Single-component water-based black paint for automobile and preparation method thereof

A single-component, water-based technology, applied in the field of coatings, can solve the problems of film compactness, raw material miscibility, fluidity, loss of fluidity, unbalanced acid and alkali resistance, etc., and improve the compatibility of raw materials. Sexual problems, improve liquidity, stabilize the effect of good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of dispersant

[0042] Dispersant described in the present embodiment is hyperbranched polyurethane oligomer, and its preparation method is as follows:

[0043] Step S1, add 40 parts by weight of diisocyanate aqueous solution with a mass fraction of 45% to the container, then add 2 parts by weight of dibutyltin dilaurate, stir, and control the temperature at 40 ° C, add 2 parts by weight of p-hydroxyanisole and 30 Parts by weight of an aqueous solution of hydroxyethyl methacrylate with a mass fraction of 50%, reacted for 2.5 hours to obtain an intermediate solution;

[0044]In step S2, the temperature of the intermediate solution obtained in step S1 is raised to 60°C, and 35 parts by weight of a hyperbranched polyester aqueous solution with a mass fraction of 30% is added, reacted for 2.5 hours, and the resulting mixture is added to deionized water, and stirred until the liquid becomes clear Color and solid powder, filtered, air-dried, that is.

[0045] Am...

Embodiment 2

[0047] The single-component water-based black paint for automobiles is obtained by mixing components A, B and C in a weight ratio of 4:4:0.05:

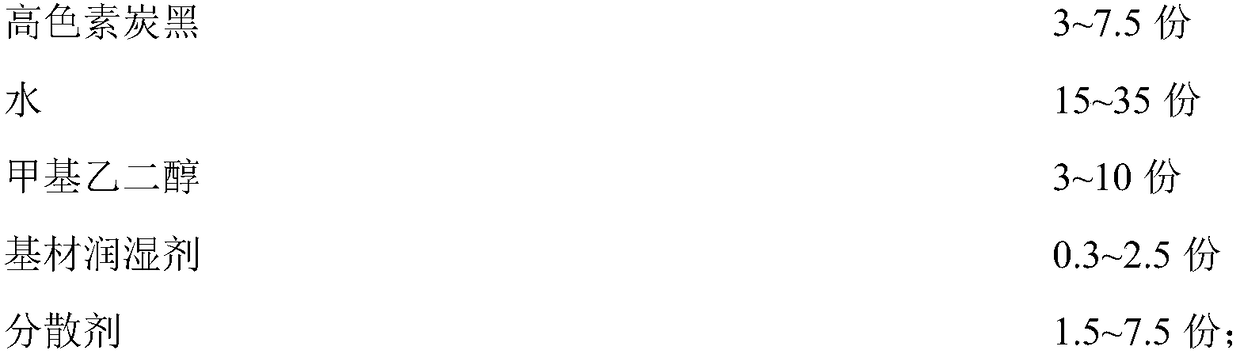

[0048] Wherein A component is made up of the composition of following parts by weight:

[0049]

[0050]

[0051] B component is: aliphatic polyurethane dispersion;

[0052] C component is: Tego TEGO3060 rheological agent.

[0053] Wherein, described dispersant is the hyperbranched polyurethane oligomer that embodiment 1 makes, and described aliphatic polyurethane dispersion is by weight ratio 35:64 by aliphatic anionic polyurethane, N-ethyldiisopropylamine and water: 1 composition.

[0054] The preparation method of the single-component water-based black paint for automobiles is as follows:

[0055] Step 1: Preparation of component A:

[0056] Add methyl glycol, substrate wetting agent, and dispersant to water and mix evenly, and stir for 10 minutes at a speed of 500 rpm, then add high-pigment carbon black, and stir for 30 ...

Embodiment 3

[0059] The single-component water-based black paint for automobiles is obtained by mixing components A, B and C in a weight ratio of 4:5.9:0.1:

[0060] Wherein A component is made up of the composition of following parts by weight:

[0061]

[0062] B component is: aliphatic polyurethane dispersion;

[0063] C component is: Tego TEGO3060 rheological agent.

[0064] Wherein, described dispersant is the hyperbranched polyurethane oligomer that embodiment 1 makes, and described aliphatic polyurethane dispersion is by weight ratio 35:64 by aliphatic anionic polyurethane, N-ethyldiisopropylamine and water: 1 composition.

[0065] The preparation method of the single-component water-based black paint for automobiles is similar to that of Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com