Patents

Literature

76 results about "Silicon nanocrystal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for forming a nanocrystal floating gate for a flash memory device

InactiveUS20060046383A1Improve uniformityMore controllabilityNanoinformaticsSolid-state devicesSilanesDisilane

One embodiment of a method used to form a floating gate for a memory device comprises forming a crystallization nucleus seed layer using a process comprising disilane (Si2H6), then converting the seed layer into a plurality of electrically-isolated silicon nanocrystals using a process comprising silane (SiH4). The method described uses lower temperatures than previous silicon nanocrystal formation with improved uniformity of the completed silicon nanocrystals.

Owner:MICRON TECH INC

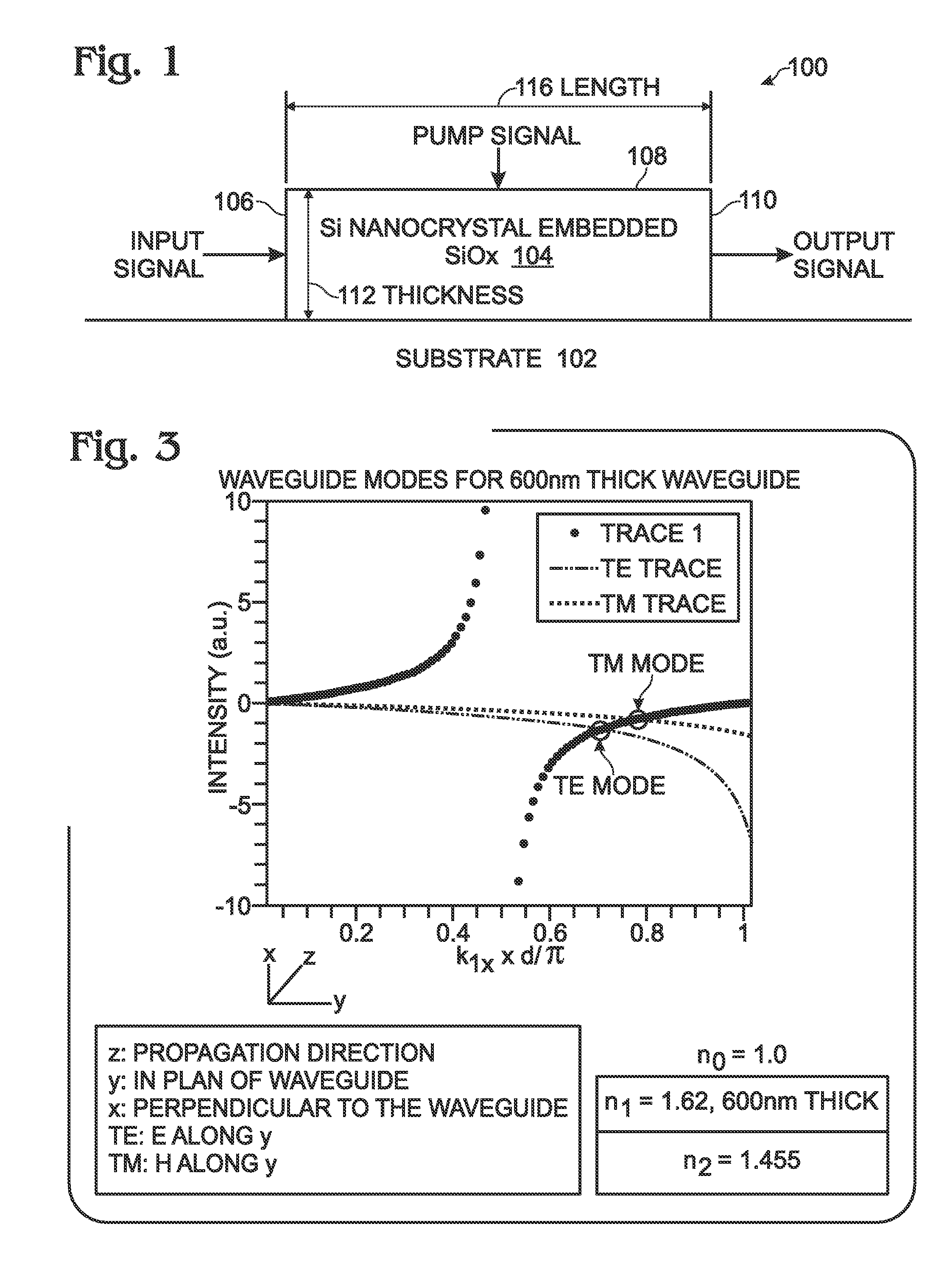

Silicon nanocrystal/erbium doped waveguide (SNEW) laser

InactiveUS20060039433A1High refractive indexLaser detailsSemiconductor lasersEnergy transferErbium doping

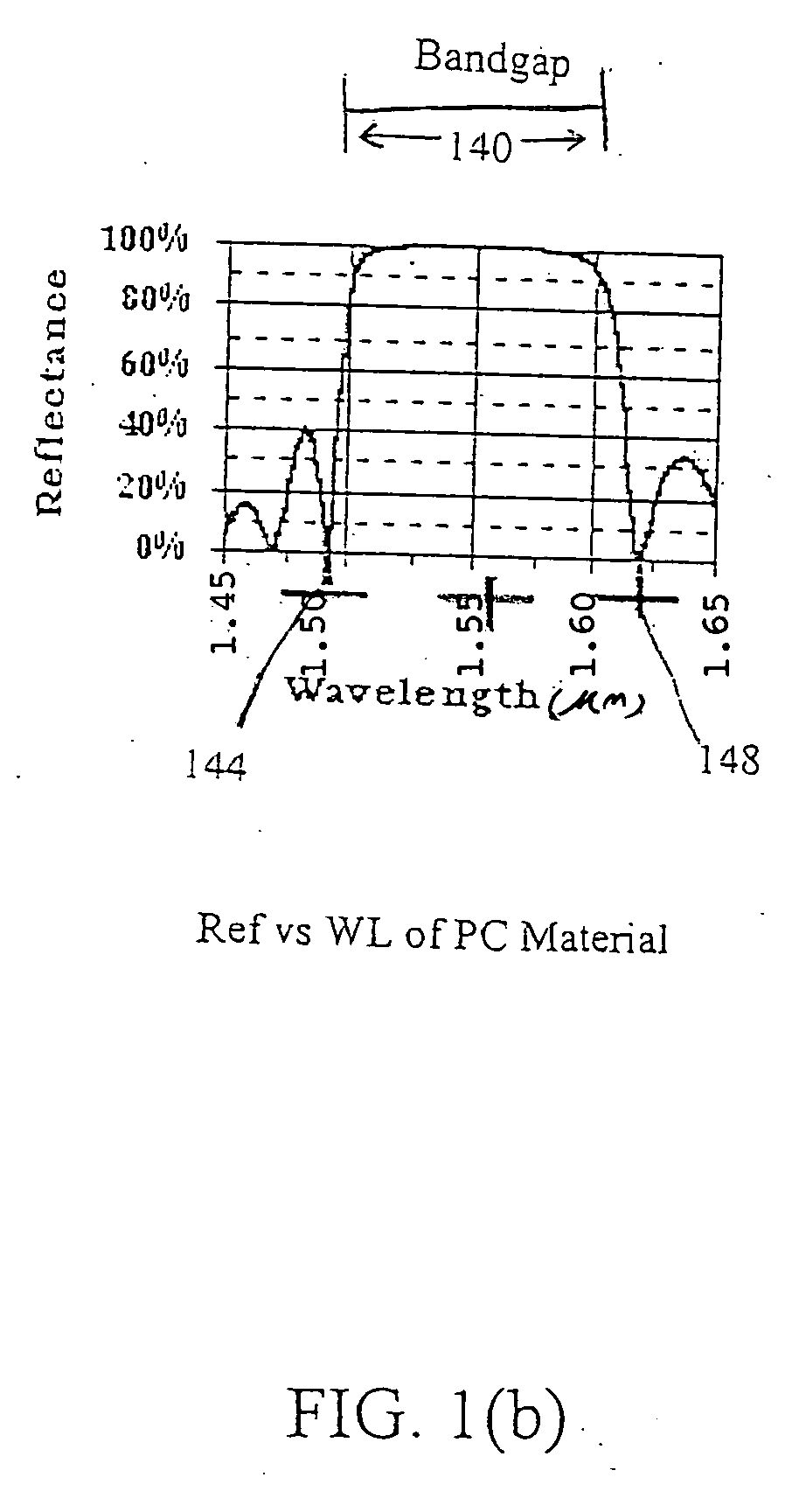

A rare earth-doped solid-state integrated laser which includes an optical waveguide, and a laser cavity including at least one subwavelength mirror. The subwavelength mirror is disposed in or on the optical waveguide. The optical waveguide portion within the laser cavity includes active media comprising both a rare earth and semiconducting atoms or compounds. A structure for pumping the semiconducting semiconducting atoms or compounds is provided, such as electrodes sandwiching the active media wherein the semiconducting atoms or compounds transfer energy obtained from the pumping to the rare earth, thus permitting the laser to laze.

Owner:UT BATTELLE LLC

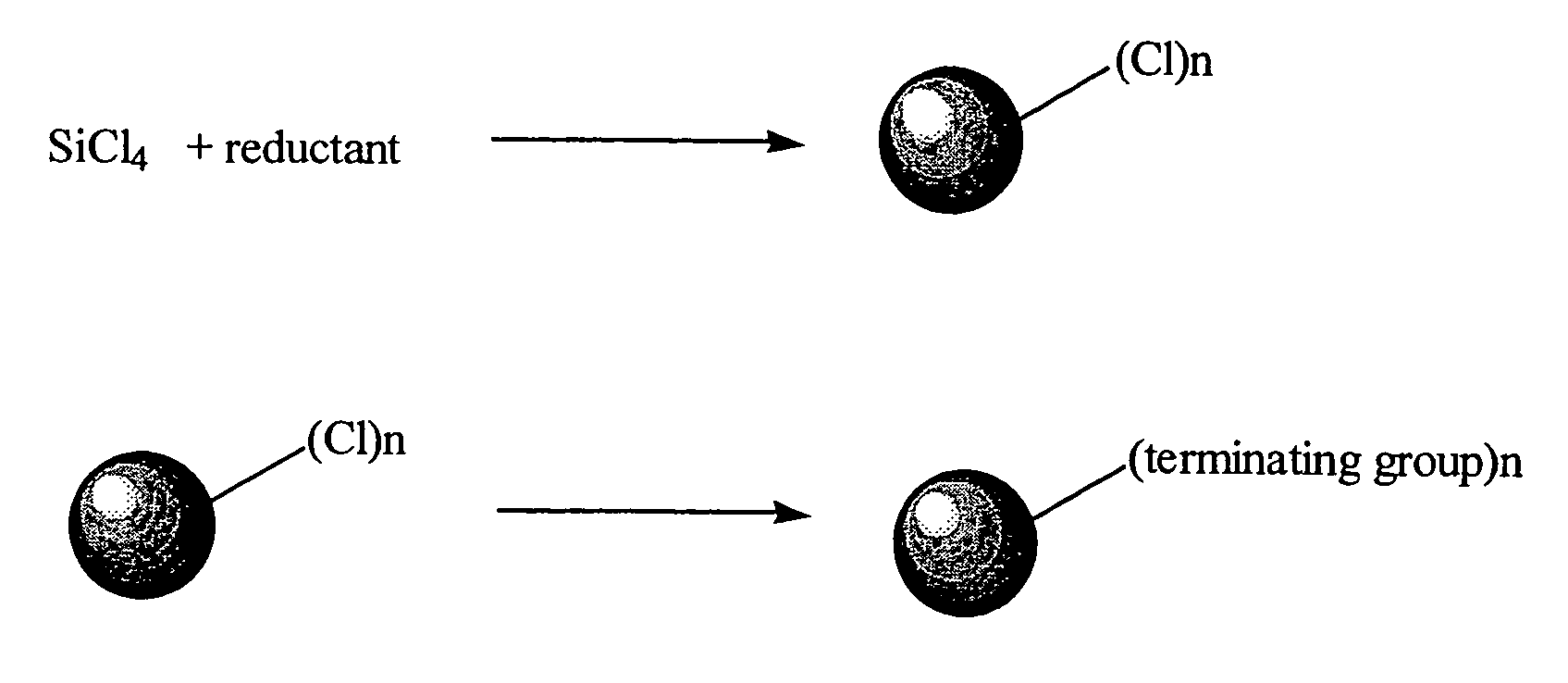

High yield method for preparing silicon nanocrystals with chemically accessible surfaces

InactiveUS6855204B2Material nanotechnologyPolycrystalline material growthSilicon nanocrystalMoisture

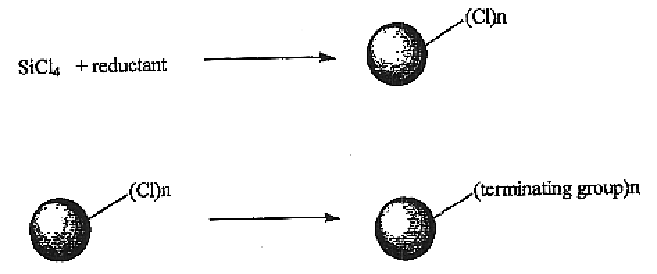

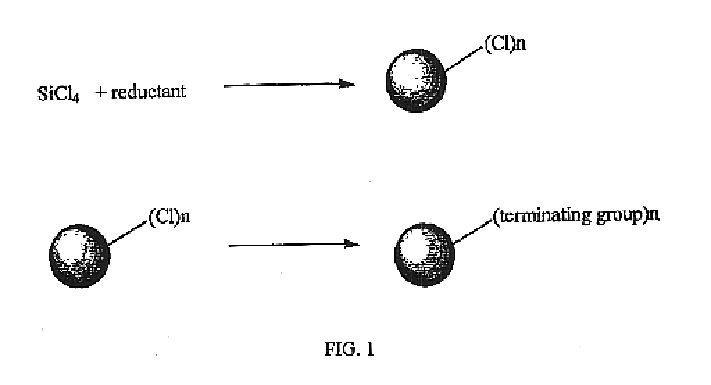

Silicon nanocrystals with chemically accessible surfaces are produced in solution in high yield. Silicon tetrahalide such as silicon tetrachloride (SiCl4) can be reduced in organic solvents, such as 1,2-dimethoxyethane (glyme), with soluble reducing agents, such as sodium naphthalenide, to give halide-terminated (e.g., chloride-terminated) silicon nanocrystals, which can then be easily functionalized with alkyl lithium, Grignard or other reagents to give easily processed silicon nanocrystals with an air and moisture stable surface. The synthesis can be used to prepare alkyl-terminated nanocrystals at ambient temperature and pressure in high yield. The two-step process allows a wide range of surface functionality.

Owner:EVERGREEN SOLAR

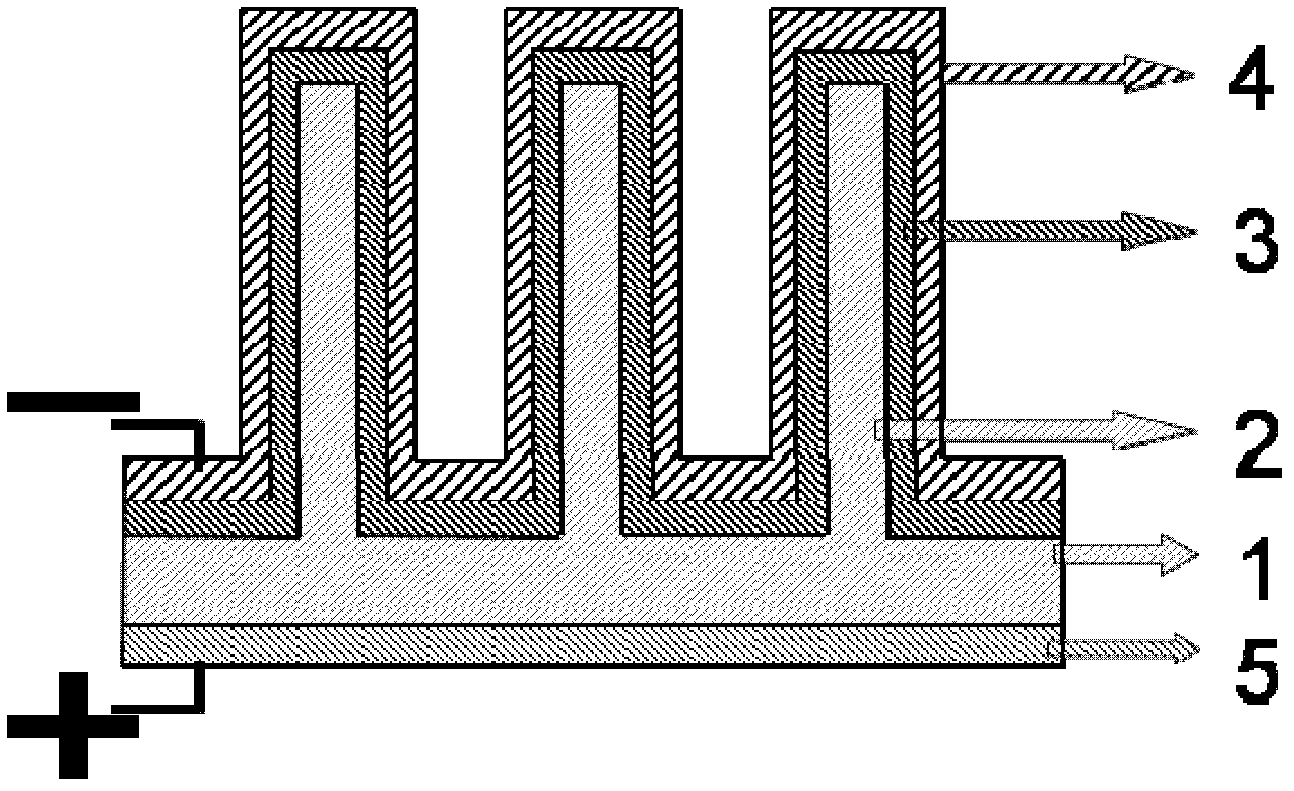

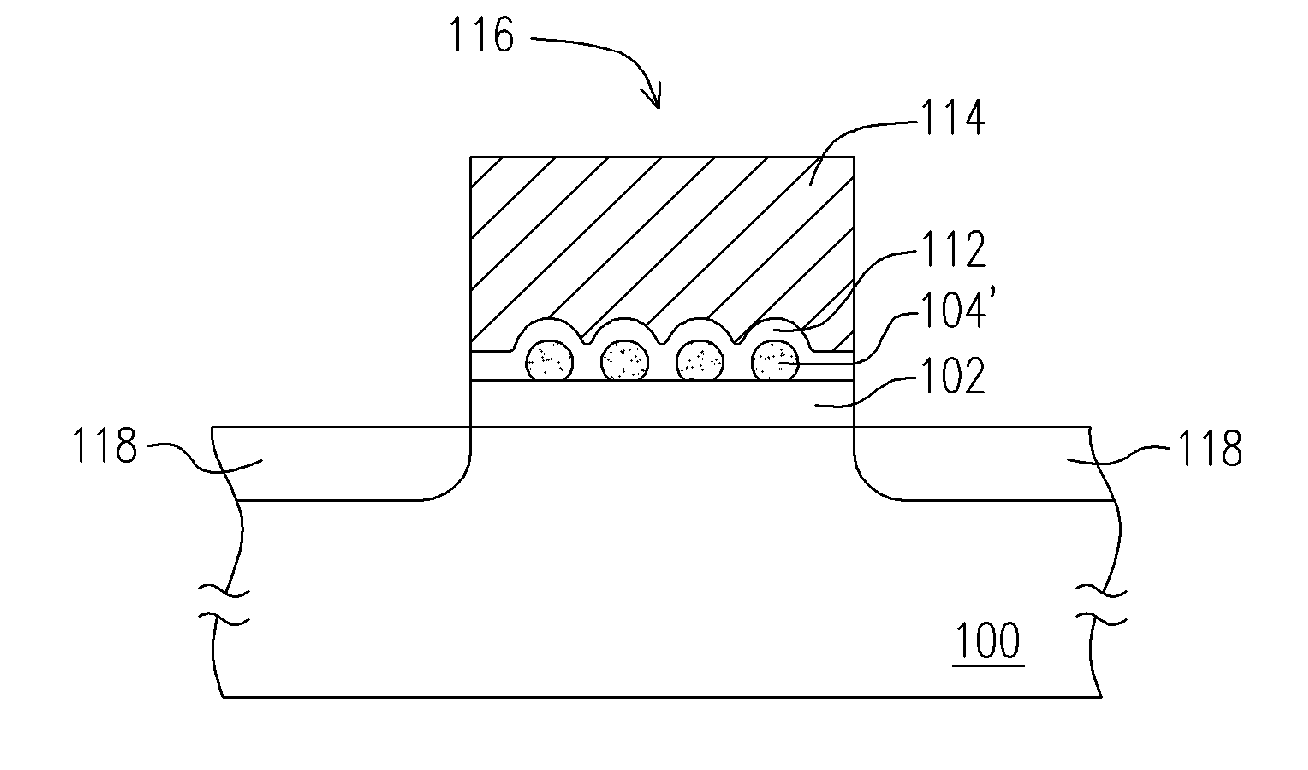

Silicon-based light-emitting device and preparation method thereof

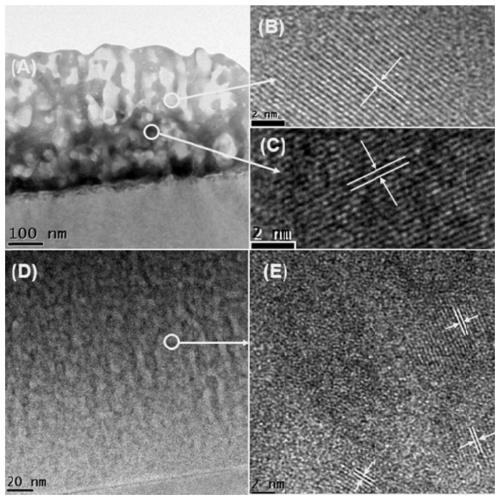

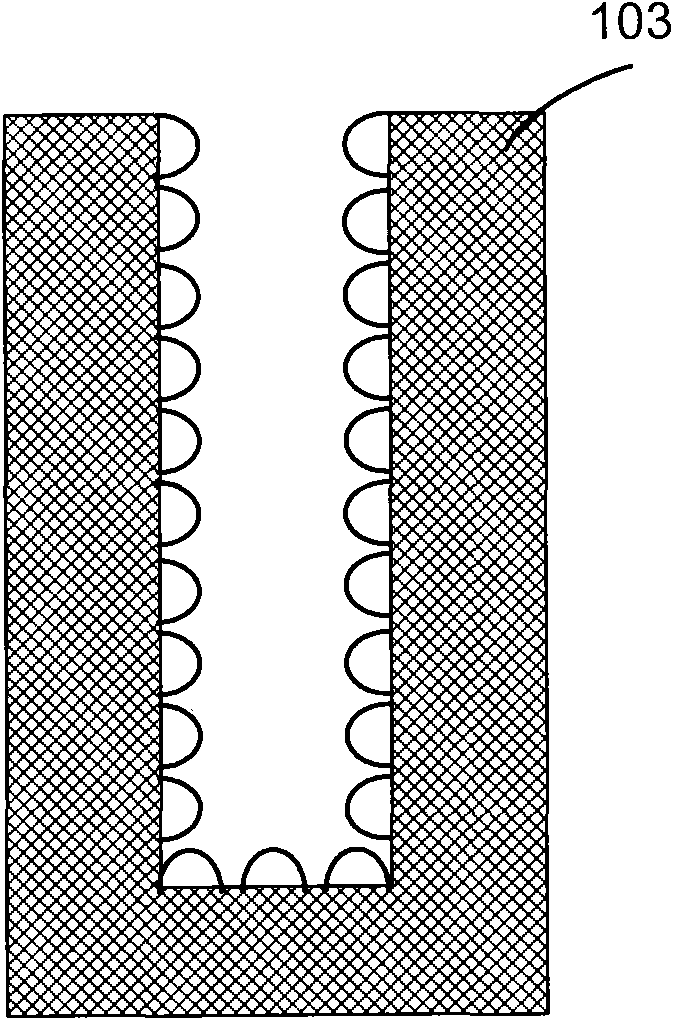

InactiveCN102280545AImprove injection efficiencyImprove light extraction efficiencySemiconductor devicesNano siliconNanopillar

