Refrigerating machine oil, preparation method thereof and working fluid composition for refrigerating machine

A technology of refrigeration oil and composition, applied in lubricating composition, petroleum industry, etc., can solve the problems of low mixing viscosity, affecting the reliability of compressor, compatibility of R32 refrigerant, etc., and achieve the effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

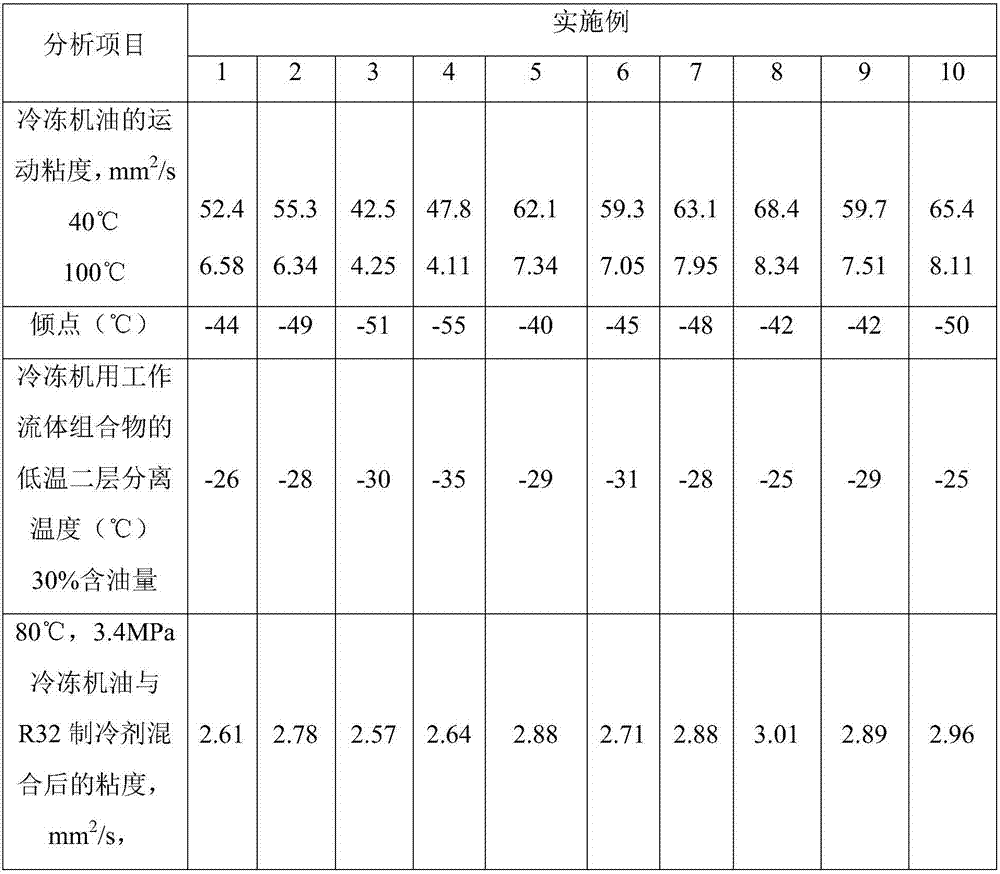

Examples

preparation example Construction

[0073] Second, the embodiments of the present invention specifically introduce the preparation method of the aforementioned refrigerating machine oil. Wherein, the preparation method mainly includes the following steps:

[0074] (1) Esterifying the polyhydric alcohol and the fatty acid to obtain an esterification reaction product.

[0075] This step is specifically as follows: Under vacuum conditions, polyhydric alcohols and fatty acids are subjected to esterification reaction under the action of a catalyst to obtain an esterification reaction product, wherein the temperature of the esterification reaction is 150-250 ° C, and the time of the esterification reaction is 5 ~15 hours.

[0076] Wherein, the molar ratio of polyhydric alcohol and fatty acid is 1:1.0~1:4.0. By further limiting the amount of polyhydric alcohol and fatty acid added, the adequacy of the esterification reaction is ensured, and the esterification rate is higher.

[0077] Preferably, the catalyst is any ...

Embodiment 1

[0091] Add 272g of pentaerythritol, 2-ethylvaleric acid and n-heptanoic fatty acid mixture 650g of mol ratio 1:1, catalyzer stannous oxalate 10g in 2 liters of three-necked flasks with thermometer, condenser tube, electric stirrer, in vacuum degree Under the conditions of -0.06MPa and temperature of 160°C, the esterification reaction was carried out for 4 hours to obtain the first-stage esterification reaction product.

[0092] The above-mentioned first-stage esterification reaction product was subjected to an esterification reaction for 5 hours at a vacuum degree of -0.08MPa and a temperature of 200°C to 240°C to obtain a second-stage reaction product, which was deacidified, washed with water, dried, and filtered Remove excess acid, catalyst, water and other mixture to obtain base oil.

[0093] Add 95% of the base oil obtained above into the mixing container, add 0.5% 2,4-di-tert-butylphenol, 2% phosphorodithioate, 0.5% glycidyl ether, 2% polyether modified silicone oil, and ...

Embodiment 2

[0095] Pentaerythritol 272g, 2-ethylpentanoic acid and n-heptanoic fatty acid mixture 650g of mol ratio 7:3, catalyzer stannous oxalate 10g are added in the 2 liters of three-necked flasks that have thermometer, condensing tube, electric stirrer, in vacuum degree Under the conditions of -0.06MPa and 170°C, the esterification reaction was carried out for 4 hours to obtain the first-stage esterification reaction product.

[0096] The above-mentioned first-stage esterification reaction product was subjected to an esterification reaction for 5 hours at a vacuum degree of -0.08MPa and a temperature of 200°C to 240°C to obtain a second-stage reaction product, which was deacidified, washed with water, dried, and filtered Remove excess acid, catalyst, water and other mixture to obtain base oil.

[0097] Add 95% of the base oil obtained above into the mixing container, add 0.5% 2,4-di-tert-butylphenol, 2% phosphorodithioate, 0.5% glycidyl ether, 2% polyether modified silicone oil, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com