Production of silicon hydride thin film by hydrogen argon high dilution method

A silicon hydrogenation and thin-film technology, applied in the field of solar energy materials, can solve the problems of difficult control, unused, poor repeatability, etc., and achieve the effect of improved stability and good photoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

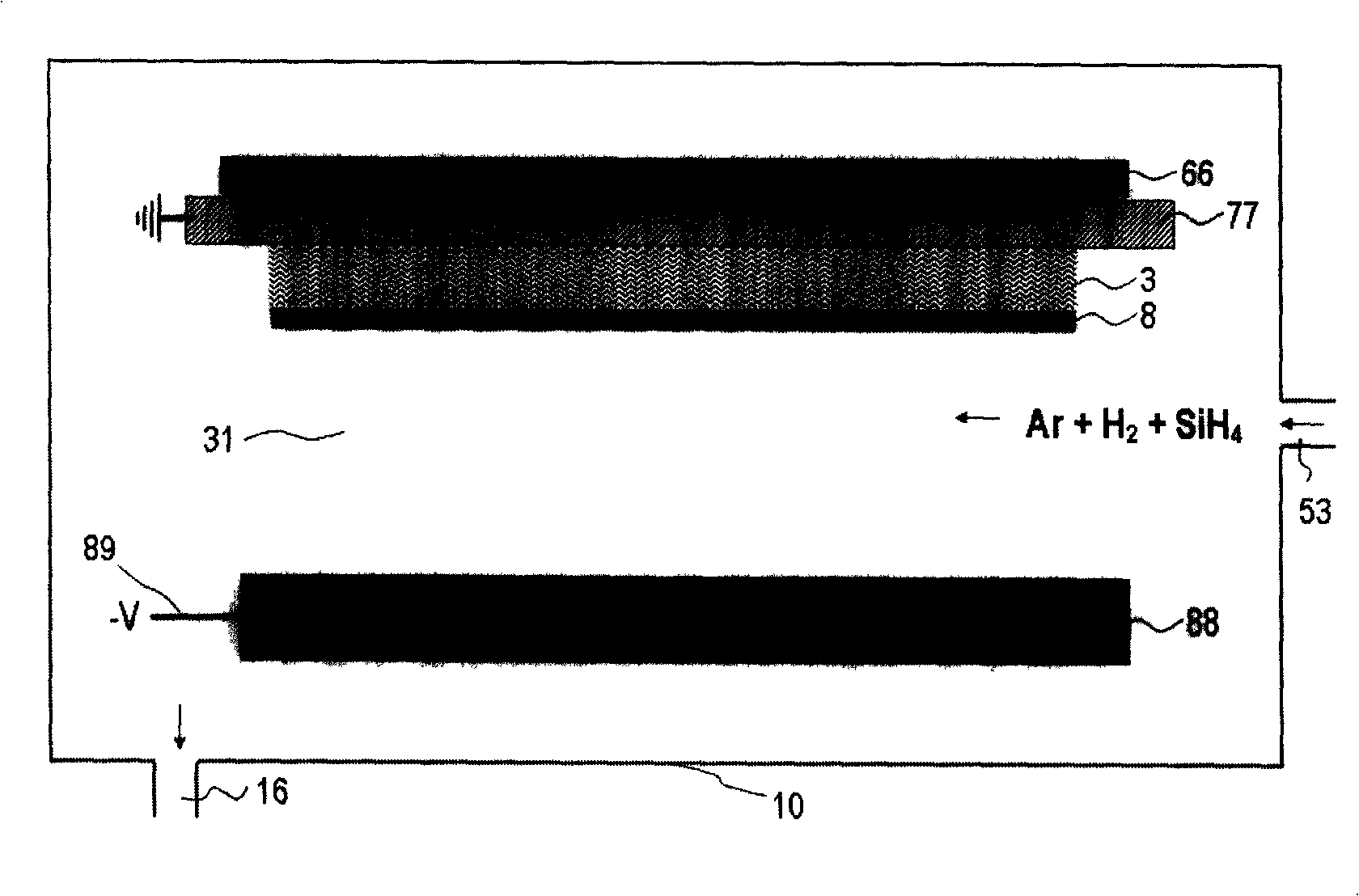

[0018] Below is an embodiment of the present invention, as shown in the accompanying drawings, a conventional capacitively coupled PECVD system includes the following components: a vacuum box 10; a source gas inlet 53; a gas outlet 16 after the reaction; An excitation electrode 88 (negative electrode); a ground electrode 77 (positive electrode) parallel to the excitation electrode; a substrate 3 placed on the surface of the ground electrode facing the excitation electrode; a heater 66 placed on the back side of the ground electrode and a Excitation electrode power supply cable 89. When using this system to deposit hydrogenated silicon thin film, the excitation electric energy provided by the outside is applied to the negative electrode 88 through the cable 89, and plasma is generated in the region 31 between the two electrodes. The source gas mixture used contains not more than 10% silane, and contains a high percentage of inert gas and hydrogen at the same time, wherein the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com