The invention discloses a silicon-based light-emitting device and a preparation method thereof. The device includes a silicon substrate, the front of the substrate is etched to form a nano-column photonic crystal array, and a film layer containing a silicon nanocrystal quantum dot structure is conformally deposited on the array, and the film layer is covered with a transparent conformal electrode. Ohmic contact electrodes are deposited on the bottom and back; the method is as follows: using microsphere mask etching technology on the front of the substrate to obtain a silicon nanocolumn photonic crystal array through deep reactive ion etching, and then co-existing on the silicon nanocolumn photonic crystal array. Formally grow a thin film layer containing a nano-silicon quantum dot structure and a transparent conformal electrode, and deposit an ohmic contact electrode on the back of the substrate to obtain the target product. The silicon-based light-emitting device of the present invention adopts photonic crystal nano-column array and silicon nano-crystal quantum dot structure at the same time, which effectively improves the light extraction efficiency and carrier injection efficiency, thereby improving the luminous intensity and light emission efficiency of the device, and the device structure is simple, The process is simple and the cost is low.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

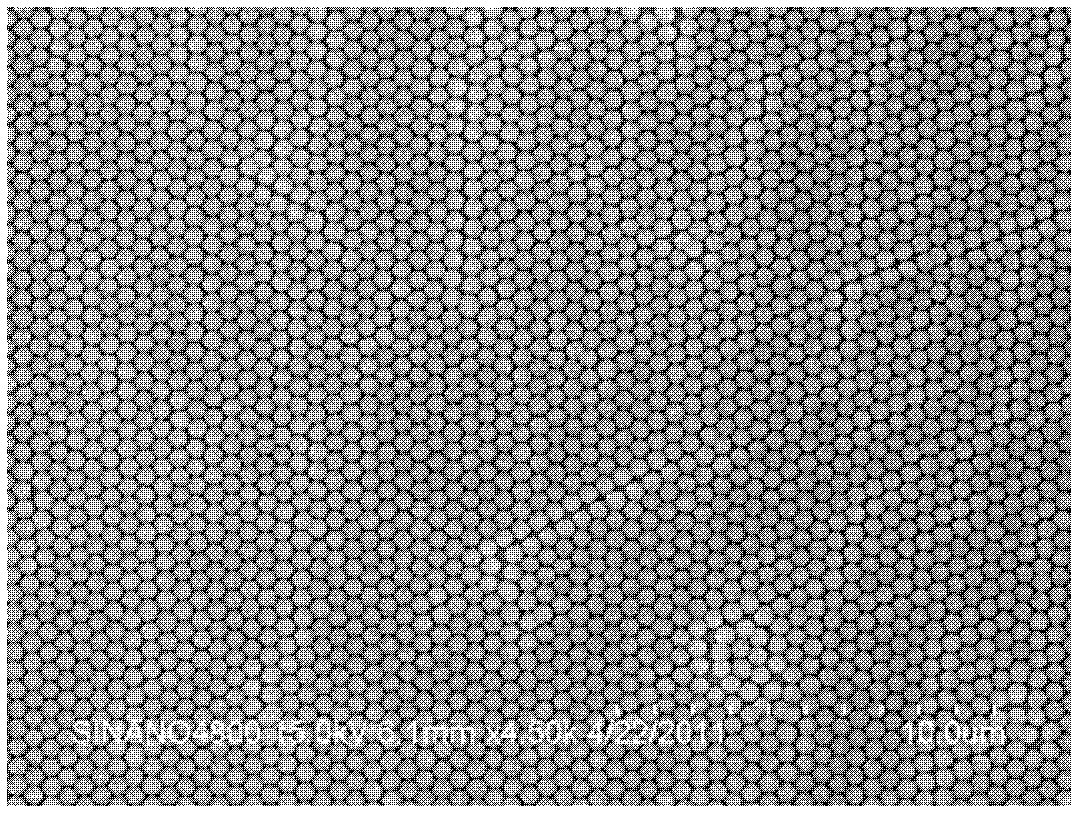

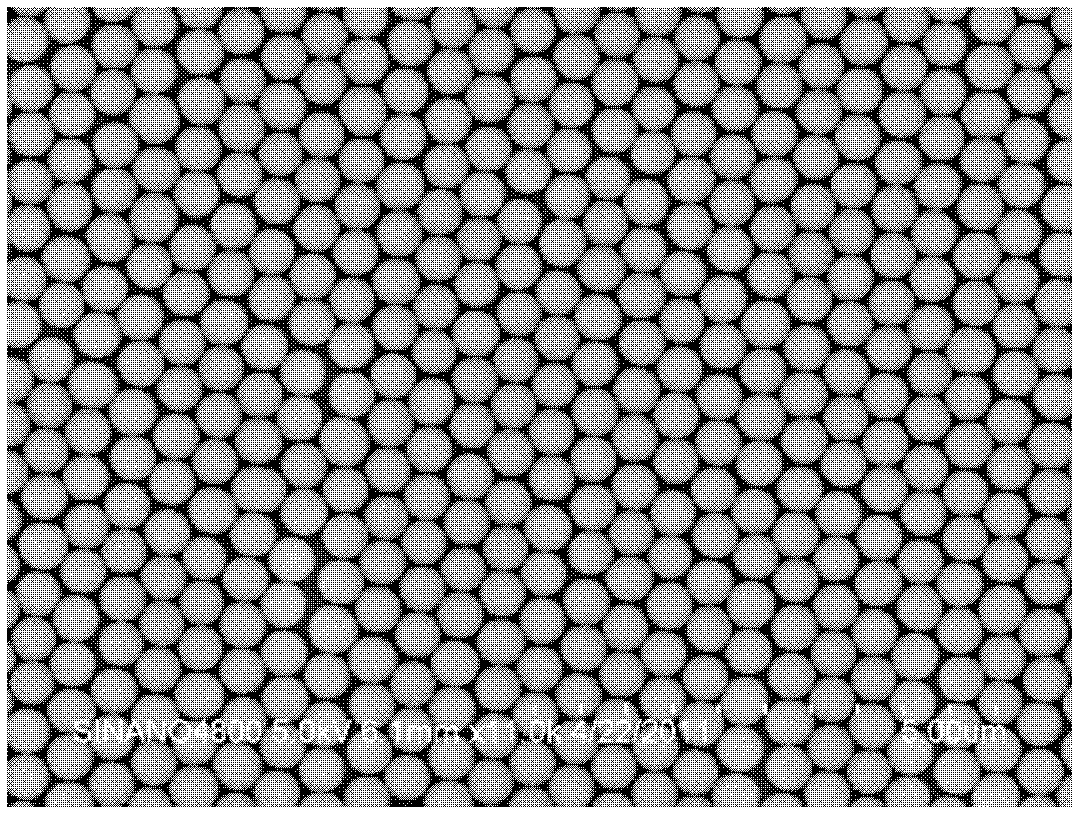

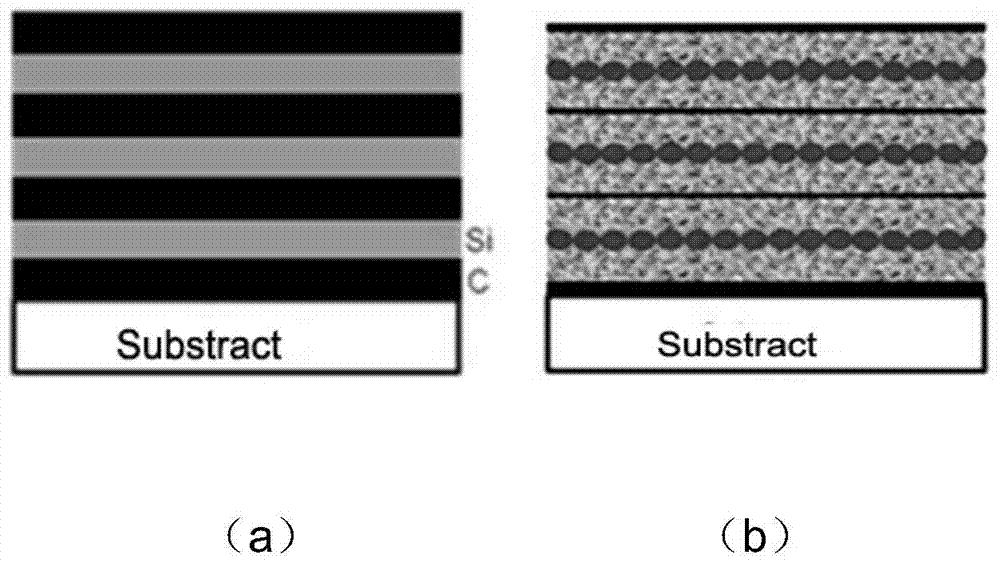

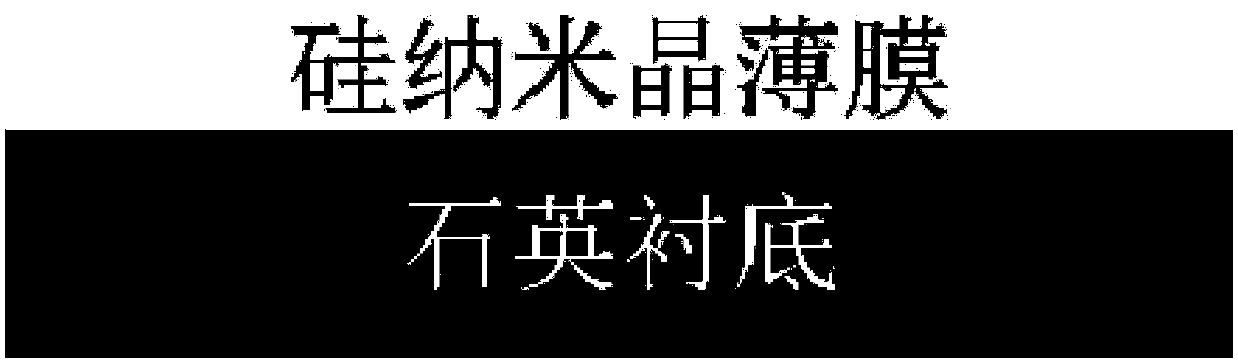

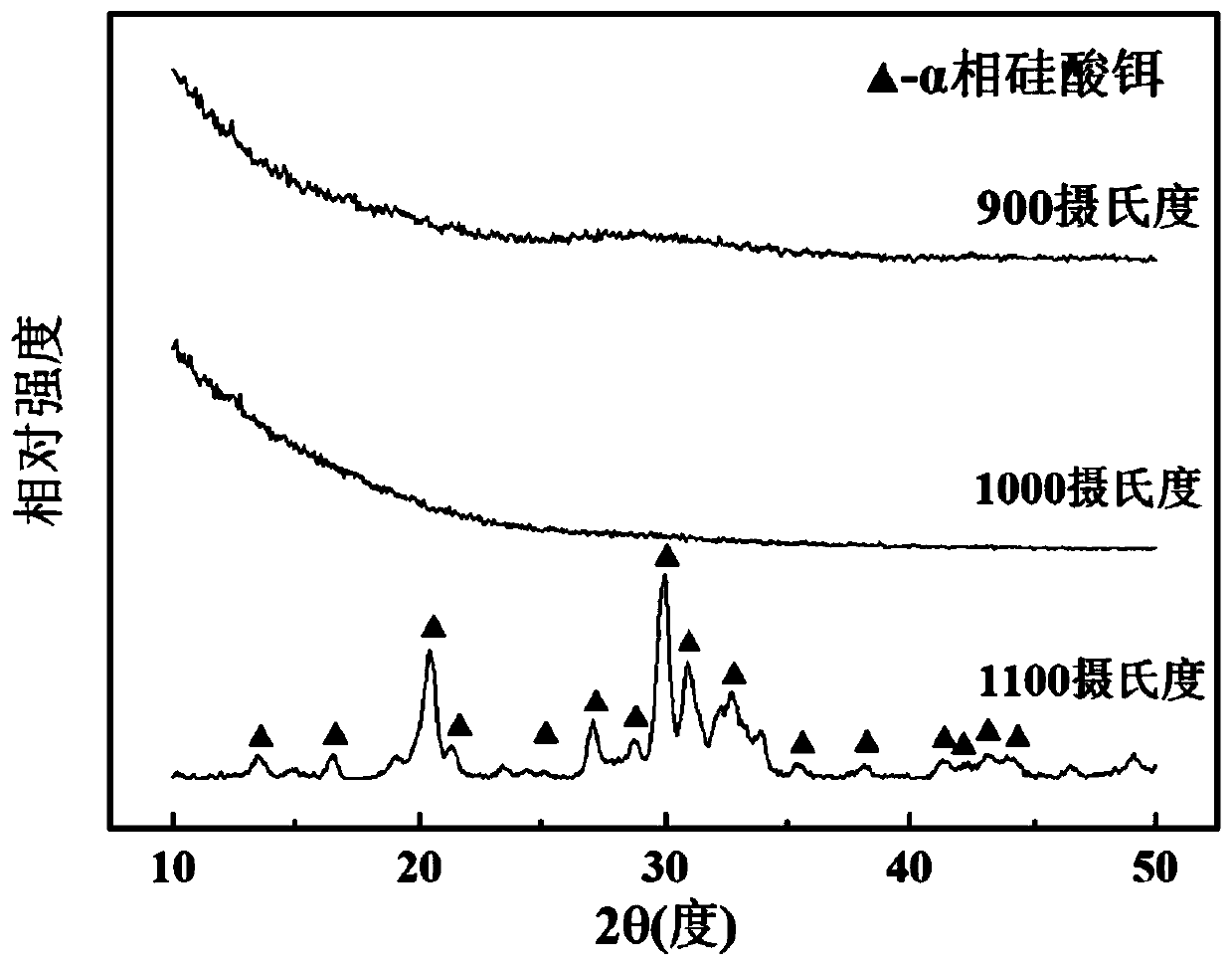

Preparing method of self-assembly forming-dimension-controllable silicon nanocrystal films

ActiveCN103700576AImprove photoelectric conversion efficiencyThe interface is complete and clearSemiconductor/solid-state device manufacturingPhotovoltaic energy generationCarbon filmSilicon nanocrystal

The invention relates to a preparing method of self-assembly forming-dimension-controllable silicon nanocrystal films. The method mainly comprises the following steps that firstly, after the film coating pretreatment, Ar ions are used for carrying out magnetron co-sputtering on Si targets and C targets, the sputtering powers of the Si and C targets are regulated, and amorphous silicon / carbon films of a multilayer structure are alternately deposited on a silicon and glass substrate; then, the staged annealing is carried out in the nitrogen atmosphere, and the alpha-SiC / nc-Si multilayer structure films are formed. The silicon nanocrystal dimension formed by the films is controllable in a range being 2 to 10nm, meanwhile, the density of silicon nanocrystals is also controllable, and the optical band gap of the silicon nanocrystals in the range is controllably changed in a range being 2.7 to 1.8eV. The preparing method provided by the invention has the advantages that the silicon nanocrystals with the controllable dimension and density can be formed through the superlattice structure Si / C multilayer films, further, the absorption spectrum range is regulated, and in addition, the photoelectric conversion efficiency of used materials can be obviously improved. Through the films, the light absorption range and the photoelectric conversion efficiency of silicon-based photovoltaic devices are hopeful to be greatly improved.

Owner:温岭艾斯达特新材料科技有限公司

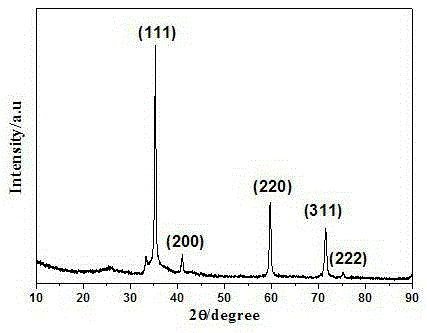

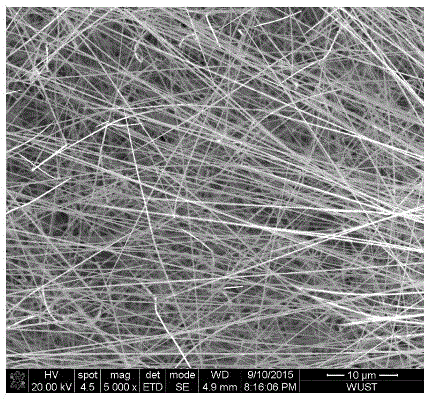

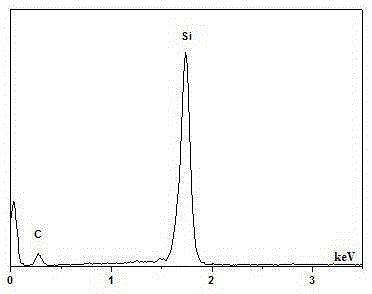

Preparation method of silicon carbide nanometer crystal whiskers

The invention discloses a preparation method of silicon carbide nanometer crystal whiskers. According to the technical scheme, 10 wt%-40 wt% of organosilicone and 60 wt%-90 wt% of pitch organic solvent soluble components or resin organic solvent soluble components, co-cracking is conducted on an obtained solution for 2-6 h on the condition that the temperature ranges from 250 DEG C to 450 DEG C, and silicon-doped pitch or silicon-doped resin is obtained; carbonization is conducted on the silicon-doped pitch or the silicon-doped resin for 1-3 h on the conduction that the temperature ranges from 700 DEG C to 900 DEG C, and silicon-doped pitch-based carbon materials or silicon-doped resin-based carbon materials are obtained. The silicon-doped pitch-based carbon materials or the silicon-doped resin-based carbon materials are ground into fine powder and filled into a mold, mechanical pressing is conducted, and demoulding is conducted; a graphite crucible filled with a green body is put into a high-temperature carbonization furnace, heat treatment is conducted for 1-3 h at the temperature ranging from 1200 DEG C to 1800 DEG C in an inert atmosphere, natural cooling is conducted, and the silicon carbide nanometer crystal whiskers are obtained. According to the preparation method of the silicon carbide nanometer crystal whiskers, a catalyst does not need to participate, and the prepared silicon carbide nanometer crystal whiskers have the advantages of being high in purity, large in length-diameter radio and easy to collect.

