Patents

Literature

41 results about "Polysilicon hydride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polysilicon hydrides are polymers containing only silicon and hydrogen. They have the formula (SiHₙ)ₓ where 0.2 ≤ n ≤ 2.5 and x is the number of monomer units. The polysilicon hydrides are generally colorless or pale-yellow/ocher powders that are easily hydrolyzed and ignite readily in air. The surfaces of silicon prepared by MOCVD using silane (SiH₄) consist of a polysilicon hydride.

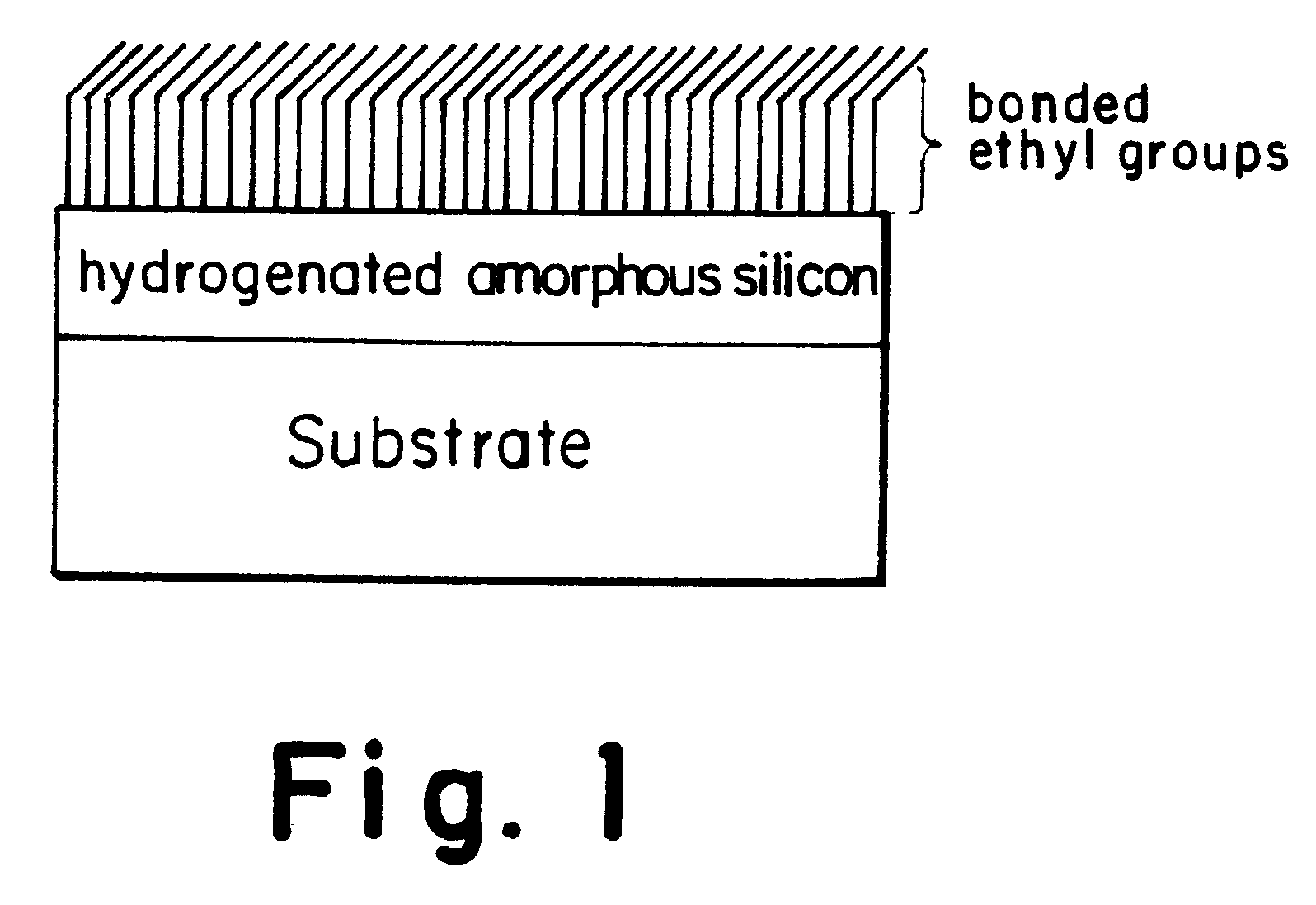

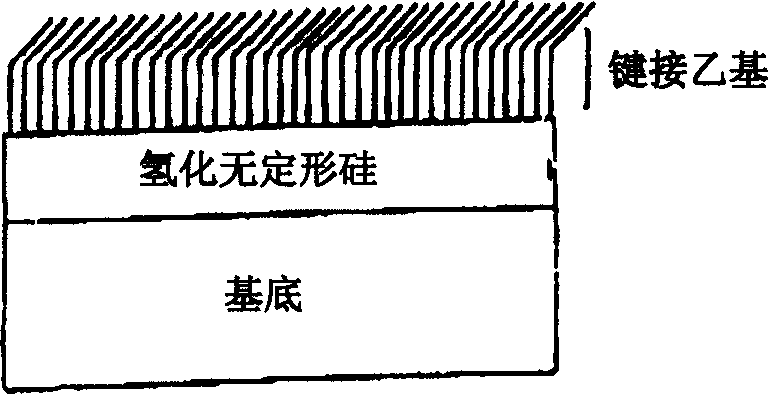

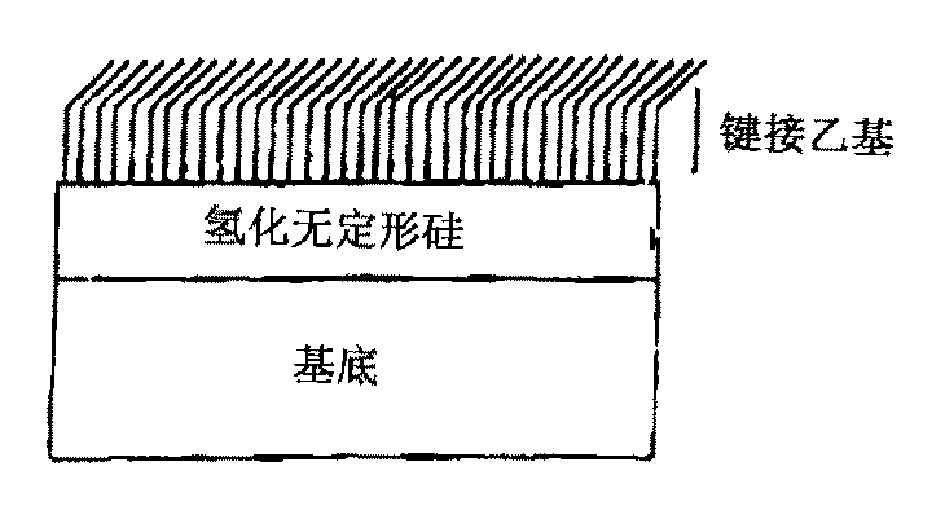

Surface modification of solid supports through the thermal decomposition and functionalization of silanes

InactiveUS6444326B1Inhibition formationGaseous chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsUnsaturated hydrocarbonSilanes

Method of modifying the surface properties of a substrate by depositing a coating of hydrogenated amorphous silicon on the surface of the substrate and functionalizing the coated substrate by exposing the substrate to a binding reagent having at least one unsaturated hydrocarbon group under pressure and elevated temperature for an effective length of time. The hydrogenated amorphous silicon coating is deposited by exposing the substrate to silicon hydride gas under pressure and elevated temperature for an effective length of time.

Owner:SILCOTEK CORP

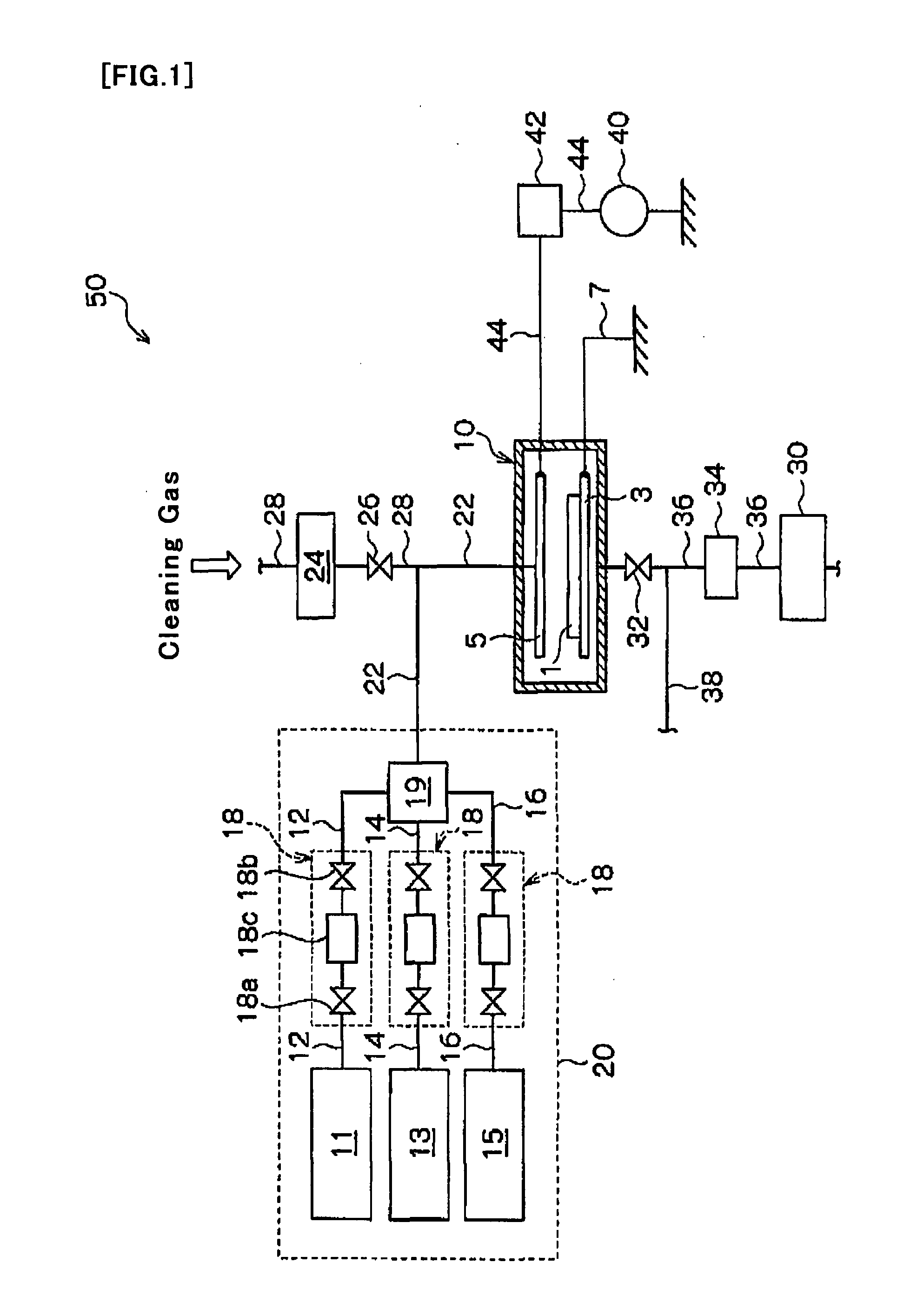

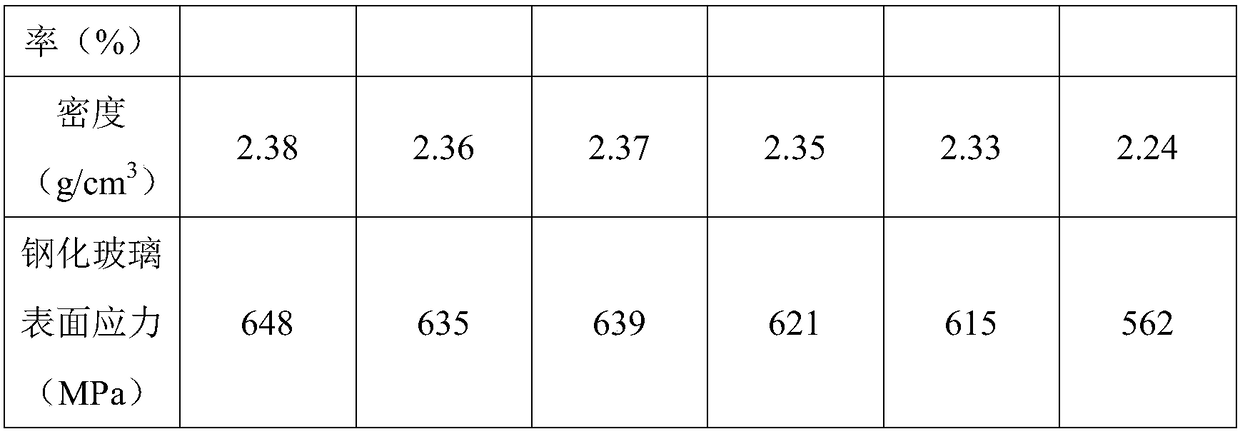

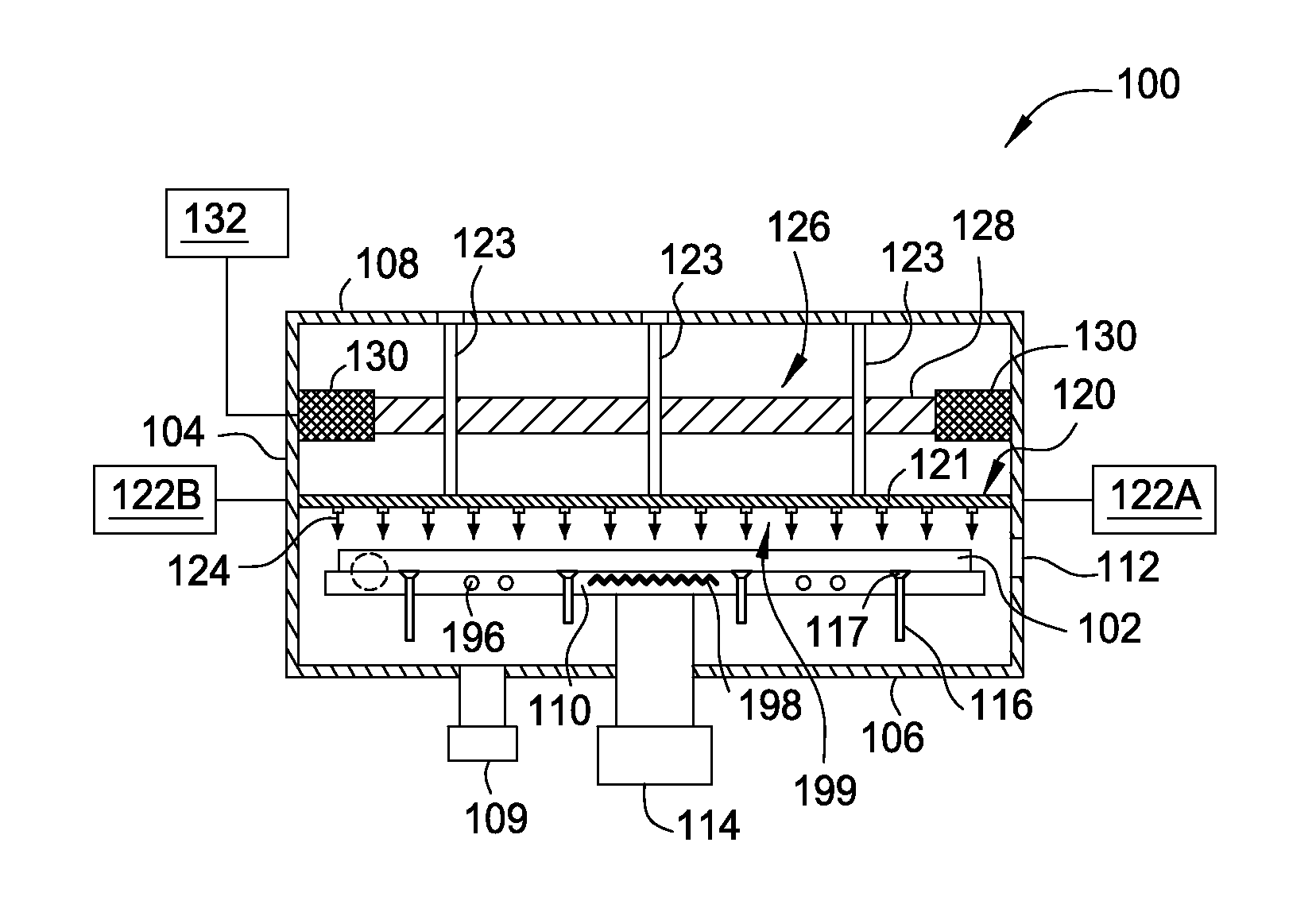

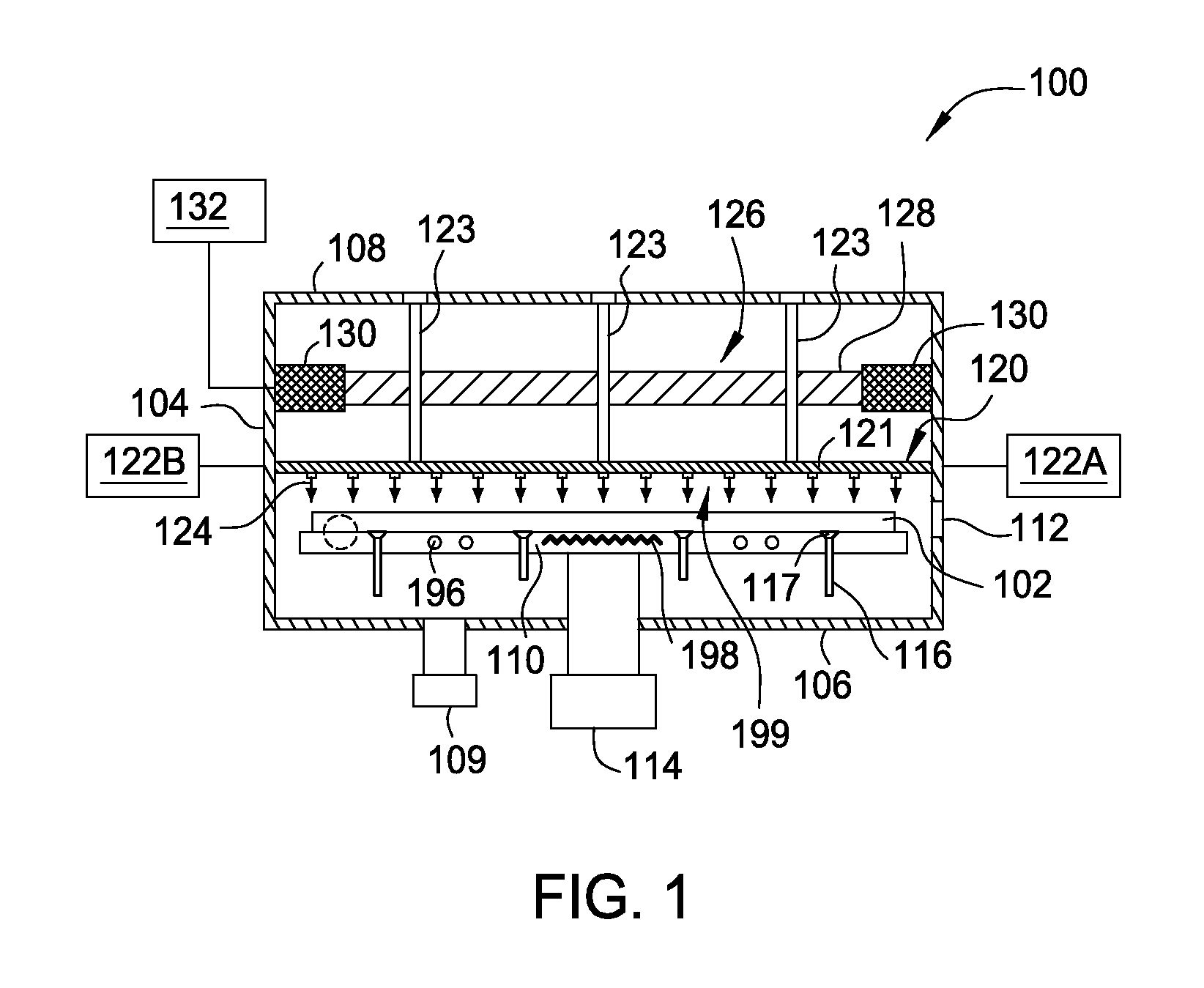

Method for chemical vapor deposition of silicon on to substrates for use in corrosive and vacuum environments

InactiveUS7070833B2Improve propertiesReduce outgassingPretreated surfacesSolid state diffusion coatingRoom temperatureSurface conditions

A method of passivating the surface of a substrate to protect the surface against corrosion, the surface effects on a vacuum environment, or both. The substrate surface is placed in a treatment environment and is first dehydrated and then the environment is evacuated. A silicon hydride gas is introduced into the treatment environment, which may be heated prior to the introduction of the gas. The substrate and silicon hydride gas contained therein are heated, if the treatment environment was not already heated prior to the introduction of the gas and pressurized to decompose the gas. A layer of silicon is deposited on the substrate surface. The duration of the silicon depositing step is controlled to prevent the formation of silicon dust in the treatment environment. The substrate is then cooled and held at a cooled temperature to optimize surface conditions for subsequent depositions, and the treatment environment is purged with an inert gas to remove the silicon hydride gas. The substrate is cycled through the silicon depositing step until the surface of the substrate is covered with a layer of silicon. The treatment environment is then evacuated and the substrate cooled to room temperature.

