Ziegler-Natta olefin polymerization catalysts with single-site center property

A single active site, olefin polymerization technology, applied in the field of Ziegler-Natta olefin polymerization catalysts, can solve the problems of a large number of co-catalysts, low stability of the main catalyst, and difficult synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

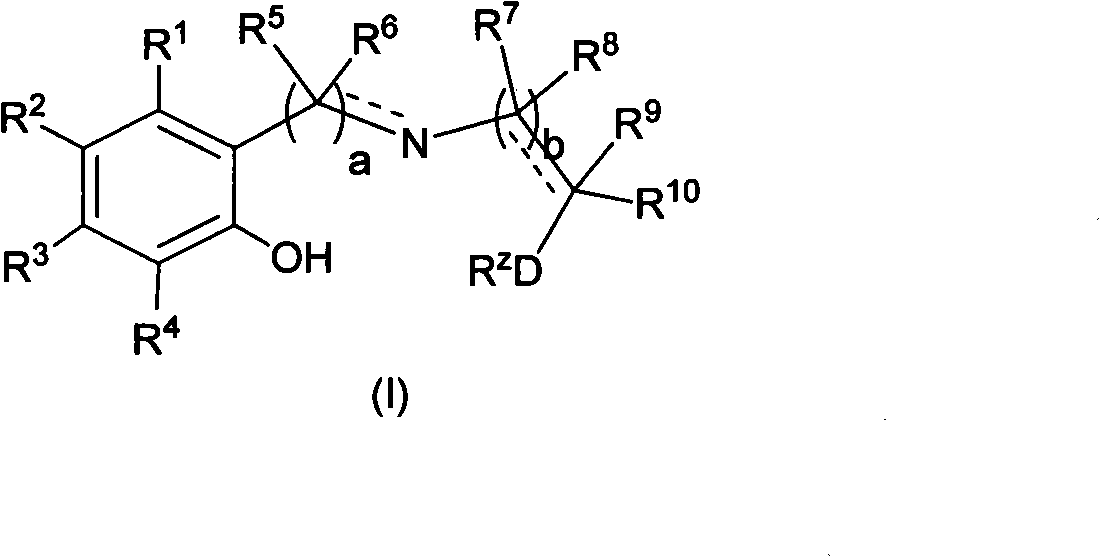

Image

Examples

Embodiment 1

[0066] The preparation of embodiment 1 catalyst 1:

[0067] (1) Heat treatment of the carrier

[0068] Get ES70 type silica gel (product of PQ company) and bake under nitrogen atmosphere. The calcination conditions are as follows: treat at 200°C for 2 hours, then raise the temperature to 400°C for 2 hours, then treat at 600°C for 4 hours, and cool naturally under nitrogen atmosphere. Denoted as ES70 vector.

[0069] (2) The electron donor is:

[0070]

[0071] Add 1.0g of anhydrous magnesium chloride to 40mL of tetrahydrofuran (hereinafter referred to as THF), stir at 60°C for 2h; add dropwise 3.4mmol of TiCl 4, reacted at 60°C for 4h, then added 1.0g of ES70 carrier after heat treatment, reacted at 60°C for 4h; finally added 4.0mmol of electron donor L1 prepared above, reacted at 60°C for 12h. After the reaction, the solvent was evaporated under reduced pressure, and the product was washed with hexane (3×20 mL), and then dried under reduced pressure to obtain Catalyst ...

Embodiment 2

[0072] The preparation of embodiment 2 catalyst 2

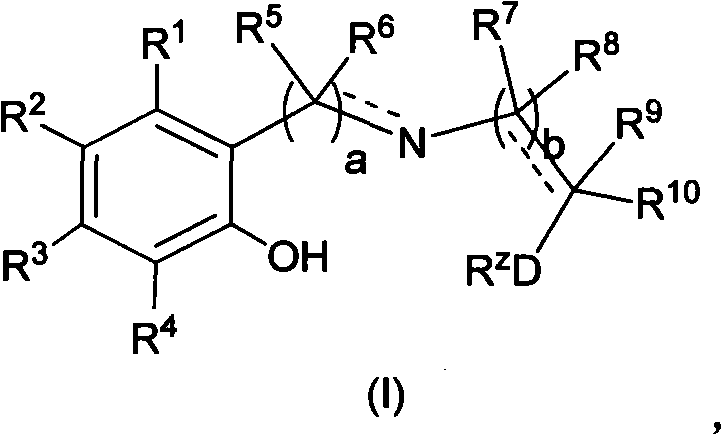

[0073] The electron donor is:

[0074]

[0075] Add 1.0g of anhydrous magnesium chloride to 40mL of tetrahydrofuran (hereinafter referred to as THF), stir at 60°C for 2h; add dropwise 3.4mmol of TiCl 4 , reacted at 60°C for 4h, then added 1.0g of ES70 carrier after heat treatment, reacted at 60°C for 4h; finally added 4.0mmol of electron donor L2 prepared above, reacted at 60°C for 12h. After the reaction, the solvent was evaporated under reduced pressure, and the product was washed with hexane (3×20 mL), and then dried under reduced pressure to obtain catalyst 2. Ti content: 2.81wt-%

Embodiment 3

[0076] The preparation of embodiment 3 catalyst 3

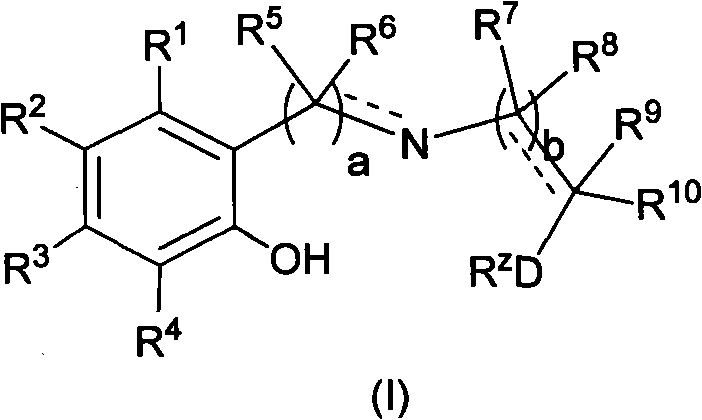

[0077] The electron donor is:

[0078] Add 1.0g of anhydrous magnesium chloride to 40mL of tetrahydrofuran (hereinafter referred to as THF), stir at 60°C for 2h; add dropwise 3.4mmol of TiCl 4 , reacted at 60°C for 4h, then added 1.0g of the above heat-treated ES70 carrier, reacted at 60°C for 4h; finally added 4.0mmol of the electron donor L3 prepared above, and reacted at 60°C for 12h. After the reaction, the solvent was evaporated under reduced pressure, and the product was washed with hexane (3×20 mL), and then dried under reduced pressure to obtain catalyst 3 with a Ti content of 3.57 wt-%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com