg of polyester, and 5kg of sodium cocoyl sarcosinate into a stirrer and stir for about 1 hour at a temperature of 60°C. Sampling and observation are completely transparent It is a kind of minimum quantity lubricant.

[0037] The preparation method of above-mentioned polyester: take 90.12kg (1000mol) of 1,4 butanediol and 174.19kg (1000mol) of sebacic acid and add in the polymerization kettle, add 1.6kg strongly acidic cation exchange resin and use nitrogen to replace the air in the kettle, The temperature is 180° C., th...

Embodiment 3

[0039] Weigh 84kg of isotridecanol, 9kg of phosphoric acid, and 7kg of boric acid, and add them to the reactor respectively, use nitrogen to convert the air in the reactor, heat to 170°C, react for 10 hours, and remove part of the moisture generated by the reaction under reduced pressure, which is A boric acid phosphate fatty acid ester.

[0040] Weigh 12kg boric acid phosphate fatty acid ester prepared above, 40kg tripalmitin, 35kg diisooctyl succinate, 6kg polyester (Perfad 8400), 7kg lauroyl sarcosine were added to the mixer at 50°C respectively Stir at high temperature for about 1 hour, and when the sample is completely transparent, it is a kind of micro lubricant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com