Lubricating grease composition and preparation method thereof

A lubricating grease composition, the technology of the composition, applied in the direction of lubricating composition, petroleum industry, thickener, etc., to achieve the effect of reducing carbon emission and avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

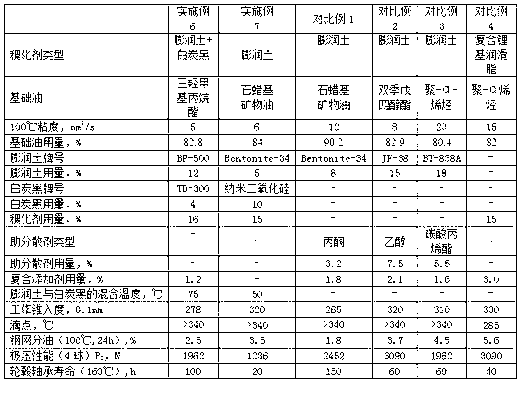

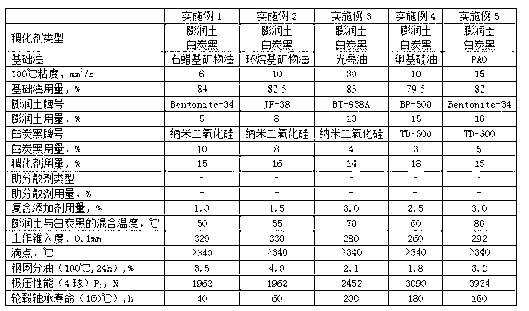

Embodiment 1

[0046] Paraffinic mineral oil (6 mm 2 / s) 84%

[0047] Composite additive 1%

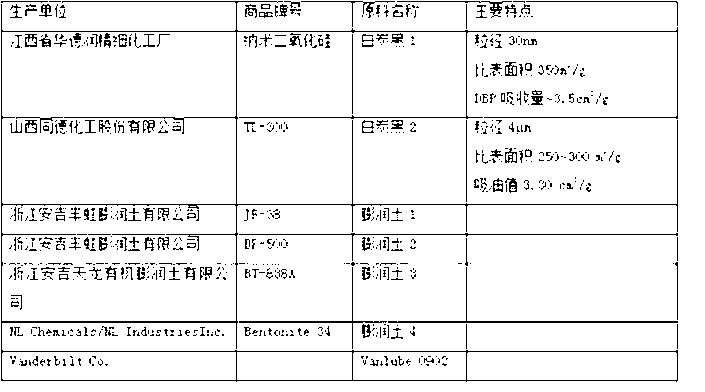

[0048] Add 30% base oil to the fat-making kettle, then add all the bentonite, then add white carbon black (or auxiliary dispersant) according to the calculated amount, heat to 50°C under full stirring, the reactant gradually thickens, and gradually add The remaining base oil is added with additives, and the grease made is ground three times to obtain a grease product. The information of the raw materials used in this embodiment is shown in Table 2.

[0049] Example 2

[0050]Bentonite (JF-38) 8%

Embodiment 2

[0052] Naphthenic mineral oil (10 mm 2 / s) 82.5%

[0053] Compound additive 1.5%

[0054] Add 30% base oil to the fat-making kettle, then add all the bentonite, then add white carbon black (or auxiliary dispersant) according to the calculated amount, heat to 55°C under full stirring, the reactant gradually thickens, and gradually add The remaining base oil is added with additives, and the grease made is ground three times to obtain a grease product. The information of the raw materials used in this embodiment is shown in Table 2.

[0055] Example 3

[0056] Bentonite (BT-838A) 10%

Embodiment 3

[0058] Bright oil (30mm 2 / s) 83%

[0059] Composite additives 3%

[0060] Add 30% base oil to the fat-making kettle, then add all the bentonite, then add white carbon black (or auxiliary dispersant) according to the calculated amount, heat to 70°C under full stirring, the reactant gradually thickens, and gradually add The remaining base oil is added with additives, and the grease made is ground three times to obtain a grease product. The information of the raw materials used in this embodiment is shown in Table 2.

[0061] Example 4

[0062] Bentonite (BP-500) 15%

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com