New olefine polymerization catalyst

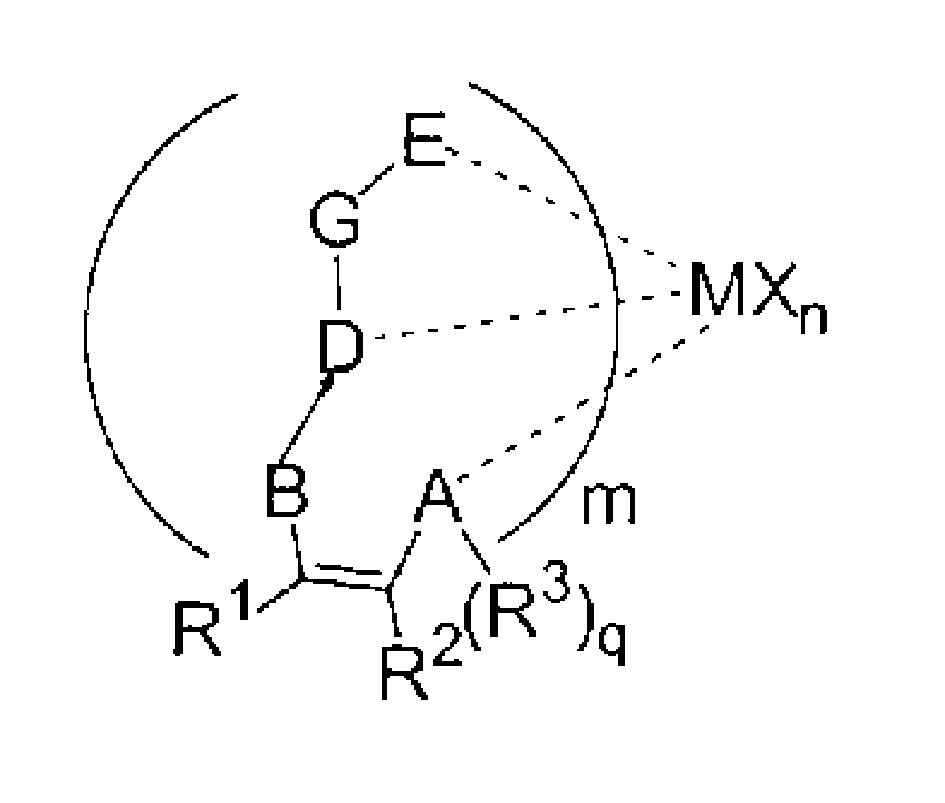

A technology of olefin polymerization and catalyst, which is applied in the field of new olefin polymerization catalysts, and can solve problems such as the inability to control the structure and properties of polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] Example 1 Synthesis of Ligand L1

[0096] In a 250ml reaction flask, add 2.34g (10.0mmol) 3,5-di-tert-butyl salicylaldehyde, 2.3g (8.8mmol) (o-aminophenyl) diphenylamine, 100ml absolute ethanol, heat After reflux for 24 hours, the reaction was stopped and allowed to cool to room temperature to obtain the product, which was washed several times with cold ethanol and dried to obtain 3.5 g (81%) of yellow crystal L1. Elemental analysis: Measured (calculated value): C: 83.19 (83.15) H: 7.60 (7.61) N: 5.87 (5.88) 1 HNMR (300MHz CDCl 3 ): δ13.6 (s O-H); 8.6 (s CH=N); 7.5-7.0 (m, Aryl H) 1.5, 1.3 (s, st-Bu-H)

Embodiment 2

[0097] Example 2 Synthesis of Ligand L2

[0098] In a 250ml reaction flask, add 5.62g (24mmol) 3,5-di-tert-butyl salicylaldehyde, 3.68g (20mmol) phenyl o-dimethylaminophenyl ether, 100ml absolute ethanol, and heat to reflux for 20h Afterwards, the reaction was stopped, cooled to room temperature to obtain the product, washed several times with absolute ethanol, and dried to obtain 5.2 g (65%) of yellow crystal L2. Elemental analysis: measured (calculated value): C: 80.76 (80.76); H: 7.77 (7.78); N: 3.51 (3.49) 1 HNMR (300MHz CDCl 3 ): δ (ppm) 13.4 (s, O-H); 8.7 (s CH=N); 7.4-7.0 (m, Aryl-H); 1.4, 1.3 (s, s t-Bu-H)

Embodiment 3

[0099] Example 3 Synthesis of Ligand L3

[0100] In reaction bottle, add 2.8g (12.0mmol) 3,5-di-tert-butyl salicylaldehyde, 2.01g (10.0mmol) phenyl, 2-aminophenyl sulfide, 25ml absolute ethanol, a small amount of glacial acetic acid, After reflux and stirring for 2 h, the reaction was stopped, and a yellow-green solid precipitated after cooling, and 1.3 g (44.4%) of ligand L3 was obtained after recrystallization. Elemental analysis: measured (calculated value): C: 77.70 (77.65), H: 7.50 (7.48), N: 3.38 (3.35): 1 HNMR (300MHz CDCl 3 ): δ (ppm) 13.3 (s O-H), 8.6 (s CH = N), 7.45-7.11 (m Aryl H), 1.47, 1.32 (s, s t-Bu-H)

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com