Owner:WUHAN UNIV OF SCI & TECH

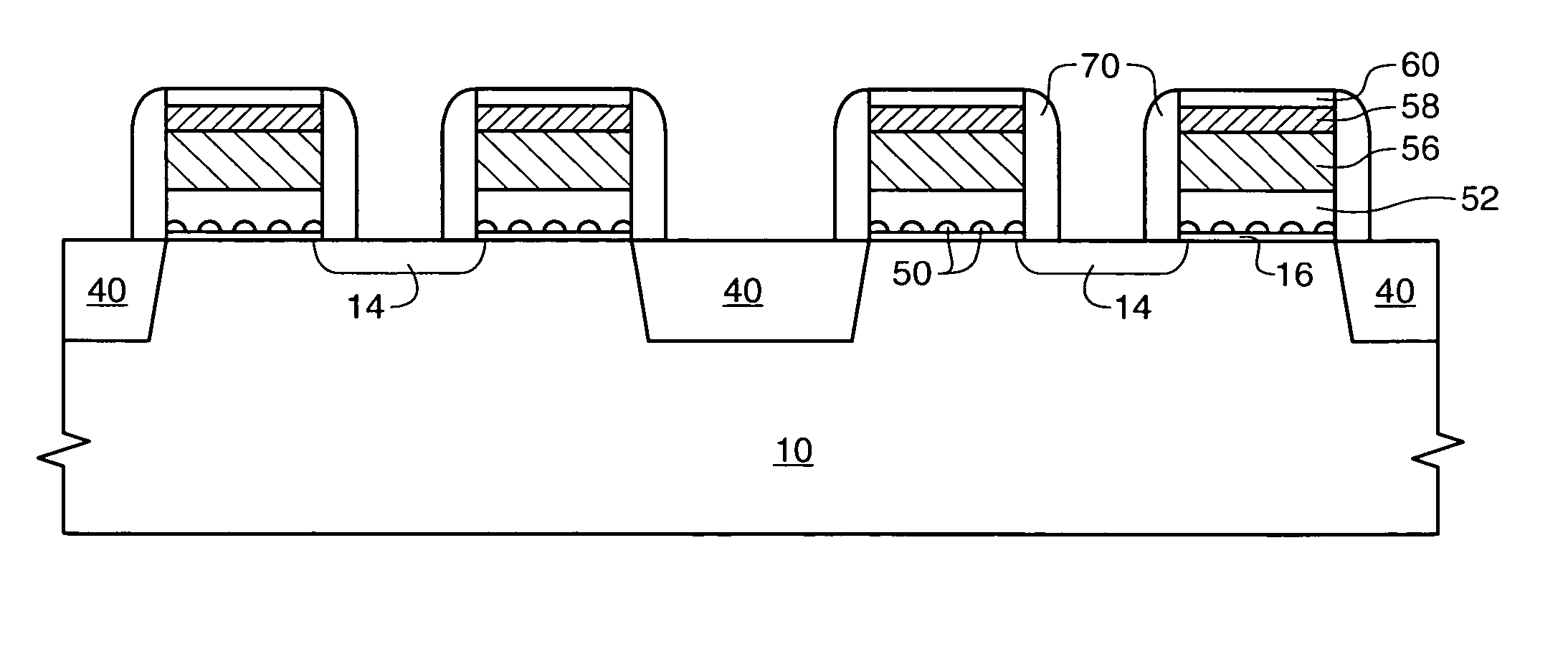

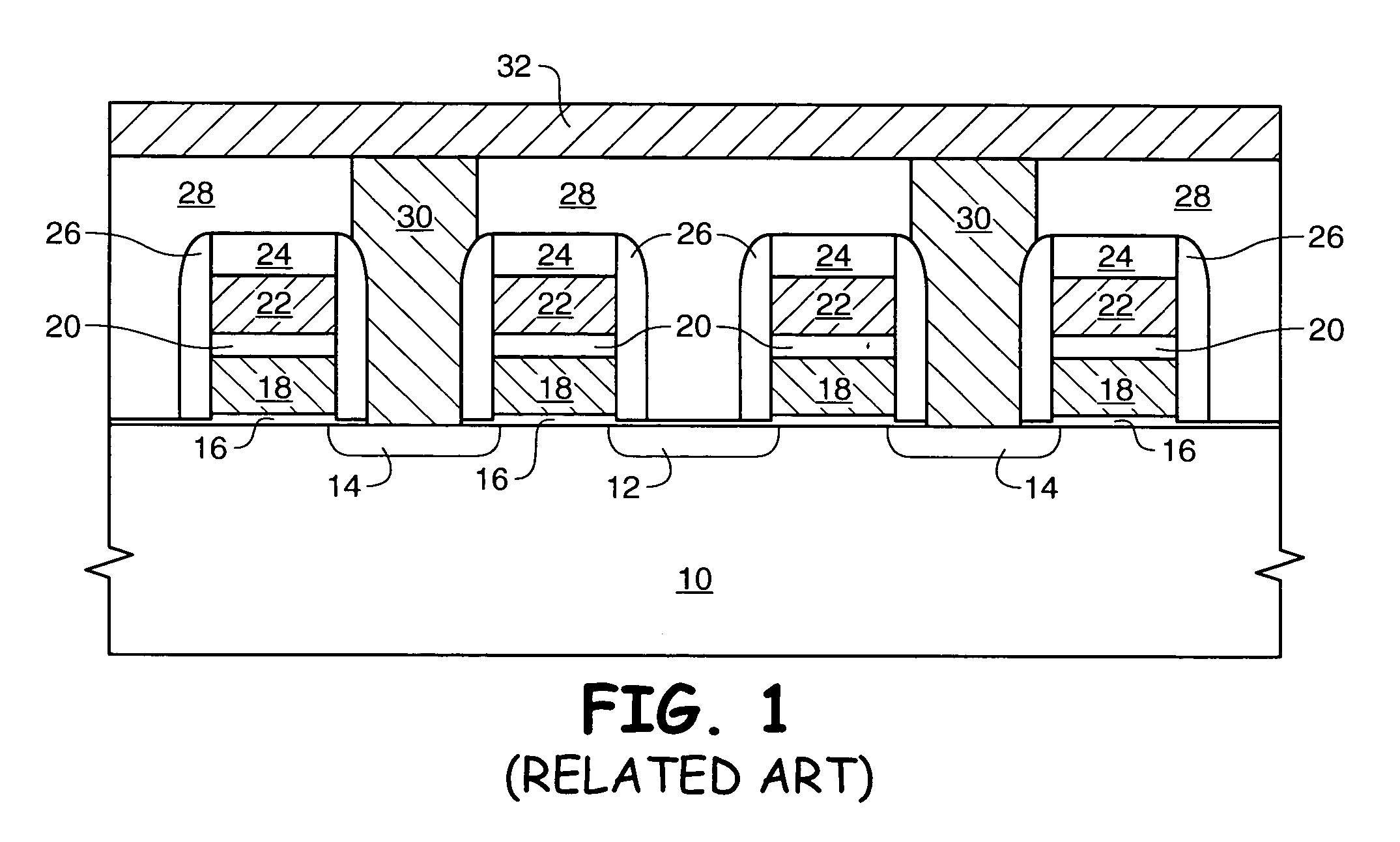

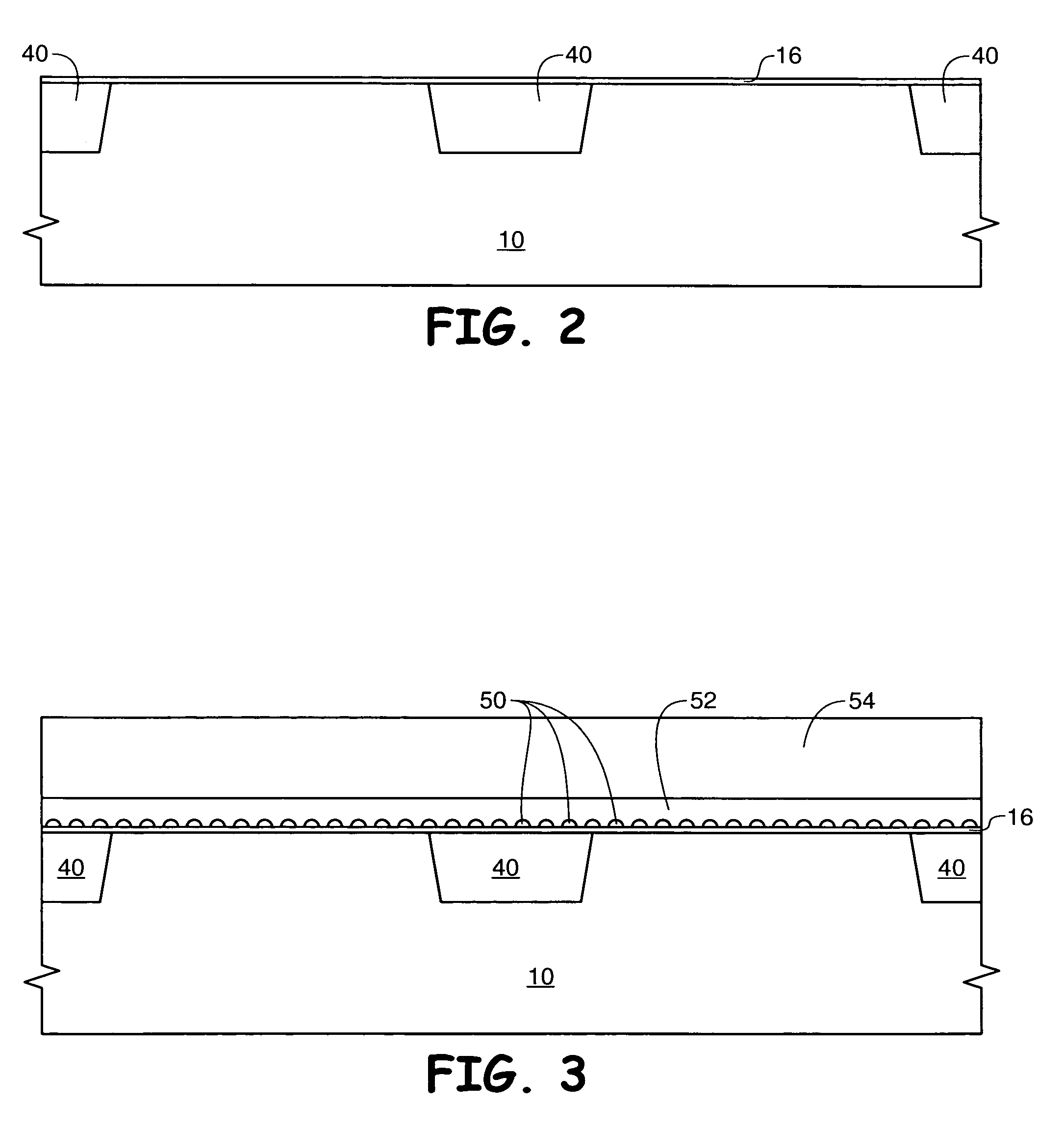

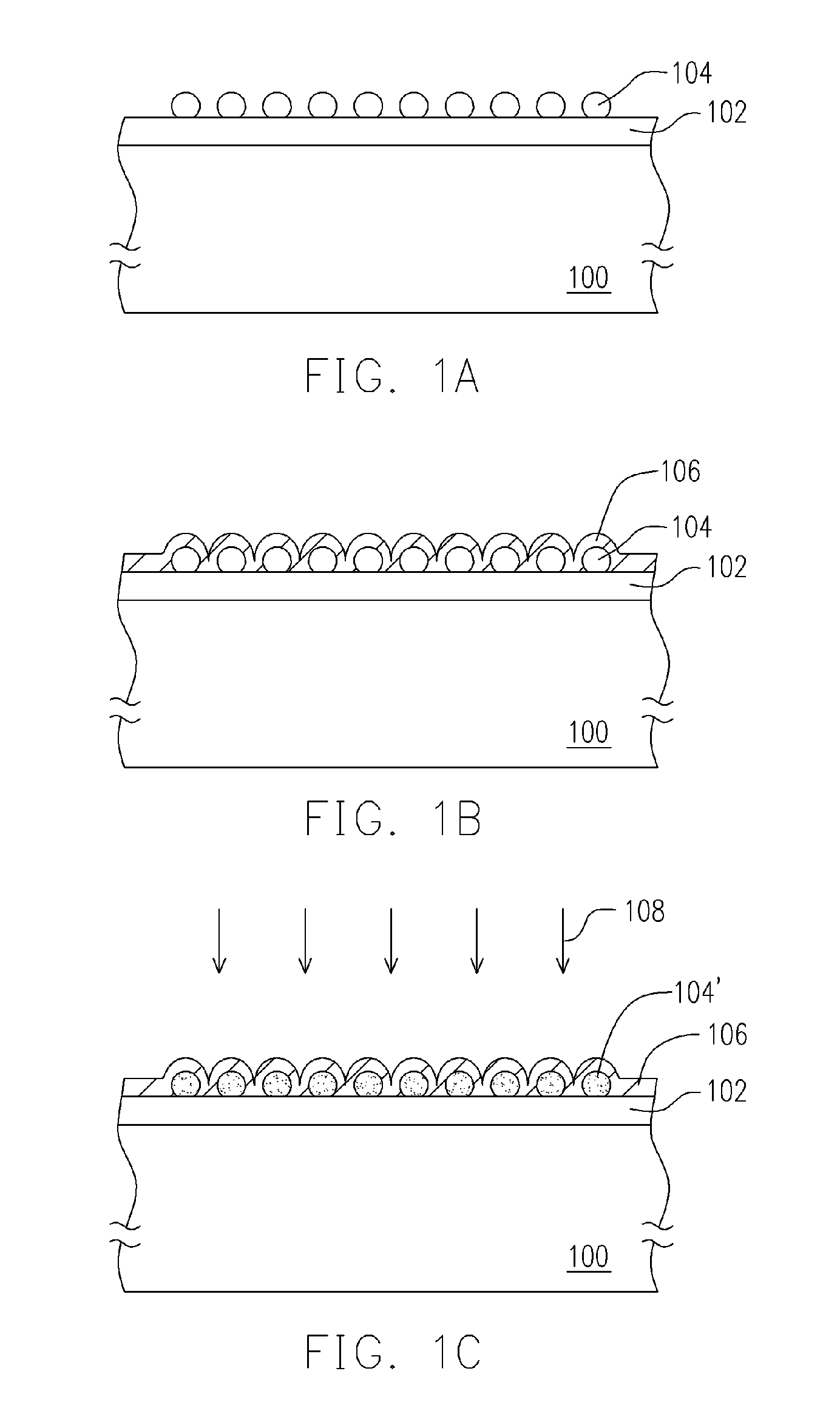

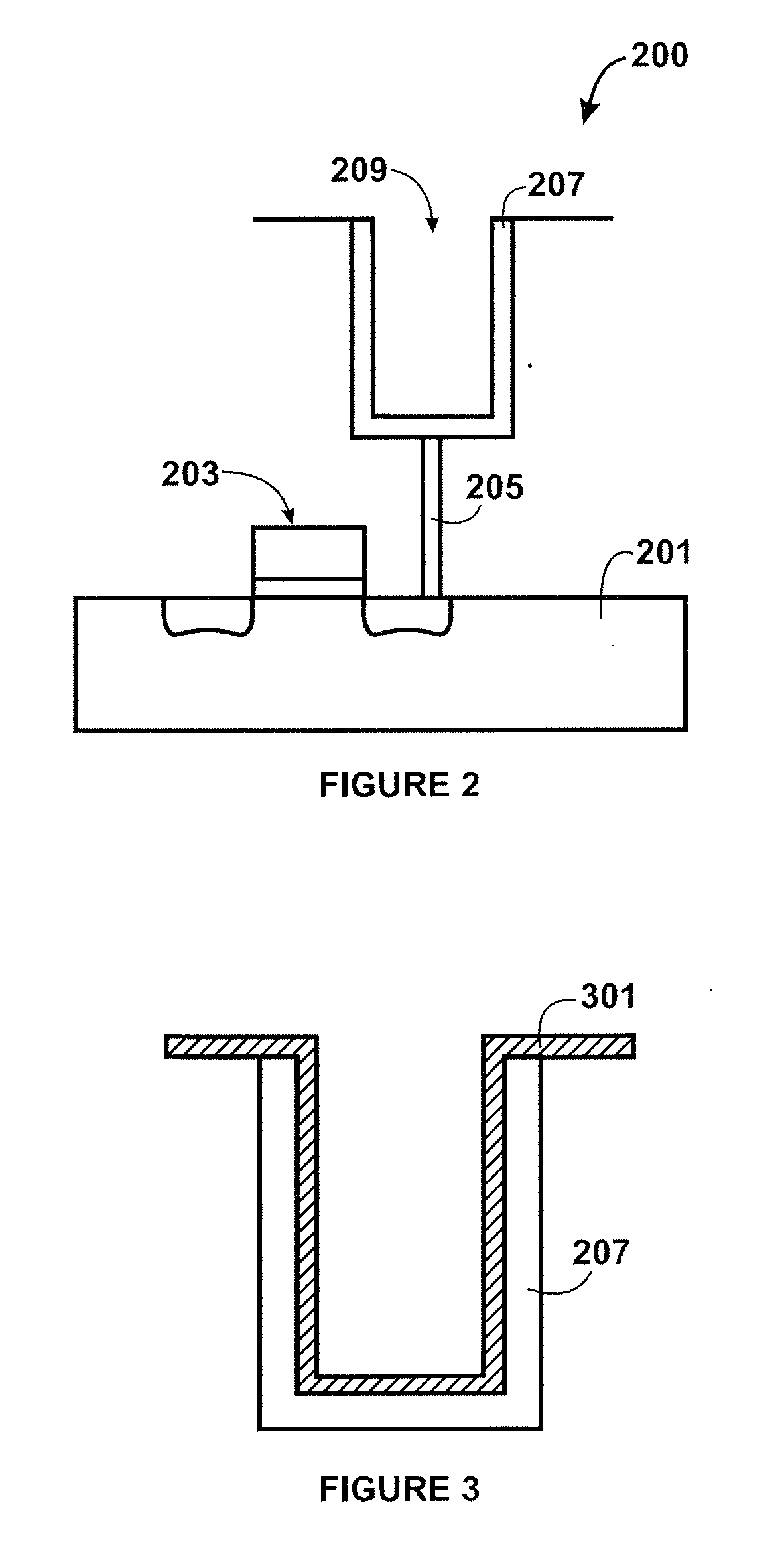

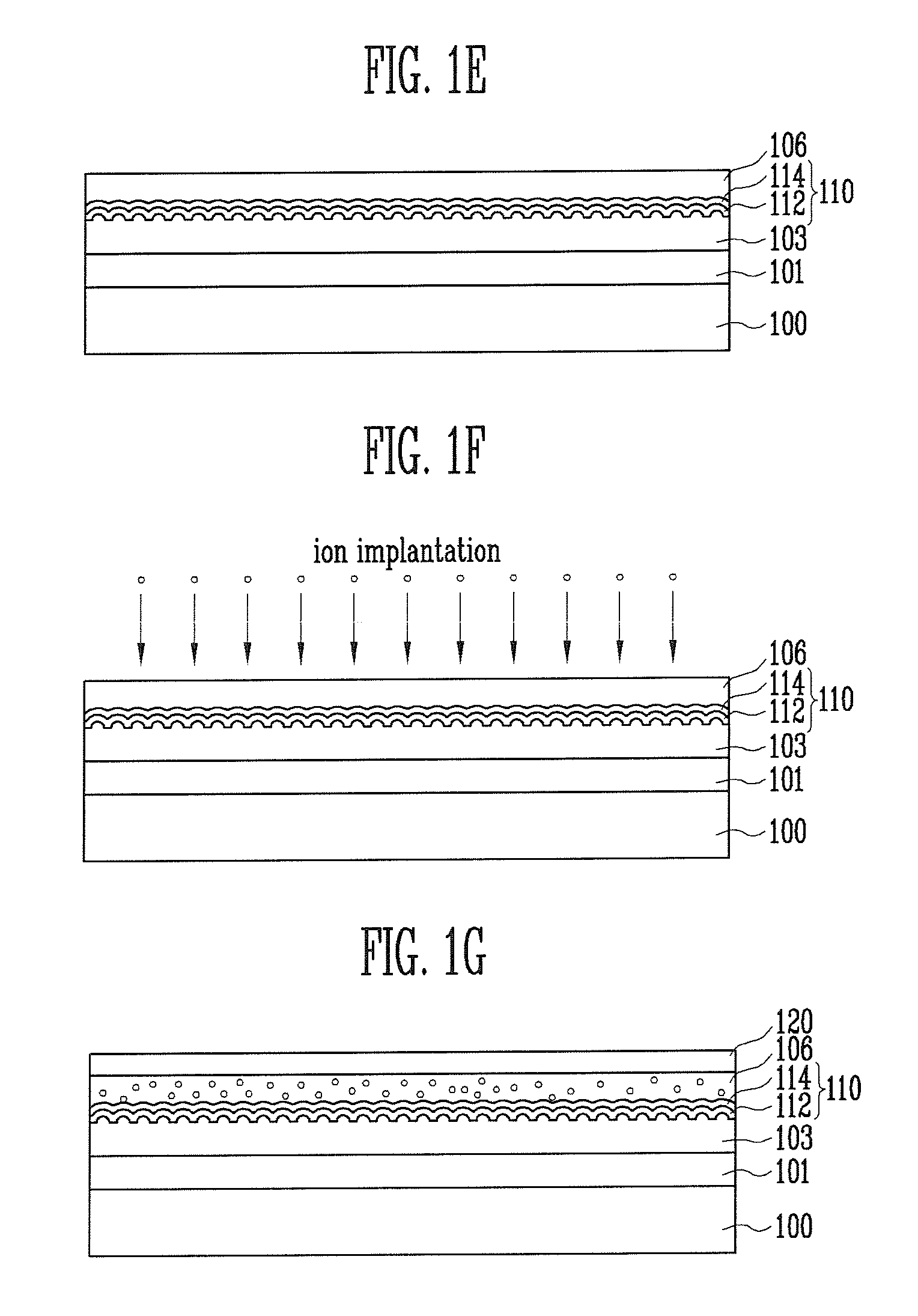

Method for manufacturing non-volatile memory

InactiveUS20070128796A1Reduce the possibilityImprove equipment reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingSalicideSilicon nanocrystal

A method for manufacturing a non-volatile memory is provided. First, a tunneling dielectric layer is formed over a substrate. A plurality of silicon nanocrystals is formed on the tunneling dielectric layer. A silicide process is performed on the silicon nanocrystals to form a plurality of salicide nanocrystals. A dielectric layer and a conductive layer are sequentially formed on the substrate to cover the salicide nanocrystals and the tunneling dielectric layer. The conductive layer, the dielectric layer, the salicide nanocrystals and the tunneling dielectric layer are patterned to form a gate structure. A source / drain region is formed in the substrate on the respective sides of the gate structure.

