Surface modification of solid supports through thermal decomposition and functionalization of silanes

A technology for modifying and substrate surface, applied in the direction of silicon compounds, physical/chemical process catalysts, chemical methods for reacting gases with non-granular solids, etc., can solve problems such as poor surface activity and difficult removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

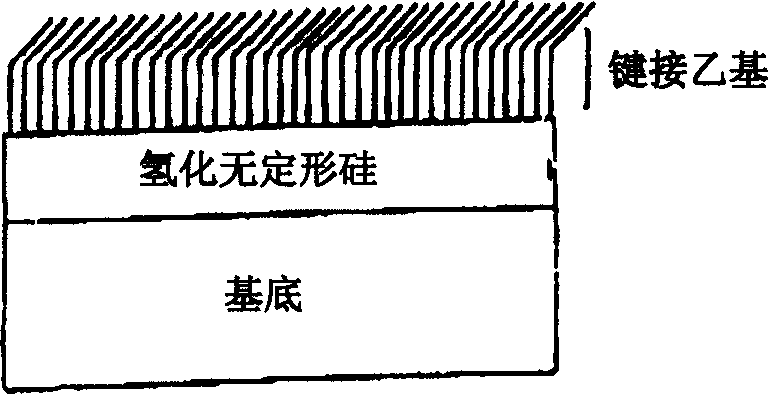

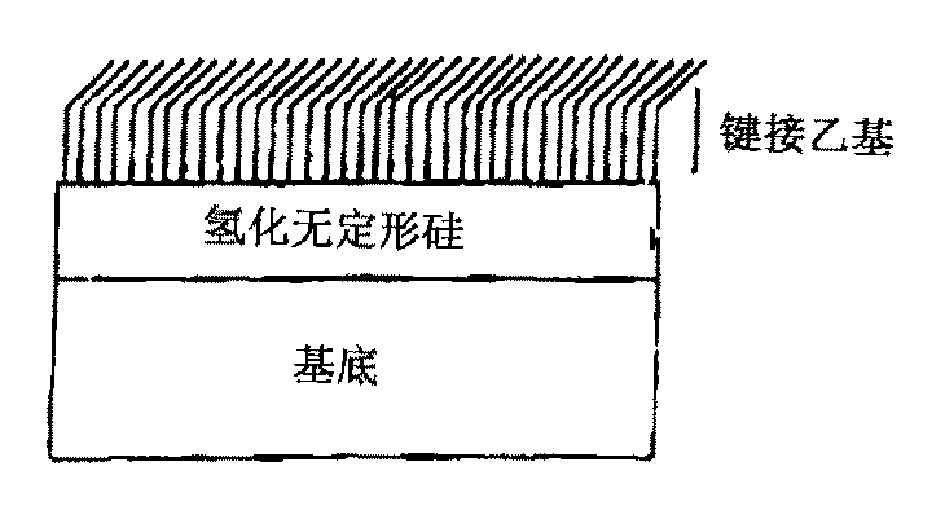

Image

Examples

Embodiment 1

[0033] Borosilicate inlet liners are used in gas chromatographic devices as the sample introduction region and transfer to the gas chromatographic column. Due to their active surface and their adsorptive properties for many compounds, coarse borosilicate glasses are typically deactivated by silanization. Standard silanization will provide a relatively inert surface, but will not be generally inert to acidic as well as basic compounds (eg, carboxylic acids and amines). Some liners are suitable for acidic compounds and a few for basic compounds. The present invention provides a surface that prevents adsorption of acidic and basic compounds on the inlet liner surface.

[0034] The borosilicate inlet liner is packed in a sealed stainless steel container with inlet and outlet tubing attached. The tubes pass through the oven celling and are connected to two separate manifolds through which aeration and vacuum will be applied to the vessel by a system of valves. With atmospheric p...

Embodiment 2

[0035] Uncoated fused silica capillary columns are used in gas chromatographic apparatus as inlet transfer lines connecting the inlet liner to coated fused silica capillary analytical columns. Coarse fused silica glass is typically deactivated by silanization because of its active surface and its adsorptive properties for many compounds. Standard silanization processes will produce relatively inert surfaces, but are not inert to all acidic and basic compounds (eg, carboxylic acids and amines). Some deactivated fused silica columns are suitable for acidic compounds and a few types are suitable for basic compounds. Also, general deactivation is not durable in repeated corrosive environments. The present invention produces a surface on fused silica capillaries that will prevent the adsorption of acidic or basic compounds, as well as resist decomposition by corrosive environments.

[0036] Fused silica capillary tubes were coiled and connected in lengths of 30 m, the ends of whi...

Embodiment 3

[0038] Steel containers are best used to store low levels of sulfur compounds such as hydrogen sulfide and mercaptans. Steel is highly adsorbent for such compounds, making it an unsuitable storage medium for low parts per billion concentrations. The present invention will provide a surface that will prevent the adsorption of low levels of sulfur compounds on the surface of steel vessels.

[0039] The steel vessel is encased in a large stainless steel hermetic container which is sealed and connected with inlet and outlet pipes. The tubes pass through the oven chamber and are connected to two separate manifolds through which inflation and vacuum can be performed via a system of valves. With the air pressure in the vessel at atmospheric pressure, the temperature in the vessel was raised to 120°C and maintained for 1 hour. After 1 hour, the vessel was inert by nitrogen purge and evacuated. The vessel was heated to 400°C. After the container is evacuated, 100% silane gas (SiH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com