Method for preparing bipeak molecular weight distribution polyethylene by calalyst comixing system

A molecular weight distribution and catalyst technology, applied in the field of preparing bimodal molecular weight distribution polyethylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

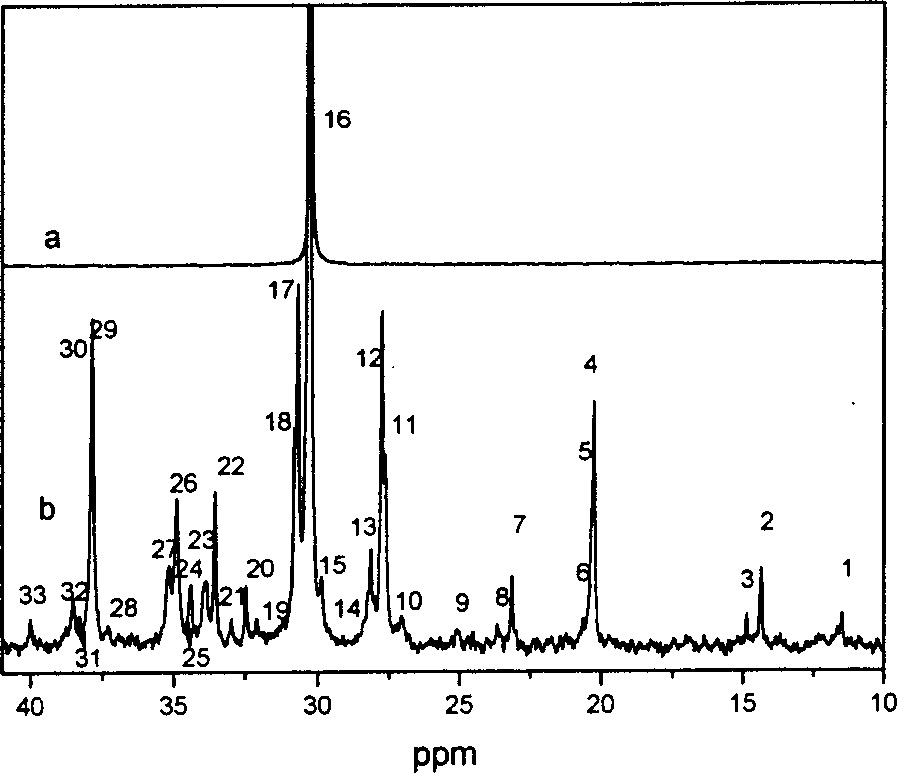

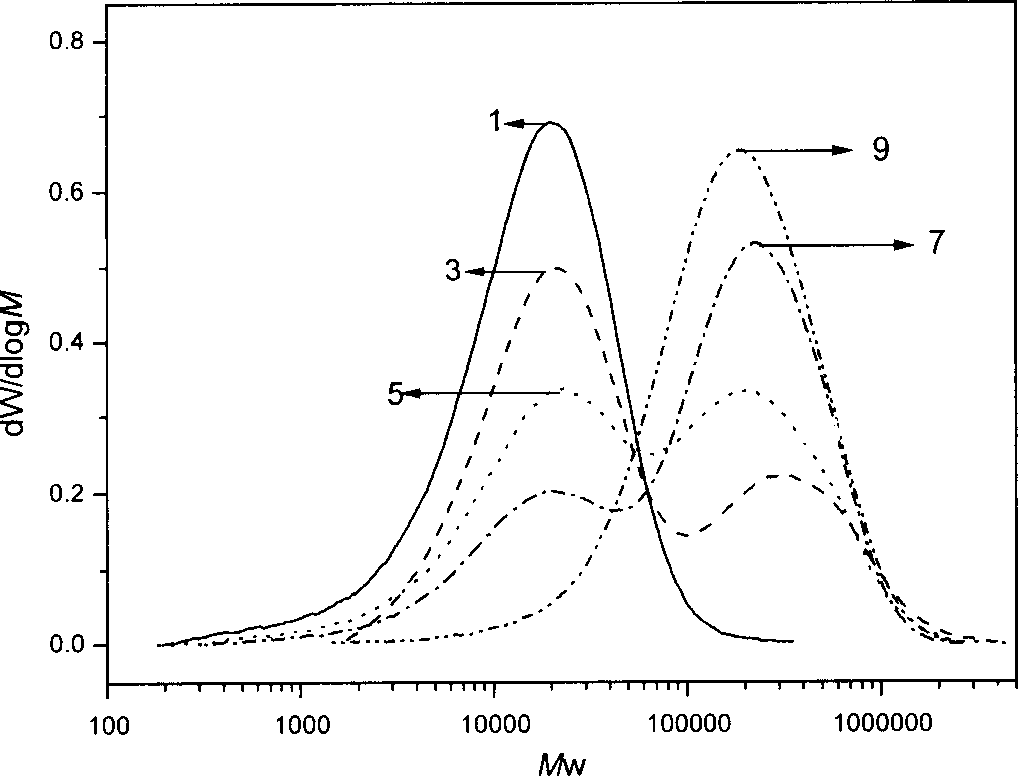

[0025] Under ethylene atmosphere, in 2L reactor, add catalyst a to be 0.0372g, be equivalent to 60μmol Co, anhydrous toluene 1300ml, 2mol / L modified methyl aluminoxane (MMAO) 45ml, adjust ethylene pressure to be 10 atmospheres, room temperature Polymerize for 60 minutes, pour the reaction mixture into 2000ml of 1% hydrochloric acid ethanol solution, make it fully precipitate and filter. The product was washed with ethanol and acetone respectively, and then vacuum-dried at 60° C. for 24 hours to obtain a monomodal molecular weight distribution polyethylene product 1 with a yield of 198.22 g. The catalytic efficiency is 1637Kg polyethylene / molNi·h, the relative weight average molecular weight is 22.87Kg / mol, the relative molecular weight distribution is 3.03, and the relative molecular weight distribution is a narrow single peak. pass 13 C-NMR spectrum analysis proves that it is a linear structure, and its melting temperature is 133.1°C, crystallization temperature is 120.8°C a...

Embodiment 2