Owner:PROMOS TECH INC

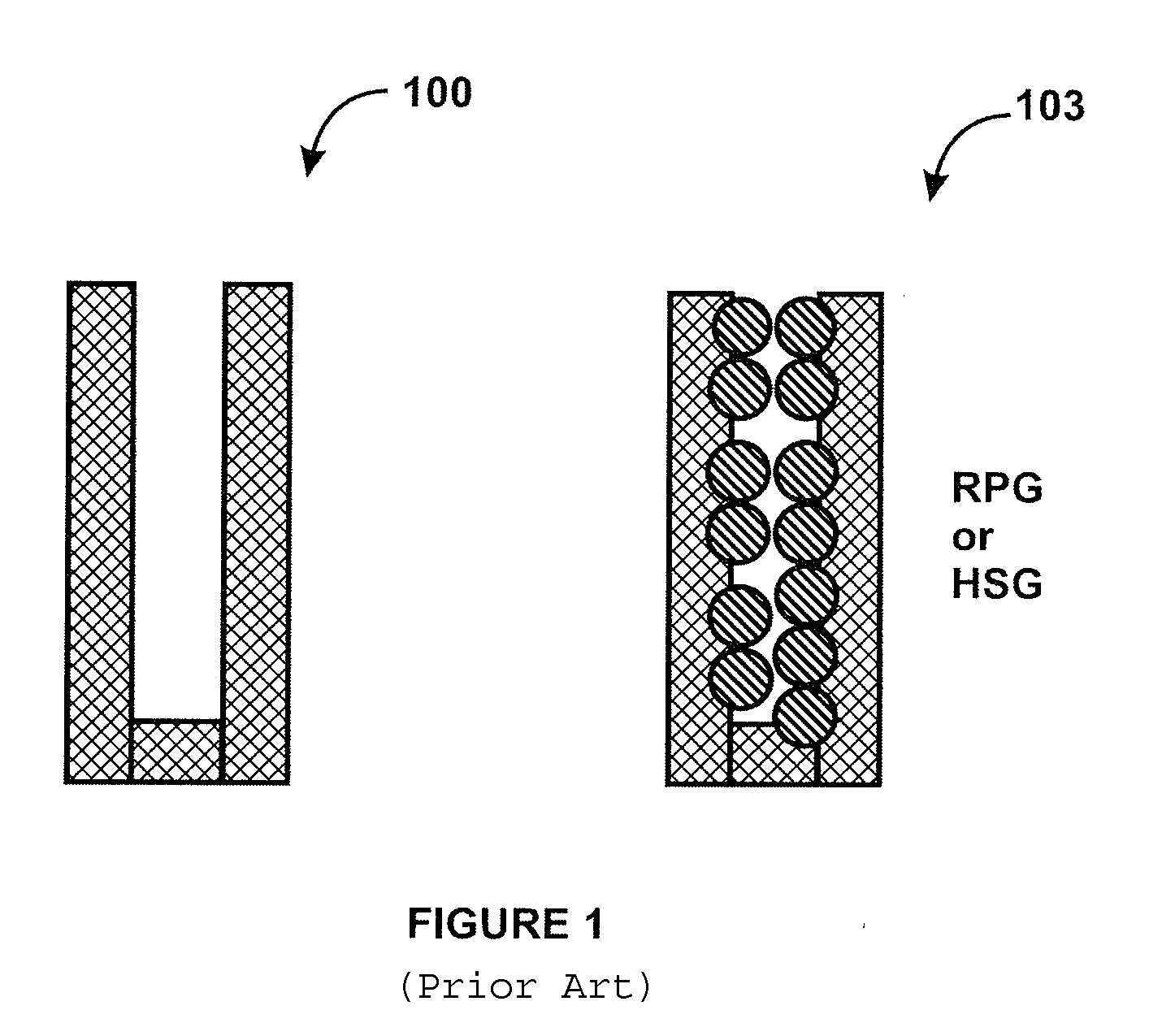

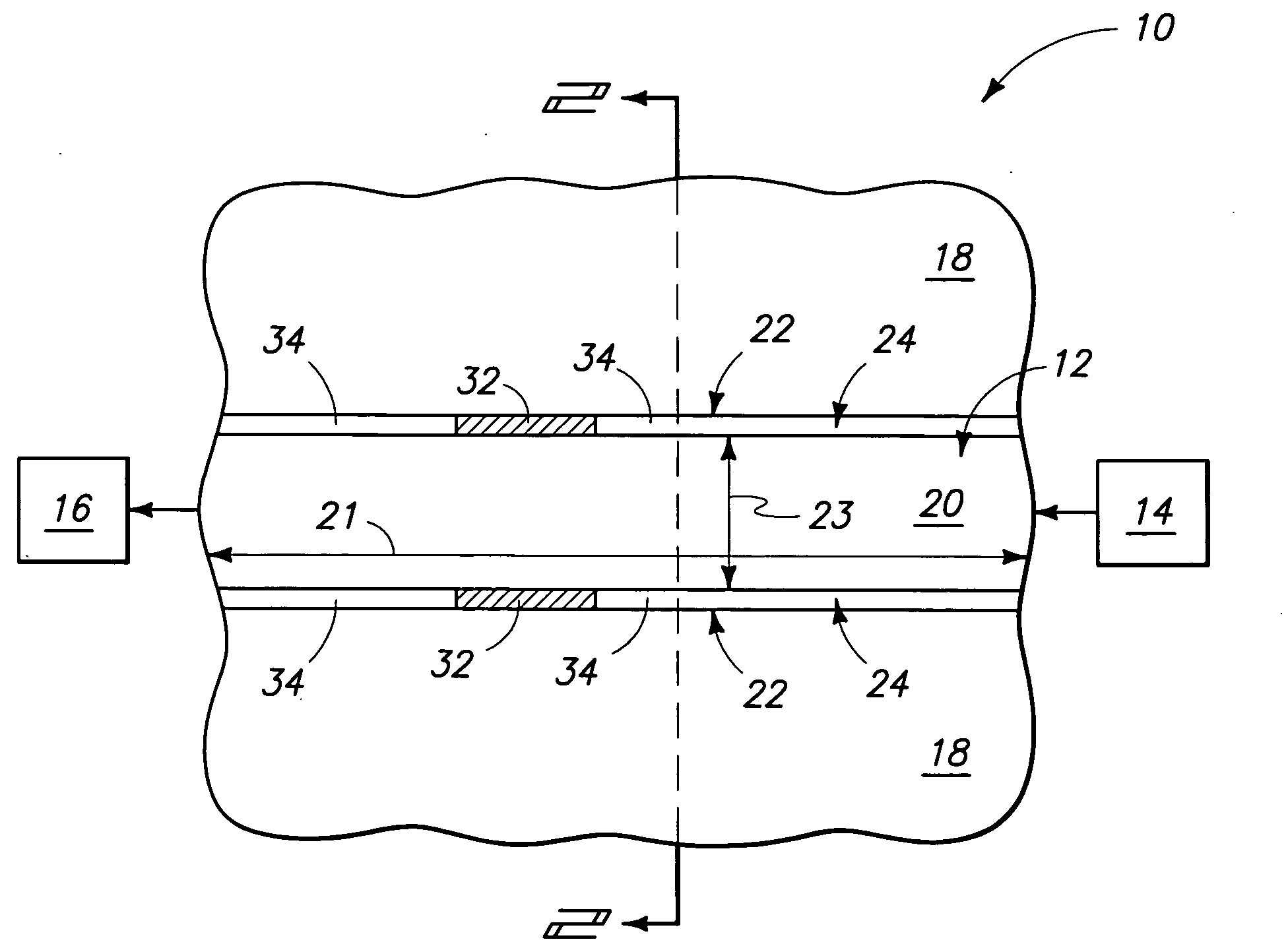

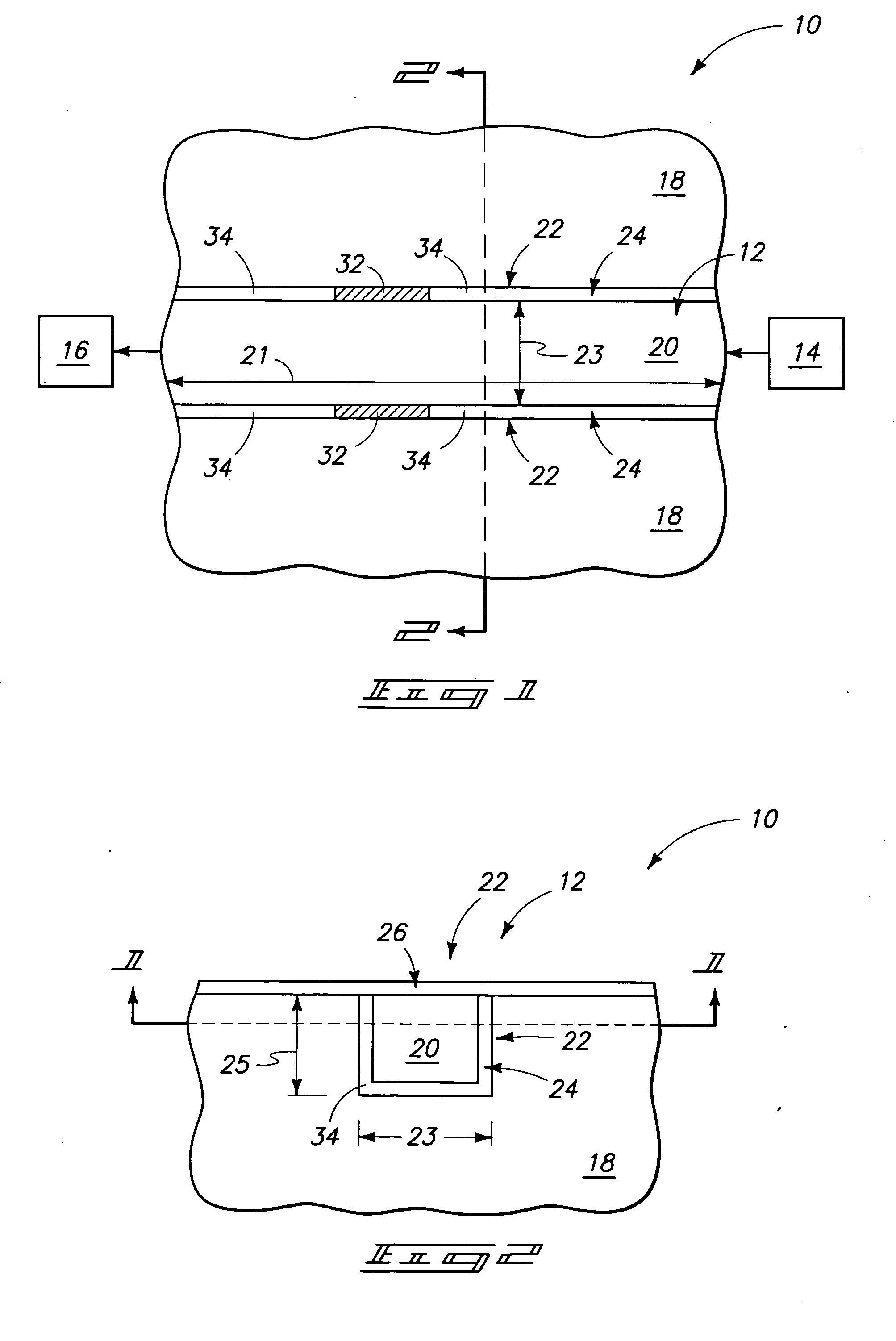

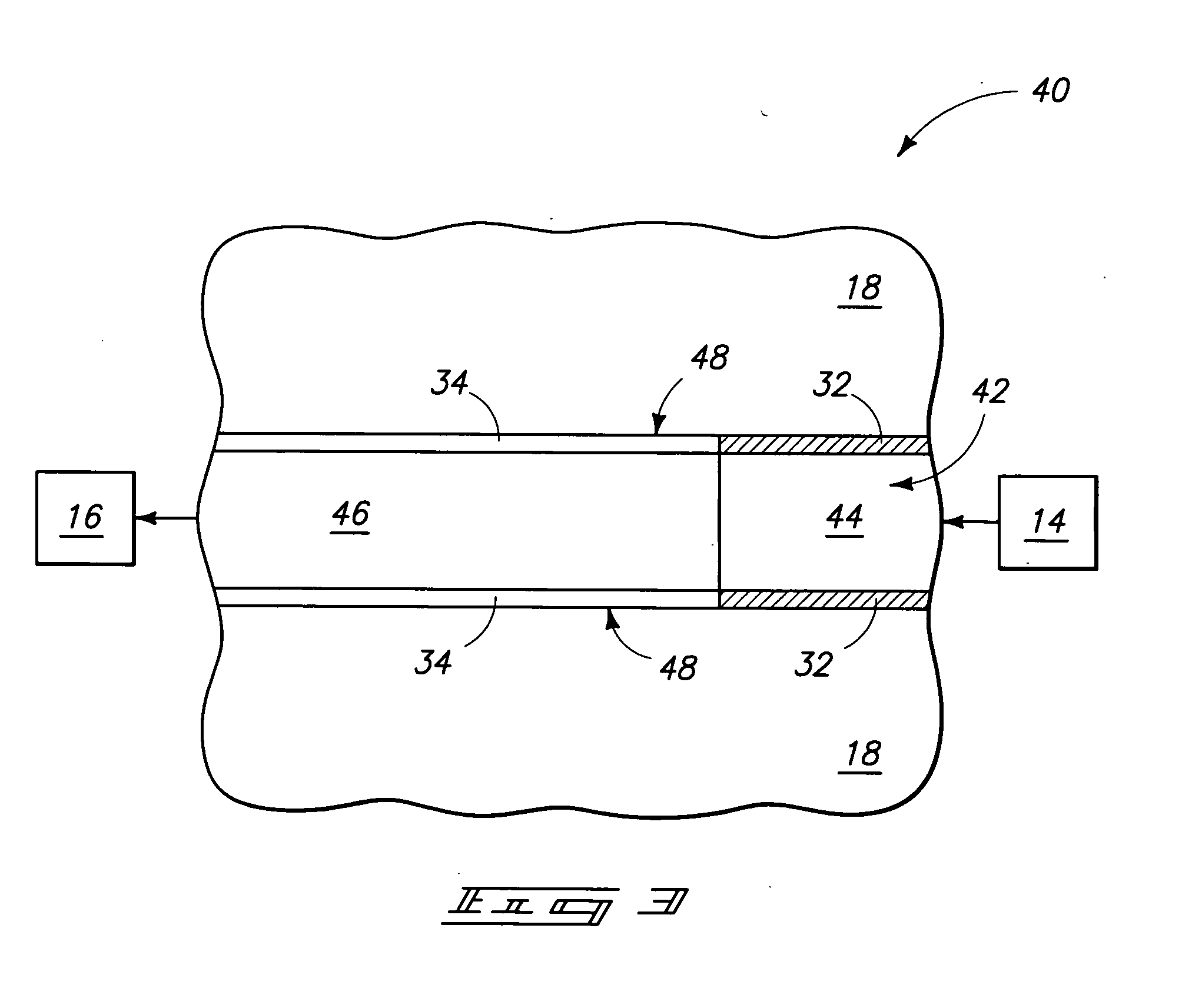

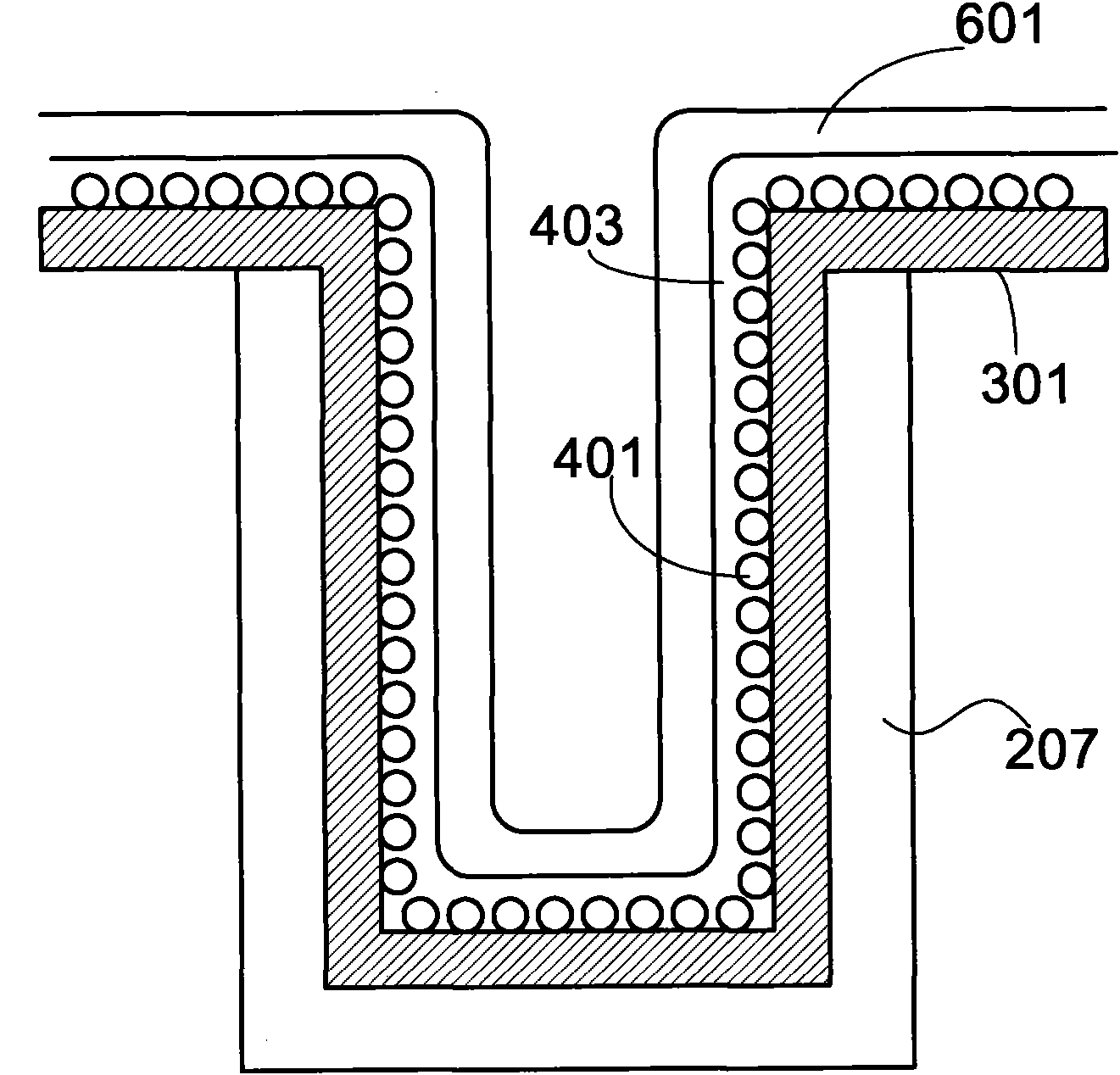

Method and structure for silicon nanocrystal capacitor devices for integrated circuits

InactiveUS20110095396A1Easy to useHigh device yieldNanoinformaticsSolid-state devicesDielectricElectricity

An improved semiconductor device, including a capacitor structure. The device has a first electrode member, which has a first length and a first width. The device also has a second electrode member, which has a second length and a second width. Additionally, the device includes a capacitor dielectric material provided between the first electrode member and the second electrode member according to a specific embodiment. Depending upon the embodiment, the capacitor dielectric material is made of a suitable material or materials such as Al2O3, HfO2, SiN, NO, Al2O3 / HfO2, AlNyOx, ZrO2, any combinations of these, and the like. The device further includes a plurality of silicon nanocrystals spatially disposed in an area associated with the first width and the first length of the first electrode member. Each one of the nanocrystals has a size of about 20 nanometers and less according to a specific embodiment.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

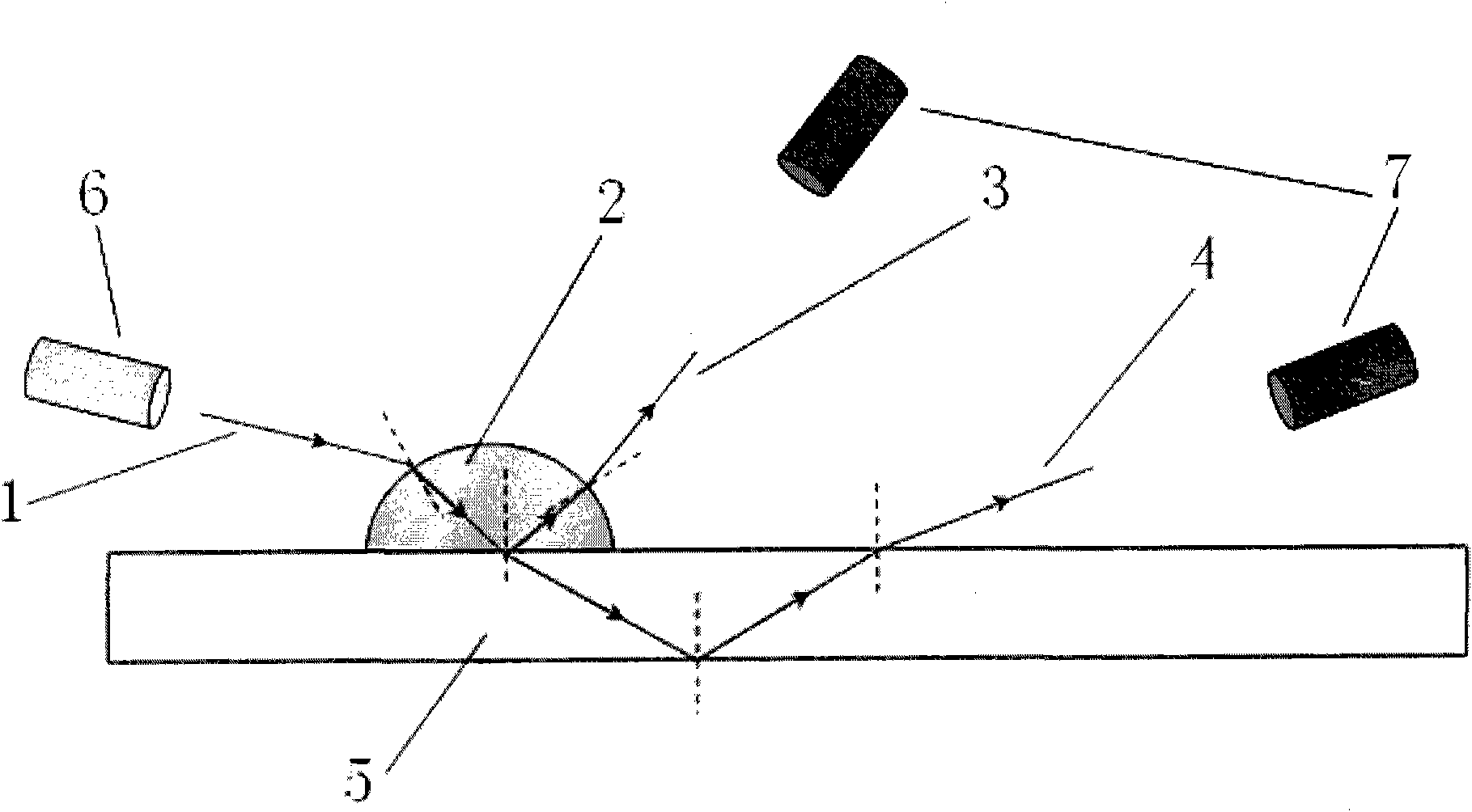

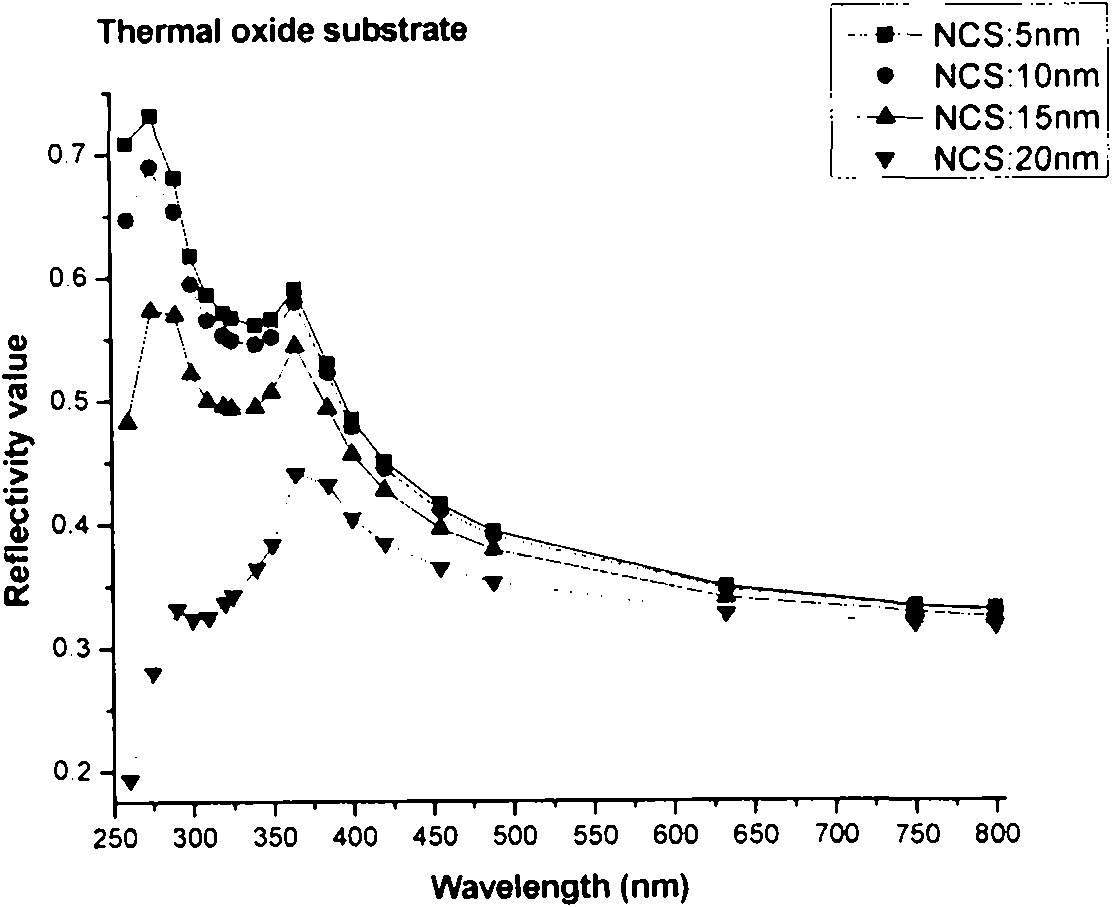

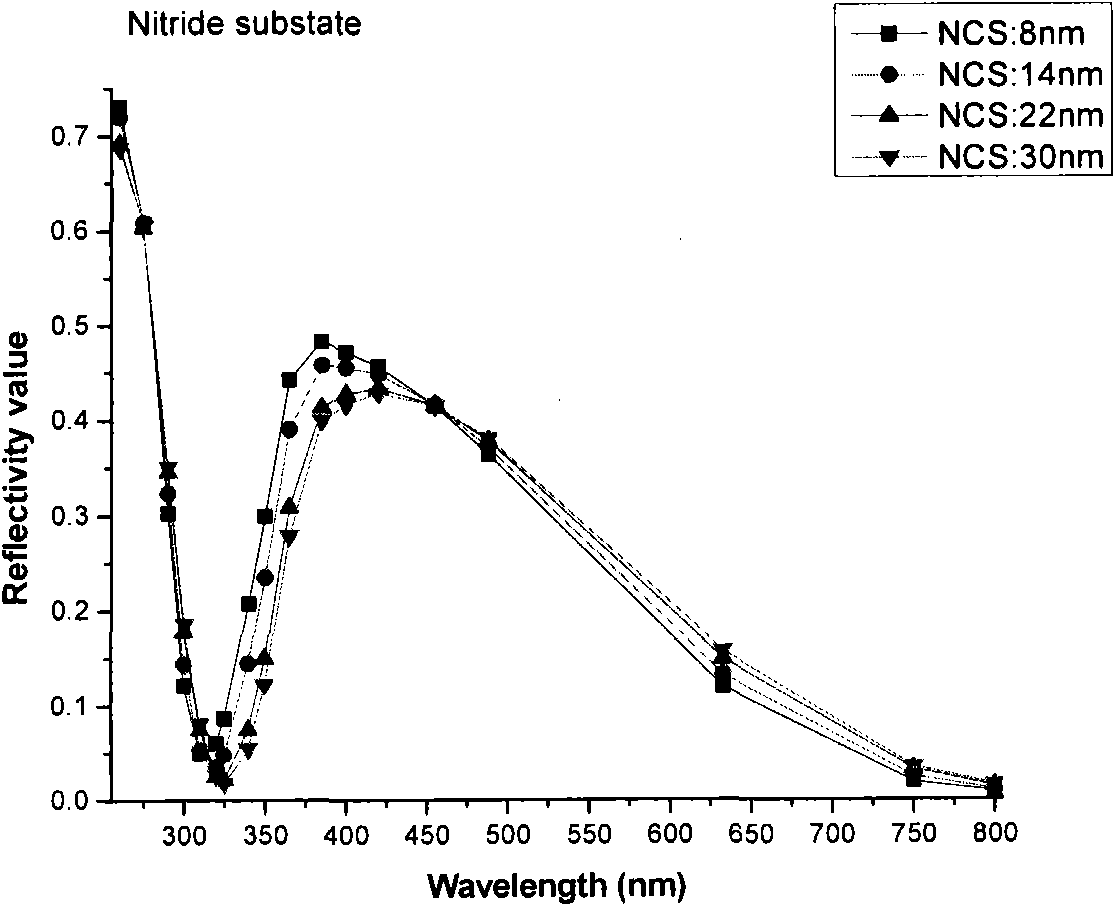

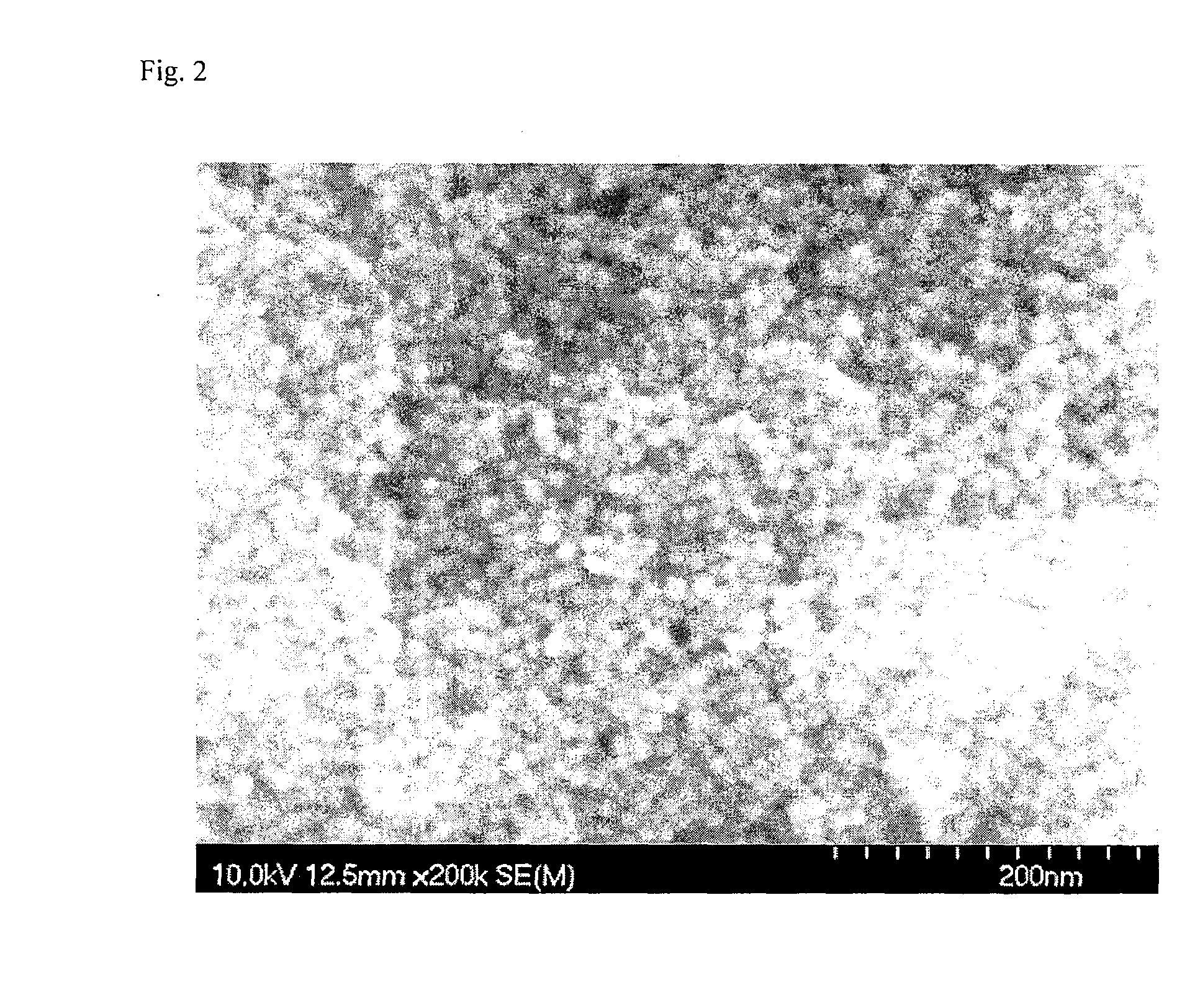

Method for on-line detection of form of silicon nanocrystals

ActiveCN101813624ARealize online detectionQuick checkScattering properties measurementsHydrofluoric acidNanocrystalline silicon