Owner:SILCOTEK CORP

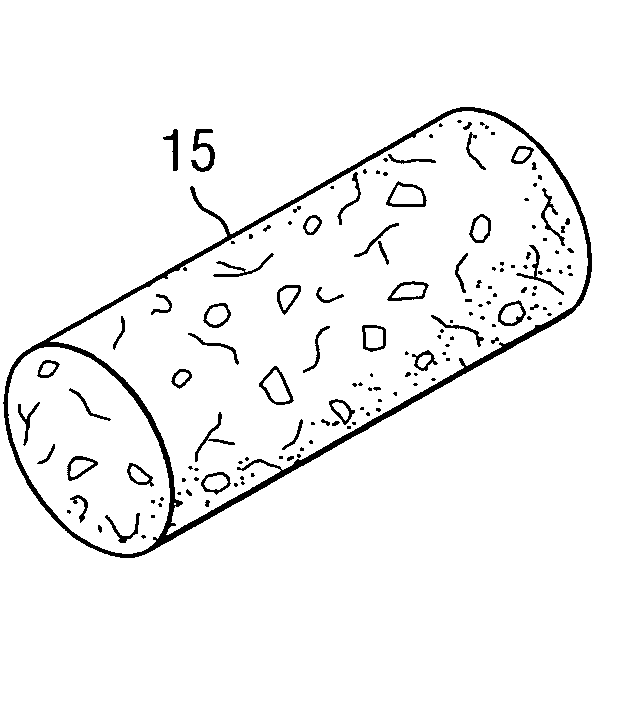

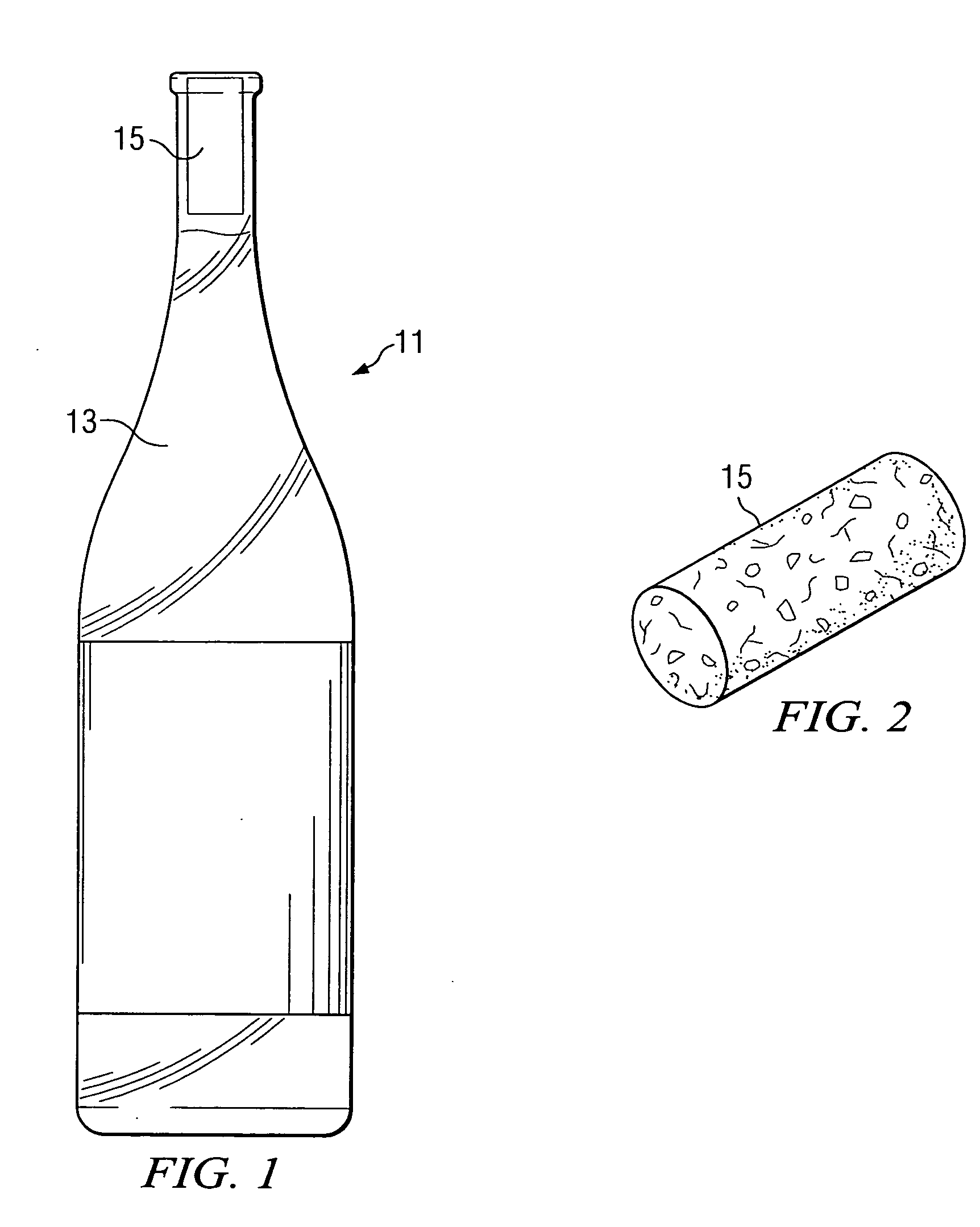

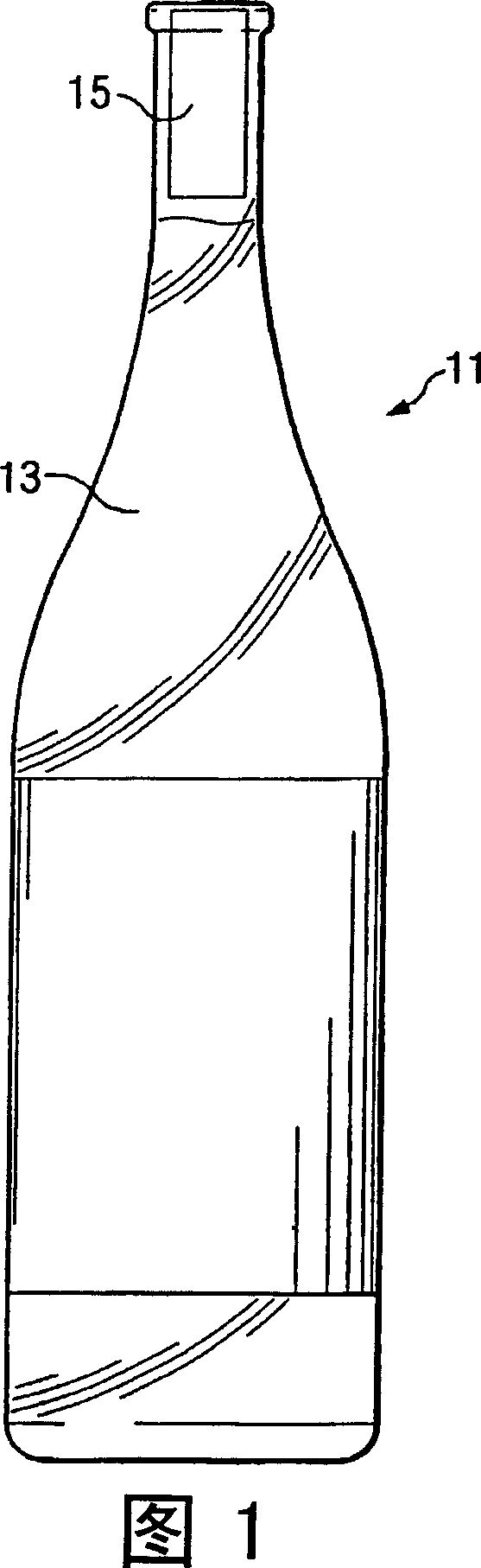

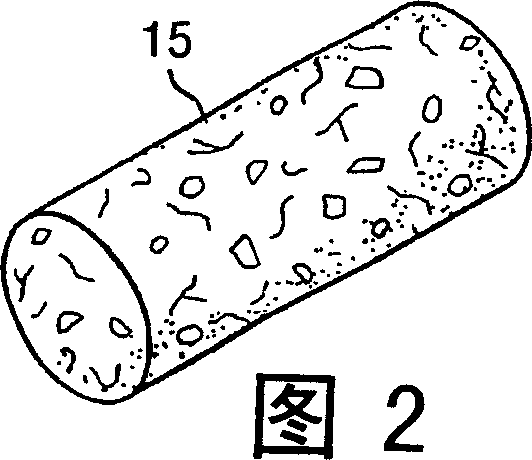

Synthetic cork compound

A synthetic cork compound includes a methyl vinyl silicone polymer with a microsphere agent such as soda lime borosilicate in an amount of approximately 5 to 50 weight percent. The microsphere agent gives the compound a low density. The methyl vinyl silicone polymer preferably includes polydimethylvinylsiloxane polymer from about 45 to 90 weight percent and fumed silica from about 5 to 50 weight percent. Preferably, the compound is catalyzed using chloro-platanic acid from about 0.1 to 5 percent. Additional components of the compound include toasted oak dust from about 0.1 to 25 weight percent, ground cork from about 5 to 50 weight percent, a pigment from about 0.1 to 5 weight percent, silicon hydride from about 0.1 to 25 weight percent, and ethynyl cyclohexanol from about 0.05 to 5 weight percent.

Owner:M MANAGEMENT TEX

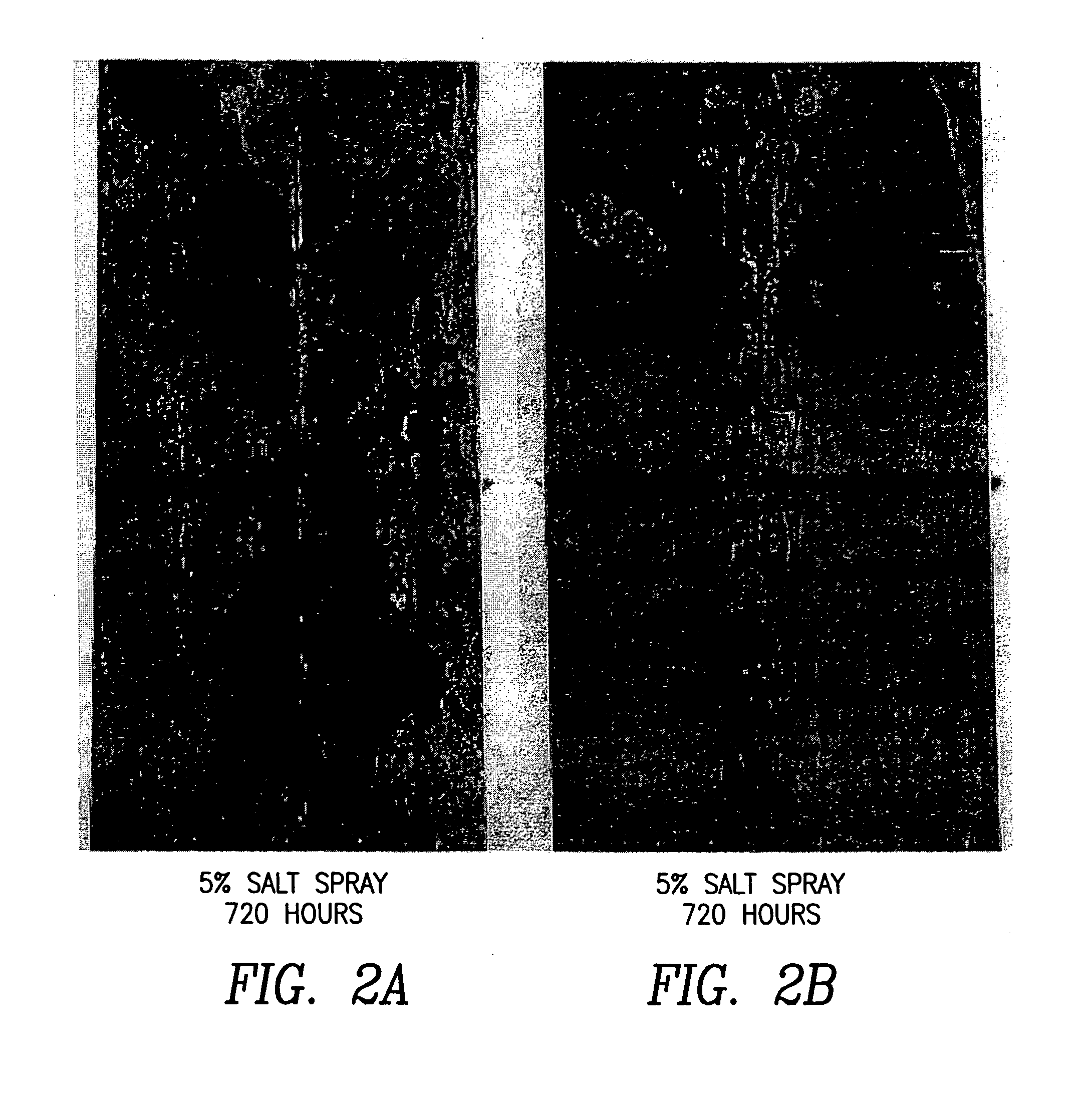

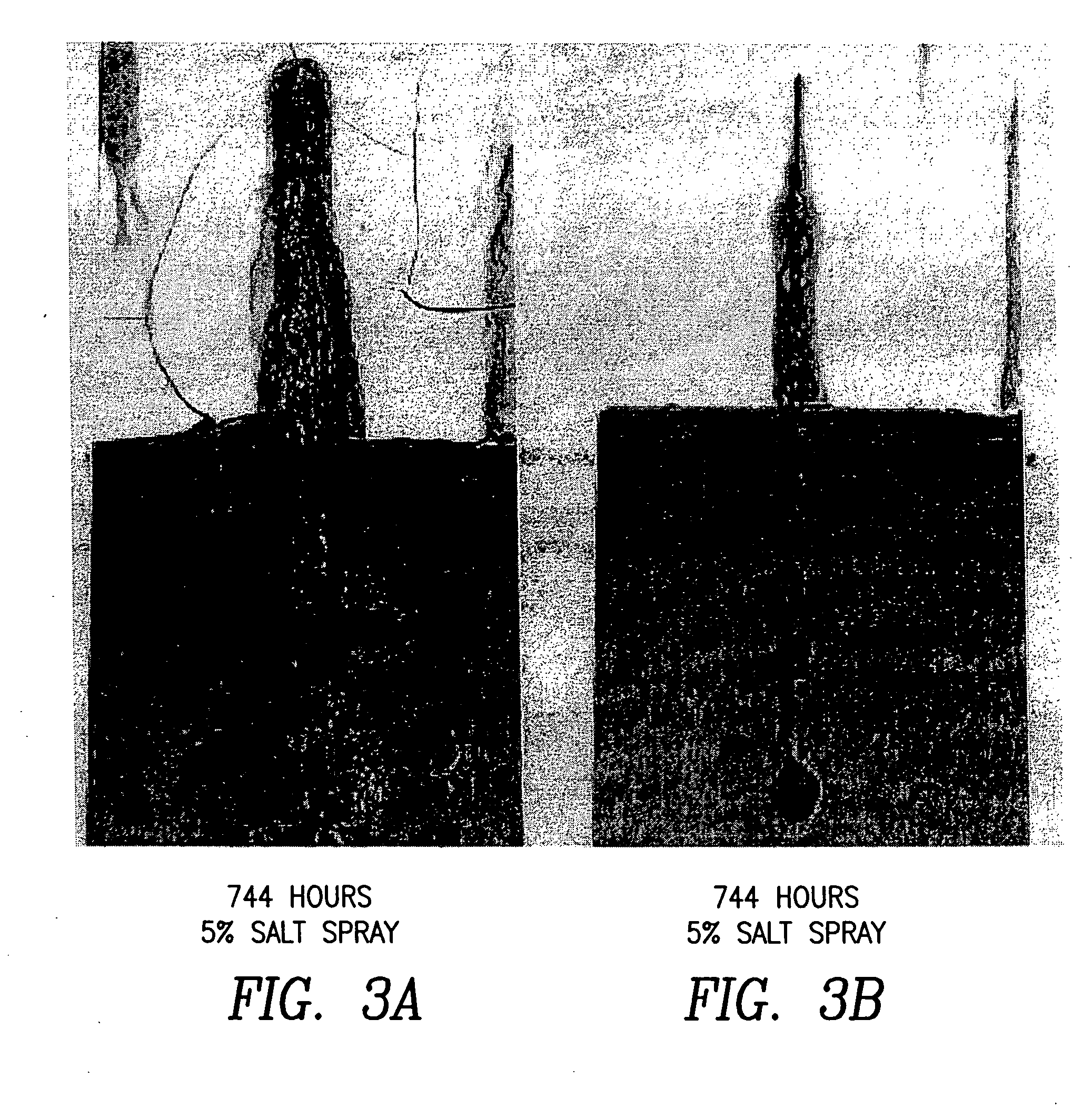

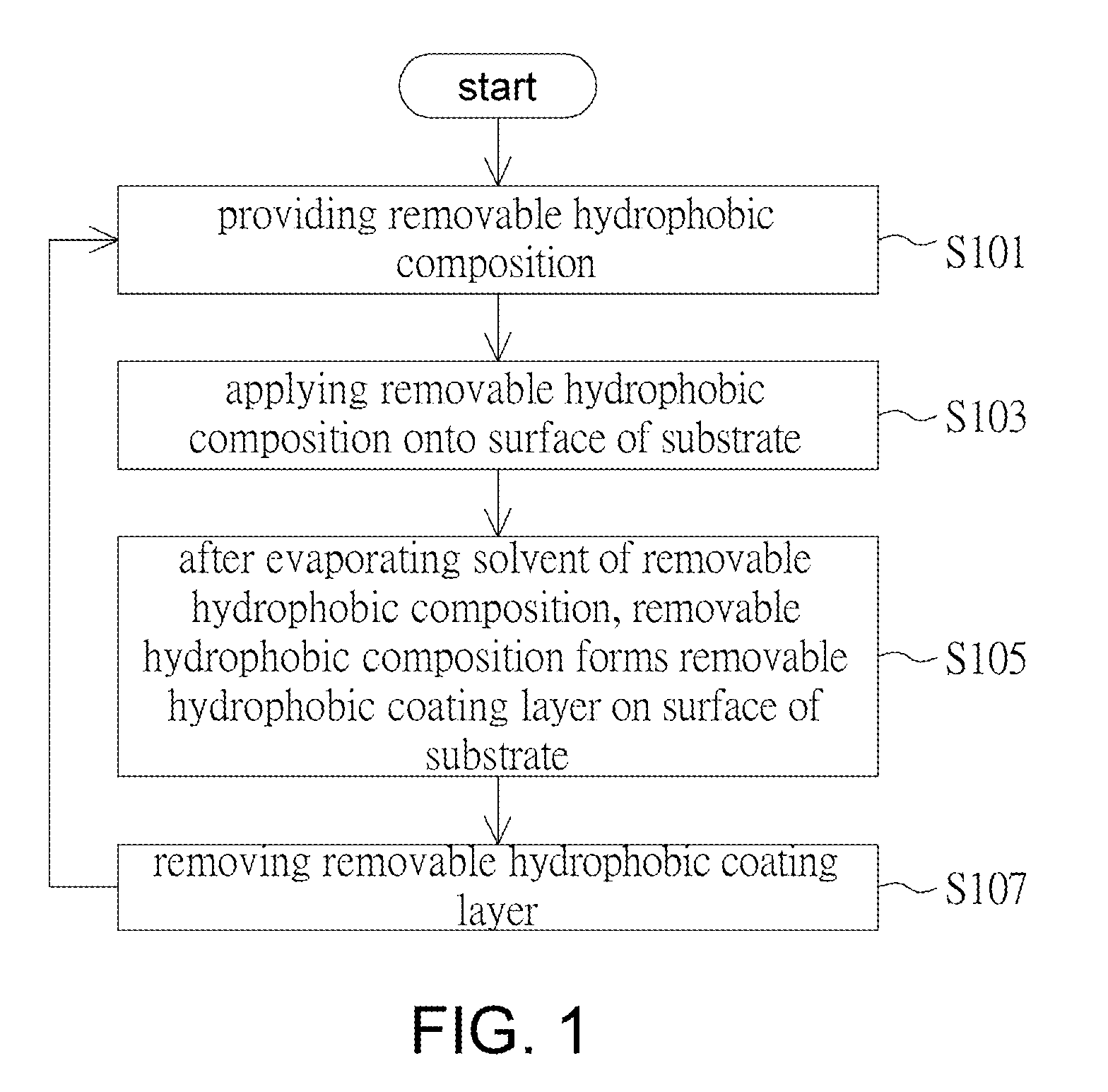

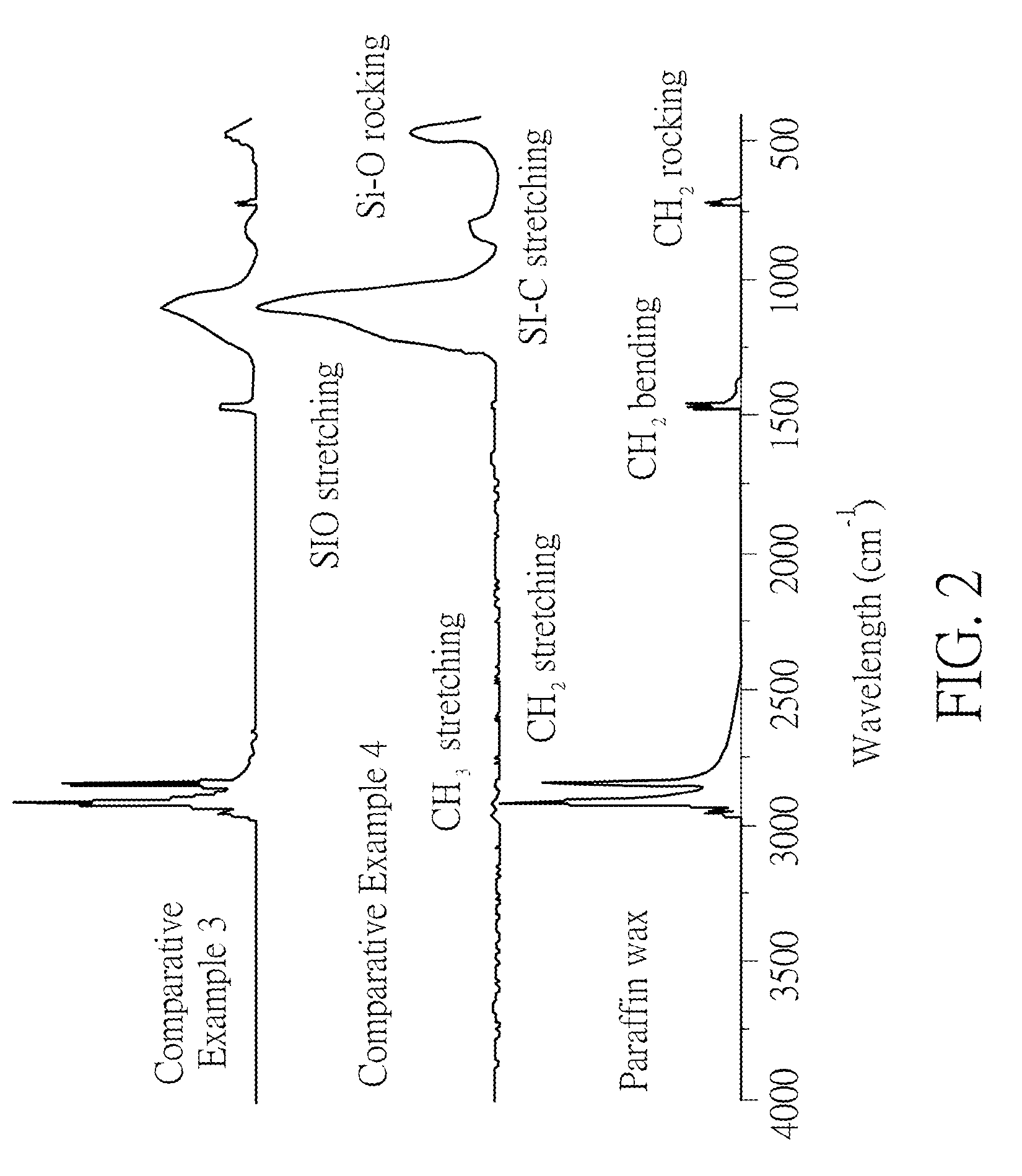

Removable Hydrophobic Composition, Removable Hydrophobic Coating Layer and Fabrication Method Thereof

ActiveUS20100317780A1Small diameterPlastic/resin/waxes insulatorsPretreated surfacesNanoparticleSolvent

A removable hydrophobic composition, a removable hydrophobic coating layer and a fabrication method thereof are provided. The removable hydrophobic composition comprises 0.1-50 parts by weight of nano-particles having diameters smaller than 100 nm and of which surfaces are modified with silicon hydride compound, 0.1-5 parts by weight of an adhesion regulator or adhesion inhibitor, 100 parts by weight of a solvent, and 0.1-50 parts by weight of a polymer compound.