[0027] Under ethylene atmosphere, in 2L reactor, add catalyst b to be 0.0432g, be equivalent to 60 μ mol Ni, other operation is the same as embodiment 1, obtain the product 9 of monomodal molecular weight distribution polyethylene, output is 129.5g, catalytic efficiency 2158Kg polyethylene / molNi h, the relative weight average molecular weight is 252.42Kg / mol, the relative molecular weight distribution is 2.80, and the relative molecular weight distribution is a relatively narrow single peak. pass 13 C-NMR spectrum analysis calculates that its branching degree reaches 30.43%, and there is no melting and crystallization in the polyethylene sample as tested by DSC.

Embodiment 3

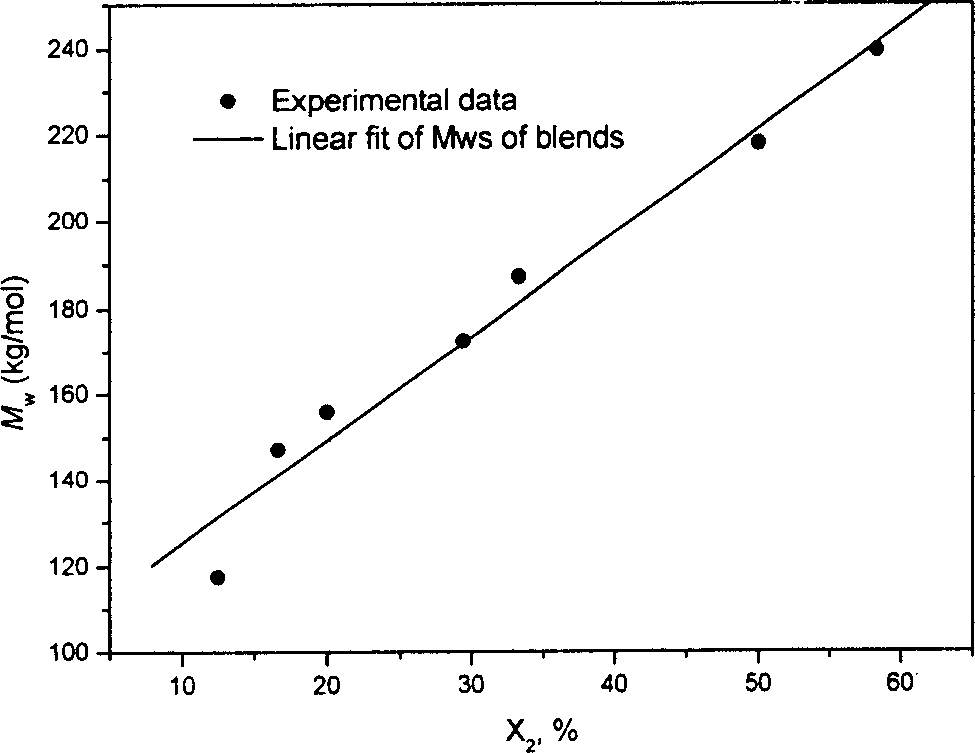

[0029] Under an ethylene atmosphere, in a 2L reactor, mix the two catalysts with a molar mass ratio of 7:1, add catalyst a 0.0326g, equivalent to 53 μmol Co and catalyst b 0.0054g, equivalent to 7 μmol Ni, and the rest of the operations are the same as in Example 1. Obtain the product 2 of bimodal molecular weight distribution polyethylene, output is 100.98g, catalytic efficiency 1683Kg polyethylene / molCat h, relative weight average molecular weight is 111.55Kg / mol, relative molecular weight distribution is 10.36, and relative molecular weight distribution is wider double peak. The low relative molecular weight component content is 79.21%, and the high relative molecular weight component content is 20.79%. According to DSC test, its melting temperature is 132.1°C, its crystallization temperature is 119.3°C, and its crystallinity is 73%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Catalytic efficiency | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

| Crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com