The invention discloses a method for on-line detection of the form of silicon nanocrystals. The method comprises the following steps of: preparing a plurality of silicon plates serving as substrates, and growing a tunneling medium layer on the surface of each substrate; treating the surfaces of the substrates by using diluted hydrofluoric acid, and growing a layer of silicon nanocrystals on the surface of each substrate; irradiating incident light which is monochromatic light with a 365nm wave length onto the surfaces of the substrates, wherein because surface materials and shapes are different, the intensity of reflected light is certainly changed; recording reflection indexes of nanocrystalline silicon chips in various growth periods, and establishing an expression of the relationship between the growth periods and the reflection indexes; performing fragment analysis of various silicon chips by using a scanning electronic microscope and a transmission electron microscope, determining the forms of the nanocrystals in different growth periods, and establishing an expression of the relationship between different forms of the nanocrystals and the growth periods; and establishing a corresponding expression of the relationship between the different forms and the reflection indexes of the nanocrystalline, and determining the form of the growing nanocrystals according to a reflection index. By the method, the on-line quick detection of the form of the silicon nanocrystals is realized.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

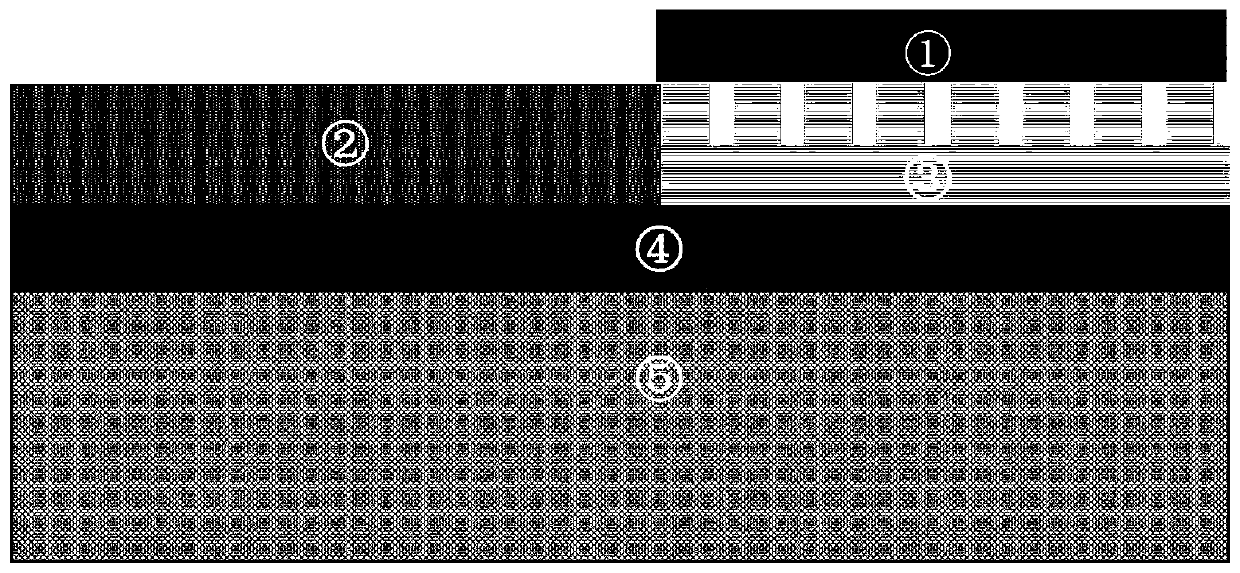

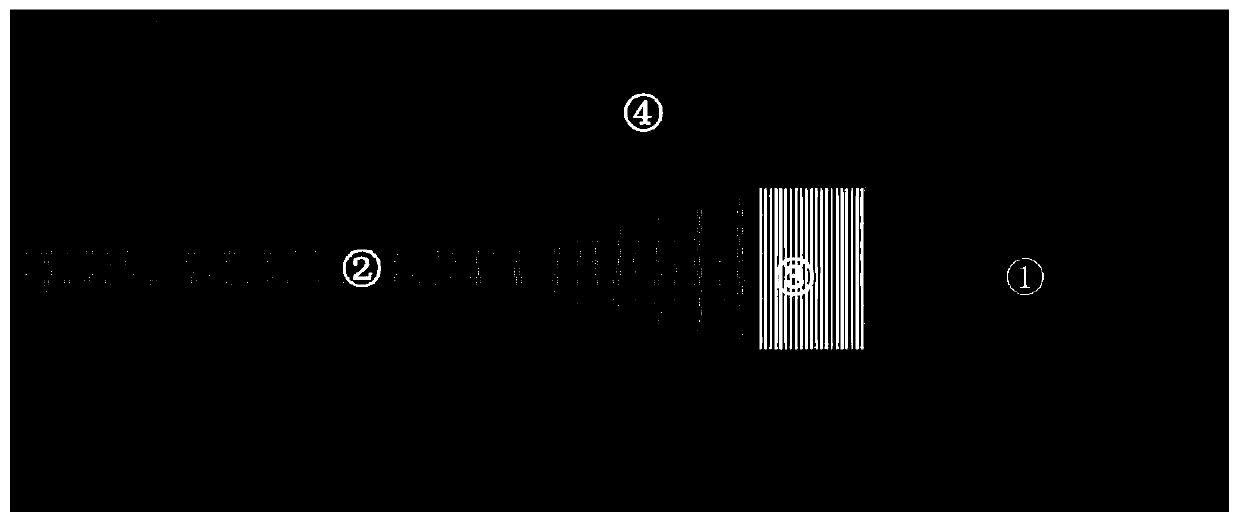

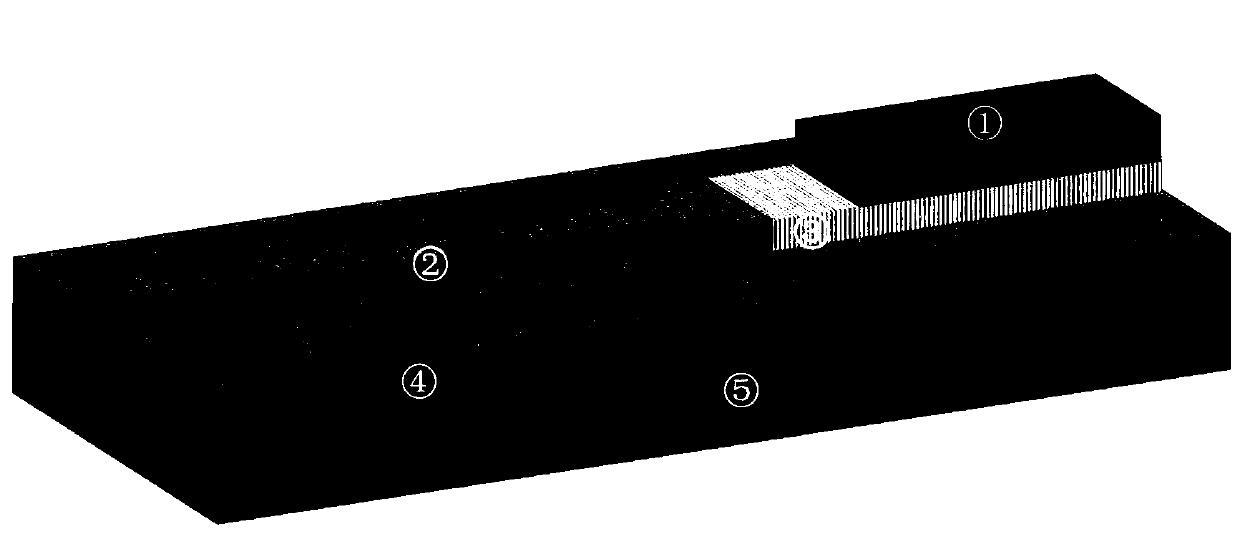

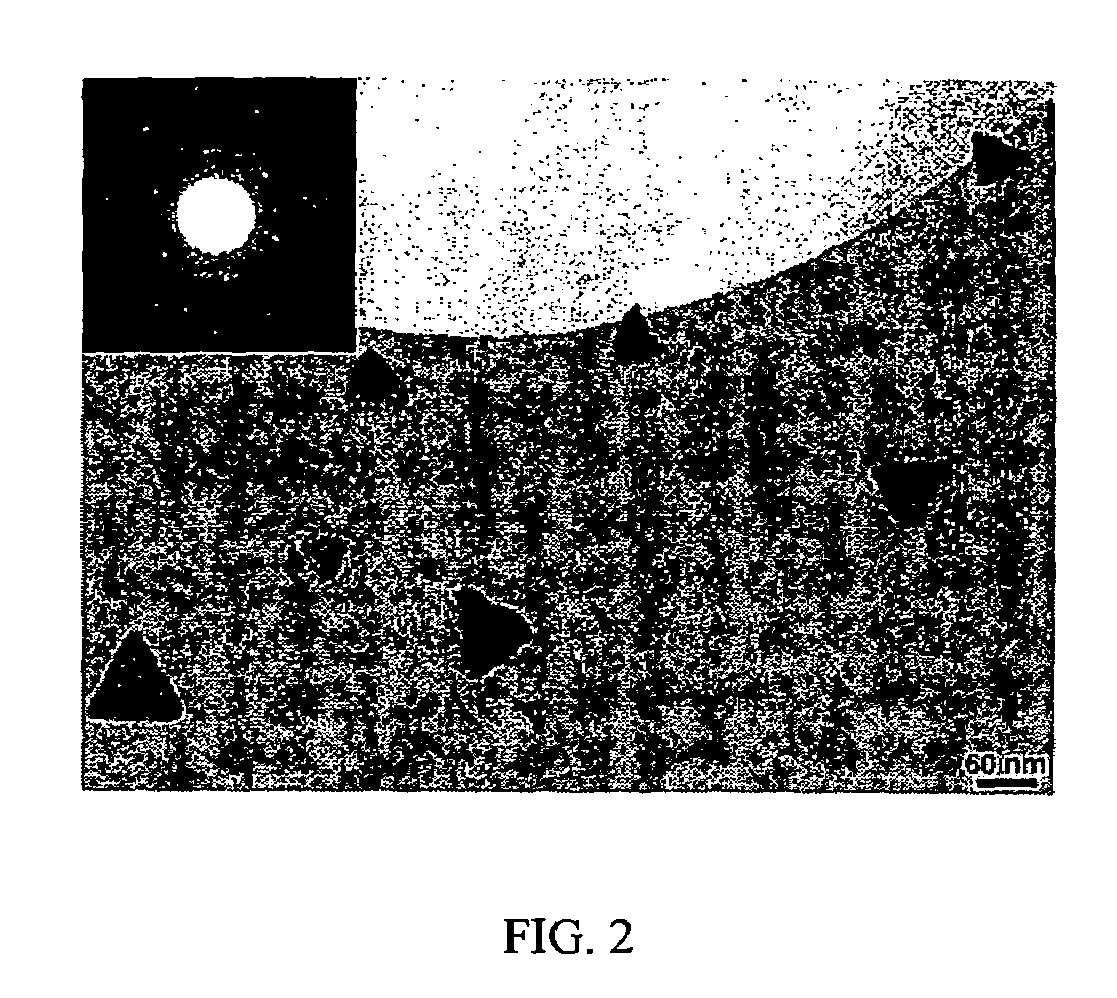

Distributed feedback laser of monolithic integrated silicon optical chip and preparation method thereof

ActiveCN110994355ACompact structureThe preparation process is matureLaser optical resonator constructionLaser active region structureDistributed feedback laserGrating

The invention belongs to the technical field of silicon light, and particularly relates to a distributed feedback laser of a monolithic integrated silicon light chip and a preparation method thereof.The laser structure comprises a silicon substrate of an SOI substrate, a silica insulating layer, a doped silicon nanocrystalline thin film layer with high laser gain, and a silicon waveguide etched by a top intrinsic silicon substrate, wherein the doped silicon nanocrystalline thin film layer comprises a one-dimensional distribution feedback structure, and a Bragg grating is formed through adoption of a photoetching technology to form the resonant cavity of the laser; a light source serving as an optical pump is an electrically excited LED or laser diode, is directly attached to the upper portion of the laser area of the optical pump, and generates laser output in an optical pumping mode; and an emergent laser is directly aligned with the silicon waveguide on the SOI, so that the very high coupling efficiency is obtained. The device is compact in structure, mature in manufacturing process and low in signal laser and waveguide coupling loss, and the defects that a silicon-based laser integrated structure based on a semiconductor gain material is complex, and waveguide and laser coupling is difficult are overcome.

Owner:FUDAN UNIV

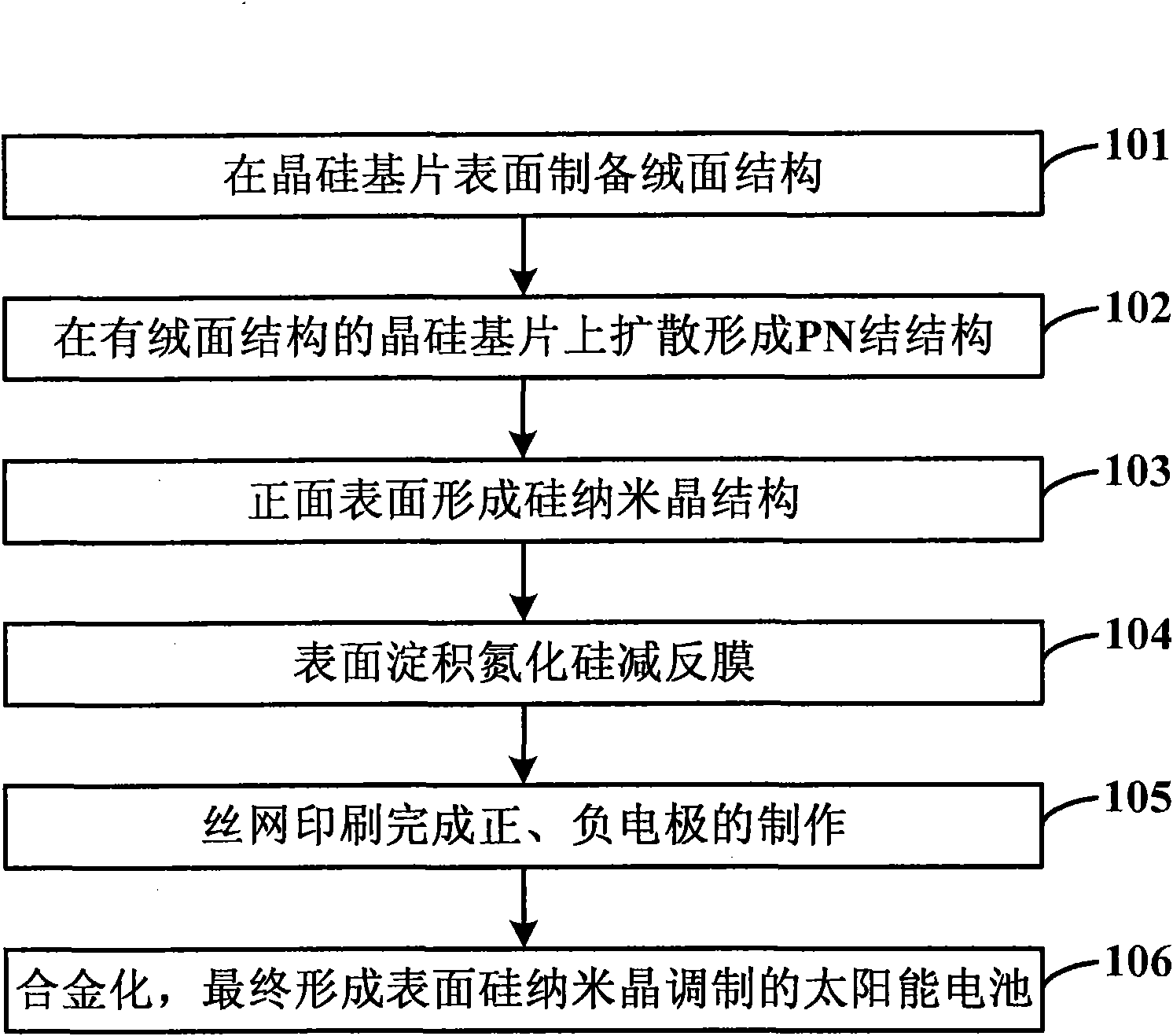

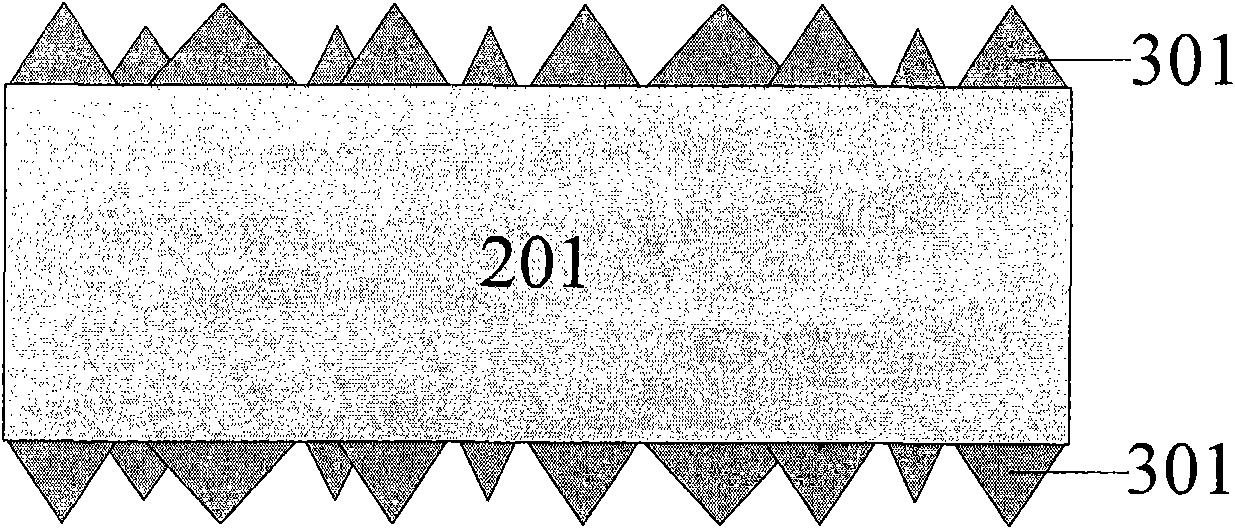

Method for manufacturing crystalline silicon high-efficiency solar cell

ActiveCN101882643AImprove conversion efficiencySimple preparation techniqueFinal product manufactureSemiconductor devicesDiffusion methodsSilicon nanocrystal

The invention discloses a method for manufacturing a crystalline silicon high-efficiency solar cell, which comprises: preparing a textured surface structure on the surface of a crystalline silicon substrate; forming a PN junction structure on the crystalline silicon substrate by a diffusion method; forming a silicon nanocrystal structure on the surface by using thin film deposition technology and heat treatment; depositing a silicon nitride antireflective film on the surface of the substrate by using a plasma-reinforced chemical vapor deposition method; making an anode and a cathode by screen printing; and alloying to make the surface silicon nanocrystal modulated solar cell. In the invention, the PN junction crystalline silicon solar cell prepared by a process means used in a mass production is used, silicon nanocrystals are formed on the surface of the PN junction crystalline silicon solar cell, and under the modulating action of the silicon nanocrystals, the crystalline silicon cell can utilize the solar wavelength more effectively to improve the efficiency of the crystalline silicon cell. The method is compatible with the convenient mature large-scale production technology, has the characteristics of simple production process, easy industrialization and the like and can effectively reduce cost and acquire the high-efficiency crystalline silicon solar cell.

