Highly branched alkyd resin with high solid content and low viscosity and preparation method of alkyd resin

A high-solid, low-viscosity, alkyd resin technology, used in coatings, polyurea/polyurethane coatings, etc., can solve the problems of pollution, low solid content, and high VOC in coating, and achieve a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

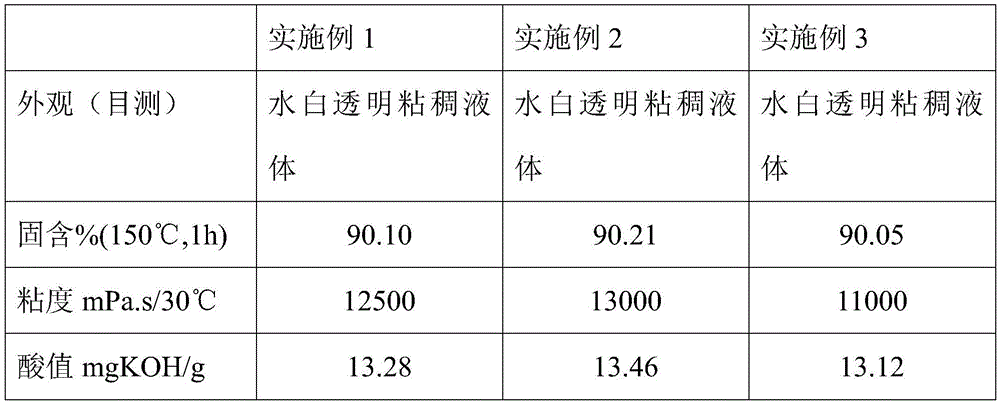

Embodiment 1

[0018] A highly branched high-solid and low-viscosity alkyd resin, comprising the following components in parts by weight: 110 parts of lauric acid, 10 parts of isooctanoic acid, 120 parts of phthalic anhydride, 5 parts of trimellitic anhydride, neopentyl glycol 100 parts, 52 parts of pentaerythritol, 18.5 parts of benzoic acid, 1 part of hypophosphorous acid, 40 parts of ethyl acetate.

[0019] The preparation method of the above-mentioned high-branched high-solid low-viscosity alkyd resin may further comprise the steps:

[0020] (1) Add hypophosphorous acid, phthalic anhydride, trimellitic anhydride, neopentyl glycol and pentaerythritol into the reaction kettle at room temperature, use xylene as a dehydrating agent, raise the temperature to reflux under the protection of an inert gas, keep it warm for 2 hours, and then raise the temperature to 160-170°C and keep it warm During this heat preservation period, the acid value of the material in the reactor is measured until the ...

Embodiment 2

[0024] A highly branched high-solid and low-viscosity alkyd resin, comprising the following components and the parts by weight of each component are: 110 parts of lauric acid, 10 parts of isononanoic acid, 130 parts of phthalic anhydride, 65 parts of neopentyl glycol, 40 parts of pentaerythritol, 50 parts of trimethylolpropane, 18.5 parts of benzoic acid, 1 part of hypophosphorous acid, 40 parts of ethyl acetate.

[0025] The preparation method of the above-mentioned high-branched high-solid low-viscosity alkyd resin may further comprise the steps:

[0026] (1) Add hypophosphorous acid, phthalic anhydride, neopentyl glycol, pentaerythritol and trimethylolpropane into the reactor at normal temperature, use xylene as a dehydrating agent, heat up to reflux under the protection of an inert gas, keep warm for 2 hours, and then heat up to 160-170°C heat preservation, during this heat preservation period, take the material in the reaction kettle to measure the acid value, until the a...

Embodiment 3

[0030] A highly branched high-solid and low-viscosity alkyd resin, comprising the following components and the parts by weight of each component are: 110 parts of lauric acid, 10 parts of isononanoic acid, 130 parts of phthalic anhydride, 50 parts of neopentyl glycol, 15 parts of diethylene glycol, 40 parts of pentaerythritol, 50 parts of trimethylolpropane, 18.5 parts of benzoic acid, 1 part of hypophosphorous acid, 40 parts of ethyl acetate.

[0031] The preparation method of the above-mentioned high-branched high-solid low-viscosity alkyd resin may further comprise the steps:

[0032] (1) Add hypophosphorous acid, phthalic anhydride, neopentyl glycol, diethylene glycol, pentaerythritol and trimethylolpropane into the reaction kettle at room temperature, use xylene as a dehydrating agent, heat up to reflux under the protection of an inert gas, and keep warm for 2 hours , and then heat up to 160-170°C for heat preservation. During this heat preservation period, the materials ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com