Pattern formation method, pattern, and device

A pattern, silane compound technology, applied in electrical components, chemical instruments and methods, photoengraving process of pattern surface, etc., can solve the problems of expensive model, large waste, and difficult to obtain dense silicon oxide film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0104] Unless otherwise specified, the following operations were performed in nitrogen with an oxygen concentration of 1 ppm or less.

[0105] The weight average molecular weights of the higher silane compounds in the following synthesis examples and the silicone resins in the comparative examples are obtained from the data of gel permeation chromatography (GPC) measured under the following conditions using the following measuring device, respectively. Styrene converted value.

[0106] The viscosity of the high-grade silane composition is a value measured using the measuring device described below.

[0107]

[0108] Measuring device: manufactured by Agilent Technologies, model "1200 series"

[0109] Column: "Packed column for HPLC KF-G" and "Packed column for HPLC K-805L" manufactured by Showa Denko Co., Ltd. were used in series.

[0110] Solvent: In the determination of advanced silane compounds, cyclohexene is used as the solvent; in the determination of silicone resin, ...

manufacture example 1

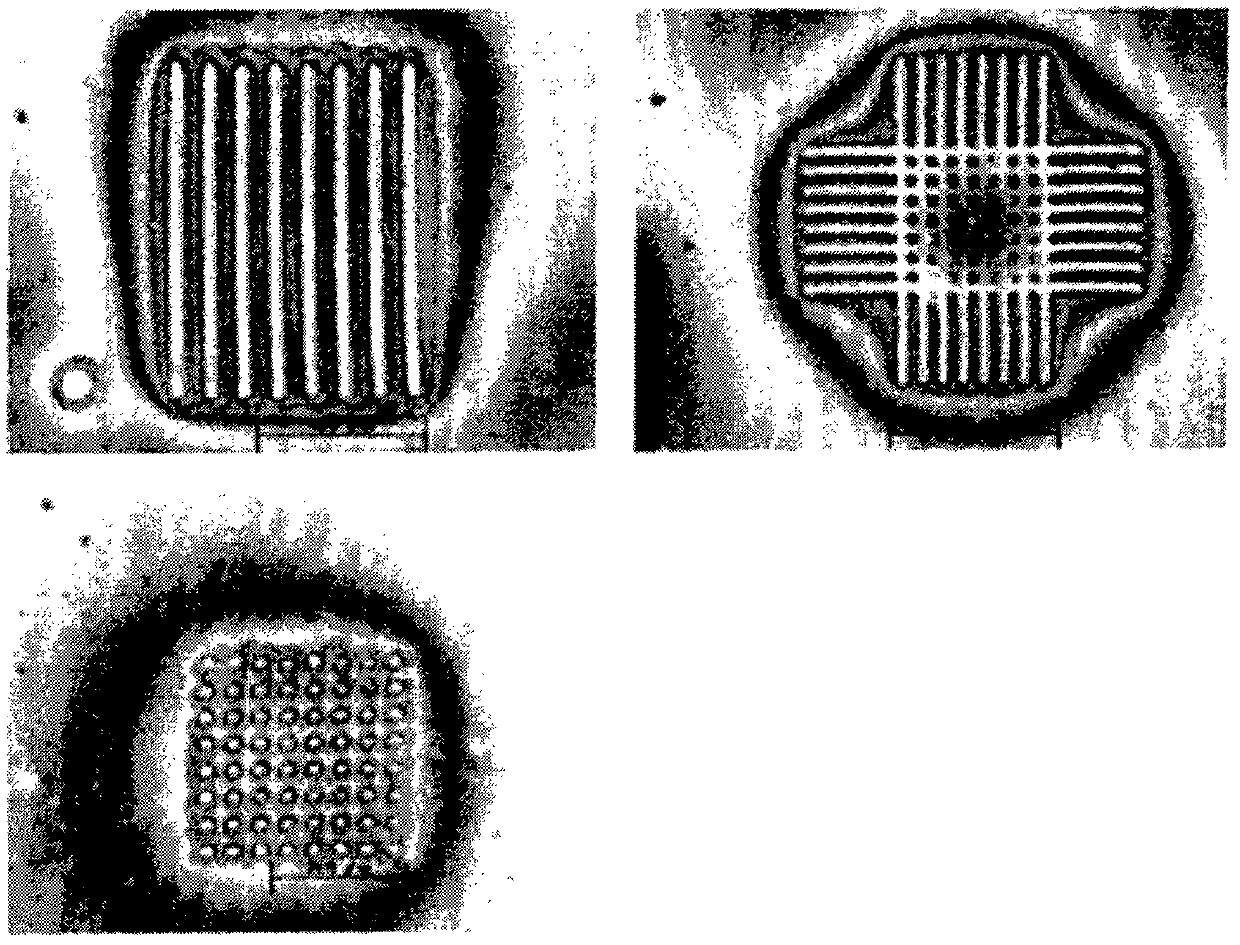

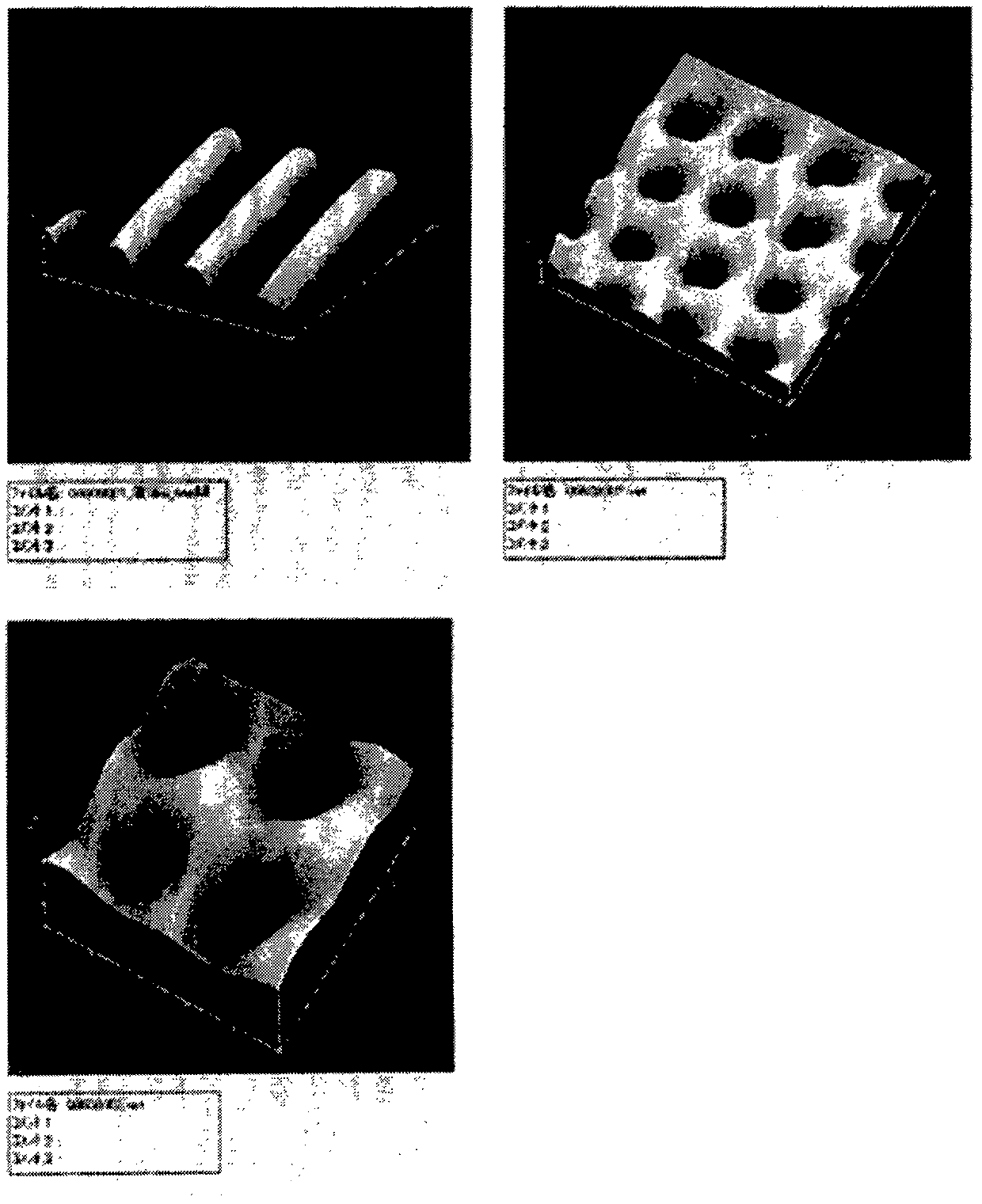

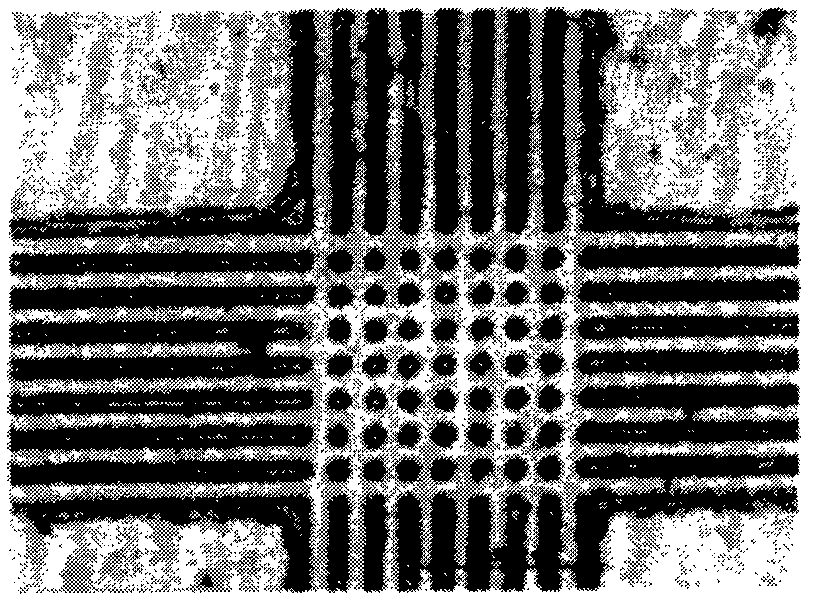

[0120] As the master mold, "PH-350" (trade name, multiple line-space patterns of different line widths with a line width of 0.35 to 3 μm, and different sizes with a diameter of 0.5 to 10 μm) was used as the master mold. A mold for nanoimprint testing with a plurality of cylindrical protrusions and a plurality of angular patterns of different sizes ranging from 0.5 to 10 μm on one side.). Before use, the master mold is coated with a precision mold release agent "Durasurf HD-1100" manufactured by Daikin Chemicals Co., Ltd. by spin coating, and then heated at 60°C for 5 minutes to perform mold release treatment. .

[0121] In addition, a glass substrate was prepared, and the same operation as that of the above-mentioned master mold was performed, and mold release treatment was performed.

[0122] SYLGARD 184 SILICONE ELASTOMER BASE (agent A) and SYLGARD 184 SILICONE ELASTOMER CURING AGENT (B agent), two-component curable polydimethylsiloxane (PDMS) manufactured by Dow Corning To...

Synthetic example 1

[0126] While stirring cyclopentasilane without solvent, irradiate 25mW / cm 2 The ultraviolet light containing the bright line with a wavelength of 390nm was used for 1 hour to carry out the photopolymerization of cyclopentasilane to obtain a high-level silane compound. By dissolving the obtained higher silane compound in cyclooctane, a cyclooctane solution containing 10% by weight of the higher silane compound, ie a higher silane composition, was obtained. The weight-average molecular weight of the higher-order silane compound contained in this higher-order silane composition was 10,000, and the viscosity was 100 mPa·s.

[0127]

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com