Owner:锐立平芯微电子(广州)有限责任公司

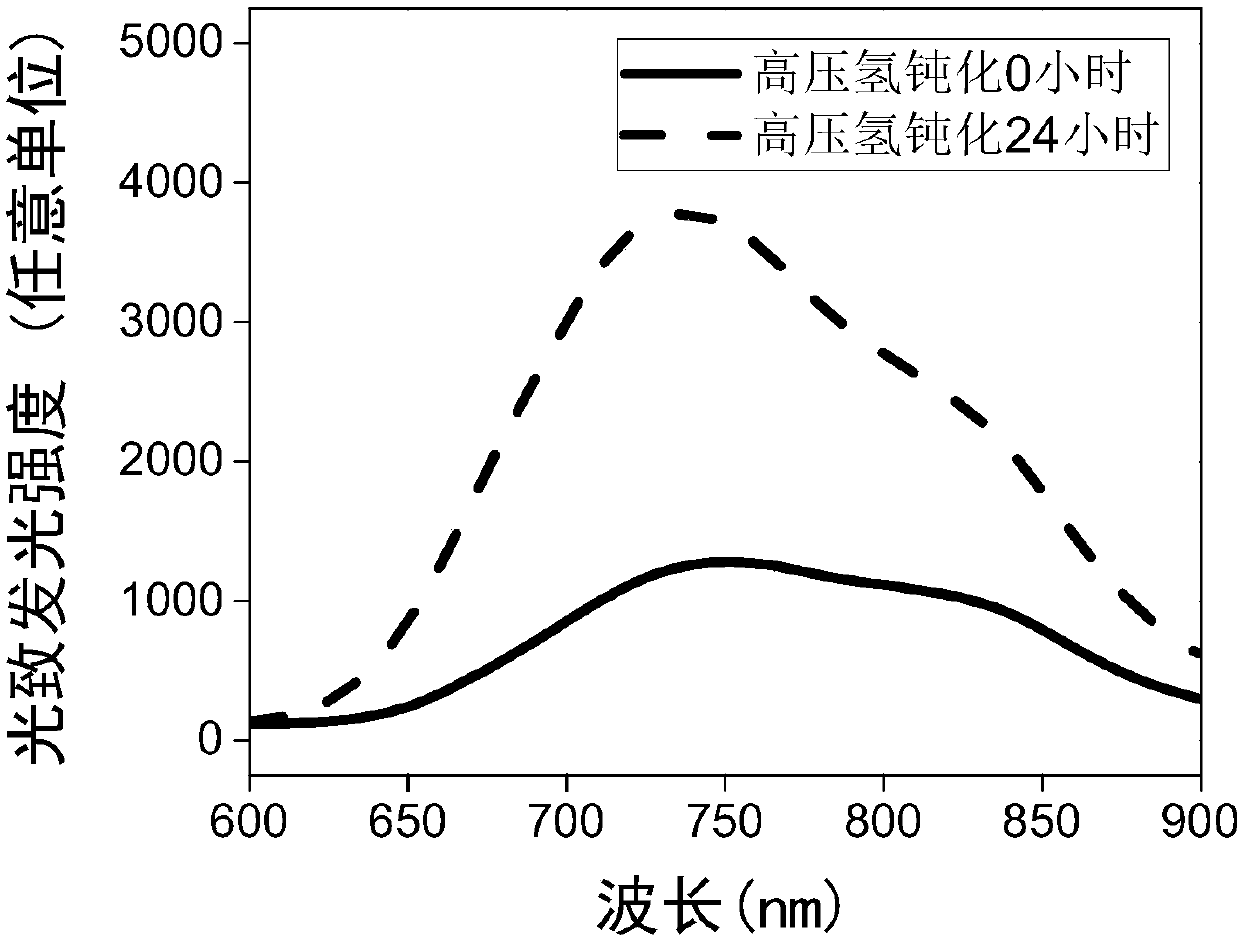

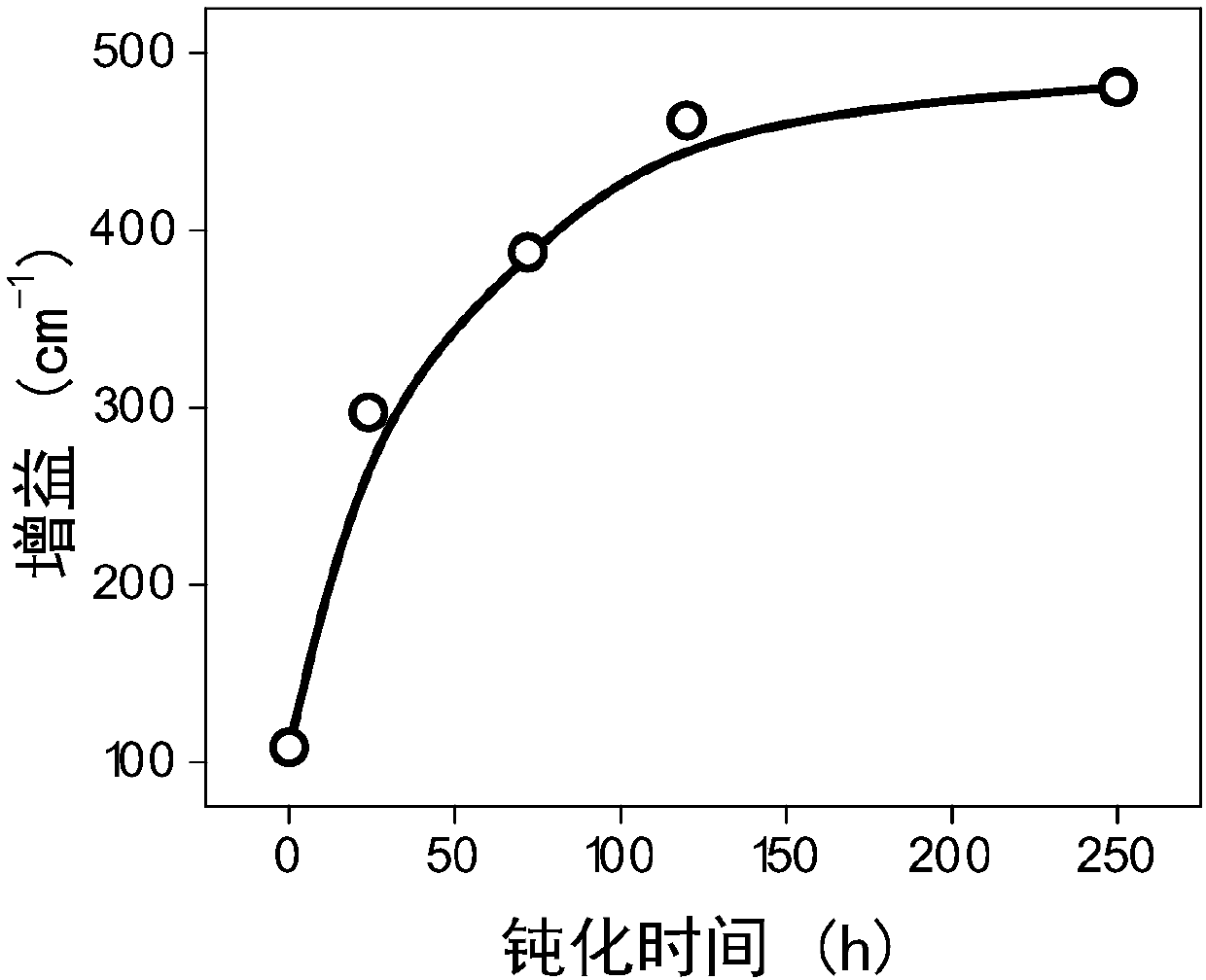

Method for preparing silicon nanocrystalline with optical gain which can be improved by high-pressure hydrogen passivation

The invention specifically relates to a method for preparing silicon nanocrystalline with optical gain which can be improved by high-pressure hydrogen passivation. According to the method provided bythe invention, in virtue of the hydrogen passivation principle which is common in the field of semiconductor electronic circuits, hydrogen is used as a basic raw material for material treatment, and the means of proper heating and high-pressure sealing are used, so that material passivation is realized. The silicon nanocrystalline is used as a whole silicon luminescent material, and a large numberof defect centers can be produced in the preparation process of the silicon nanocrystalline. Part of defects in a luminescent material can be effectively saturated and eliminated through the high-pressure hydrogen passivation, and the non-radiation recombination centers are reduced, so that the effects of remarkably increasing the luminous intensity and the optical gain of the nanocrystalline silicon can be realized, and thus the nano crystalline silicon material with improved optical gain can be used for developing a novel silicon laser. The invention provides the hydrogen passivation methodwhich is different from conventional high-temperature hydrogen passivation and plasma hydrogen passivation, and according to the process, high temperature does not need to be maintained, the plasma discharge process is not needed, the luminescence enhancing effect on the material is remarkable, the cost is low, the operation is simple, and the process is safe and controllable.

Owner:FUDAN UNIV

Erbium silicate crystal and silicon nanocrystalline co-inlaid silicon dioxide film and preparation method and application thereof

ActiveCN111304739AImprove conductivityLower turn-on voltageMaterial nanotechnologyPolycrystalline material growthSilicon nanocrystalSilicon oxide

The invention discloses an erbium silicate crystal and silicon nanocrystal co-inlaid silicon dioxide film and a preparation method and application thereof. A silicon-rich erbium silicate film is prepared by reactive co-sputtering, and the erbium silicate crystal and the silicon nanocrystal are obtained by high-temperature heat treatment. The invention also discloses a low-turn-on-voltage high-efficiency infrared light emitting diode prepared on the basis of the film. Due to the formation of the silicon nanocrystals, the conductivity of the film is enhanced, and the device turn-on voltage is reduced. Due to the formation of the erbium silicate crystal, the effective doping concentration of film erbium is improved, the infrared electroluminescence intensity of the device is improved, and theefficiency is greatly improved. The method is simple in preparation process and good in industrial compatibility, and has a wide application prospect in the fields of silicon-based integrated light source or semiconductor light emitting, optical communication and the like.

Owner:ZHEJIANG UNIV

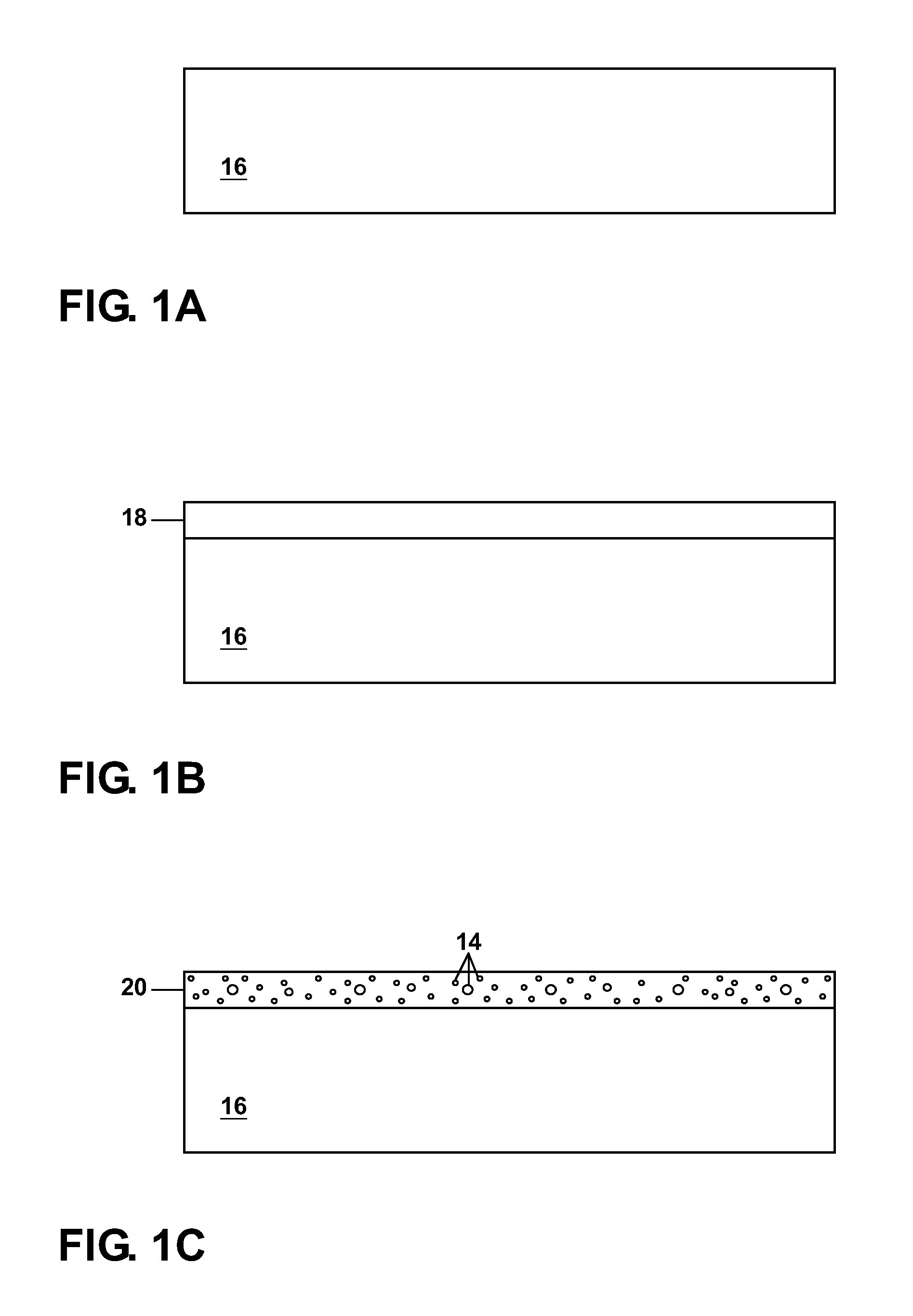

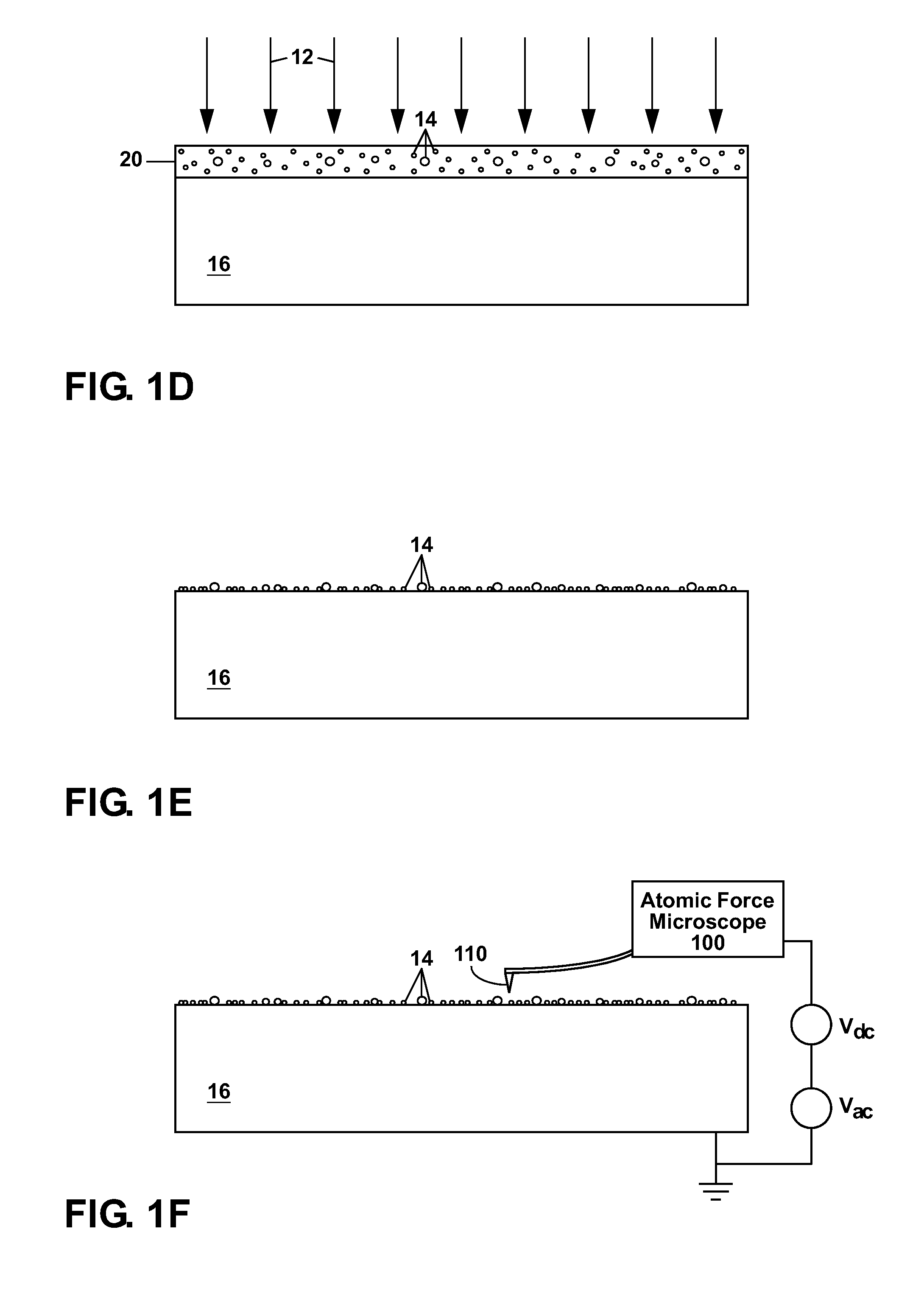

Isolating and moving single atoms using silicon nanocrystals

ActiveUS7790051B1Decorative surface effectsNanoinformaticsMagnetic force microscopeScanning capacitance microscopy

A method is disclosed for isolating single atoms of an atomic species of interest by locating the atoms within silicon nanocrystals. This can be done by implanting, on the average, a single atom of the atomic species of interest into each nanocrystal, and then measuring an electrical charge distribution on the nanocrystals with scanning capacitance microscopy (SCM) or electrostatic force microscopy (EFM) to identify and select those nanocrystals having exactly one atom of the atomic species of interest therein. The nanocrystals with the single atom of the atomic species of interest therein can be sorted and moved using an atomic force microscope (AFM) tip. The method is useful for forming nanoscale electronic and optical devices including quantum computers and single-photon light sources.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Semiconductor constructions, methods of forming semiconductor constructions, light-conducting conduits, and optical signal propagation assemblies

ActiveUS20070165992A1Laser using scattering effectsCladded optical fibreRare-earth elementSemiconductor structure

The invention includes optical signal conduits having rare earth elements incorporated therein. The optical signal conduits can, for example, contain rare earth elements incorporated within a dielectric material matrix. For instance, erbium or cerium can be within silicon nanocrystals dispersed throughout dielectric material of optical signal conduits. The dielectric material can define a path for the optical signal, and can be wrapped in a sheath which aids in keeping the optical signal along the path. The sheath can include any suitable barrier material, and can, for example, contain one or more metallic materials. The invention also includes methods of forming optical signal conduits, with some of such methods being methods in which the optical signal conduits are formed to be part of semiconductor constructions.