Owner:IND TECH RES INST

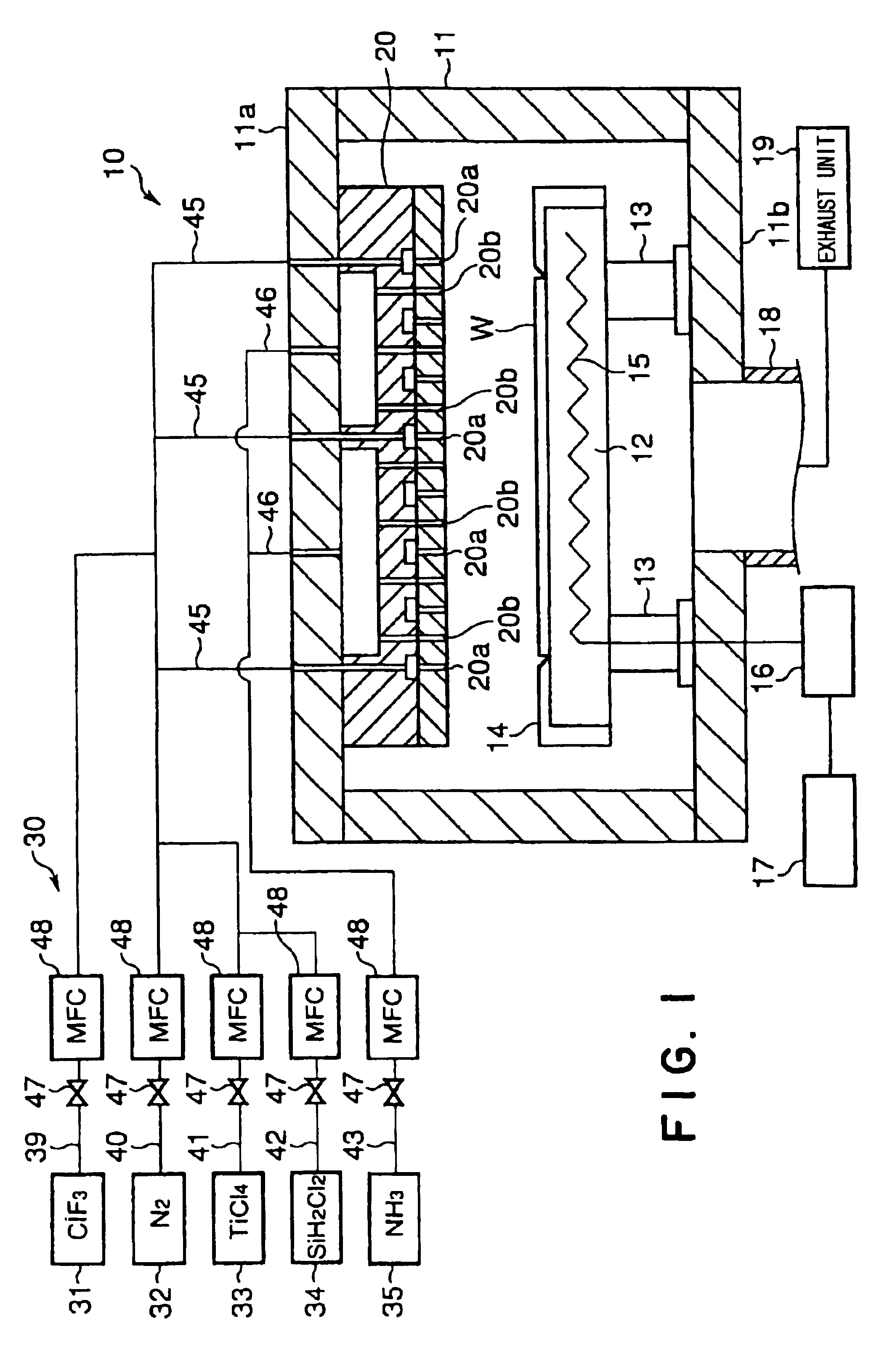

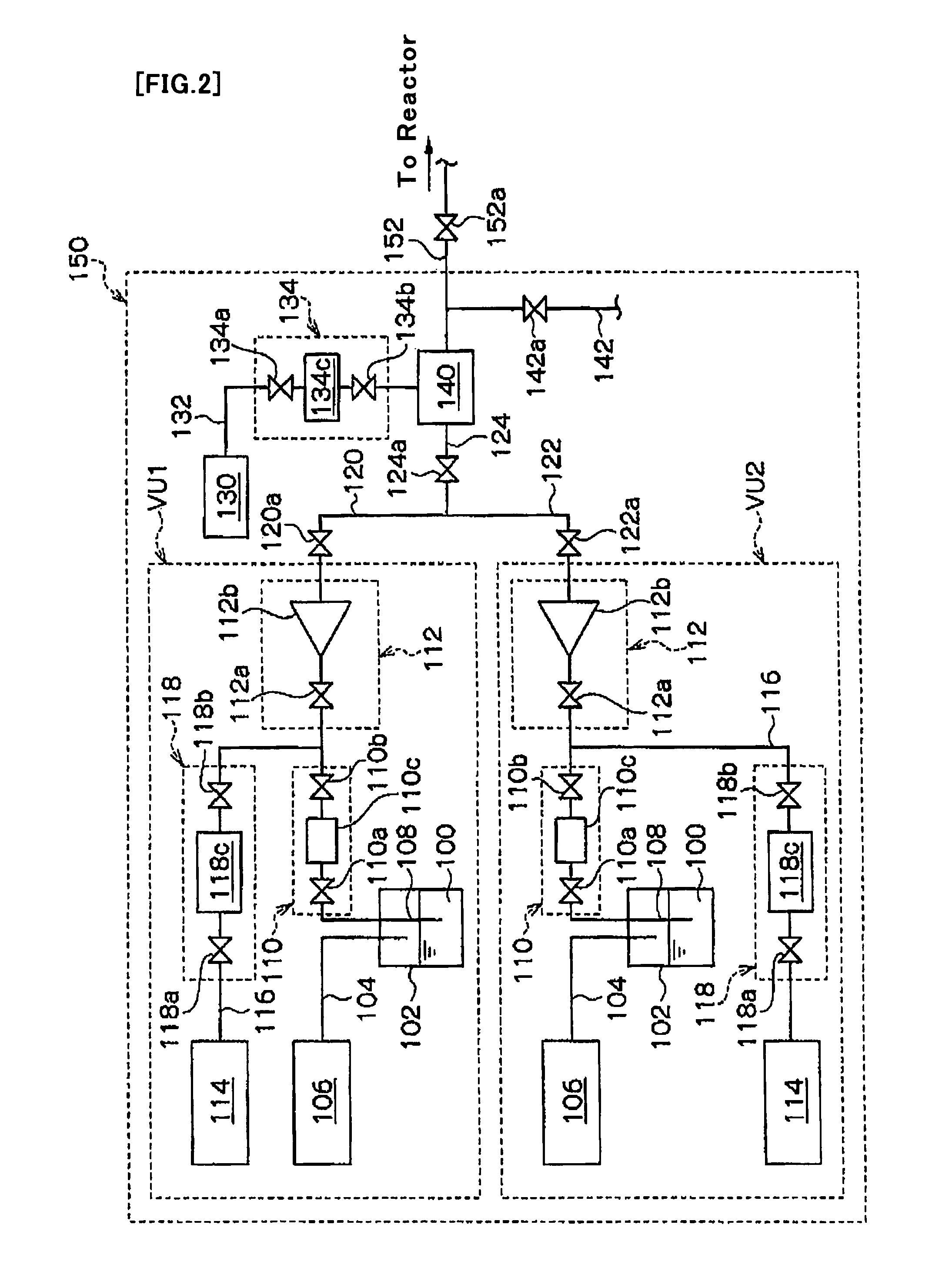

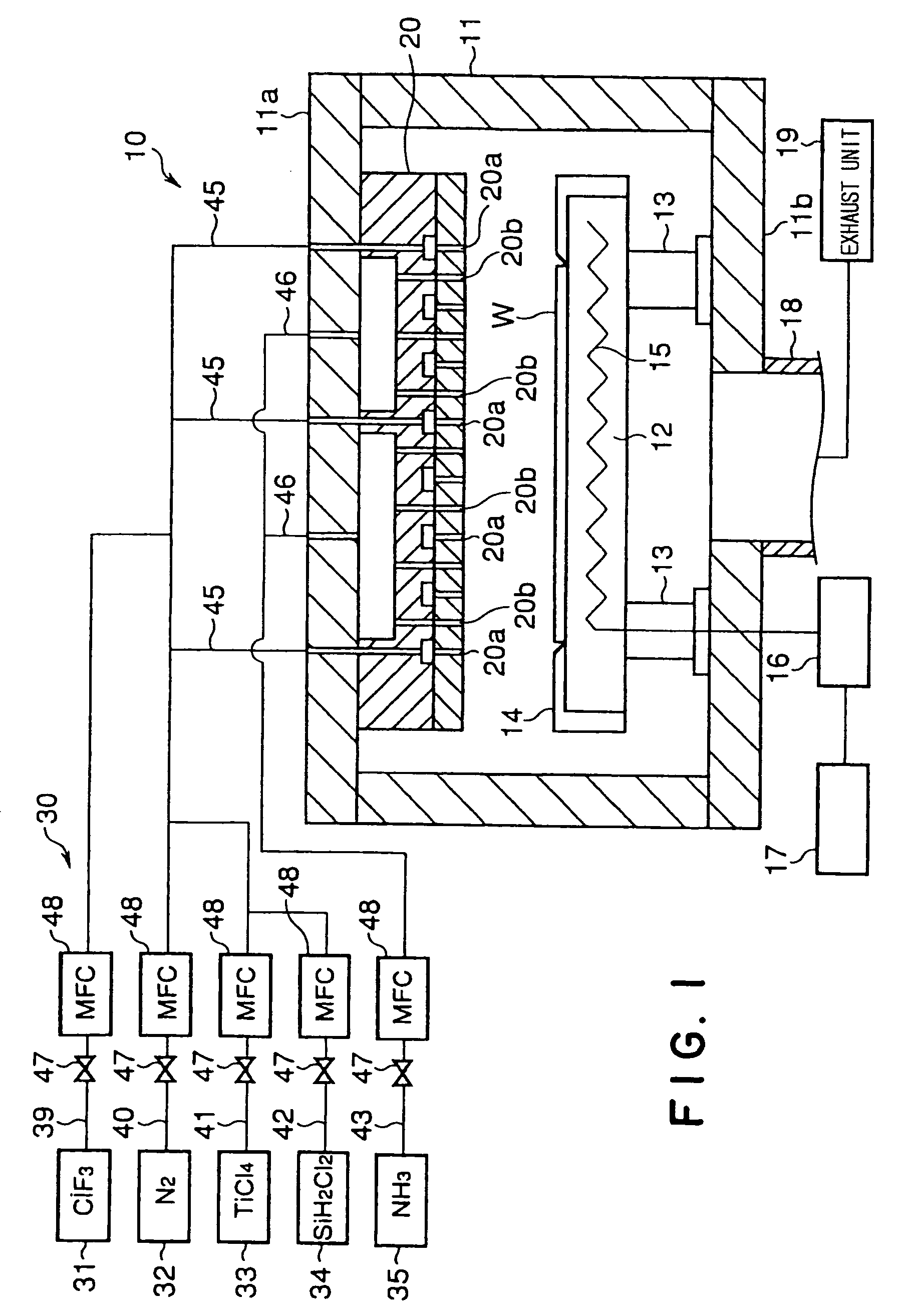

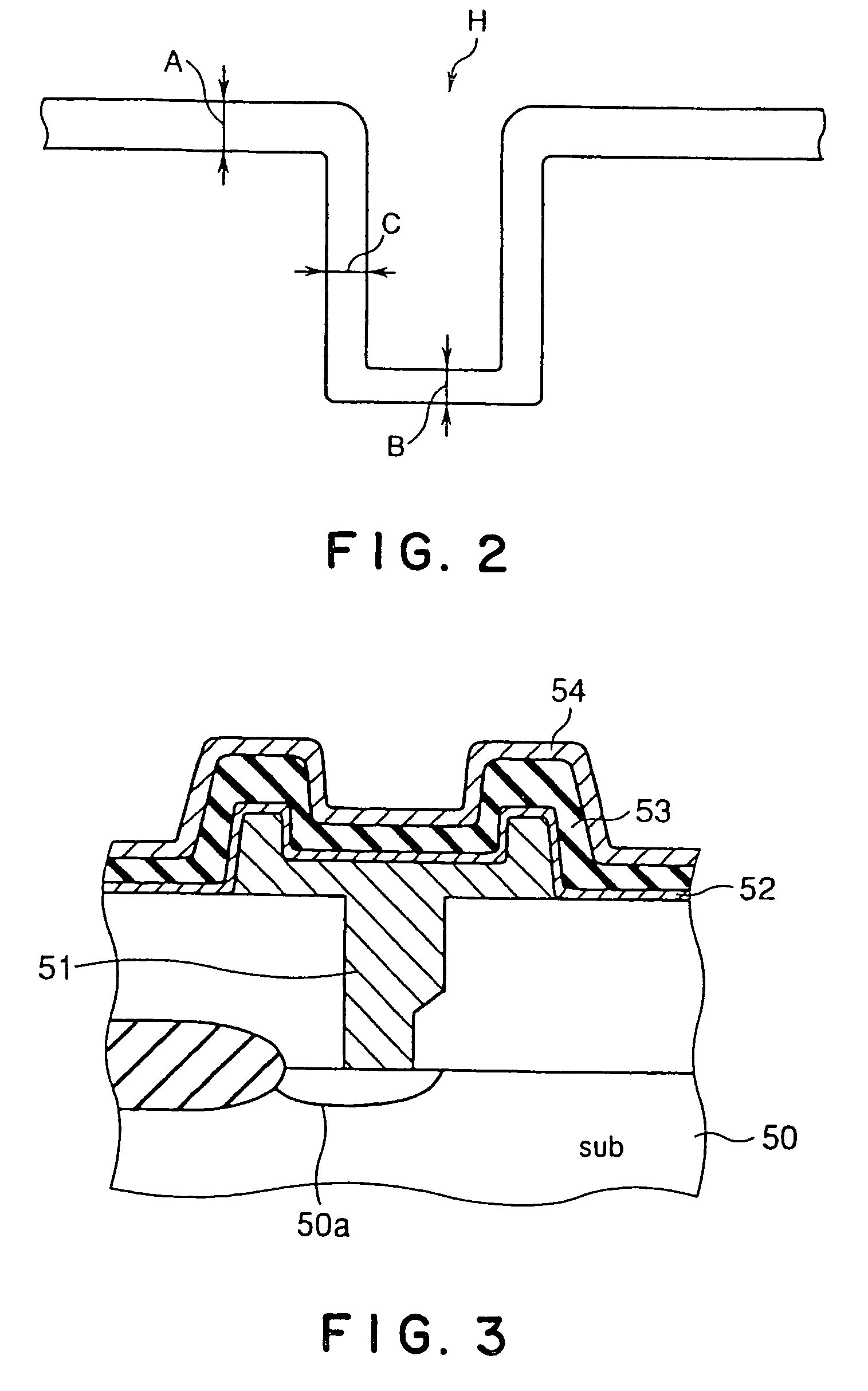

Method for forming TiSiN film, diffusion preventive film comprising TiSiN film, semiconductor device and its production method, and apparatus for forming TiSiN film

A TiSiN film is used as a barrier metal layer for a semiconductor device to prevent the diffusion of Cu. The TiSiN film is formed by a plasma CVD process or a thermal CVD process. TiCl4 gas, a silicon hydride gas and NH3 gas are used as source gases for forming the TiSiN film by the thermal CVD process. TiCl4 gas, a silicon hydride gas, H2 gas and N2 gas are used as source gases for forming a TiSiN film by the plasma CVD process.

Owner:TOKYO ELECTRON LTD

Method for preparing hydrogenated silicon film by utilizing magnetron sputtering

InactiveCN101660131AChange photoelectric propertiesFlat surfaceVacuum evaporation coatingSputtering coatingIntermediate frequencyOptoelectronics

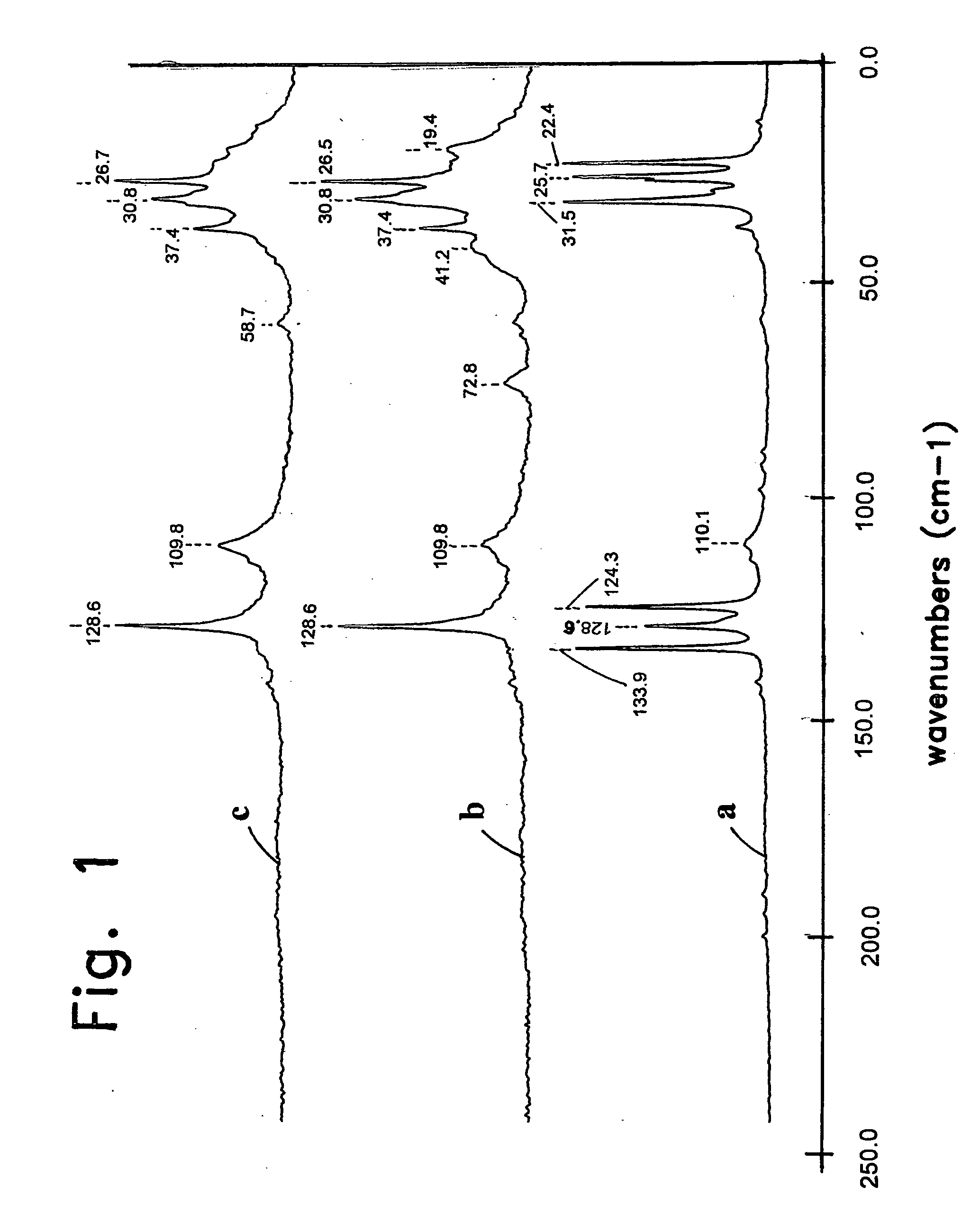

The invention discloses a method for preparing a hydrogenated silicon film by utilizing magnetron sputtering. The method comprises the following steps, pretreating a substrate and placing the substrate in a magnetron sputtering filming device; utilizing a plane Si target as a source of Si element; adjusting the power of an intermediate frequency pulse power supply to control the sputtering rate ofthe Si target; utilizing high-purity Ar gas as main ionization gas, and ensuring the effective glow discharge process; and adopting high-purity H2 gas as reaction gas, ionizing the H2, and combiningthe H2 with the Si element, forming the hydrogenated silicon film on the surface of the substrate through deposition, and annealing the film at the temperature of 550 DEG C to 950 DEG C in vacuum to obtain the nano-crystalline / non-crystalline composite structure. The invention achieves regulation and control to microstructure of the hydrogenated silicon film by changing introduction proportion ofhydrogen so as to further change the photoelectric properties of the film. The preparation method is simple and reliable, and the prepared hydrogenated silicon film is hopeful to be applied to solar batteries.

