Trace amount of boron doped intrinsic silicon hydride thin film

A technology of hydrogenated silicon and thin films, applied in the field of solar energy materials, can solve problems such as difficult extraction and performance impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

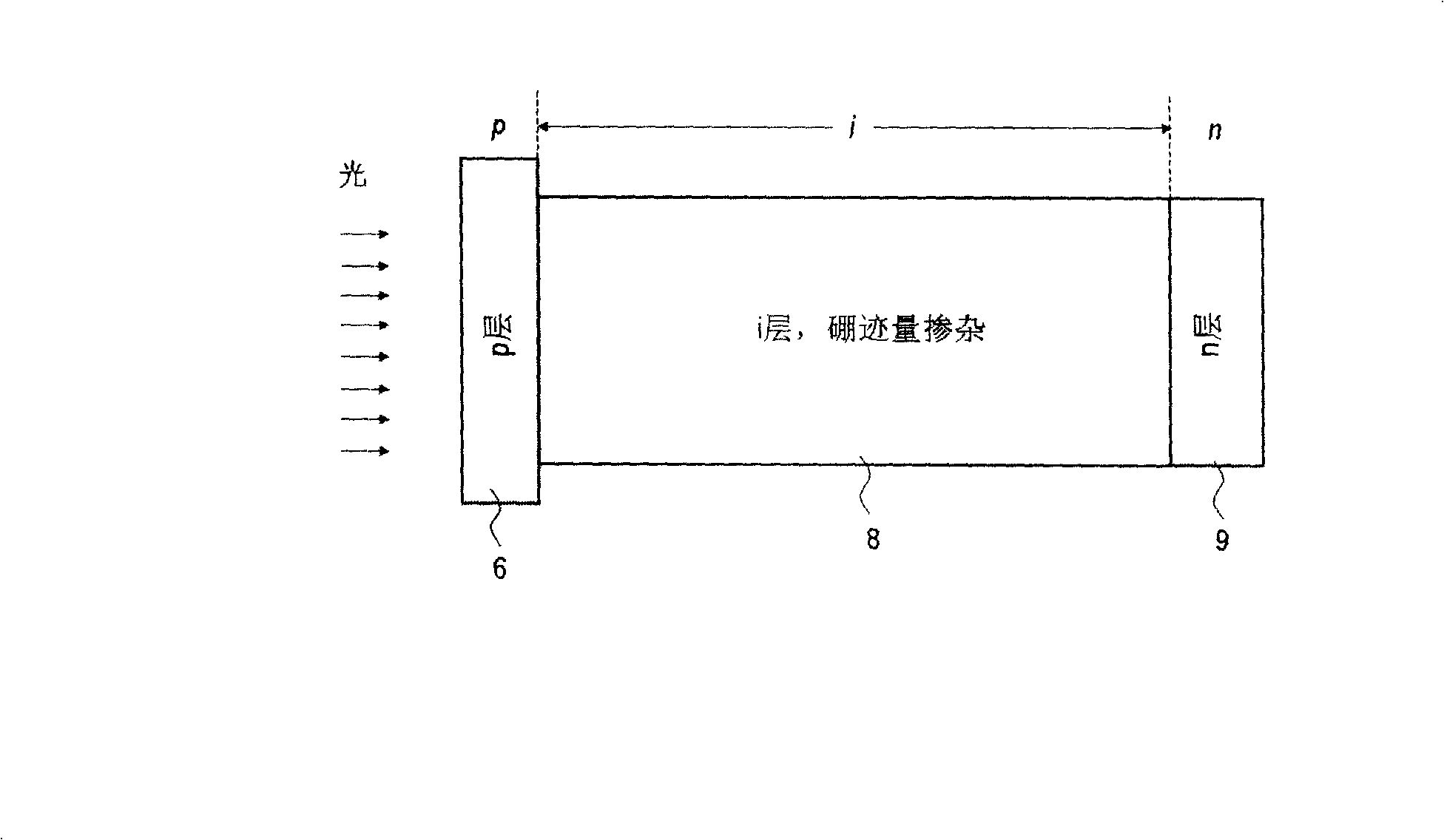

[0010] As shown in the accompanying drawings, a p-i-n type solar cell based on a hydrogenated silicon thin film sequentially contains a p-layer 6 based on hydrogenated silicon or its alloy with a boron doping degree of not less than 0.2%, a "non-doped" hydrogenated silicon The i-layer 8 and an n-layer 9 based on hydrogenated silicon or an alloy thereof with a phosphorus doping degree of not less than 0.5%. When using the plasma enhanced chemical vapor deposition method to form the hydrogenated silicon i-layer 8, the substrate temperature used does not exceed 230°C, and a trace amount of boron-containing gas is added to the provided source gas mixture containing the silicon-containing gas. , the ratio of boron-containing gas to silicon-containing gas does not exceed 2ppm. Not less than 90% of the source gas mixture is hydrogen, and the silicon-containing gas is silane. When the source gas mixture is mainly high-purity hydrogen and silane (purity not less than 99.999%), the opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com