Owner:MICRON TECH INC

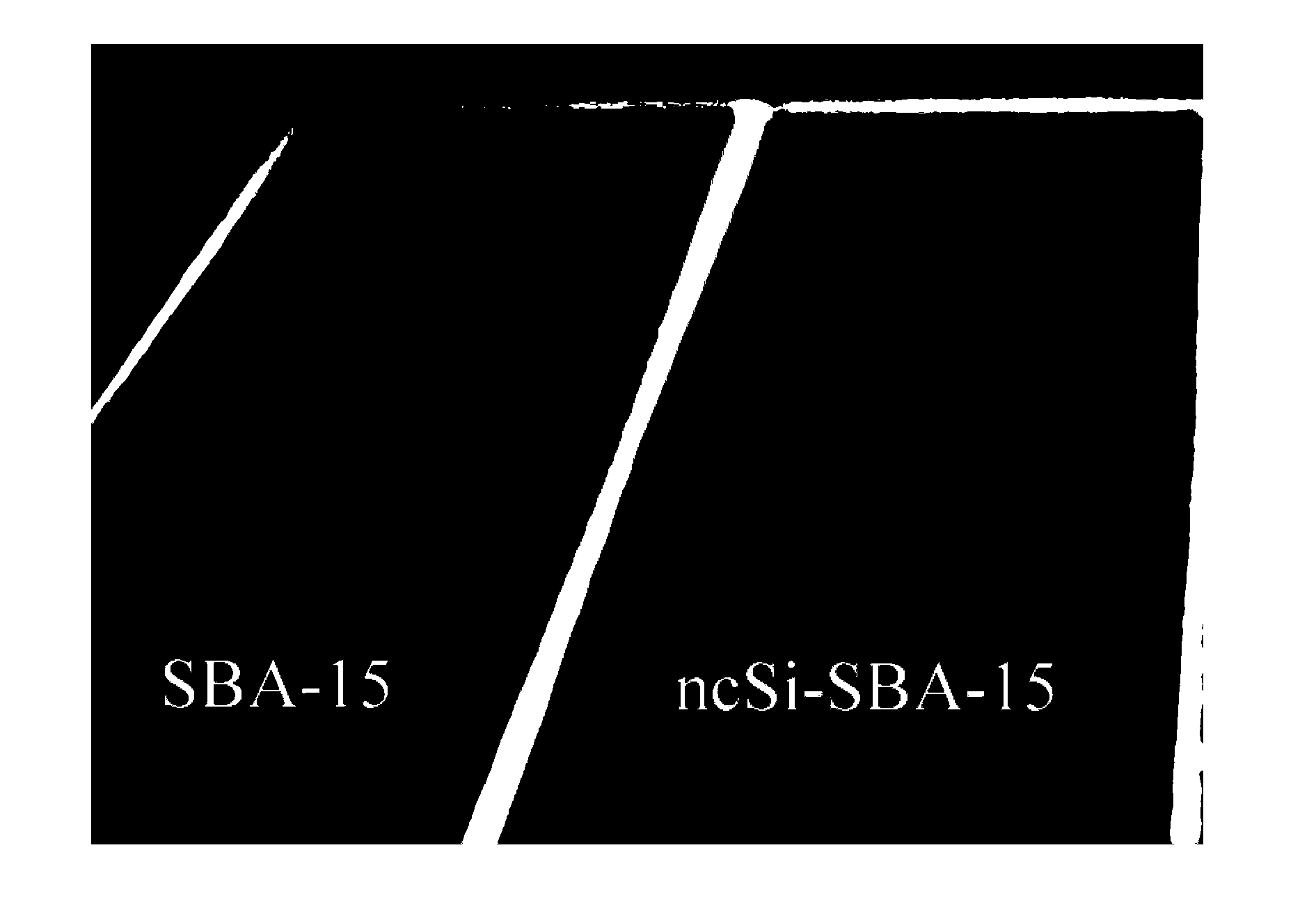

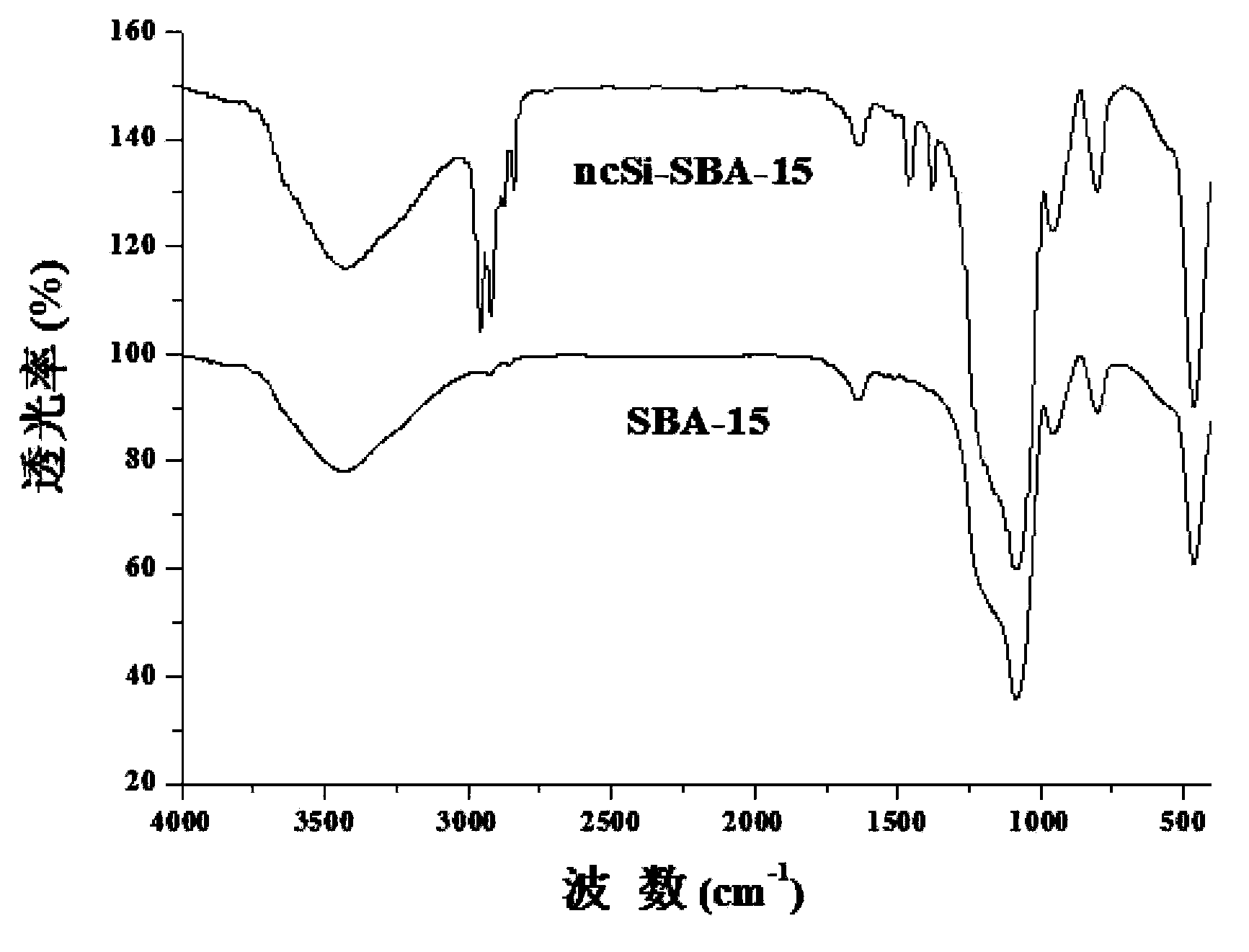

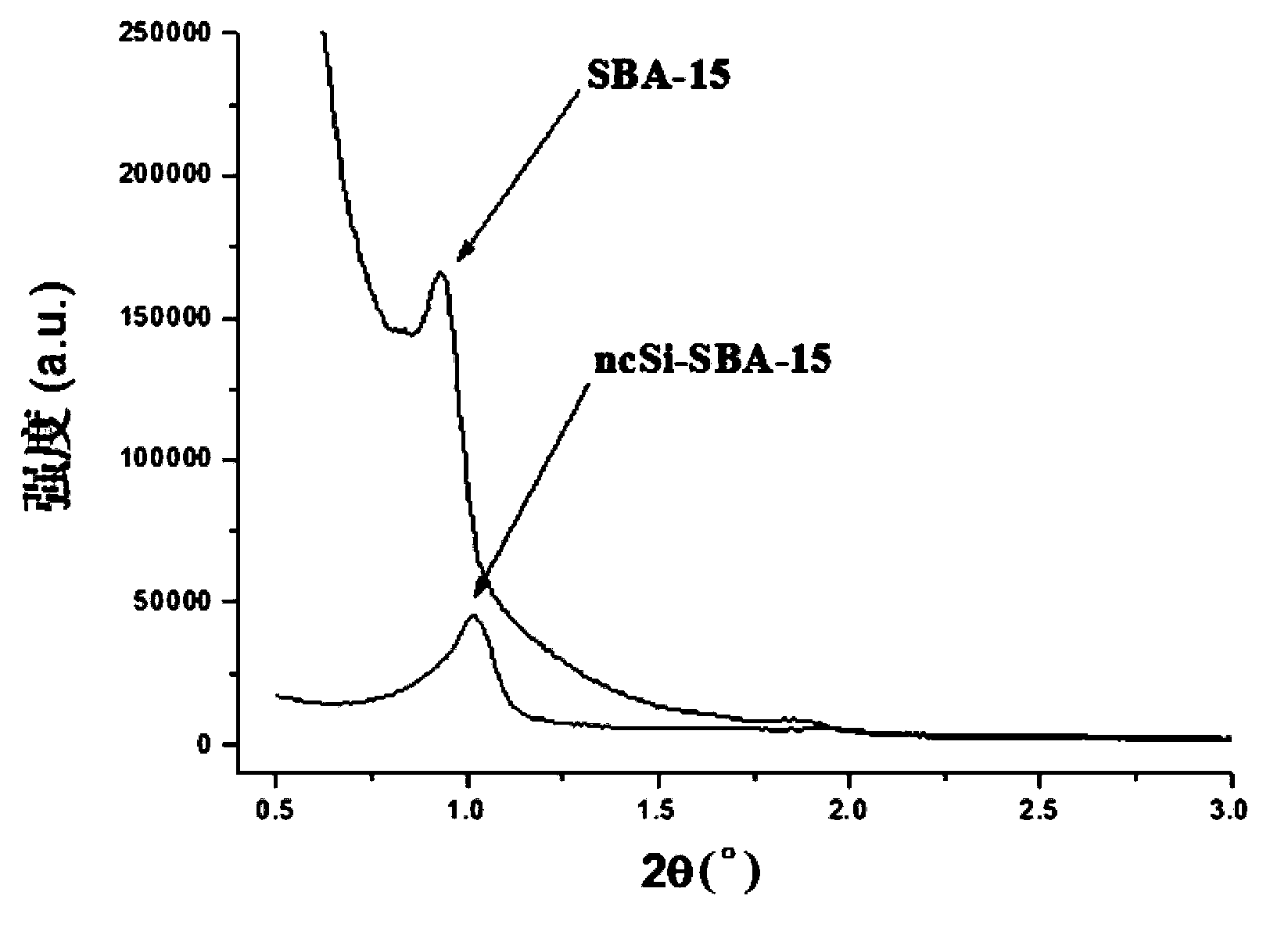

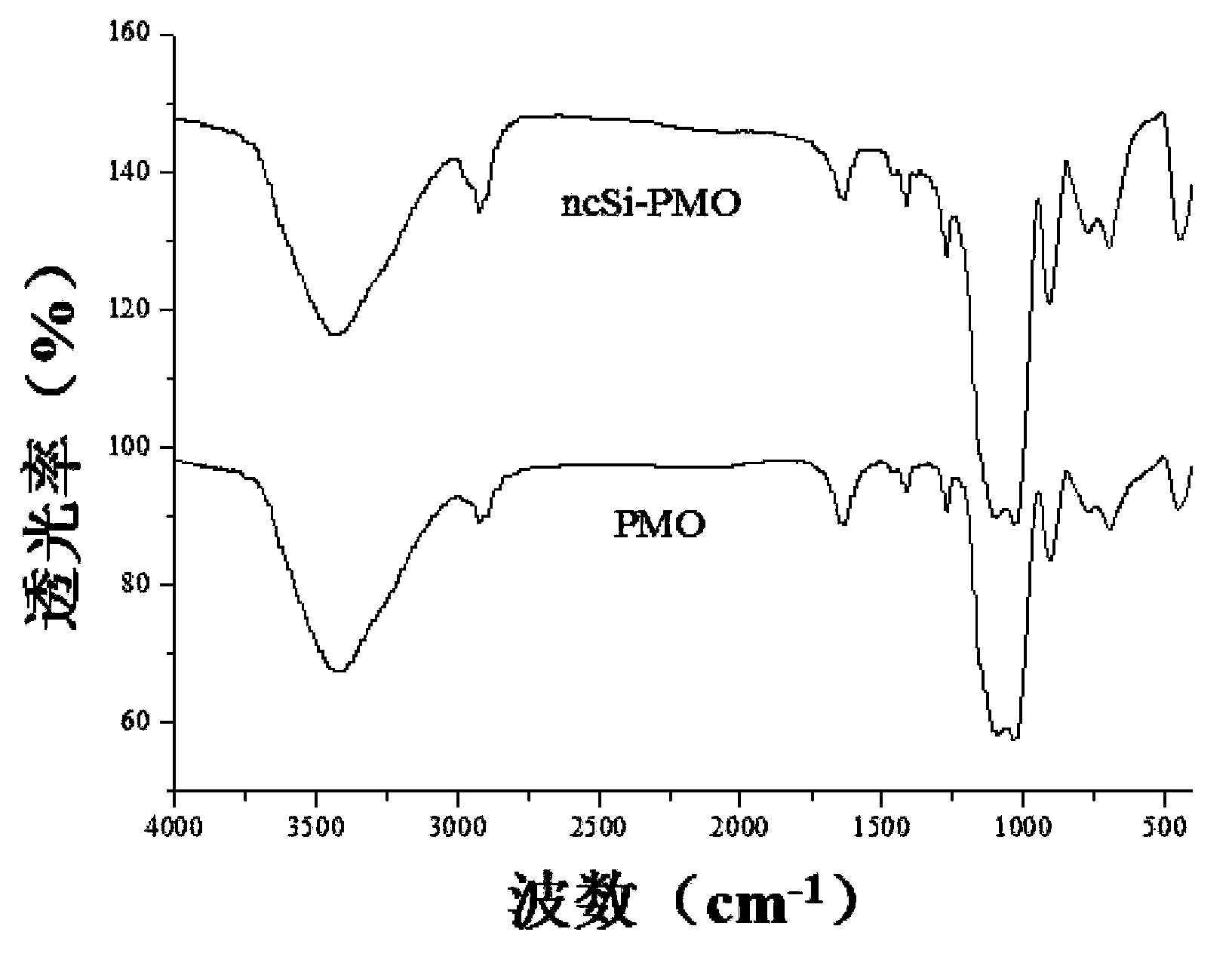

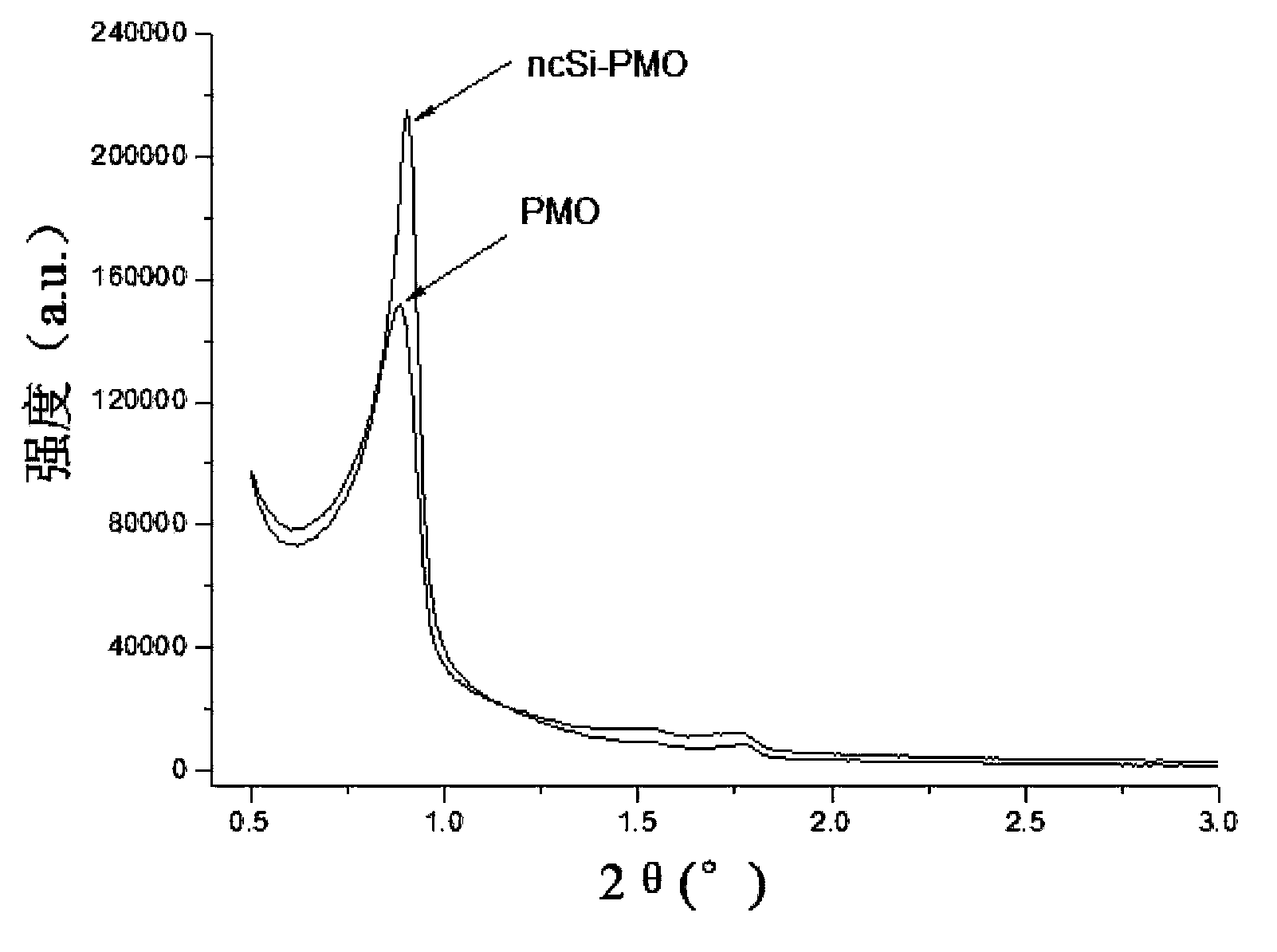

Fluorescent material, and preparation method and application thereof

ActiveCN103666462AGood biocompatibilityStrong resistance to photofadingPharmaceutical non-active ingredientsLuminescent compositionsSilane compoundsOrganic solvent

The invention provides a fluorescent material which contains a mesoporous material and a modified silicon nanocrystal. The modified silicon nanocrystal is prepared by performing silicon hydrogenation reaction on a silicon nanocrystal and silane compounds of which the general formula is R1Si(OR2)3, wherein R1 is an alkenyl group, and R2 is a substituted or unsubstituted alkyl group. The invention also provides a preparation method of the fluorescent material, which comprises the following step: in the presence of an organic solvent, mixing and contacting the modified silicon nanocrystal and the mesoporous material, wherein the modified silicon nanocrystal is prepared by performing silicon hydrogenation reaction on the silicon nanocrystal and silane compounds of which the general formula is R1Si(OR2)3, wherein R1 is an alkenyl group, and R2 is a substituted or unsubstituted alkyl group. The invention also provides application of the fluorescent material as a drug conduction carrier. The fluorescent material has fluorescent characteristic, and has the advantages of high capacity for resisting photofading and better drug slow-release property.

Owner:CHINA PETROLEUM & CHEM CORP +1

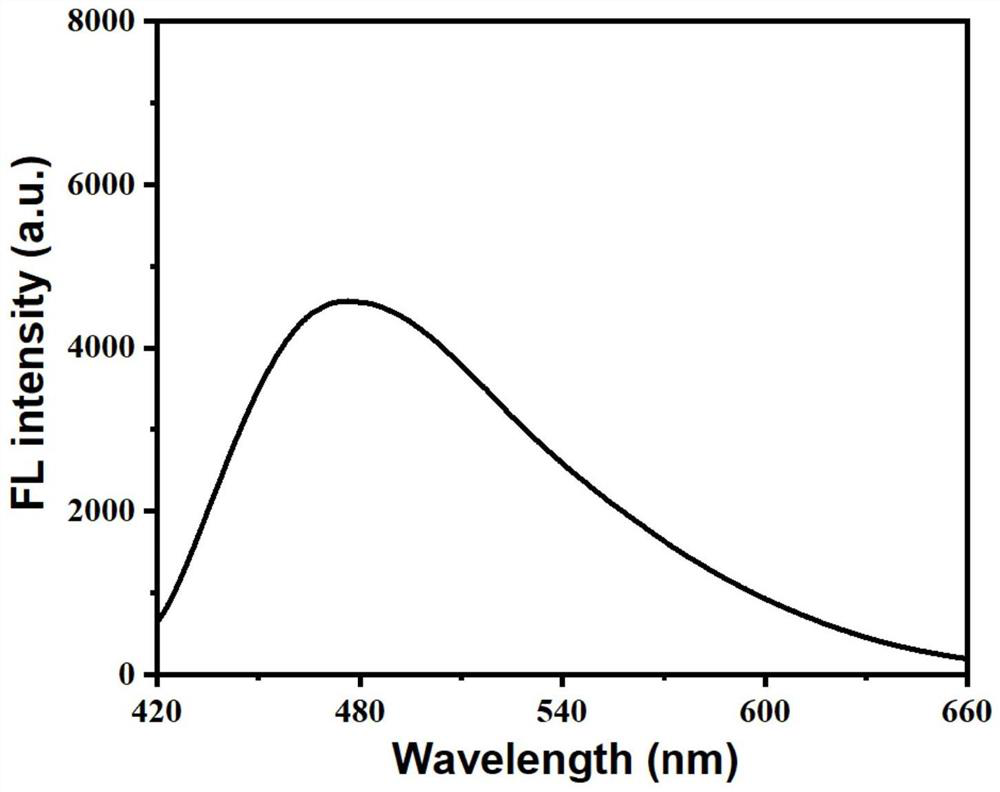

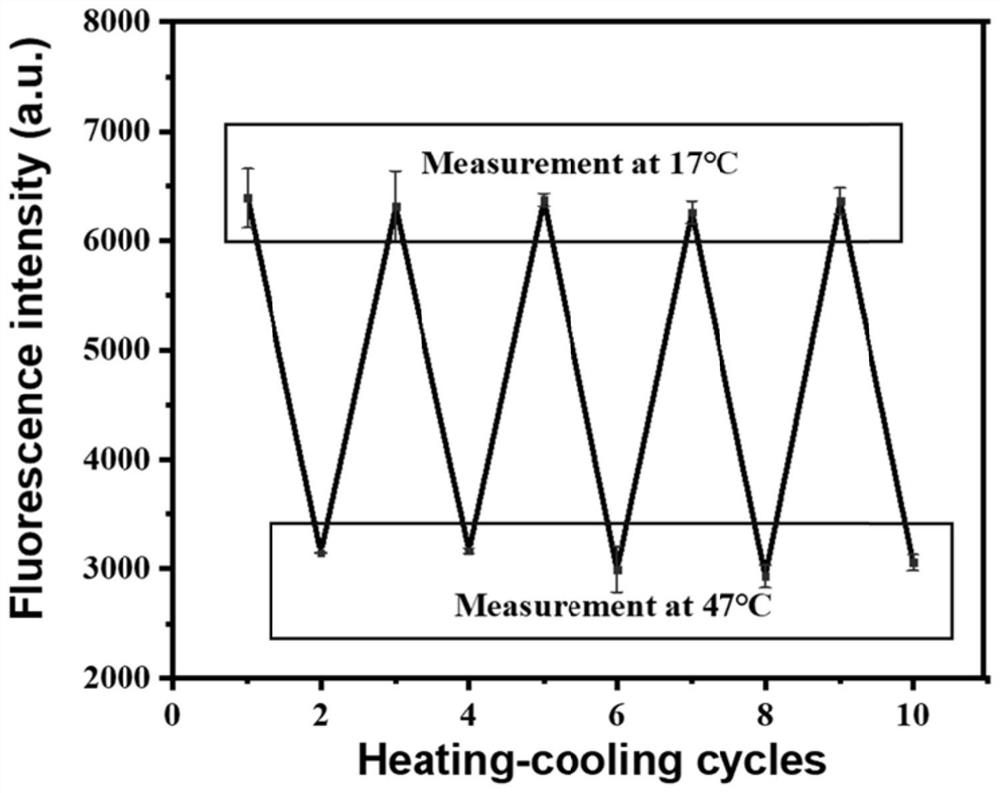

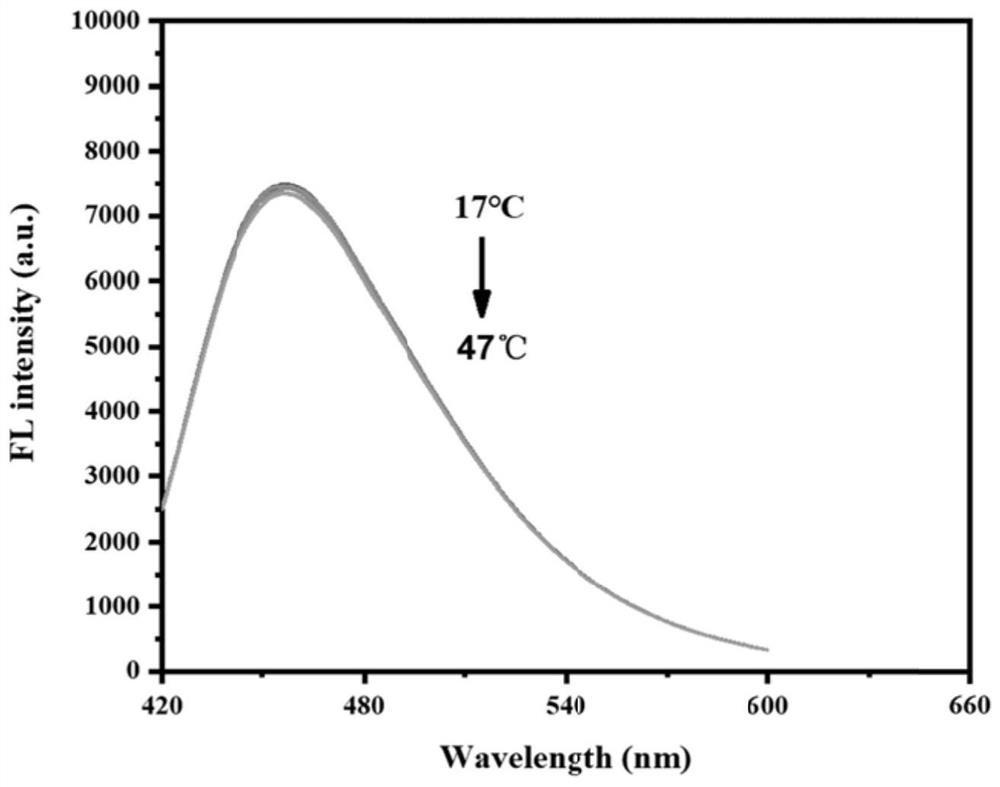

Preparation method of polyisoacrylamide sphere modified fluorescent silicon dot, prepared fluorescent silicon dot and application of fluorescent silicon dot

InactiveCN112521565AGood water solubilitySmall particle sizePowder deliveryNanoopticsPotassium persulfateCancer cell

The invention discloses a preparation method of a poly(N-isopropyl acrylamide) sphere modified fluorescent silicon dot, the prepared fluorescent silicon dot and application. The preparation method comprises the following steps: reacting sodium citrate and 3-aminopropyl triethoxysilane in glycerol to prepare a silicon nanocrystalline quantum dot; reacting silicon nanocrystalline quantum dots, 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, N-hydroxysuccinimide and folic acid in pure water to obtain folic acid modified silicon nanocrystalline quantum dots; and reacting N-isopropylacrylamide, N,N'-methylene diacrylamide, the folic acid modified silicon nanocrystalline quantum dots and potassium persulfate in pure water to obtain the fluorescent silicon dots modified by the polyisoacrylamide spheres. The polyisoacrylamide sphere modified fluorescent silicon dot prepared by the method is low in cytotoxicity, has a function of responding to temperature change, can be used for cancer cell in-situ imaging and temperature detection, and is simple and feasible in preparation process and easy for large-scale production.