Owner:XI AN JIAOTONG UNIV

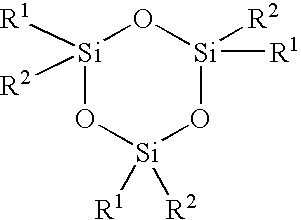

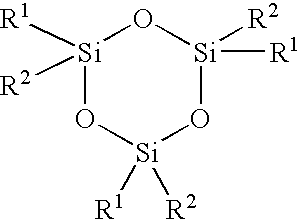

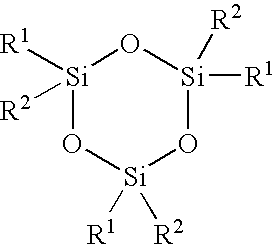

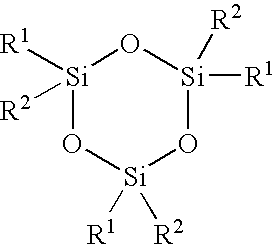

Process for making siloxane oligomer

A process for making a Si—H functional siloxane oligomer from the reaction between silicon hydride compositions and cyclic siloxane oligomer in the presence of a Lewis acid is provided. The Lewis acid is operable to interact with the hydrogen of the silicon hydride to promote ring opening of the cyclic siloxane oligomer and the insertion a siloxane oligomer segment between Si and H atom to thereby form the Si—H functional siloxane oligomer.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

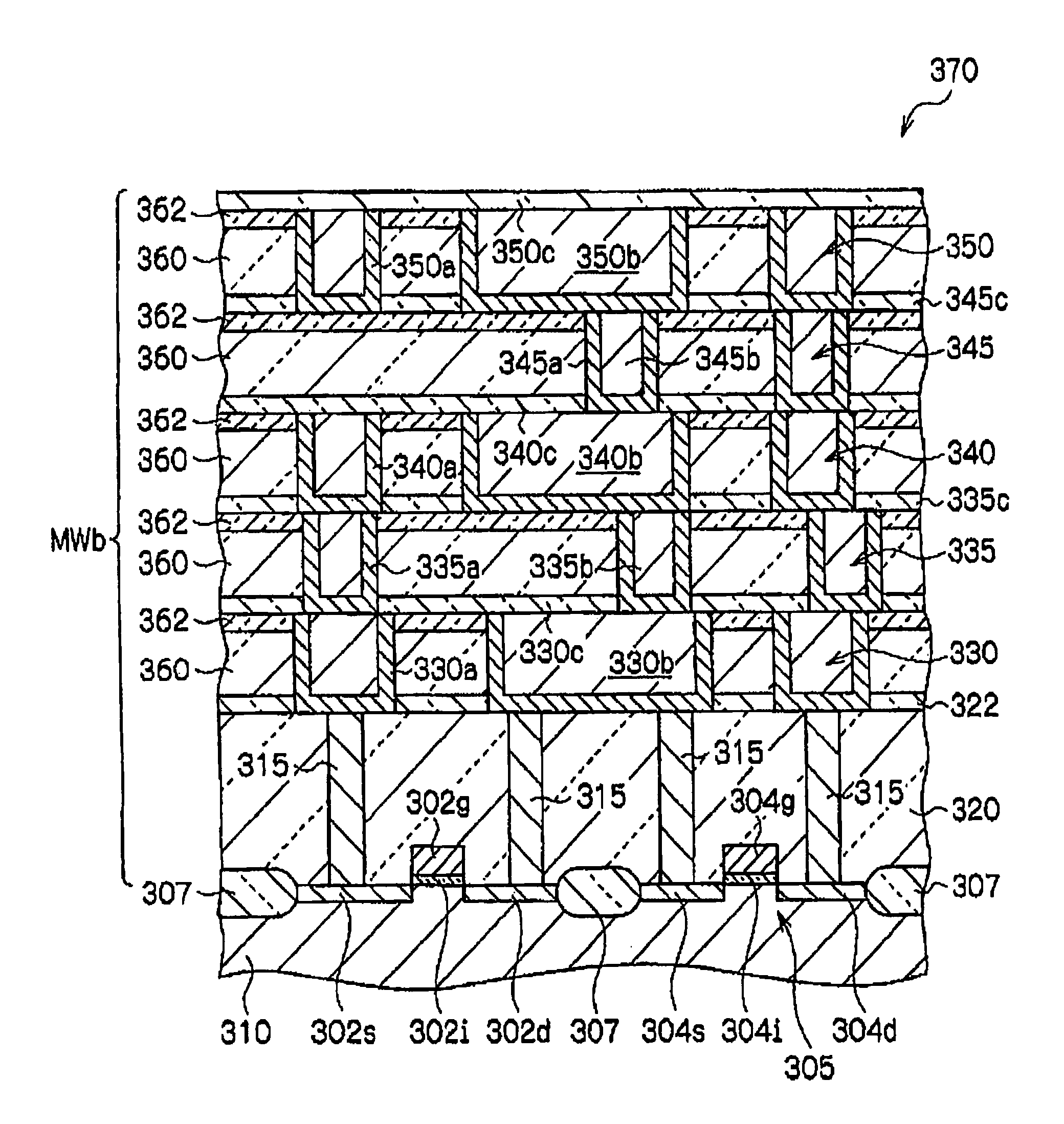

Method of Fabricating Organic Silicon Film, Semiconductor Device Including the Same, and Method of Fabricating the Semiconductor Device

ActiveUS20080251926A1Reduce leakage currentLow dielectric constantLiquid surface applicatorsSemiconductor/solid-state device detailsGas phaseChemical vapor deposition

An organic silicon film is formed by carrying out chemical vapor deposition with organic silicon compound being used as a raw material gas. The organic silicon compound contains at least silicon, hydrogen and carbon as a constituent thereof, and contains two or more groups having unsaturated bond, per a molecule thereof. The organic silicon compound is used in mixture with a silicon hydride gas.

Owner:GK BRIDGE 1

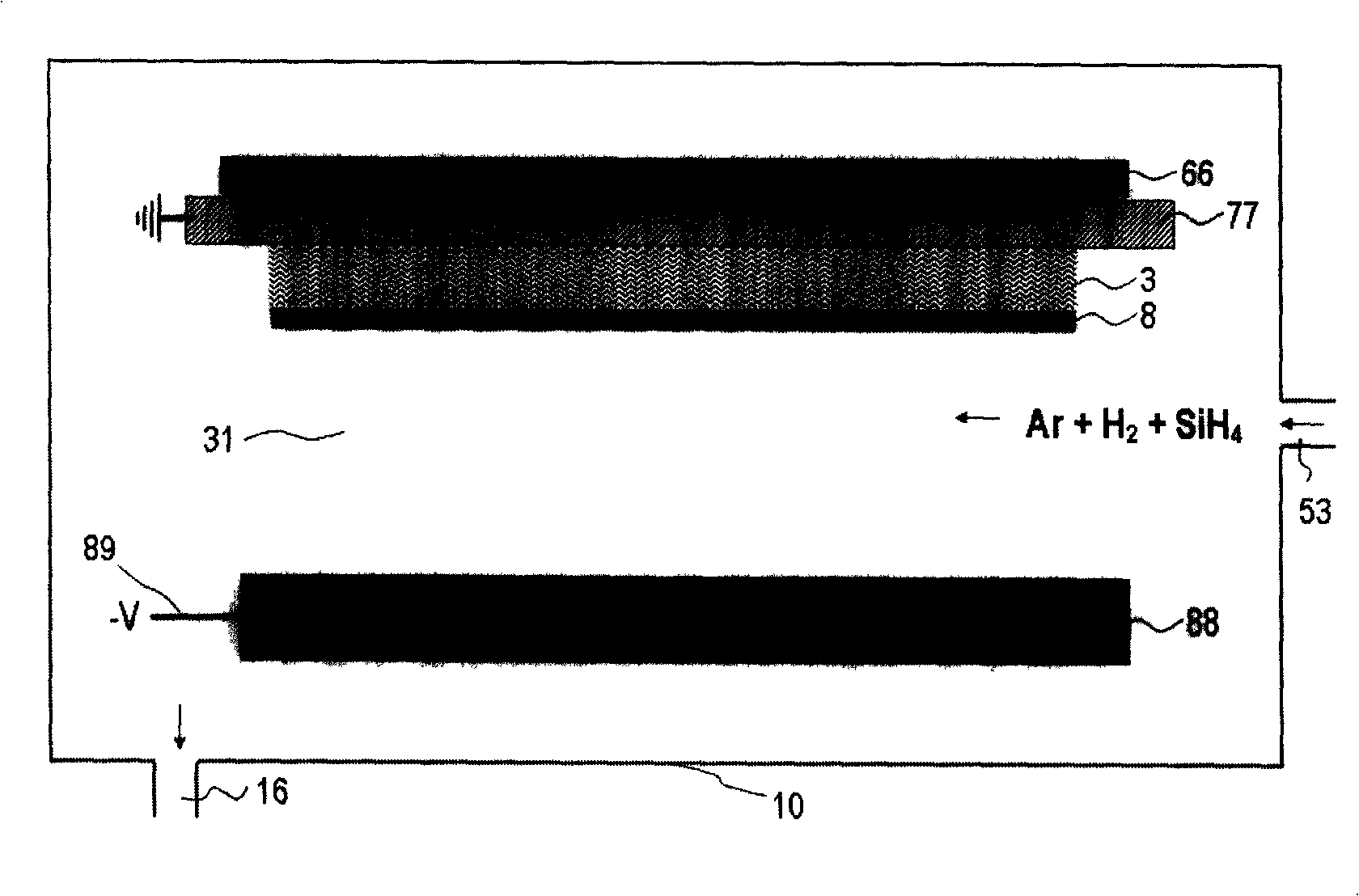

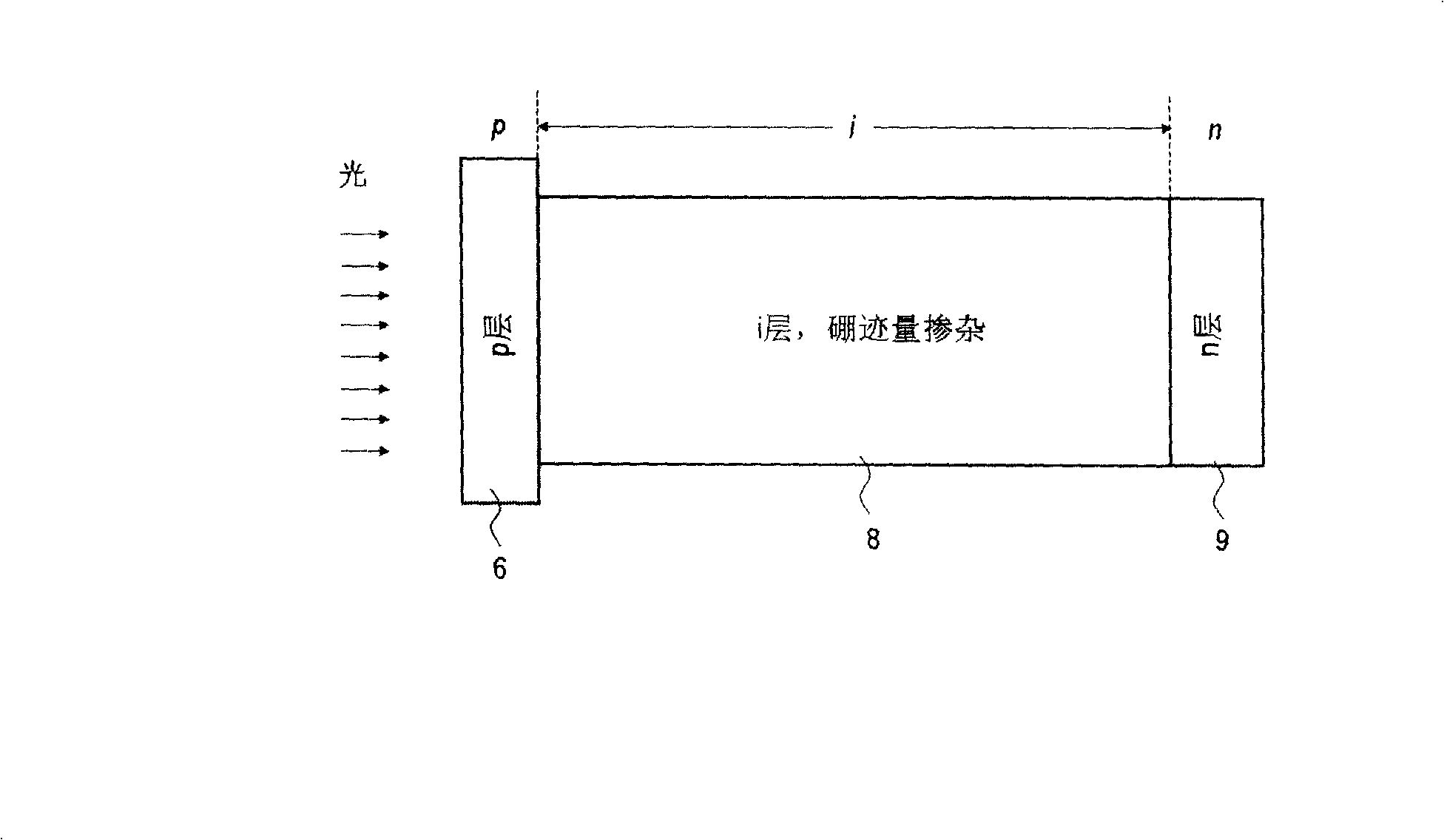

Method for manufacturing thin membrane silicon electrooptical device with single-chamber plasma case

InactiveCN101245448AIncrease productionLow costSemiconductor/solid-state device manufacturingChemical vapor deposition coatingTransducerSingle chamber

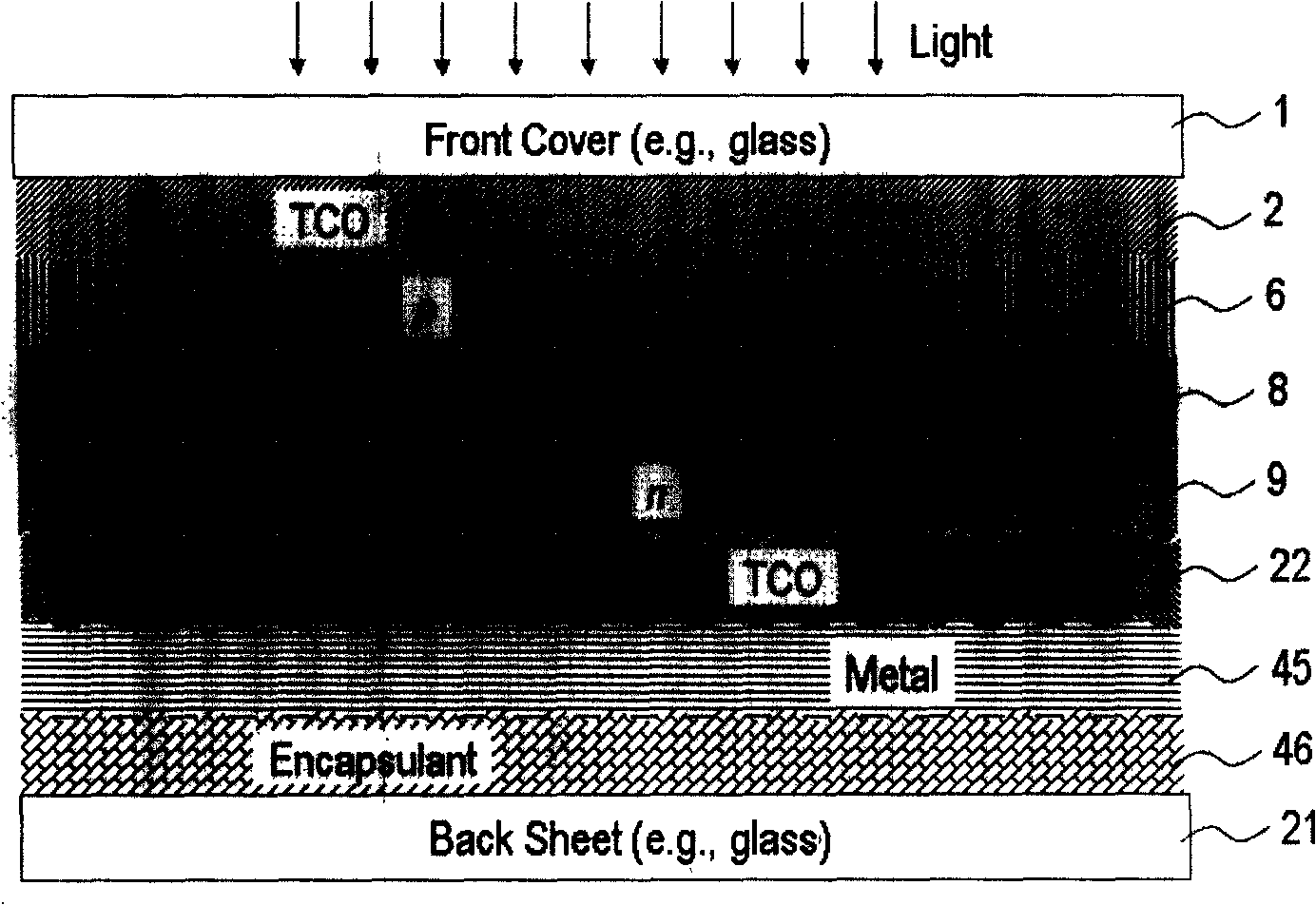

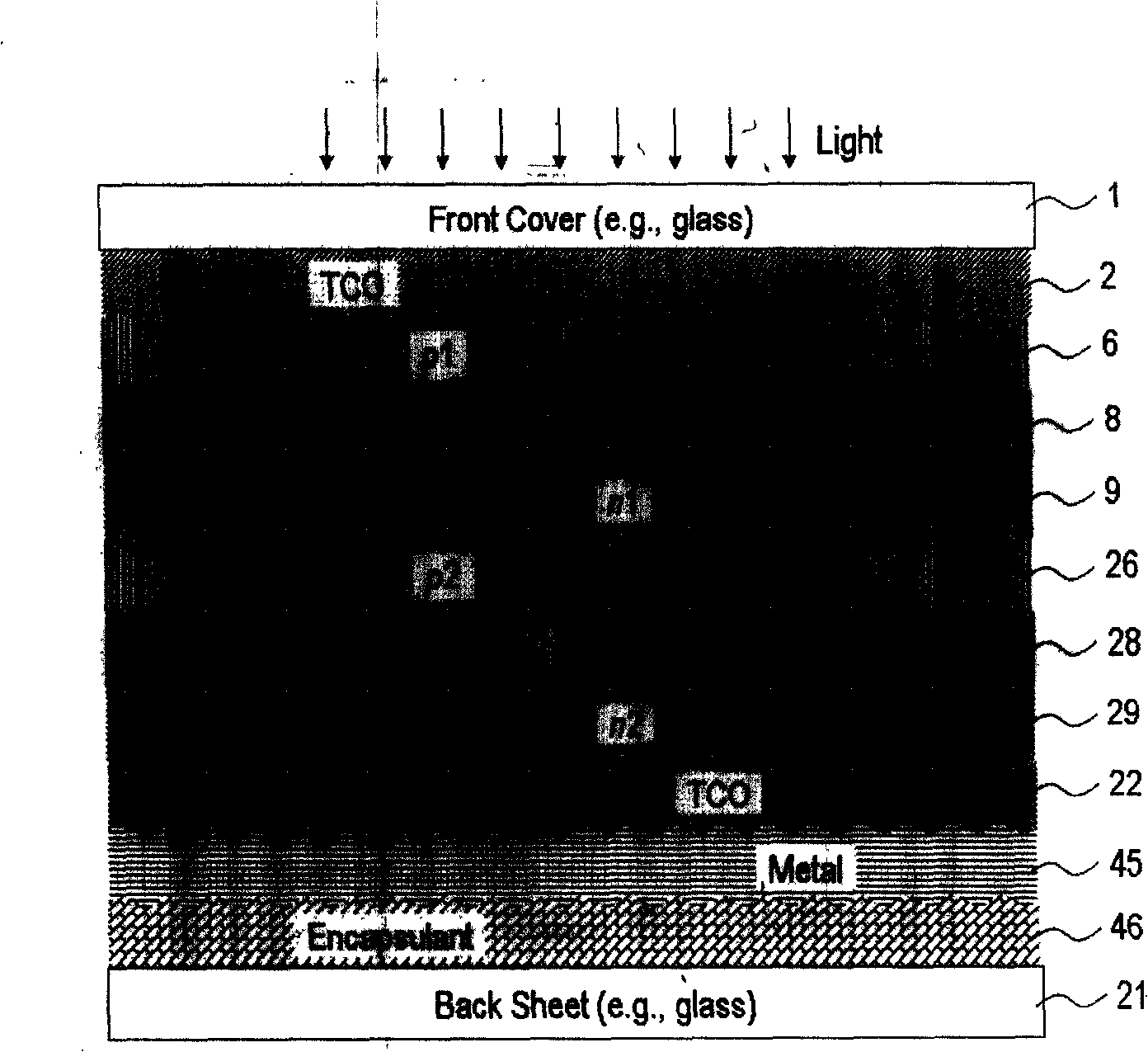

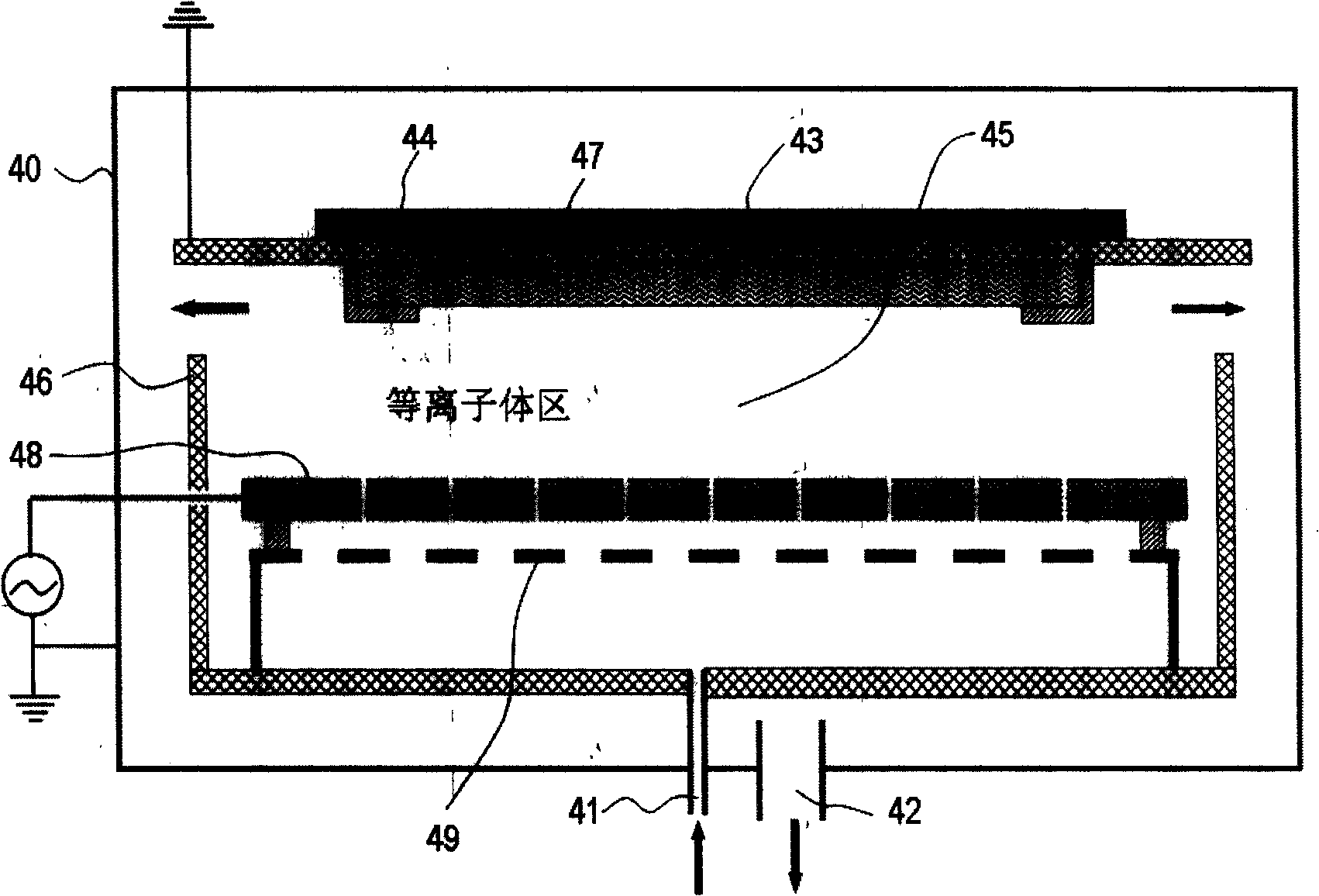

The invention discloses a device and a method for the production of a thin-film silicon optical-to-electrical transducer. A plasma enhanced chemical vapor deposition system (PECVD) used in the invention consists of a single vacuum chamber and a plasma chamber carrying a plurality of base plates in the vacuum chamber. The preparation method of the p-i-n optical-to-electrical transducer based on hydrogenated silicon films comprises the steps as follows: a p-type, an i-type and an n-type thin-film silicon layer sequentially generated on most of the base plates in the same plasma chamber are fixedly arranged in the same vacuum chamber. In the deposition process of each film layer, the device is not required to be cleaned and no cross contamination of the i layer is caused. The steps can be repetitively processed in the same base plates to obtain a multi-junction optoelectronic device. The method for the production of thin-film the silicon optical-to-electrical transducer has incomparable advantages of low cost and high productivity.

Owner:BEIJING XINGZHE MULTIMEDIA TECH

Silicon-modified crumb rubber composition

The present invention relates to a modified crumb rubber particle having carbon to silicon bonds created by the reaction of the unsaturation in the crumb rubber particle and silicon hydride, with or without the use of a catalyst. Bound silicon content ranges from about 0.1% to 10% by weight. The silicon-modified crumb rubber can be used as is or a reinforcing filler in formulations. Typically the silicon-modified crumb rubber is used in up to 25% by weight of the total rubber present in virgin rubber compositions.

