Graphene lubricating oil additive, preparation method and application of graphene lubricating oil additive and lubricating oil with graphene lubricating oil additive

A lubricating oil additive and graphene technology, applied in the field of lubricating oil, can solve the problems of short service life, poor lubricity and high cost, and achieve the effects of good stability, good wear resistance and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A kind of graphene lubricating oil additive, is made up of the component of following mass parts:

[0056] Graphene 0.01 part;

[0057] 5 parts of polyesteramide;

[0058] 50 parts of mineral base oil of 500N.

[0059] The graphene lubricating oil additive is in an emulsion state.

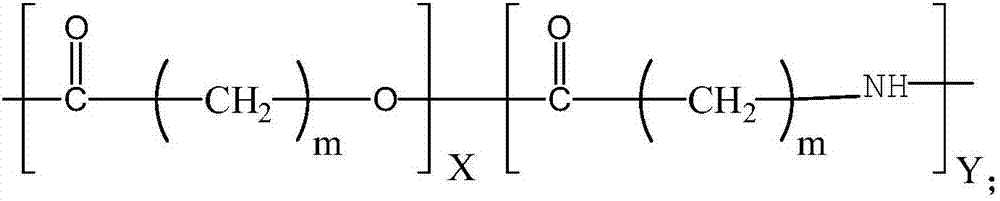

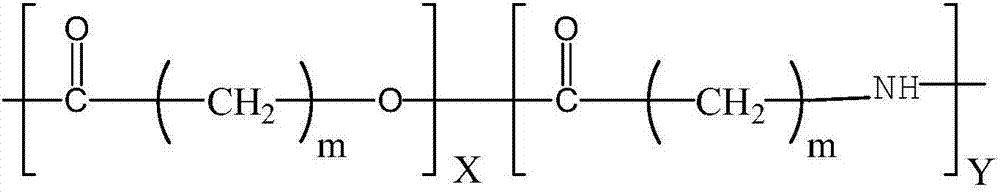

[0060] The average number of carbon atom layers of graphene used is 6 layers, and the structural formula of polyester amide is:

[0061]

[0062] Wherein, m=5, n=10, X=35, Y=5.

[0063] The preparation steps of this graphene lubricating oil additive are as follows:

[0064] 1) Add graphene to the base oil according to the above mass fraction, pre-stirring at a rate of 1000r / min at 30°C for 100min, and then ultrasonically dispersing at 20kHz for 75min to obtain a premix;

[0065] 2) According to the above-mentioned parts by mass, polyester amide is added to the premix obtained in step 1), and stirred at a rate of 1000 r / min for 100 min at 65° C. to obtain a graphene lubricating oil ad...

Embodiment 2

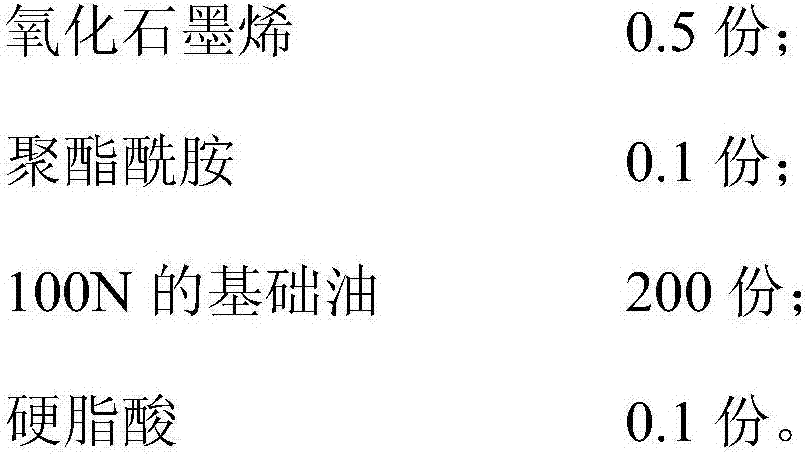

[0076] A kind of graphene lubricating oil additive, is made up of the component of following mass parts:

[0077]

[0078] The graphene lubricating oil additive is in an emulsion state.

[0079] The average number of carbon atom layers of graphene oxide used is 8 layers, and the structural formula of polyester amide is:

[0080]

[0081] Wherein, m=10, n=5, X=42, Y=21.

[0082] The preparation steps of this graphene lubricating oil additive are as follows:

[0083] 1) Add graphene into the base oil according to the above mass fraction, pre-stirring at 65°C at a rate of 5000r / min for 20min, and then ultrasonically dispersing at 200kHz for 30min to obtain a premix;

[0084] 2) According to the above-mentioned parts by mass, the polyester amide is added to the premix obtained in step 1), and stirred at a rate of 3000 r / min for 20 min at 75° C. to obtain a graphene lubricating oil additive.

Embodiment 3

[0088] A kind of graphene lubricating oil additive, is made up of the component of following mass parts:

[0089]

[0090] The graphene lubricating oil additive is in an emulsion state.

[0091] The average number of carbon atomic layers of graphene used is 5 layers, and the structural formula of polyester amide is:

[0092]

[0093] Wherein, m=8, n=8, X=30, Y=10.

[0094] The preparation steps of this graphene lubricating oil additive are as follows:

[0095]1) Add the graphene into the base oil according to the above mass parts, pre-stirring at a rate of 3000r / min at 40°C for 50min, and then ultrasonically dispersing at 40kHz for 60min to obtain a premix;

[0096] 2) According to the above-mentioned parts by mass, polyester amide is added to the premix obtained in step 1), and stirred at a rate of 1500 r / min for 50 min at 70° C. to obtain a graphene lubricating oil additive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum non-jamming load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com