Owner:MICHELIN RECH & TECH SA

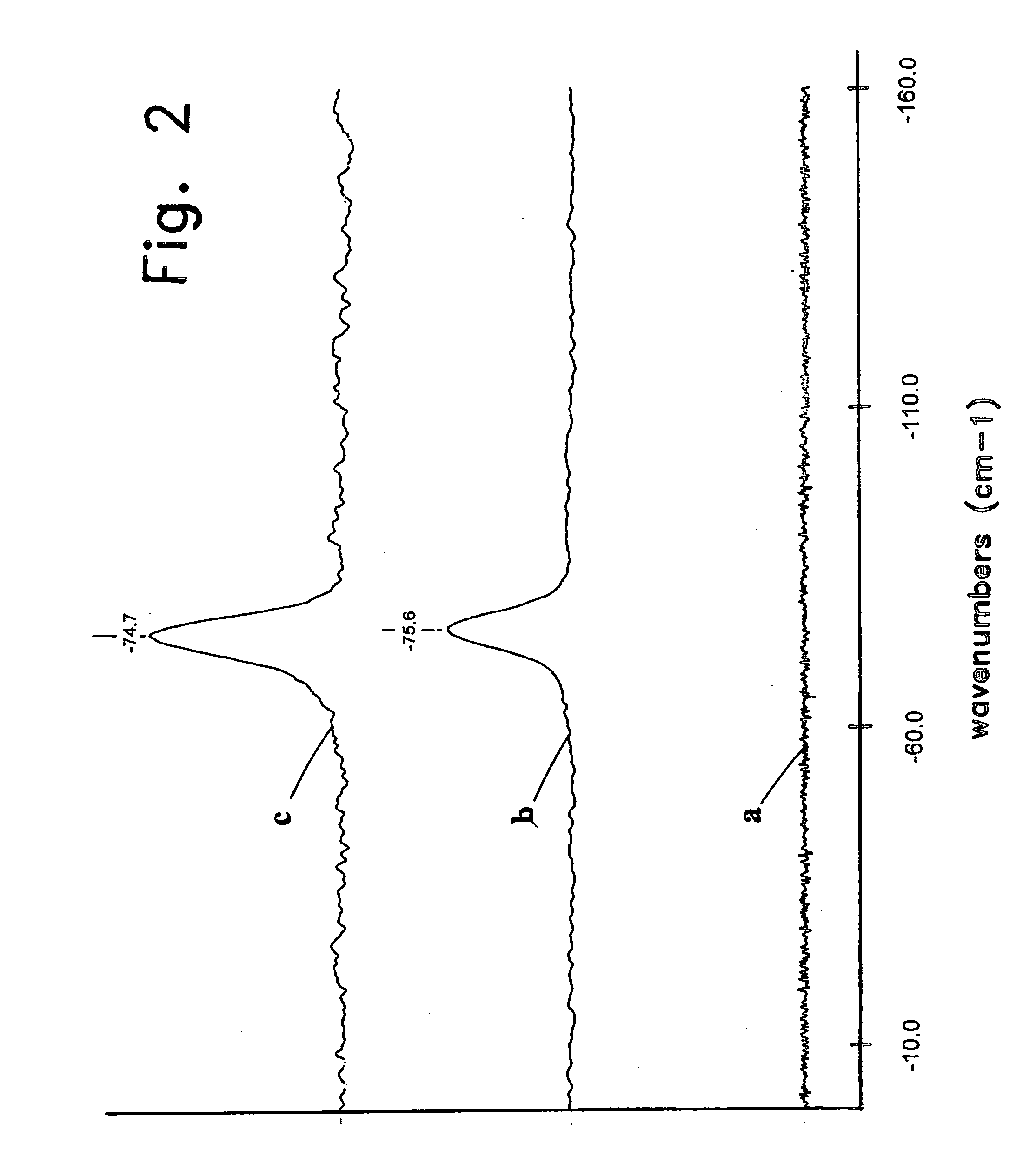

Production of silicon hydride thin film by hydrogen argon high dilution method

InactiveCN101246932AImprove photoelectric performanceImprove stabilityFinal product manufactureChemical vapor deposition coatingSilanesGas phase

The present invention discloses technique means to produce hydrogenated Si film by hydrogen argon high dilution method in PECVD process. In the process of sensivitve sensitivity hydrogenated Si film by PECVD (plasma enhanced chemical vapor deposited method), if introducing a mount of inert gases (such as argon) and hydrogen to mixture of source gas containing silane in deposited process, the formed film has better photovoltaic capability and stability. Comparing to pure hydrogen dilution, the hydrogen and argon dilution method is more efficient, and more suitable for large area, high speed produce of solar cell based on hydrogenated Si film.

Owner:BEIJING XINGZHE MULTIMEDIA TECH

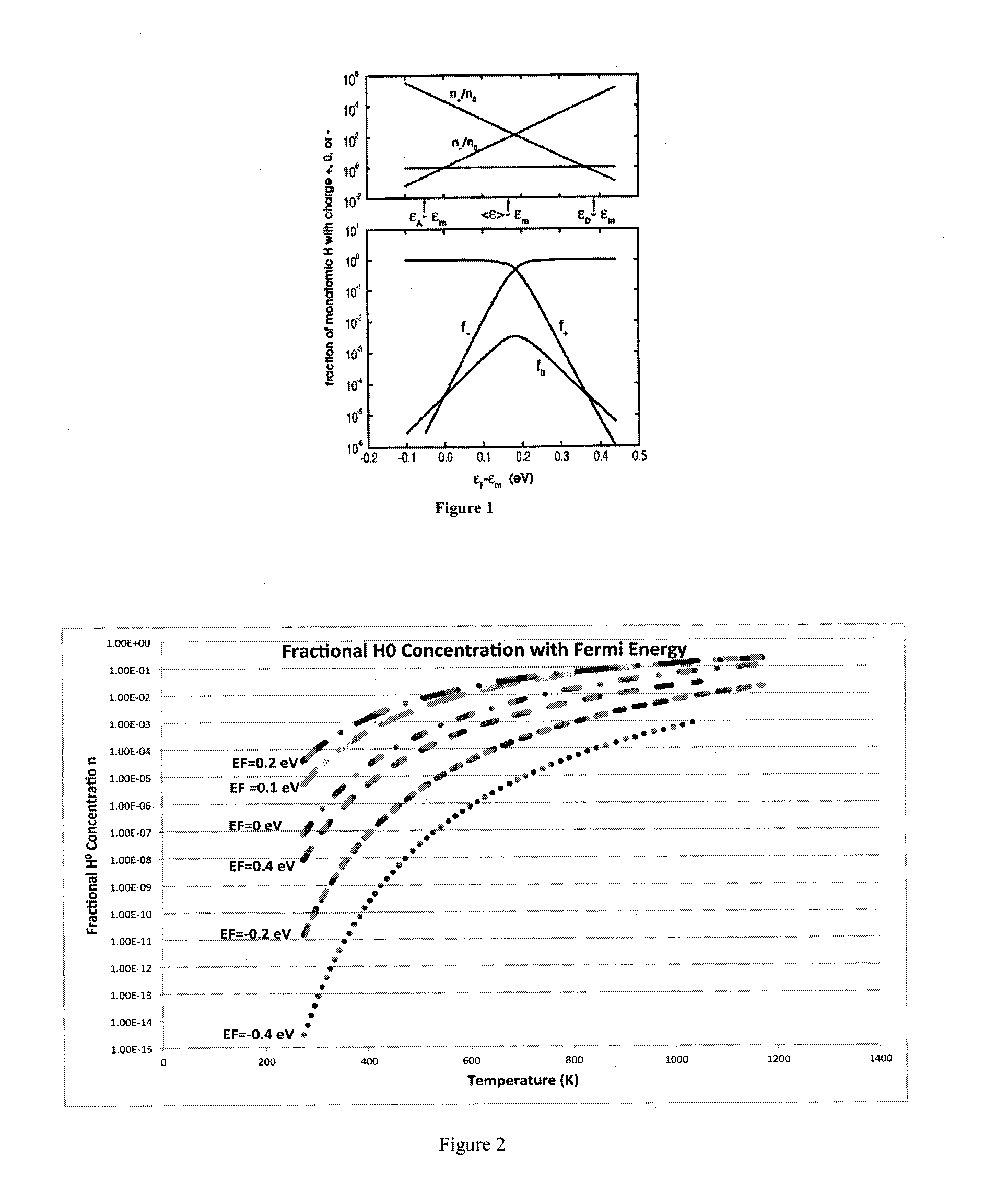

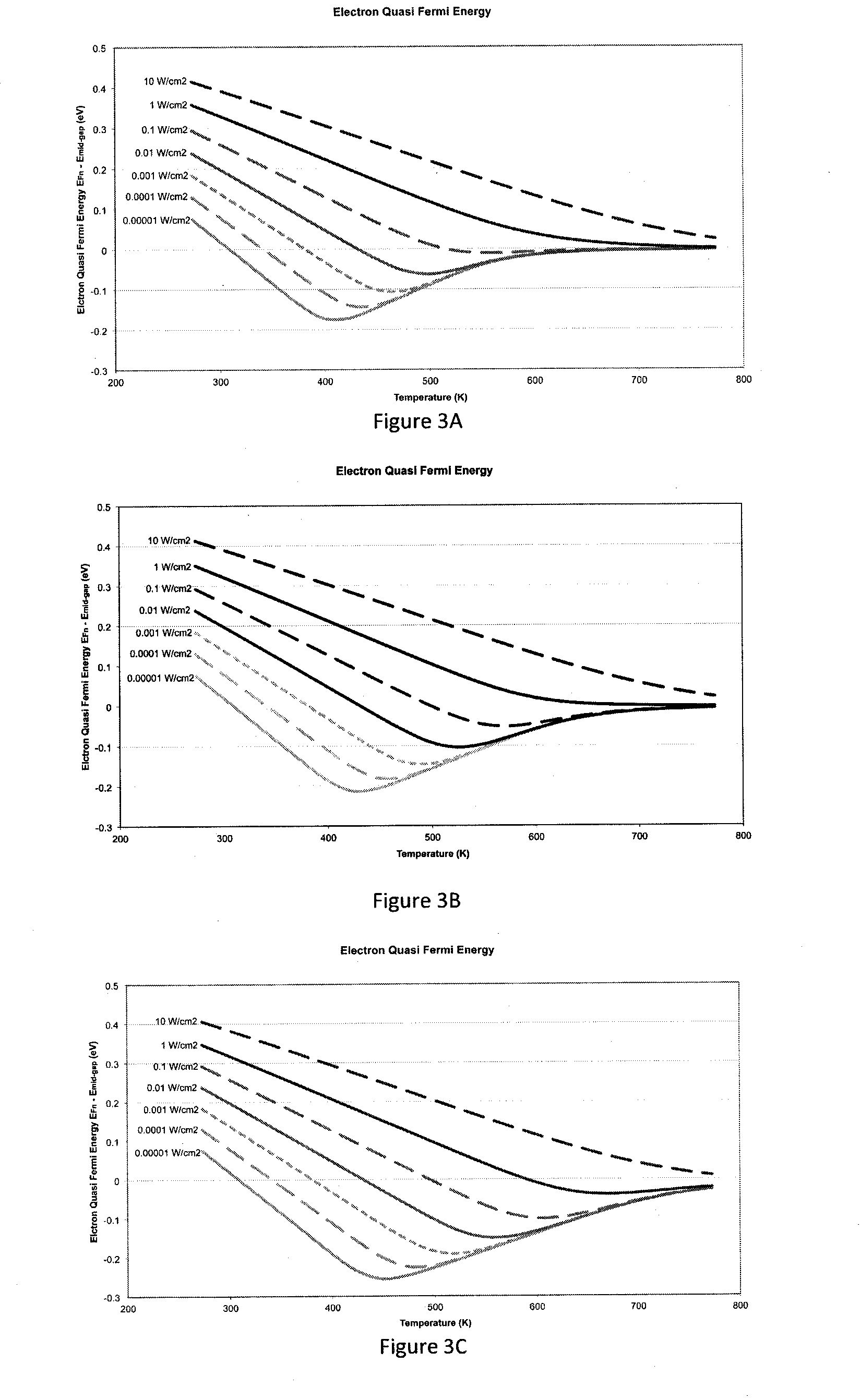

Advanced hydrogenation of silicon solar cells

ActiveUS20150132881A1Maximise H generationImprove permeabilityFinal product manufactureSemiconductor/solid-state device manufacturingSemiconductor materialsSilicon solar cell

A method of hydrogenation of a silicon photovoltaic junction device is provided, the silicon photovoltaic junction device comprising p-type silicon semiconductor material and n-type silicon semiconductor material forming at least one p-n junction.The method comprises:i) ensuring that any silicon surface phosphorus diffused layers through which hydrogen must diffuse have peak doping concentrations of 1×1020 atoms / cm3 or less and silicon surface boron diffused layers through which hydrogen must diffuse have peak doping concentrations of 1×1019 atoms / cm3 or less;ii) Providing one or more hydrogen sources accessible by each surface of the device; andiii) Heating the device, or a local region of the device to at least 40° C. while simultaneously illuminating at least some and / or advantageously all of the device with at least one light source whereby the cumulative power of all the incident photons with sufficient energy to generate electron hole pairs within the silicon (in other words photons with energy levels above the bandgap of silicon of 1.12 eV) is at least 20 mW / cm2

Owner:NEWSOUTH INNOVATIONS PTY LTD

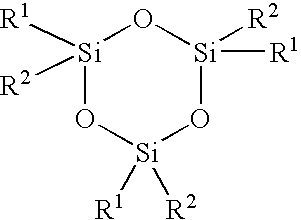

Process for making siloxane oligomer

Owner:RUBINSZTAJN SLAWOMIR +3

Chemical annealing method for making amorphous silicon battery more stable

InactiveCN101235492AFacilitate recombination optimizationAtomic structure relaxationChemical vapor deposition coatingSemiconductor devicesSilicon membraneCompound (substance)

The invention discloses a chemical annealing method for improving the stability of intrinsic amorphous silicon thin film, which comprises: alternating the growth of silicon film whose thickness is 2-10 nanometers and the chemical annealing treatment in the process that plasmas are used to intensify a chemical vapor deposition method to generate hydrogenated amorphous silicon, sufficiently rebuilding and loosening atomic structures of hydrogenated silicon material, and lowing the electronic defect concentration. The material is in particular suitable for i layers in p-i-n type photovoltaic devices.

Owner:BEIJING XINGZHE MULTIMEDIA TECH

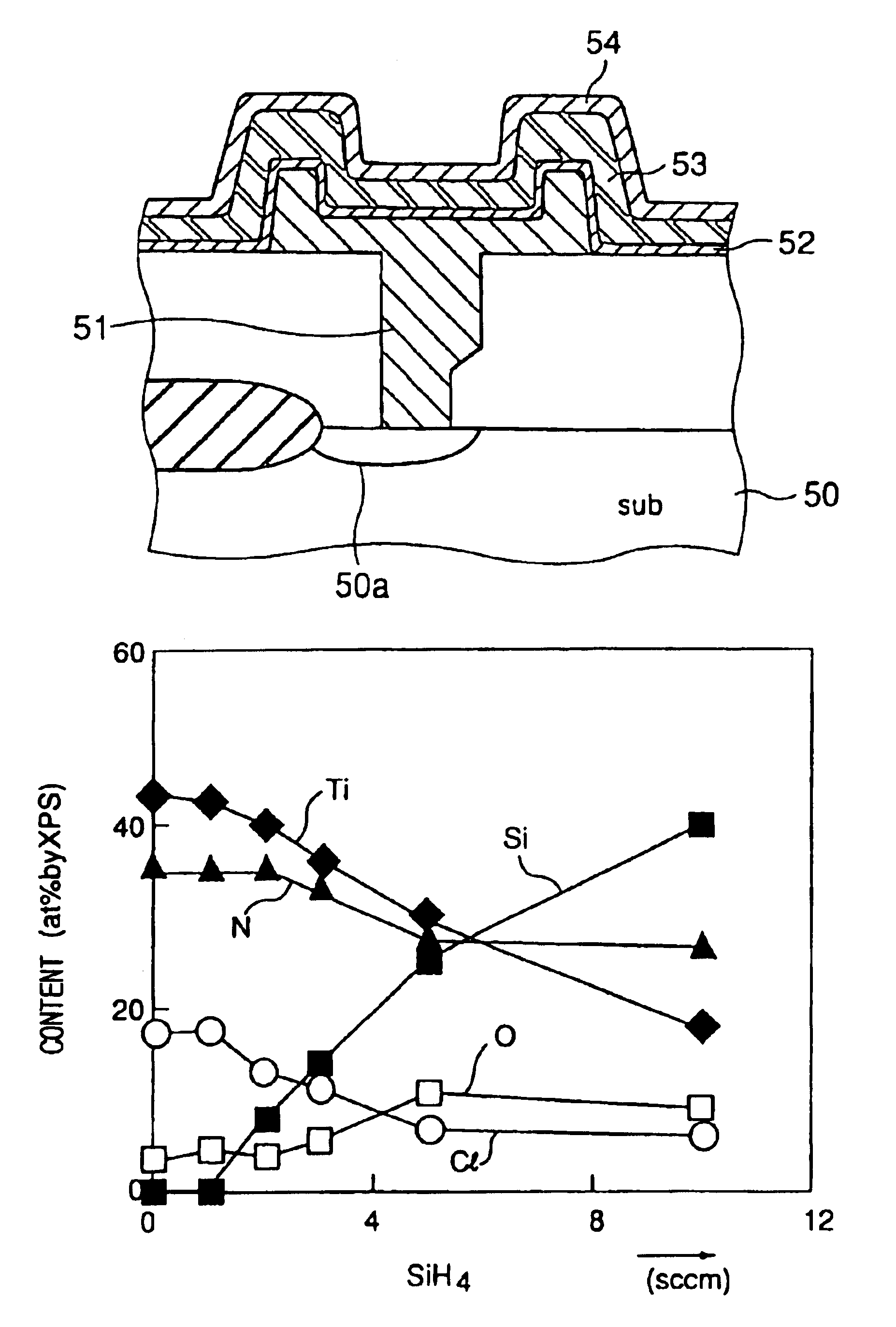

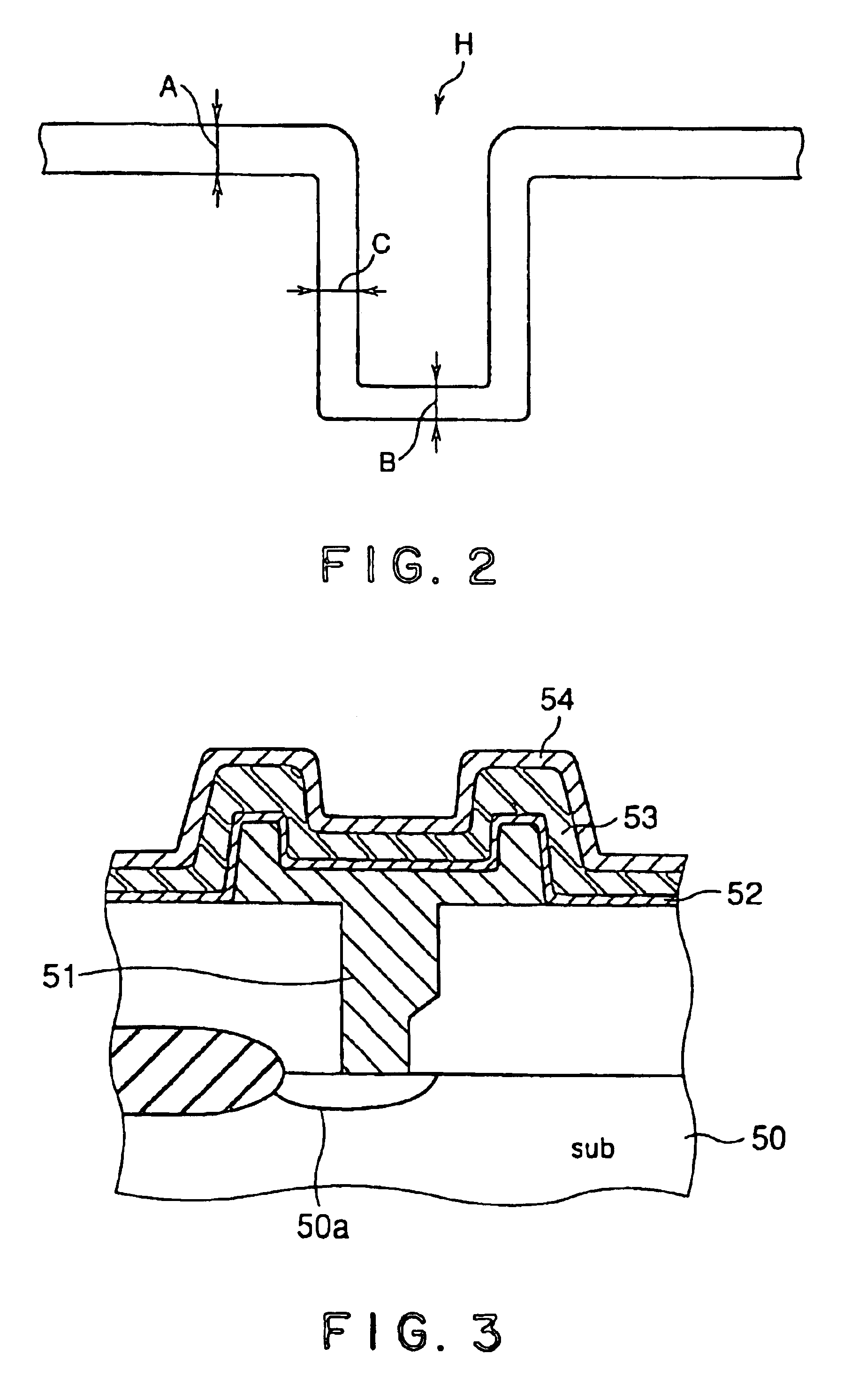

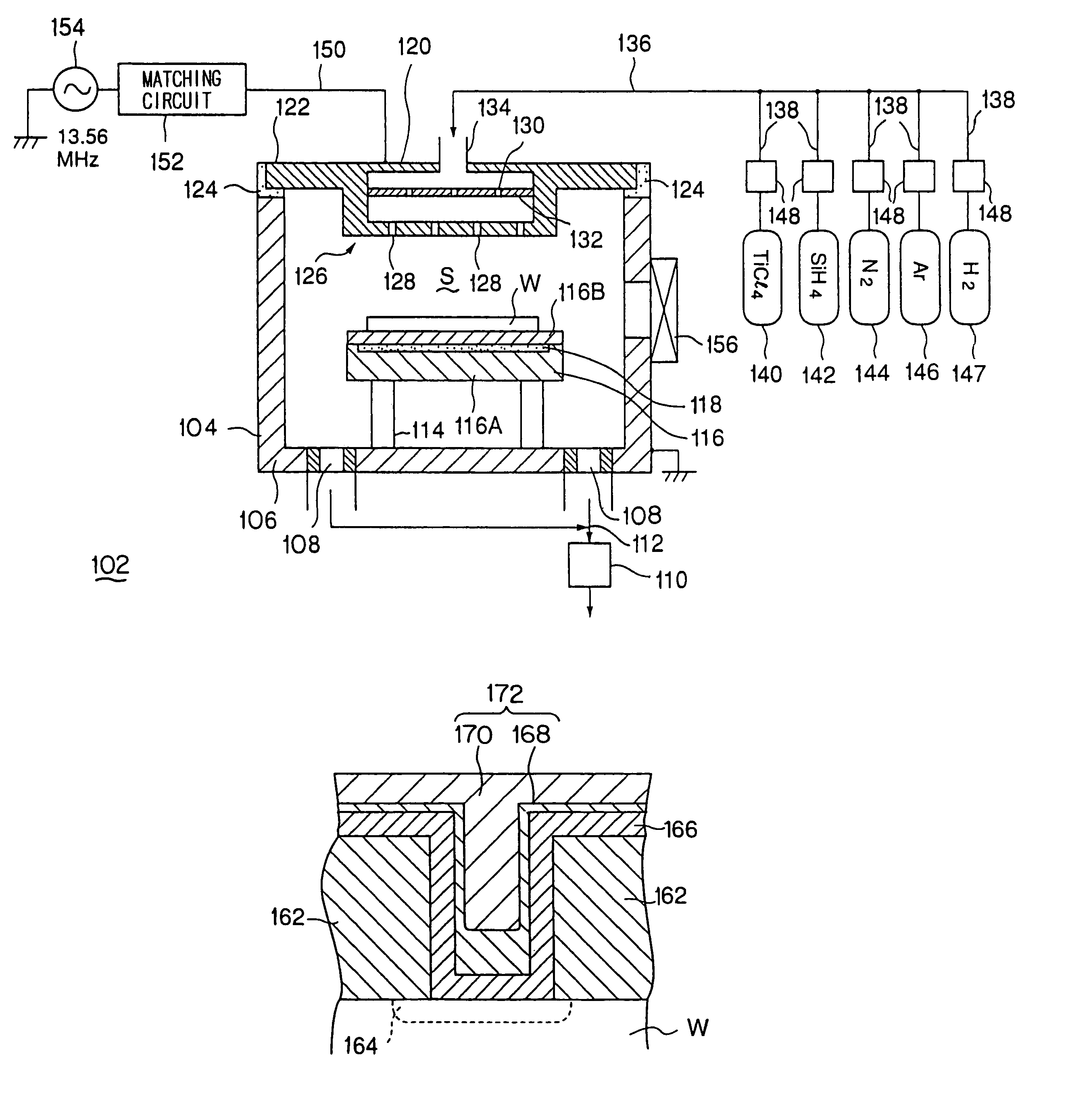

TiSiN film forming method, diffusion barrier TiSiN film, semiconductor device, method of fabricating the same and TiSiN film forming system

InactiveUS7153773B2TransistorSemiconductor/solid-state device detailsDiffusion barrierPolysilicon hydride

A TiSiN film is used as a barrier metal layer for a semiconductor device to prevent the diffusion of Cu. The TiSiN film is formed by a plasma CVD process or a thermal CVD process. TiCl4 gas, a silicon hydride gas and NH3 gas are used as source gases for forming the TiSiN film by the thermal CVD process. TiCl4 gas, a silicon hydride gas, H2 gas and N2 gas are used as source gases for forming a TiSiN film by the plasma CVD process.

Owner:TOKYO ELECTRON LTD

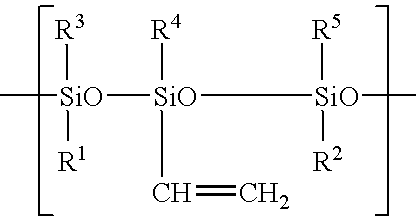

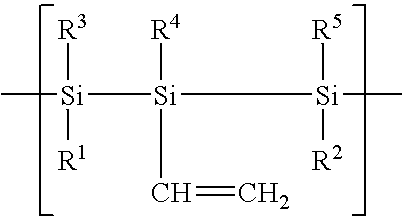

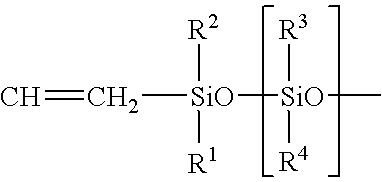

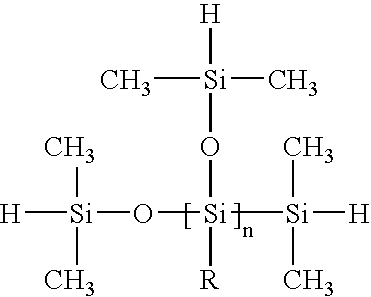

Sterically hindered reagents for use in single component siloxane cure systems

ActiveUS7211637B2Considerably lowers crosslinking rateSuppressing premature crosslinkingMaterial analysis by electric/magnetic meansOrganic groupCrosslinking reagent

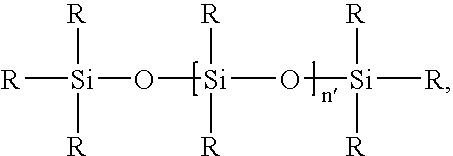

A one-component or single component cure system for a polysiloxane product is provided. The cure system includes a siloxane reagent that has an unsaturated organic functional group for reacting with a crosslinking reagent. The cure system also has a crosslinking reagent that has a silicon hydride group for crosslinking with the unsaturated organic group of the siloxane reagent. Either the unsaturated functional group of the siloxane reagent, the silicon hydride group of the crosslinking reagent, or both are sterically hindered. The siloxane reagent and the sterically hindered silicon hydride crosslinking reagent are mixed together in the presence of a catalyst reagent to form the one-component cure system. Methods of making the polysiloxane product are also provided.

Owner:THERM O DISC

Low temperature curable coating compositions, related methods and coated substrates

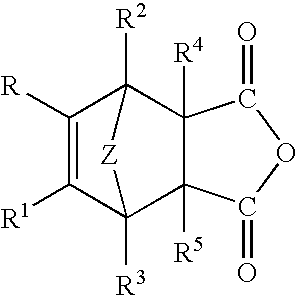

Disclosed are low temperature curable coating compositions that include a polymer comprising functional groups reactive with anhydride groups and a crosslinking agent that includes the ungelled hydrosilylation reaction product of a silicon hydride and an unsaturated polycarboxylic acid anhydride. Also disclosed are related coated substrates and methods for coating a substrate.

Owner:PPG IND OHIO INC

Heterogeneous hydrosilylation catalysts, polymers formed therewith, and related coating compositions

InactiveUS20090018301A1Good colorOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsSilanesHydrosilylation

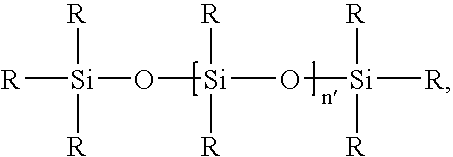

Disclosed are heterogeneous platinum group metal catalysts that are catalytically active towards hydrosilylation. These catalysts include a carrier in communication with platinum group metal particles, wherein the particles are affixed to a polyelectrolyte layer. Also disclosed are polymers that are the hydrosilylation reaction product of (a) a polysiloxane containing silicon hydride and (b) an organic compound having aliphatic unsaturation in the molecule, wherein the hydrosilylation reaction is carried out in the presence of a catalytic amount of such a catalyst, a heterogeneous platinum group metal catalyst that is catalytically active towards hydrosilylation, coating compositions that include such polymers and substrates at least partially coated with such compositions.

Owner:PPG IND OHIO INC

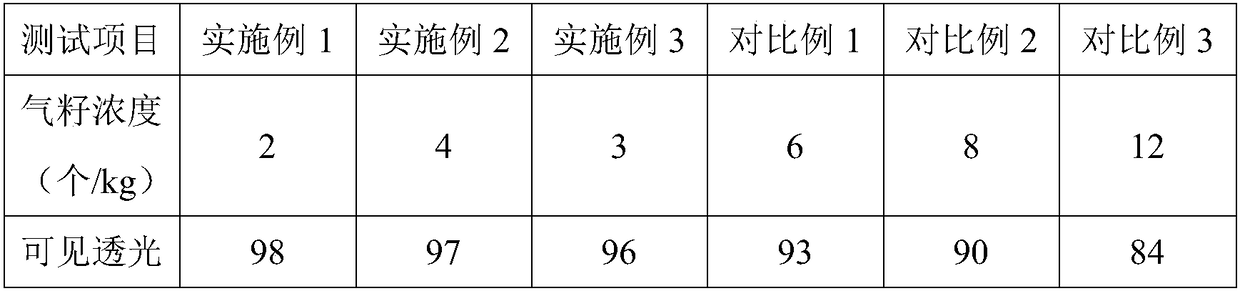

Composite glass clarifying agent

The invention discloses a composite glass clarifying agent, which belongs to the field of the glass production. The composite glass clarifying agent is prepared from the raw materials such as acrylamide and sodium dimethyl diacrylamide sulfonate and can be slowly expanded after being heated, and can form a wrapping and supporting effect for a netted structure formed by silicate and SiO2 in a glasssystem, polymer microspheres comprise partial gas in the preparation process, in the application process, the partial gas overflows rapidly, so that the dispersity is good, and a better bubble inhibition and removal effect can be achieved; and polyether is introduced into the organic silicon, no only can the hydrophilic group but also the oleophylic group be provided, by introducing the paraffinand microcrystalline paraffin, a long-chain aliphatic compound can be introduced, the silicon tetrahydride can be rapidly hydrolyzed into orthosilicic acid and hydrogen under an alkaline condition, generation of other bubbles can be prevented, the secondary bubbles can be further prevented, and a better bubble eliminating effect can be achieved. By adopting the composite glass clarifying agent, the problem that the conventional glass clarifying agent is poor in bubble removal efficiency.

Owner:CHANGZHOU UNIV

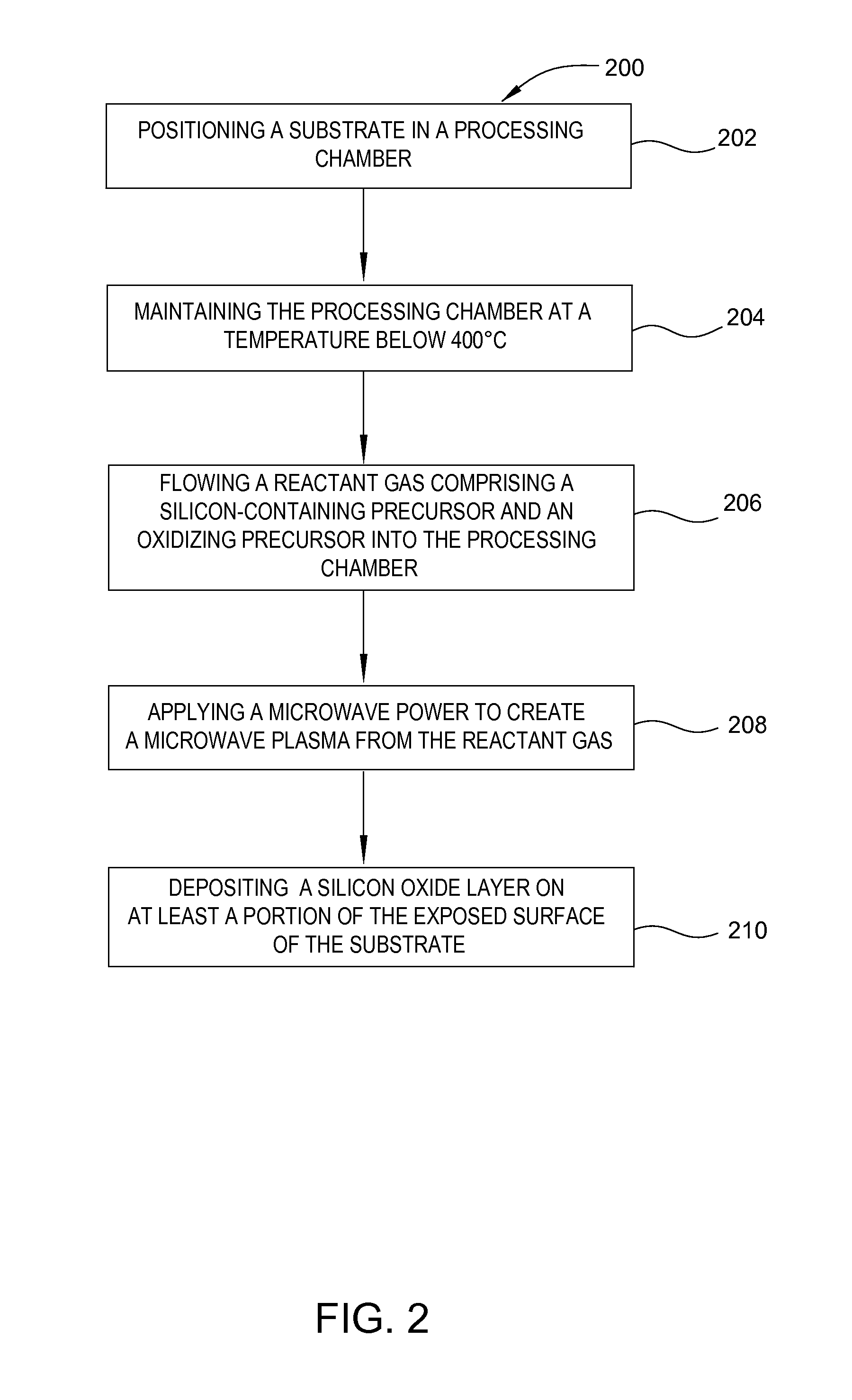

SiOx process chemistry development using microwave plasma CVD

InactiveUS8906813B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingProcess chemistrySilicon oxide

Methods for processing a substrate are described herein. Methods can include positioning a substrate in a processing chamber, maintaining the processing chamber at a temperature below 400° C., flowing a reactant gas comprising either a silicon hydride or a silicon halide and an oxidizing precursor into the process chamber, applying a microwave power to create a microwave plasma from the reactant gas, and depositing a silicon oxide layer on at least a portion of the exposed surface of a substrate.

Owner:APPLIED MATERIALS INC

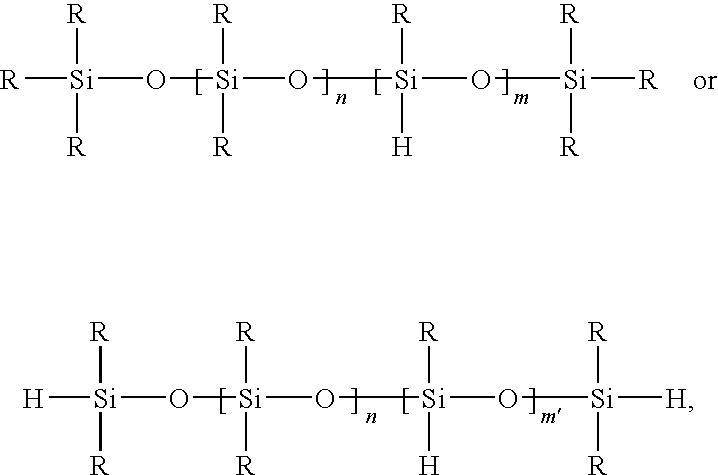

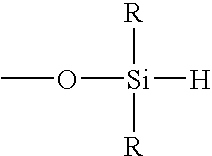

Curing rubber by hydrosilation

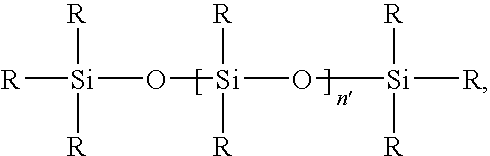

A method for preparing a thermoplastic vulcanizate, the method comprising dynamically vulcanizing a rubber within a blend that includes the rubber and a thermoplastic polymer, where said dynamically vulcanizing is effected with a cure system that includes a hydrosilating agent and a catalyst, where the hydrosilating agent includes a compound including at least 3 silicon hydride groups defined by the formulawhere each R is independently a monovalent organic group or hydrogen, and where the silicon atoms of the respective silicon hydride groups are spatially separated by at least 6 atoms.

Owner:CELANESE INT CORP

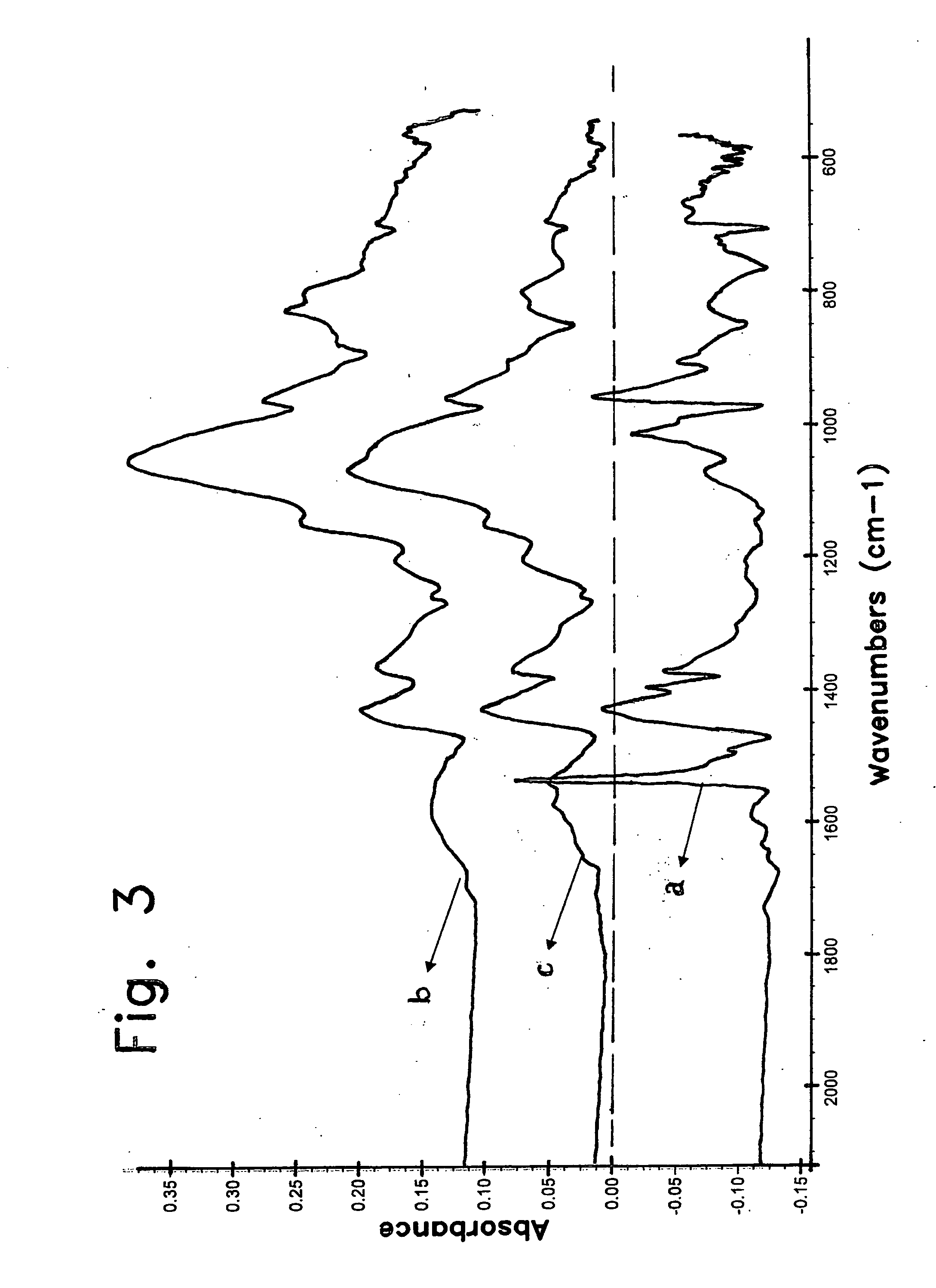

Surface modification of solid supports through thermal decomposition and functionalization of silanes

InactiveCN1356926AGaseous chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsSilanesHydrosilylation

A process of modifiying a solid's surface, comprising a first step of depositing hydrogenated armophous silicon on the surface by thermal decomposition at an elevated temperature of silicon hydride gas to form sila ne radicals which recombine to coat the surface with hydrogenated armophous silicon. A second step of surface funtionalization of the hydrogenated armophous silicon in the presence of a binding agent including hydrosilylation, disproportionation and radical quenching.

Owner:RESTEK

Trace amount of boron doped intrinsic silicon hydride thin film

InactiveCN101246931AImprove conversion efficiencyImprove stabilityFinal product manufactureSemiconductor/solid-state device manufacturingSilanesGas phase

The present invention discloses a method for making the hydrogenated Si containing hydrogenated amorphous silicon and hydrogenated nanocrystalline silicon has real intrinsic capability. In process of plasma enhanced chemical vapor deposition, adding a certain gas containing boron to mixture of hydrogen and silane, making boron counteract doping effect of inevitably n-type impurity. The hydrogenated Si film gained by this method, can improve conversion efficiency and stability of p-i-n type photovoltaic device.

Owner:BEIJING XINGZHE MULTIMEDIA TECH

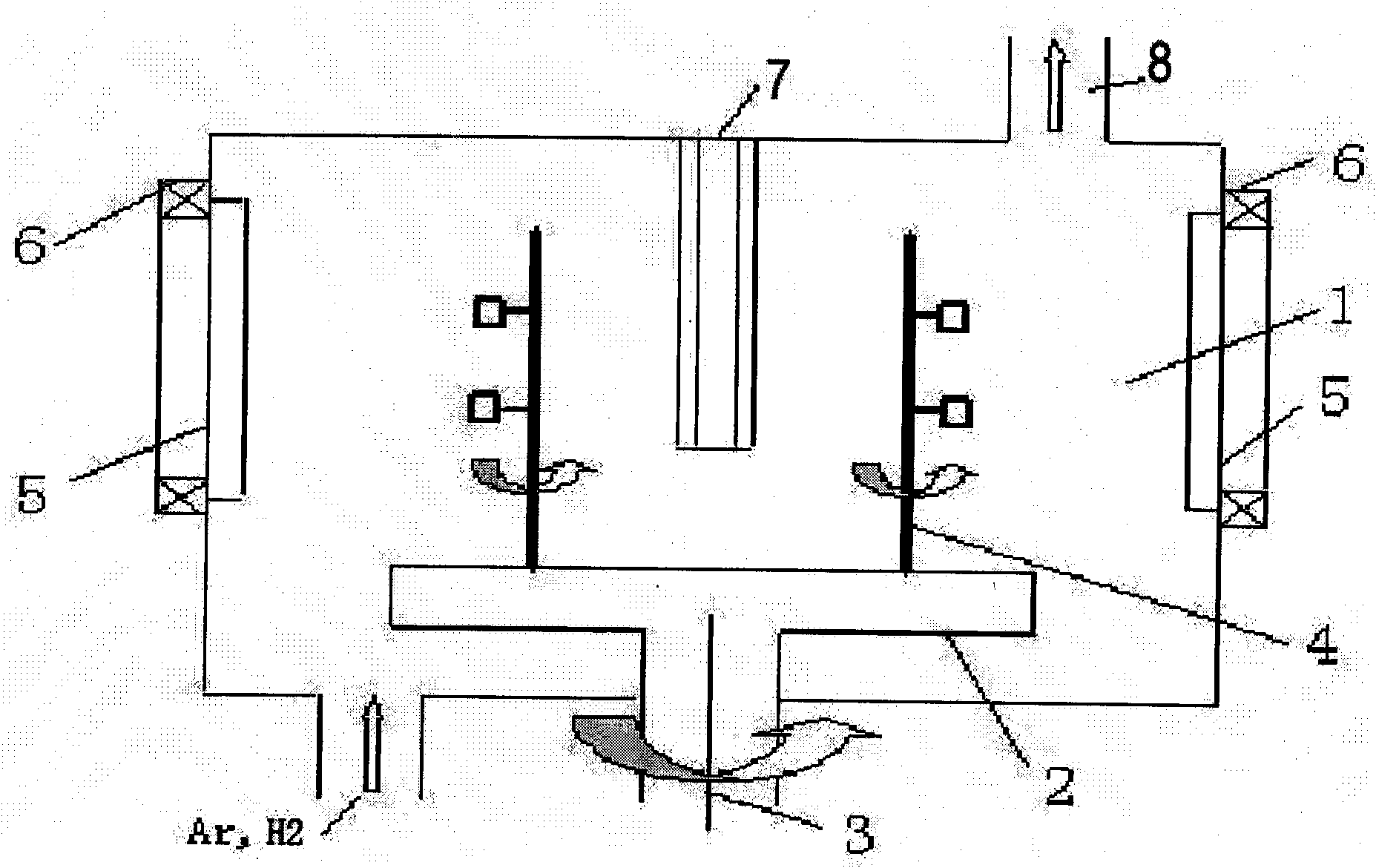

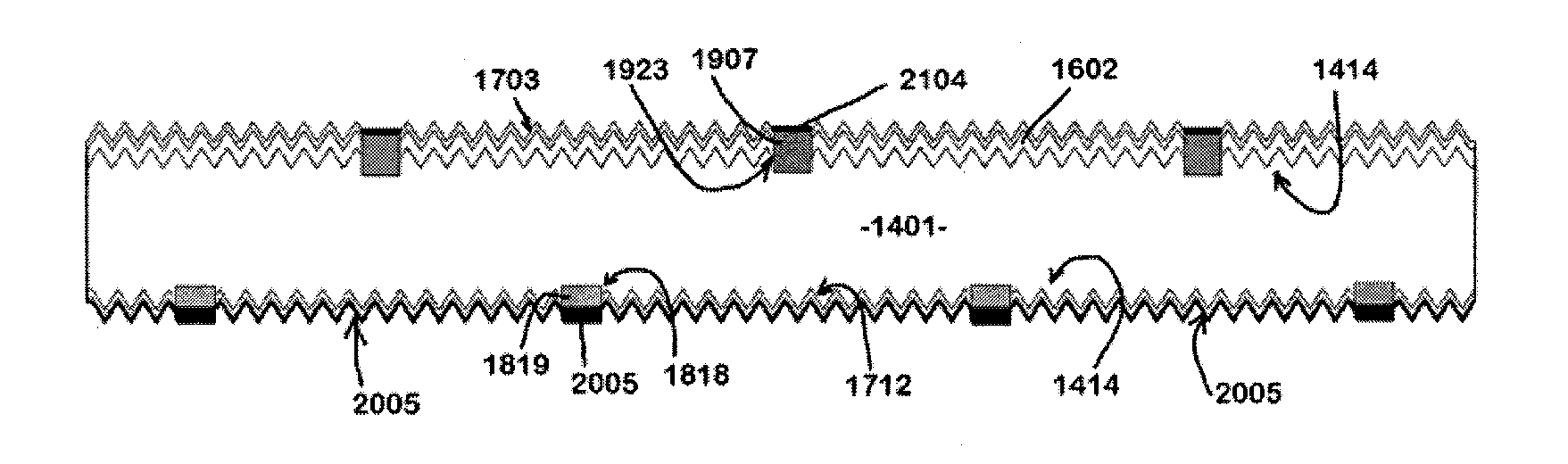

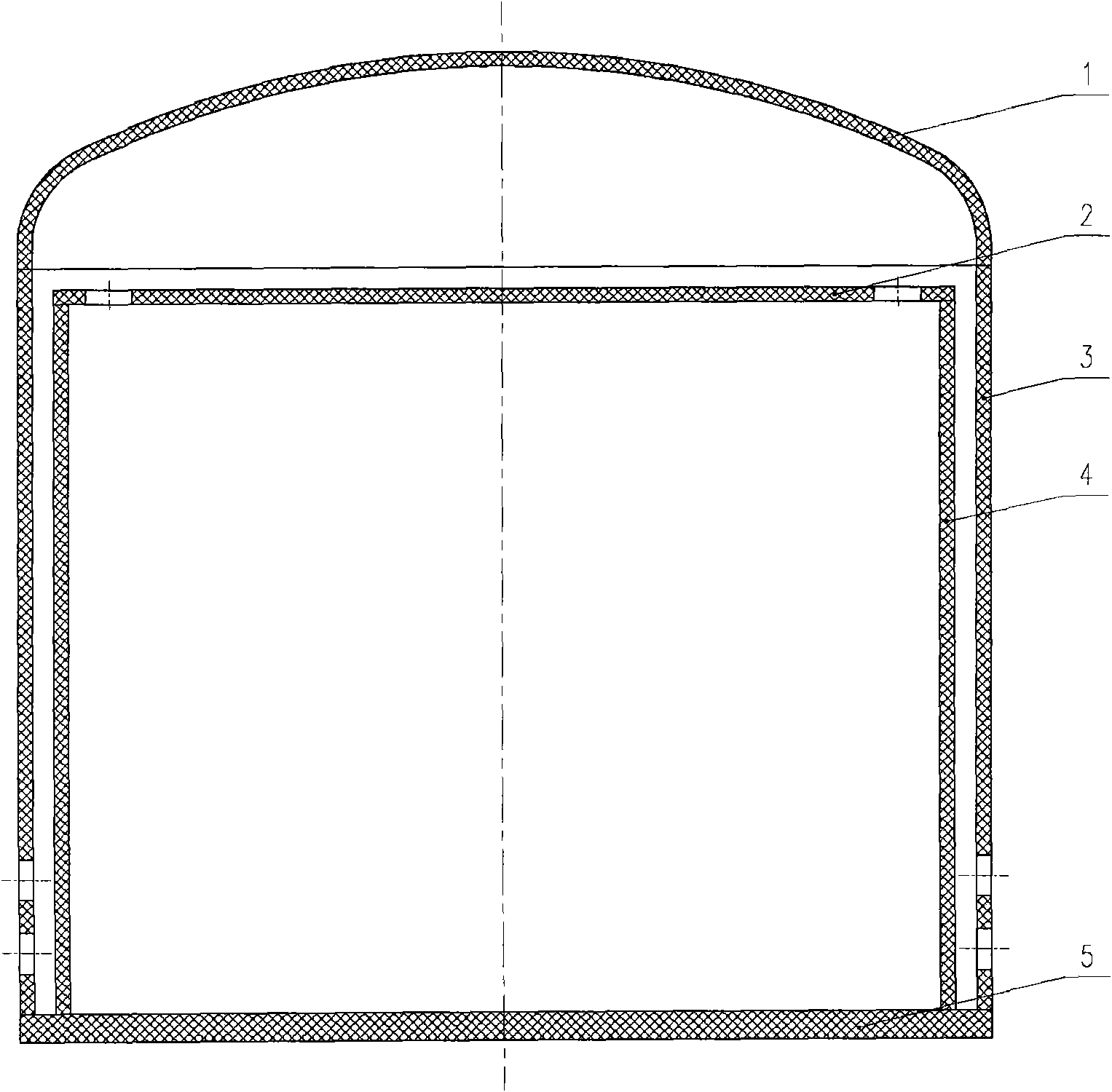

Double-layer air-guide heat insulation shield of polysilicon hydriding furnace

InactiveCN101633503AGood heat insulationImprove reaction efficiencyPolycrystalline material growthSiliconElectrical conductorInlet channel

The invention discloses a double-layer air-guide heat insulation shield of a polysilicon hydriding furnace, which comprises an inner-layer heat insulation shield and an outer-layer heat insulation shield sleeved outside the inner-layer heat insulation shield, wherein heat insulation chassises are arranged at the bottom of the inner-layer heat insulation shield and the bottom of the outer-layer heat insulation shield, and an air-guide channel is formed between the inner-layer heat insulation shield and the outer-layer heat insulation shield; an air inlet channel is arranged at the lower part of the outer-layer heat insulation shield, and an air inlet channel is arranged at the upper part of the inner-layer heat insulation shield. In the invention, two layers of heat insulation shields are arranged, and the air-guide channel is formed between the two heat insulation shields, therefore, process tail gas can enter into a reaction region in the inner-layer heat insulation shield through the air-guide channel. The invention has the advantages: firstly, the process tail gas is poor conductor of heat and can play a better heat insulation role; secondly, the process tail gas is preheated after absorbing heat transferred from the reaction region while passing the air-guide channel, thereby improving the reaction efficiency of the process tail gas after entering into the reaction region; and thirdly, the airflow direction formed by the double-layer heat insulation shield can ensure that the device is safer and more stable.

Owner:SHANGHAI MORIMATSU NEW ENERGY EQUIPMENT CO LTD

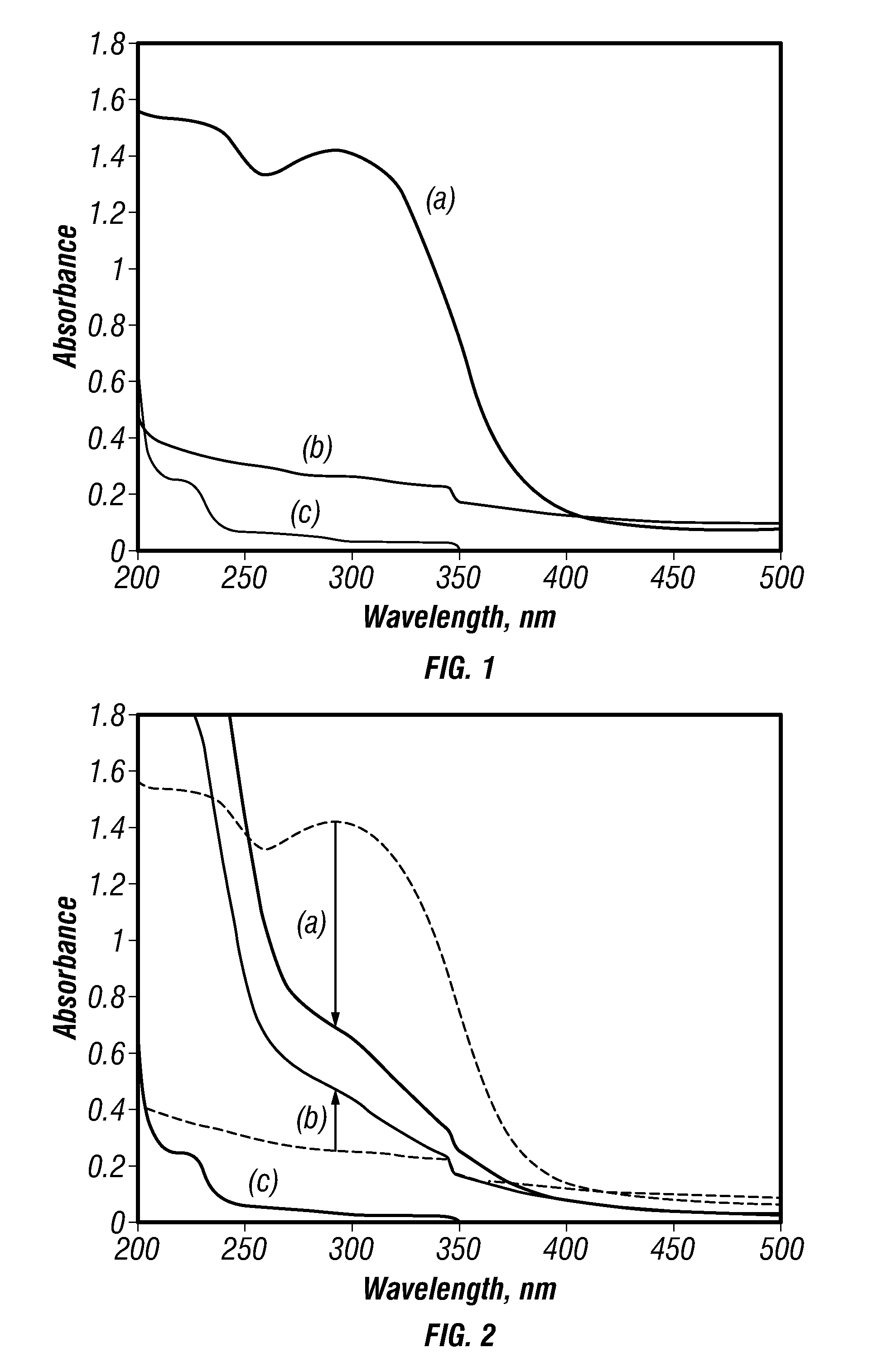

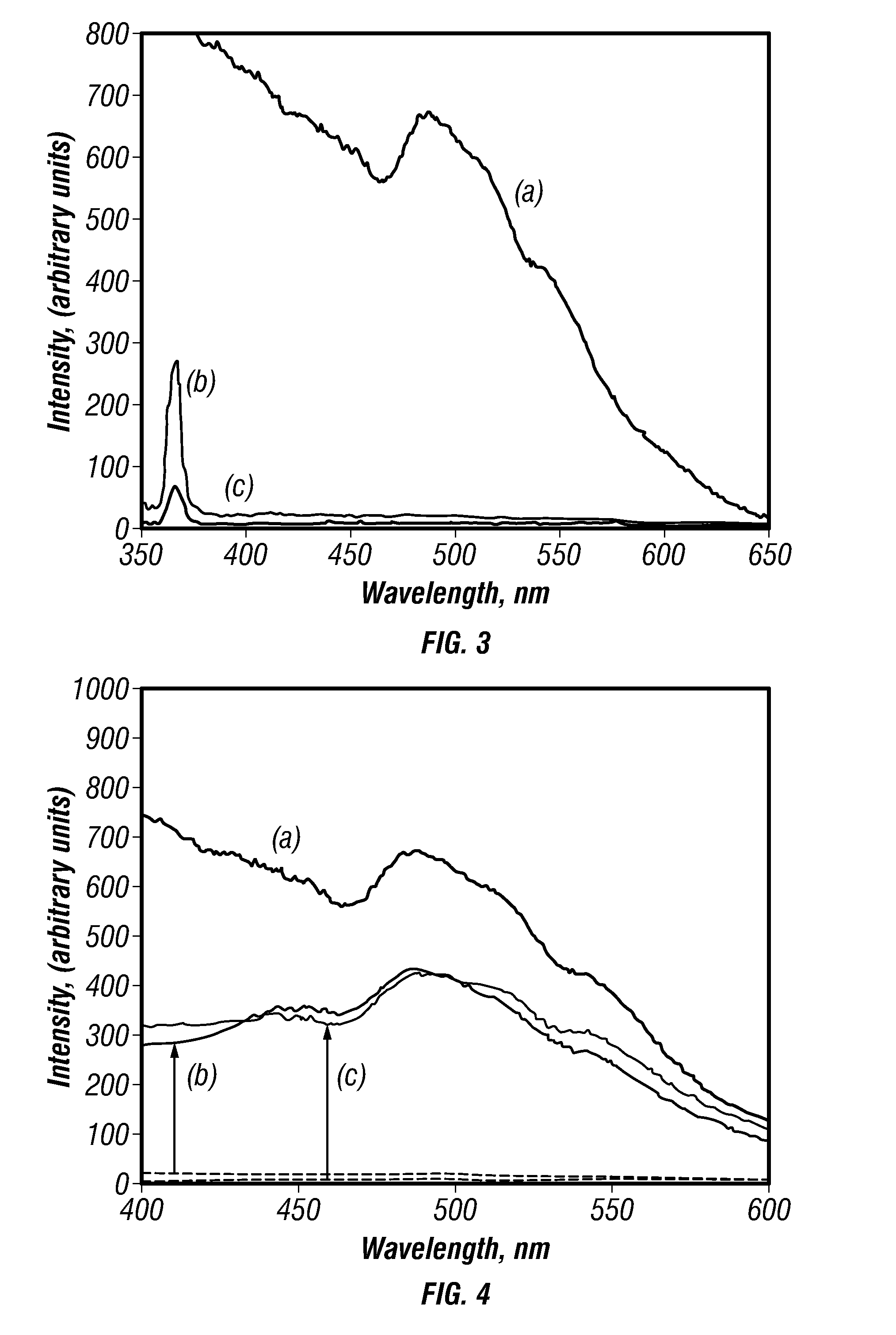

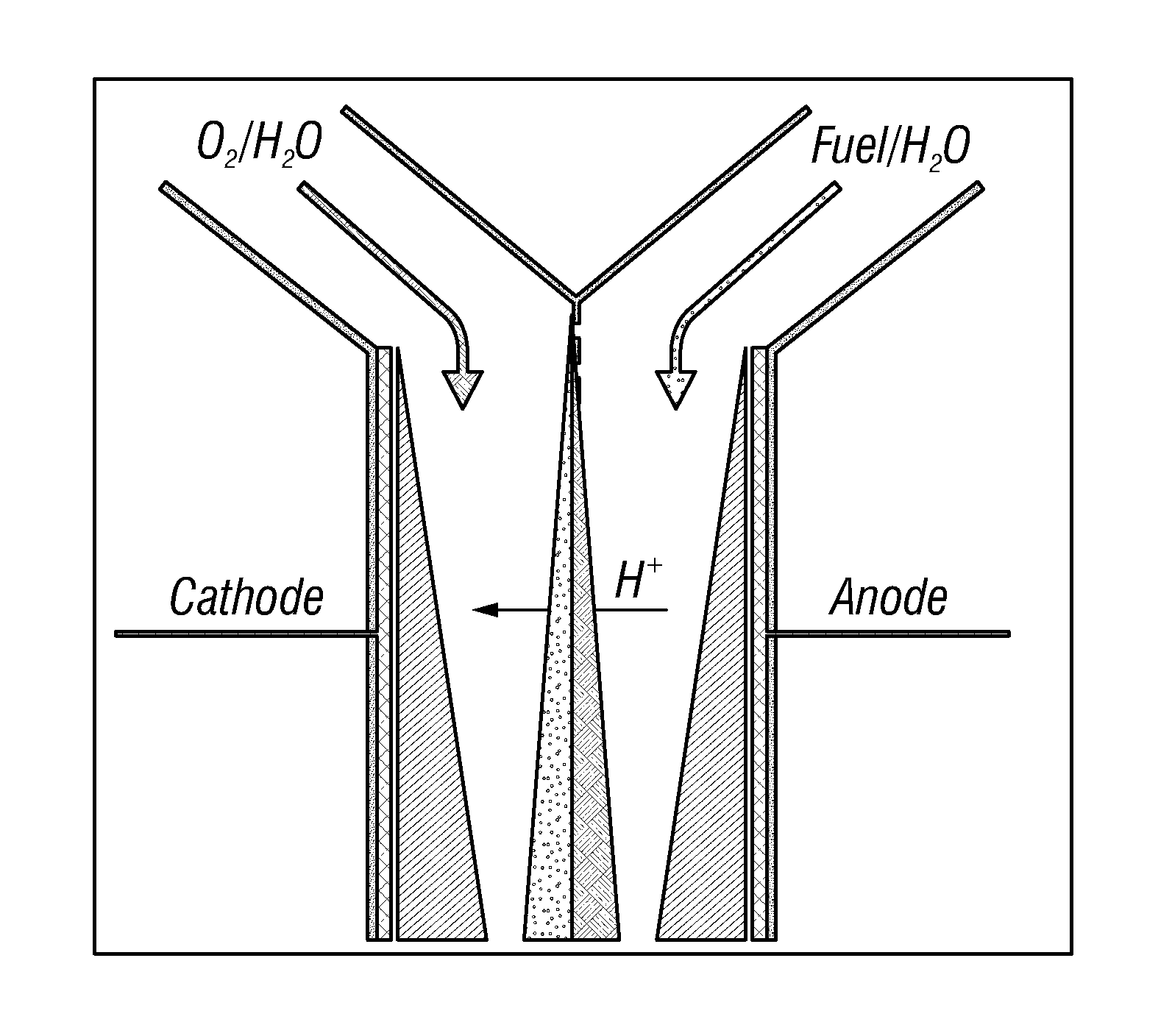

Silicon Hydride Nanocrystals as Catalysts for Proton Production in Water-Organic Liquid Mixtures

ActiveUS20120219869A1Promote divisionMaterial nanotechnologyHydrogenPresent methodPolysilicon hydride

Embodiments of the present methods may be used to produce energy in the form of an electrical current from water without the use of fossil fuel. Silicon hydride is very easy to make. This procedure in conjunction with an enzyme to produce hydrogen gas for fuel cells and other small devices. In fuel cells the production of protons may be bypassed, and an oxidant such as permanganate or oxygen from air may be used to drive the fuel cells. In such an embodiment, an intermediate reaction may not be needed to produce protons. In one embodiment, membrane-less laminar flow fuel cells with an external grid for oxygen supply from the air may be used.

Owner:KING ABDULLAH UNIV OF SCI & TECH

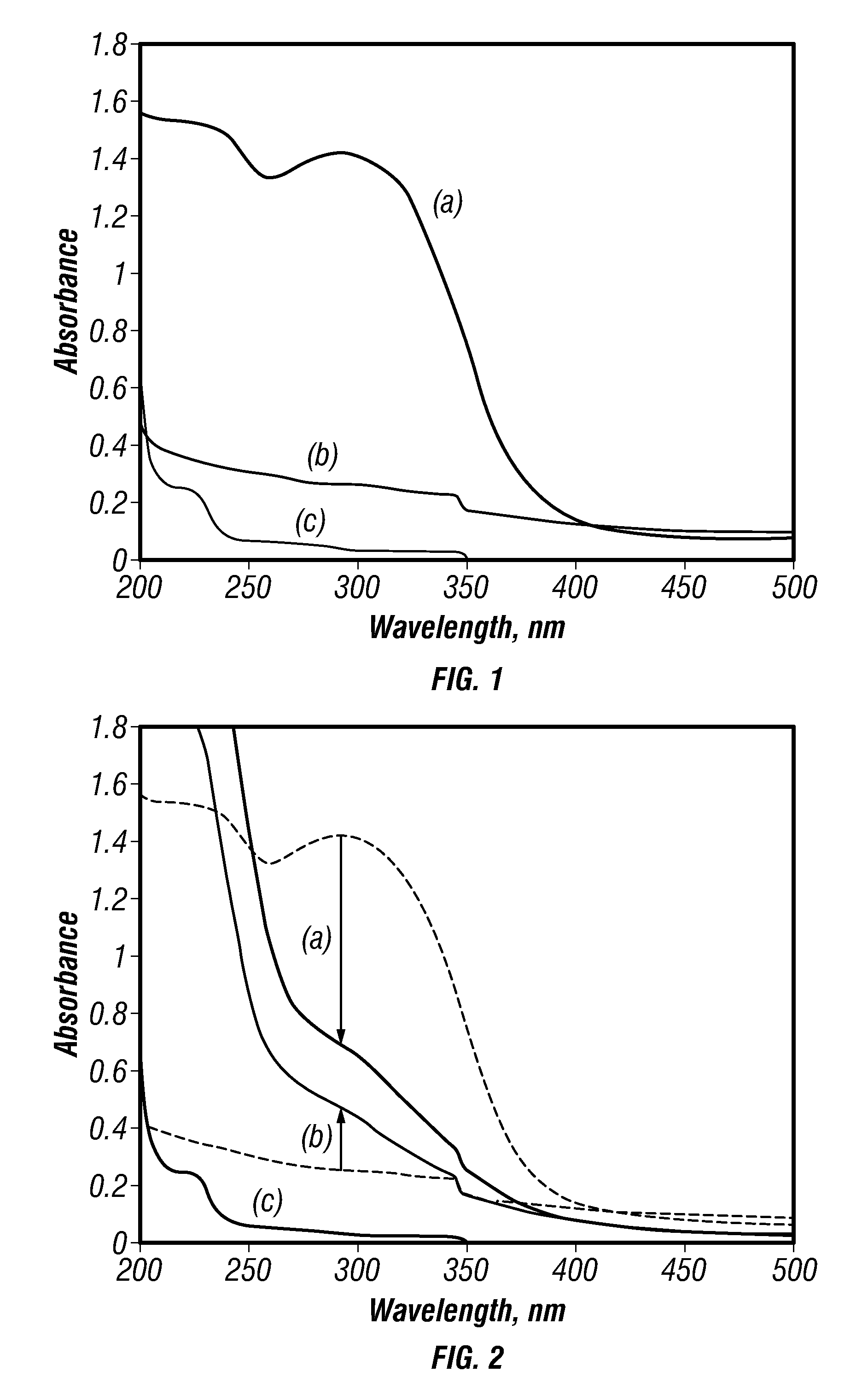

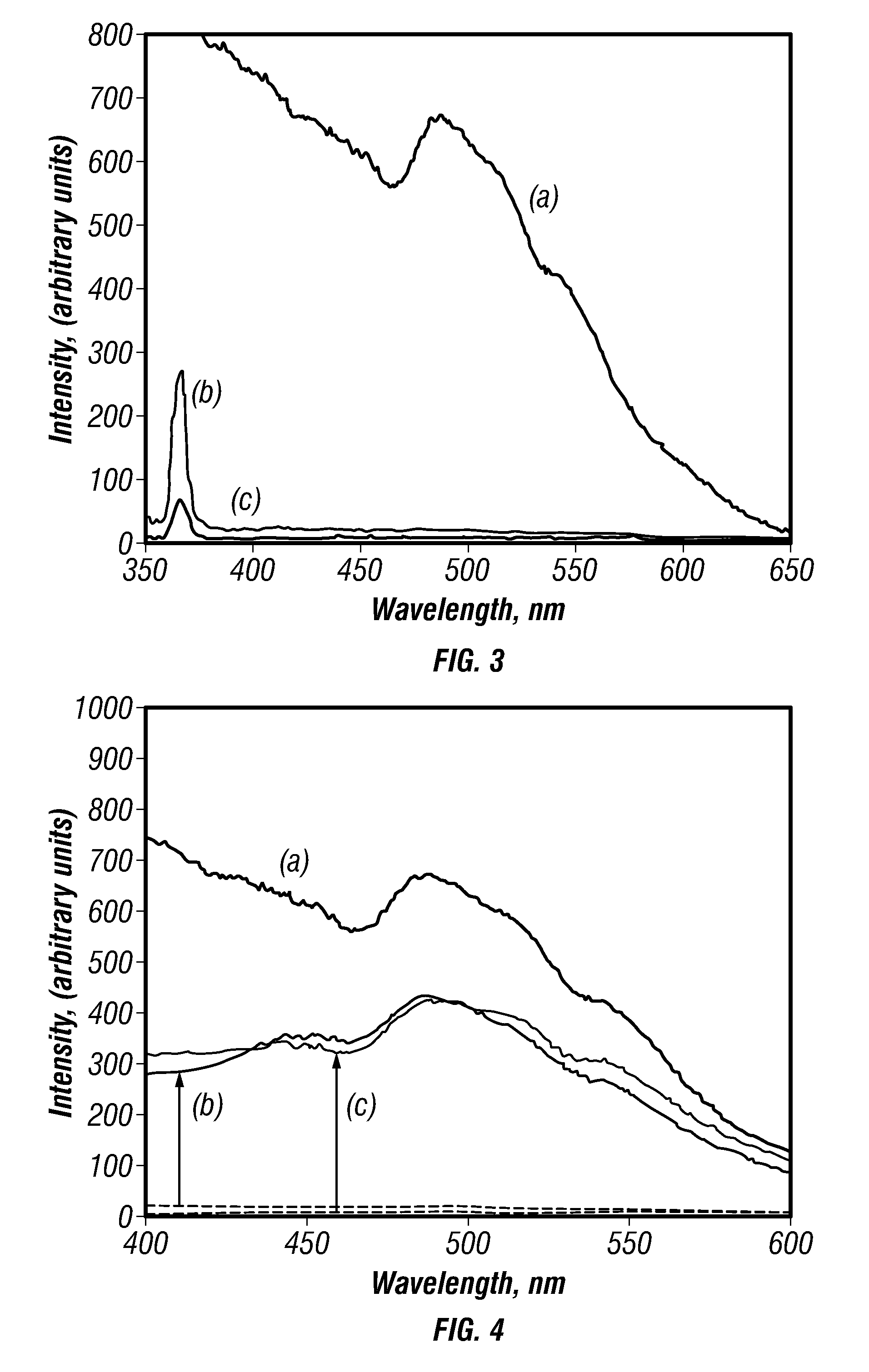

Silicon hydride nanocrystals as catalysts for proton production in water-organic liquid mixtures

Embodiments of the present methods may be used to produce energy in the form of an electrical current from water without the use of fossil fuel. Silicon hydride is very easy to make. This procedure in conjunction with an enzyme to produce hydrogen gas for fuel cells and other small devices. In fuel cells the production of protons may be bypassed, and an oxidant such as permanganate or oxygen from air may be used to drive the fuel cells. In such an embodiment, an intermediate reaction may not be needed to produce protons. In one embodiment, membrane-less laminar flow fuel cells with an external grid for oxygen supply from the air may be used.

Owner:KING ABDULLAH UNIV OF SCI & TECH

Synthetic cork compound

A synthetic cork compound includes a methyl vinyl silicone polymer with a microsphere agent such as soda lime borosilicate in an amount of approximately 5 to 50 weight percent. The microsphere agent gives the compound a low density. The methyl vinyl silicone polymer preferably includes polydimethylvinylsiloxane polymer from about 20 to 60 weight percent and fumed silica from about 20 to 60 weight percent. Preferably, the compound is catalyzed using chloro-platanic acid from about 0.1 to 5 percent. Additional components of the compound include toasted oak dust from about 0.1 to 25 weight percent, a pigment from about 0.1 to 5 weight percent, silicon hydride from about 0.1 to 25 weight percent, and ethynl cyclohexanol from about 0.05 to 5 weight percent.

Owner:M MANAGEMENT TEX

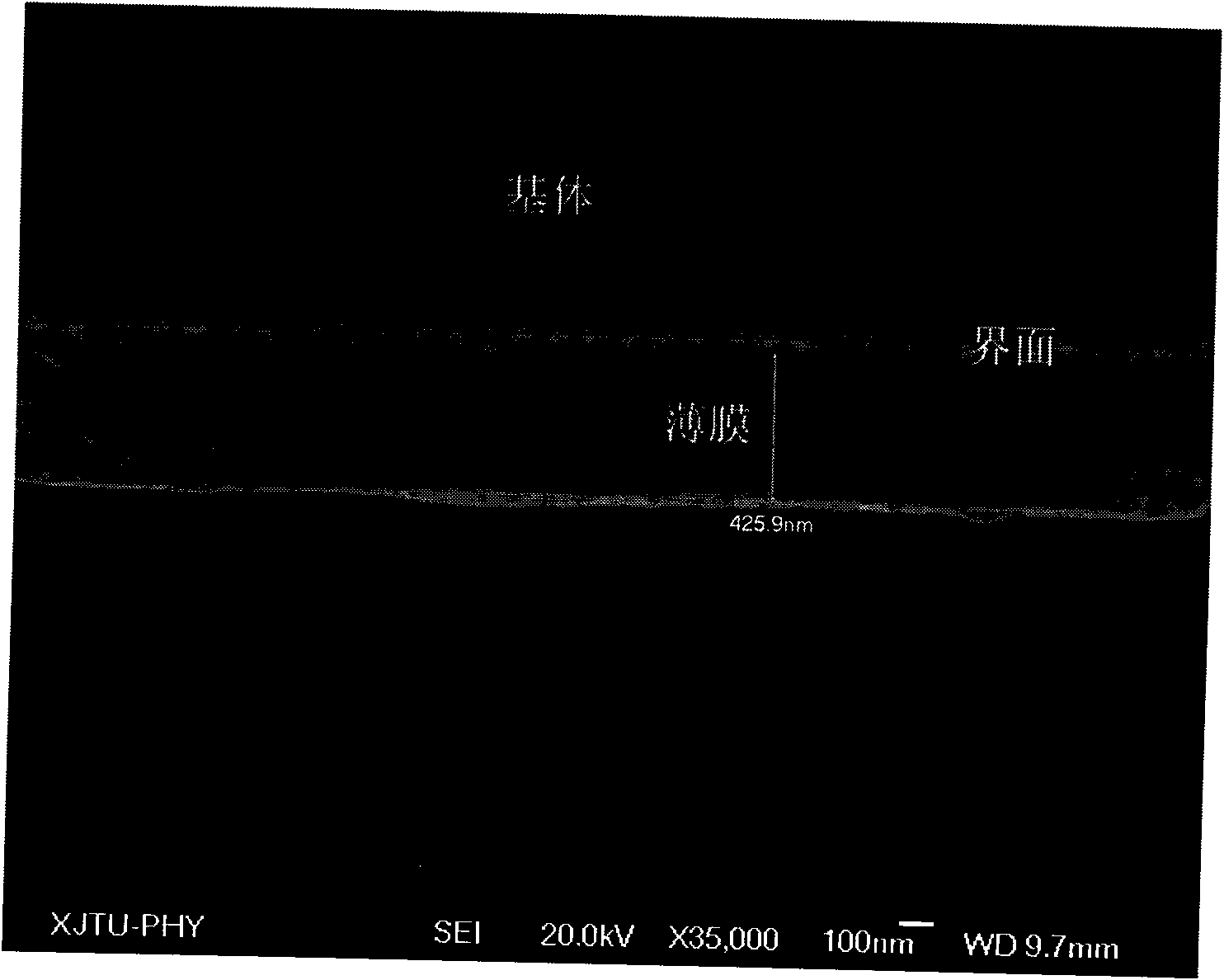

A kind of preparation method of stainless steel surface silanization treatment film

ActiveCN103866262BImprove corrosion resistanceChemical vapor deposition coatingSilanesAmorphous silicon

The invention belongs to the technical field of material surface treatment, and discloses a preparation method of a stainless steel surface silanization treatment membrane. A amorphous silicon treatment membrane is formed on a stainless steel surface through chemical vapor deposition by adopting a mixed gas formed by silanization treatment agent silicon tetrahydride and doping agent phosphorus hydride, and the mixed gas contains 95%-99% by volume of silicon tetrahydride and 0.1%-0.5% by volume of phosphorus hydride. Compared with the prior art, the preparation method disclosed by the invention has the advantages that the stainless steel surface has good corrosion-resisting property after being subjected to silanization treatment and a gas sample which contains an acidic substance is not obviously changed in concentration in the process of being stored and transported in a stainless steel tank, thereby meeting the requirements for collection and analysis of the gas sample in an atmospheric environment.

Owner:北京优得泽科技有限公司

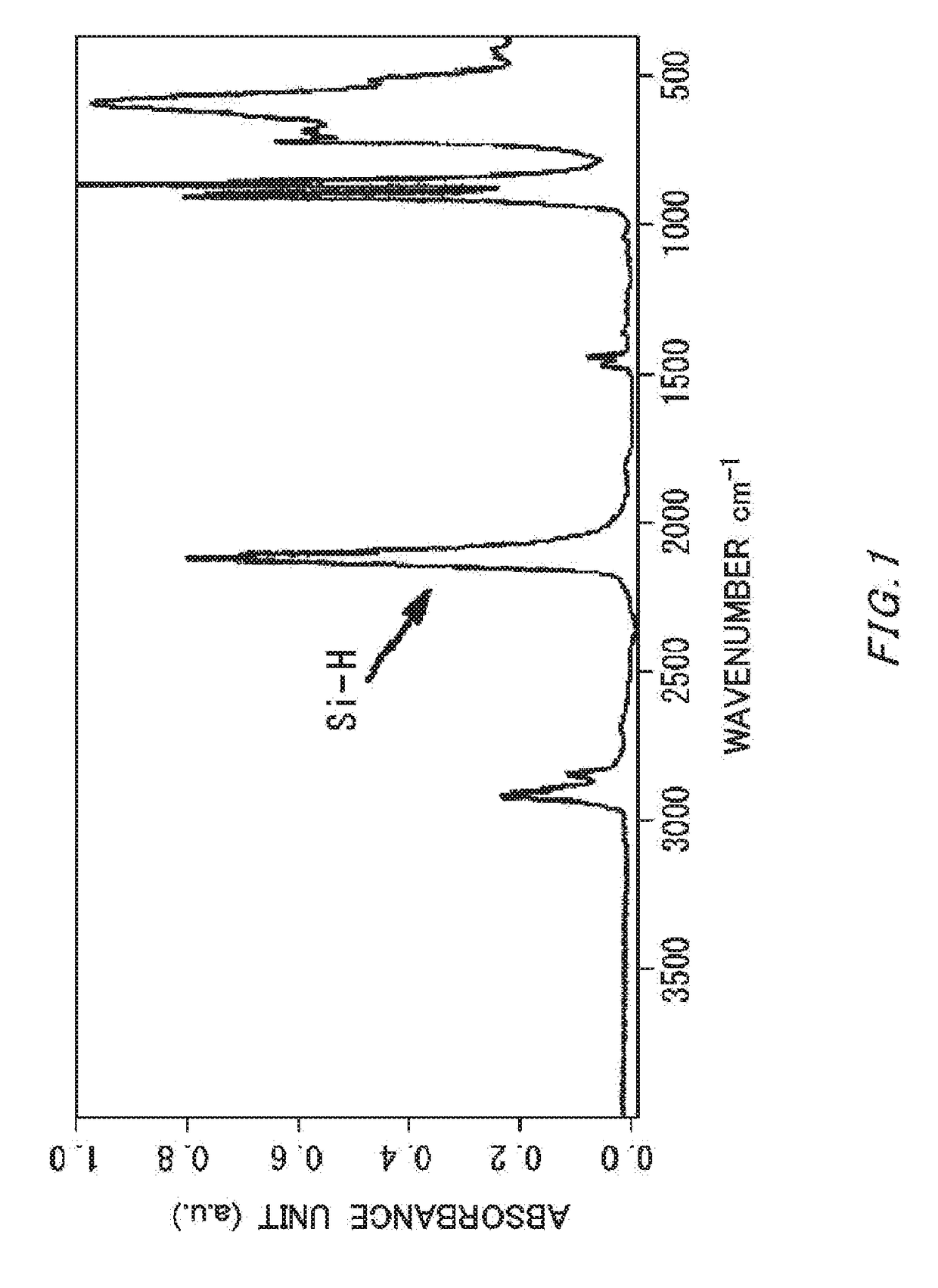

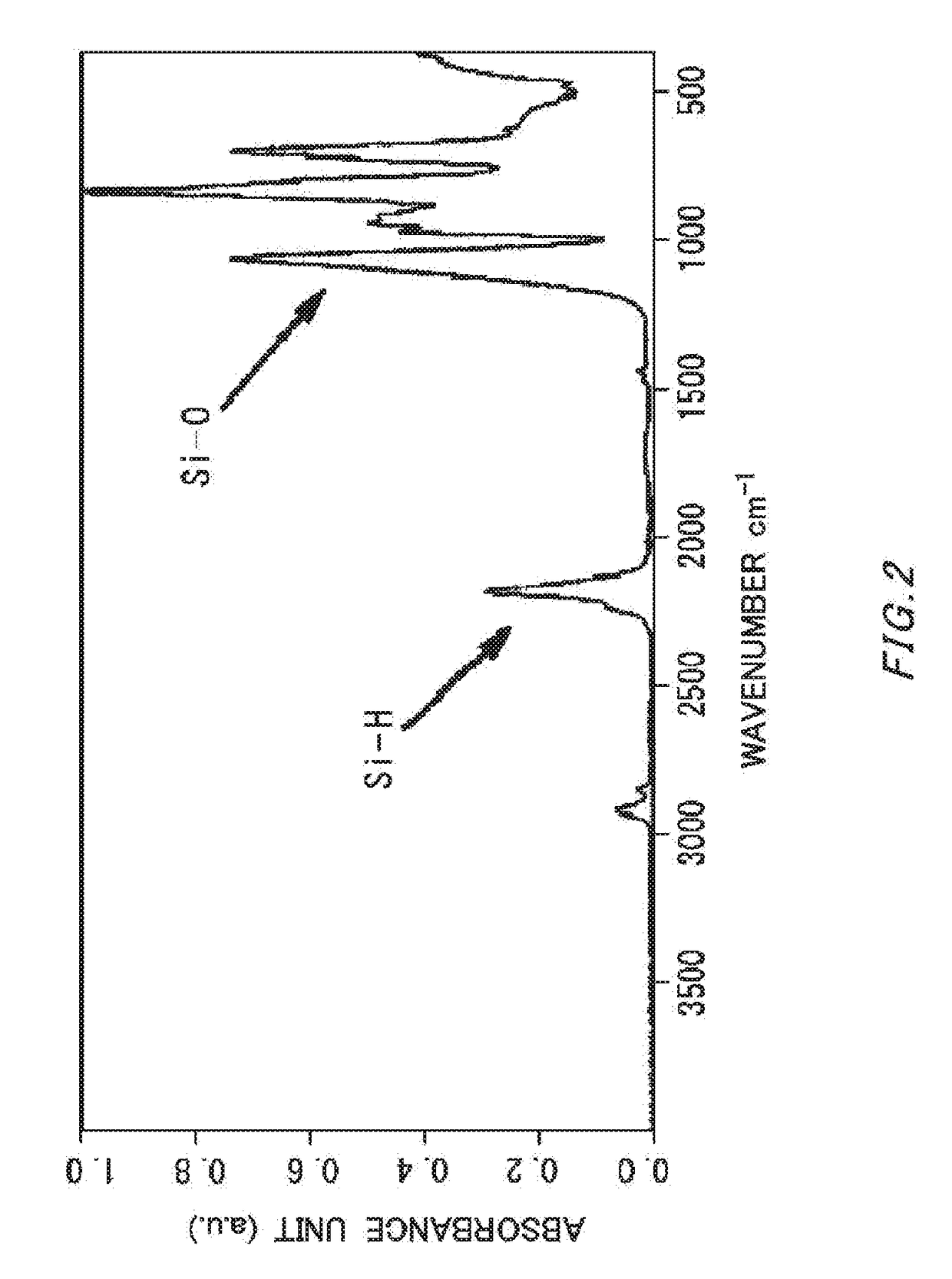

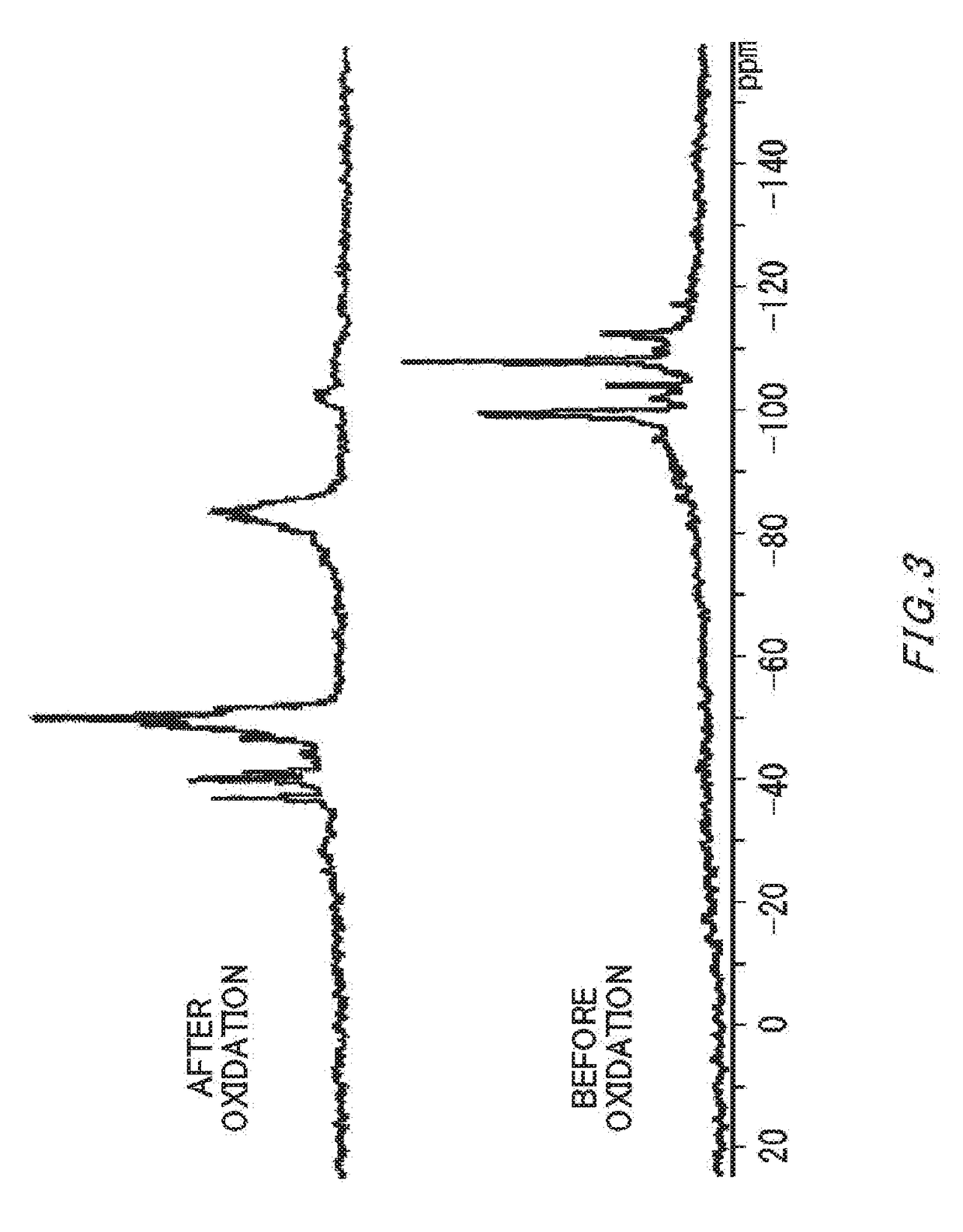

Method of Producing Silicon Hydride Oxide-Containing Organic Solvent

ActiveUS20170313592A1Considerable damageLow puritySilicon hydridesSemiconductor/solid-state device manufacturingHydrogen halideOrganic solvent

A method of producing a silicon hydride oxide-containing organic solvent (coating solution) is provided with which a silicon hydride oxide coating film can be formed on a substrate. Using the silicon hydride oxide-containing organic solvent makes it unnecessary to place a coating solution in non-oxidizing atmosphere at the time of coating or to heat the substrate after coating because the silicon hydride oxide is formed in the coating solution before it is coated. The method includes blowing an oxygen-containing gas through an organic solvent containing a silicon hydride or a polymer thereof. The silicon hydride oxide may contain a proportion of (residual Si—H groups) / (Si—H groups before oxidation) of 1 to 40 mol %. The silicon hydride can be obtained by reacting a cyclic silane with a hydrogen halide in the presence of an aluminum halide, and reducing the obtained cyclic halosilane.

Owner:ENSURGE MICROPOWER ASA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com