Owner:NANJING UNIV OF TECH

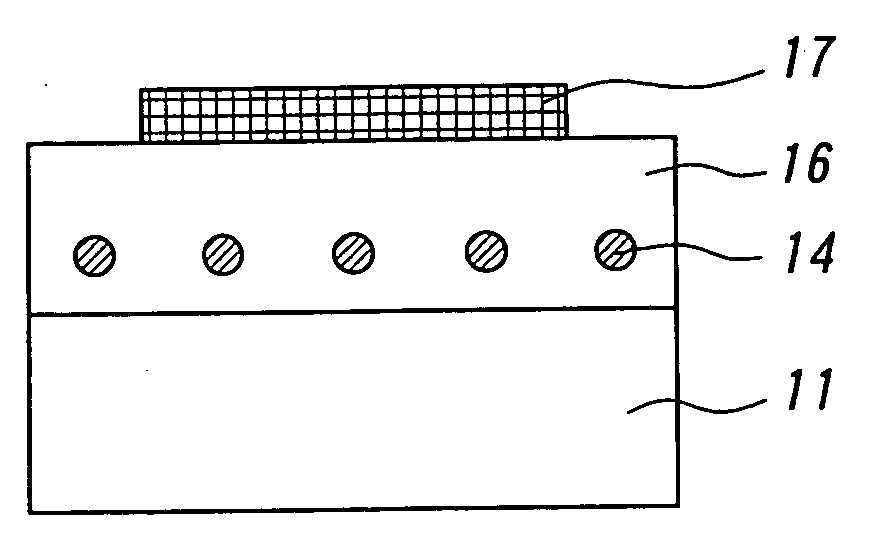

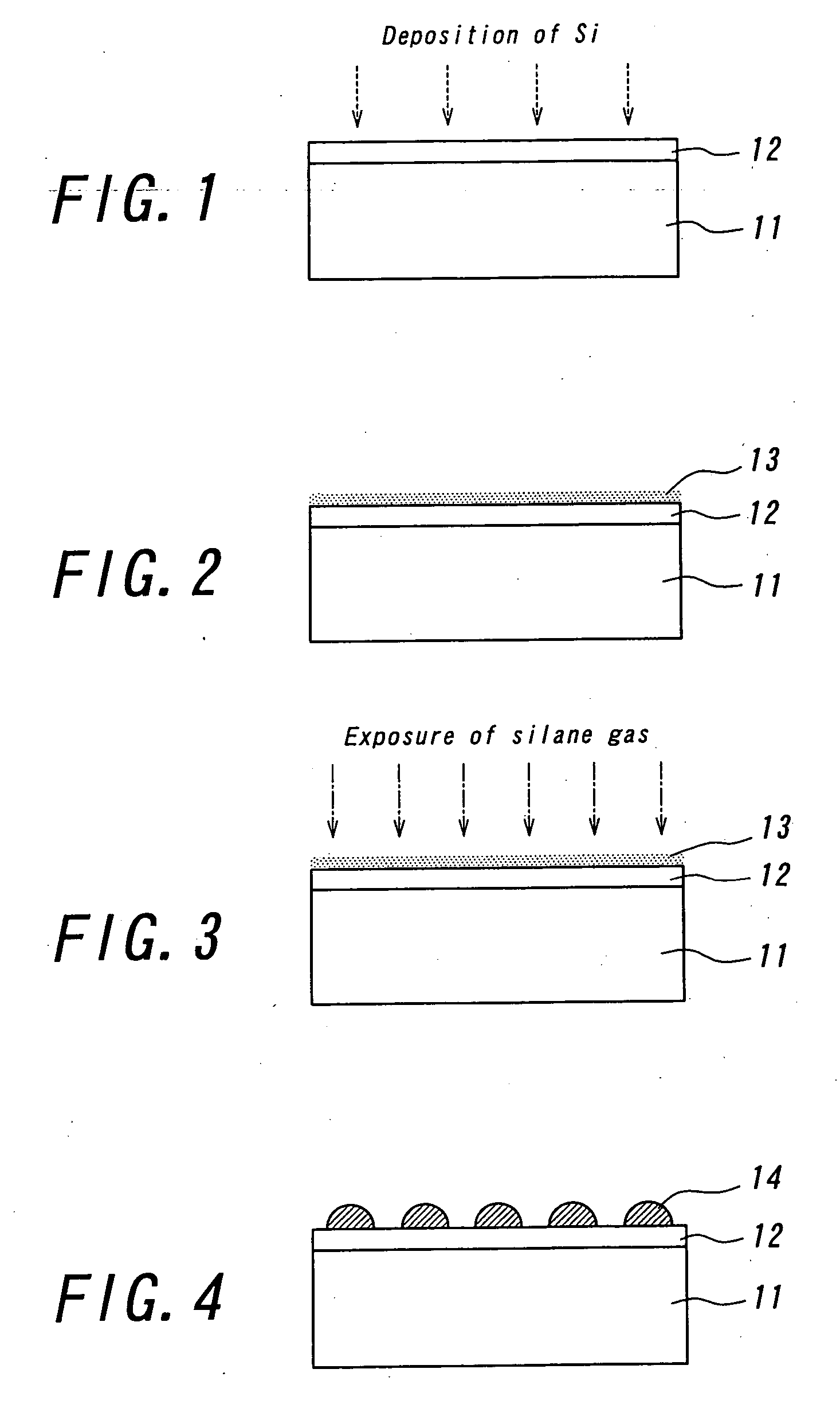

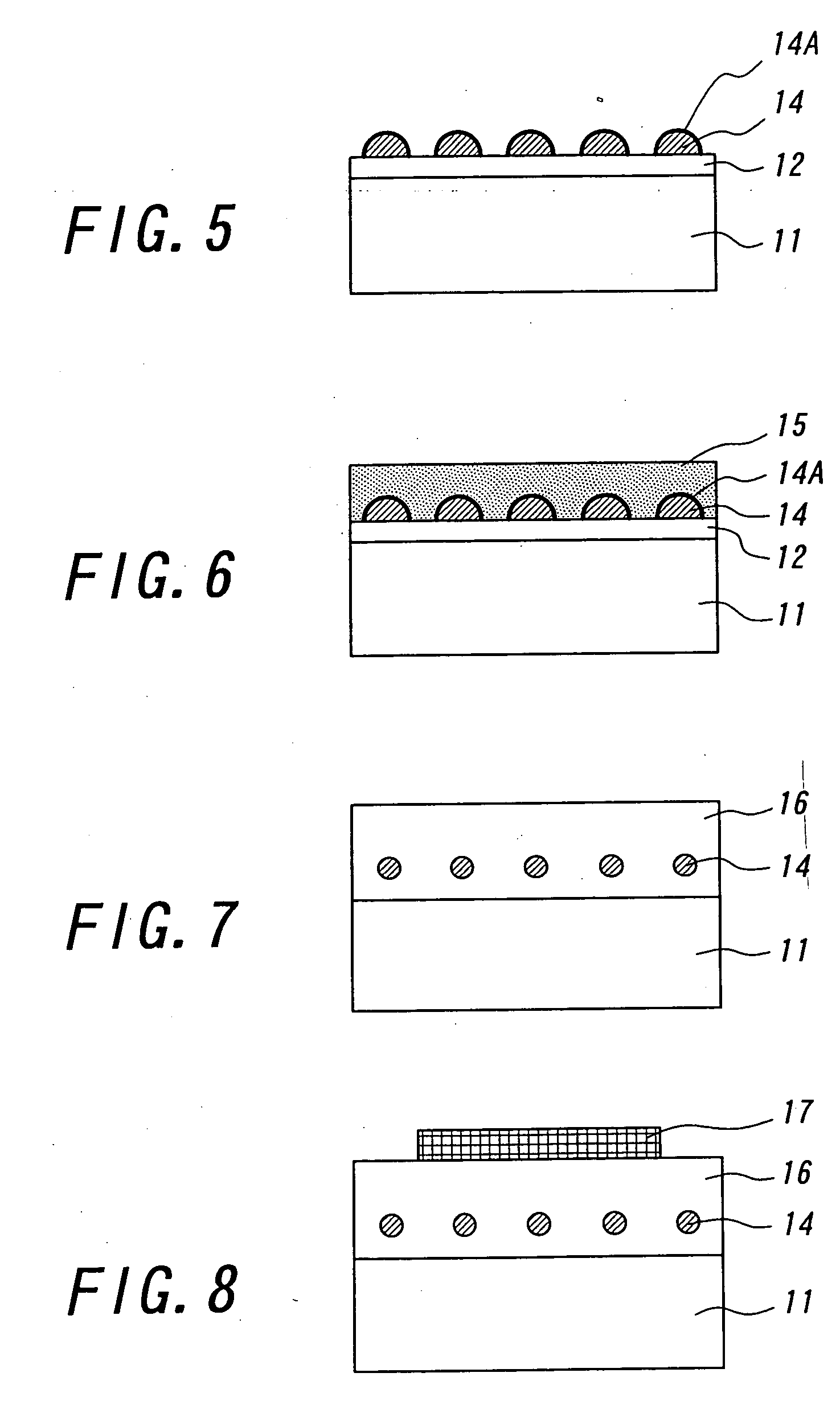

Method for fabricating a silicon nanocrystal, silicon nanocrystal, method for fabricating a floating gate type memory capacitor structure, and floating gate type memory capacitor structure

A silicon oxide layer is formed at a surface region of a silicon substrate. Then, an amorphous silicon layer 13 is formed preferably in a thickness of 1 nm or below on the silicon substrate via the silicon oxide layer. Then, the amorphous silicon layer 13 is exposed to a silane gas preferably with heating the silicon substrate within a temperature range of 400-800° C. to form a high density and minute silicon nanocrystal.

Owner:NAGOYA UNIVERSITY

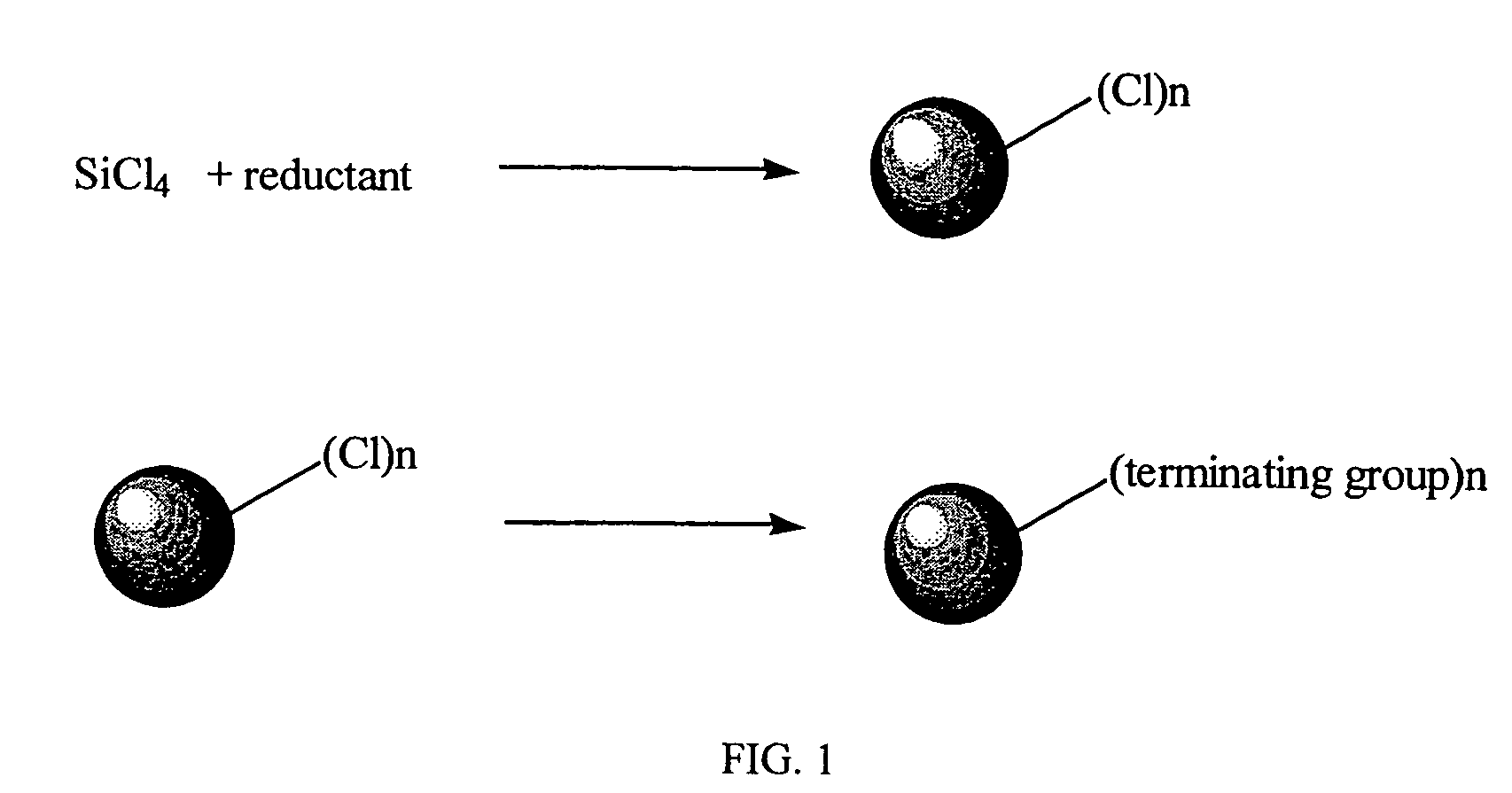

High yield method for preparing silicon nanocrystal with chemically accessible surfaces

InactiveUS7214599B2Material nanotechnologyPolycrystalline material growthPolysilicon halidesSilicon nanocrystal

Silicon nanocrystals with chemically accessible surfaces are produced in solution in high yield. Silicon tetrahalide such as silicon tetrachloride (SiCl4) can be reduced in organic solvents, such as 1,2-dimethoxyethane(glyme), with soluble reducing agents, such as sodium naphthalenide, to give halide-terminated (e.g., chloride-terminated) silicon nanocrystals, which can then be easily functionalized with alkyl lithium, Grignard or other reagents to give easily processed silicon nanocrystals with an air and moisture stable surface. The synthesis can be used to prepare alkyl-terminated nanocrystals at ambient temperature and pressure in high yield. The two-step process allows a wide range of surface functionality.

Owner:EVERGREEN SOLAR

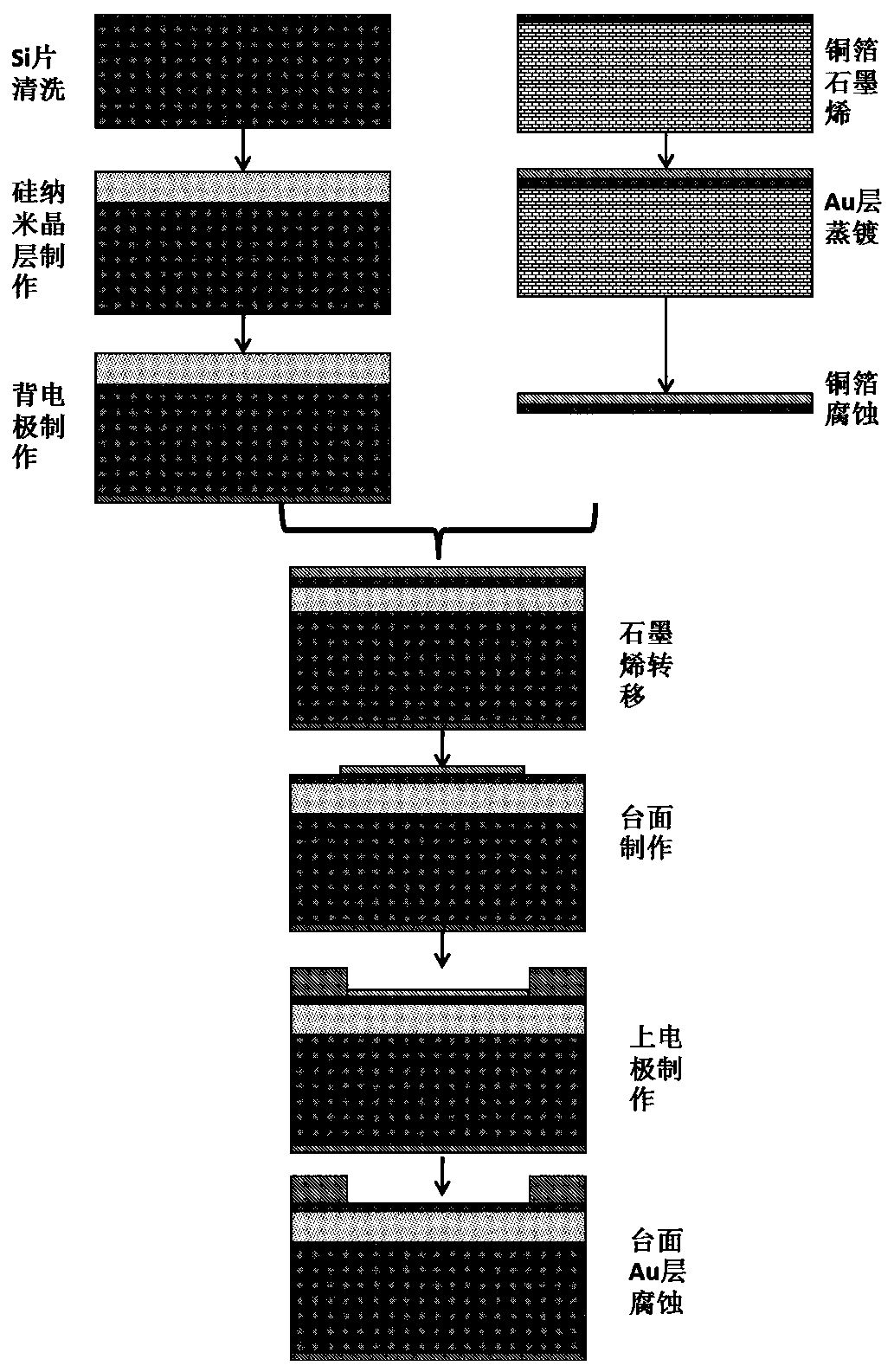

Silicon nanocrystal/graphene wide-spectrum photodetector and preparation method thereof

ActiveCN110611010AEasy to integrateOvercome the shortcomings of ineffective transmissionFinal product manufactureSemiconductor devicesPhotovoltaic detectorsPhotodetector

The invention discloses a silicon nanocrystal / graphene wide-spectrum photodetector and a preparation method thereof. The structure comprises a back electrode, a substrate, a silicon nanocrystal layer,a graphene layer and a front electrode in order from bottom to top. The back electrode is a Ti / Au / Ti electrode. The substrate is heavily doped with n-type Si. The silicon nanocrystal layer is spin-coated with hydrogen-silsesquioxane and annealed at high temperature. The graphene layer is single-layer graphene, which is acquired by transferring vapor-deposited Au. The front electrode is a Ti / Au electrode. The photodetector provided by the invention can respond to ultraviolet, visible and near-infrared optical spectrum ranges, achieves signal doubling through the photo-switching effect betweenthe silicon nanocrystal layer and the graphene layer, has a simple preparation process, and is compatible with the CMOS process.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

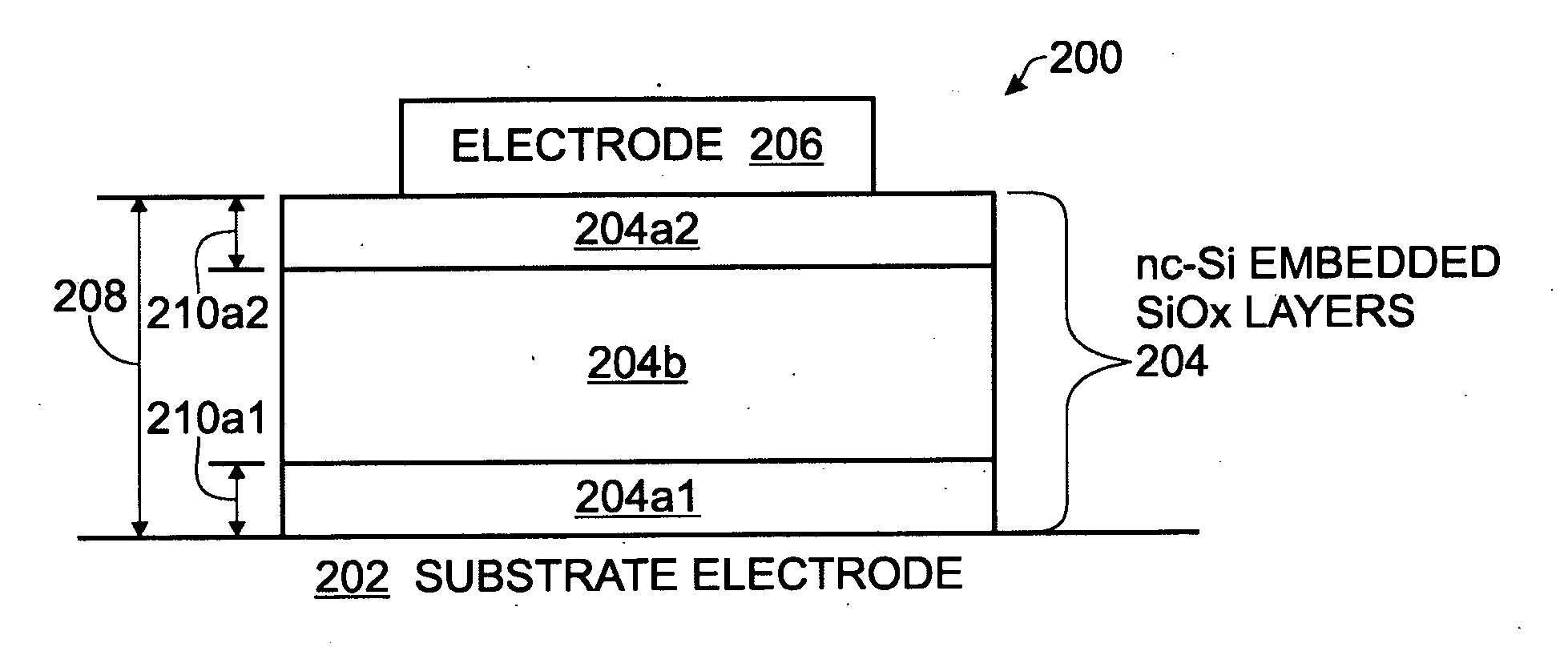

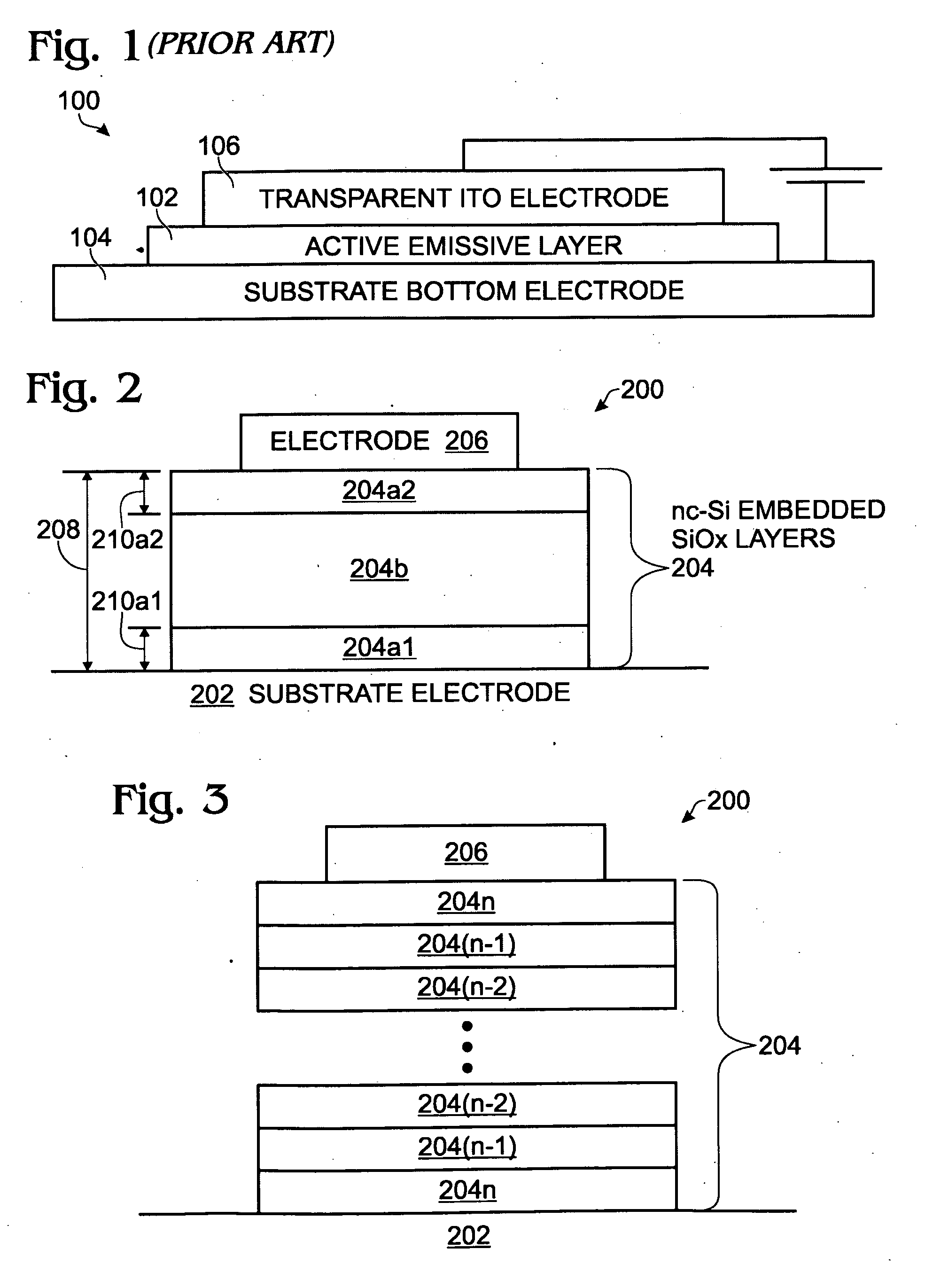

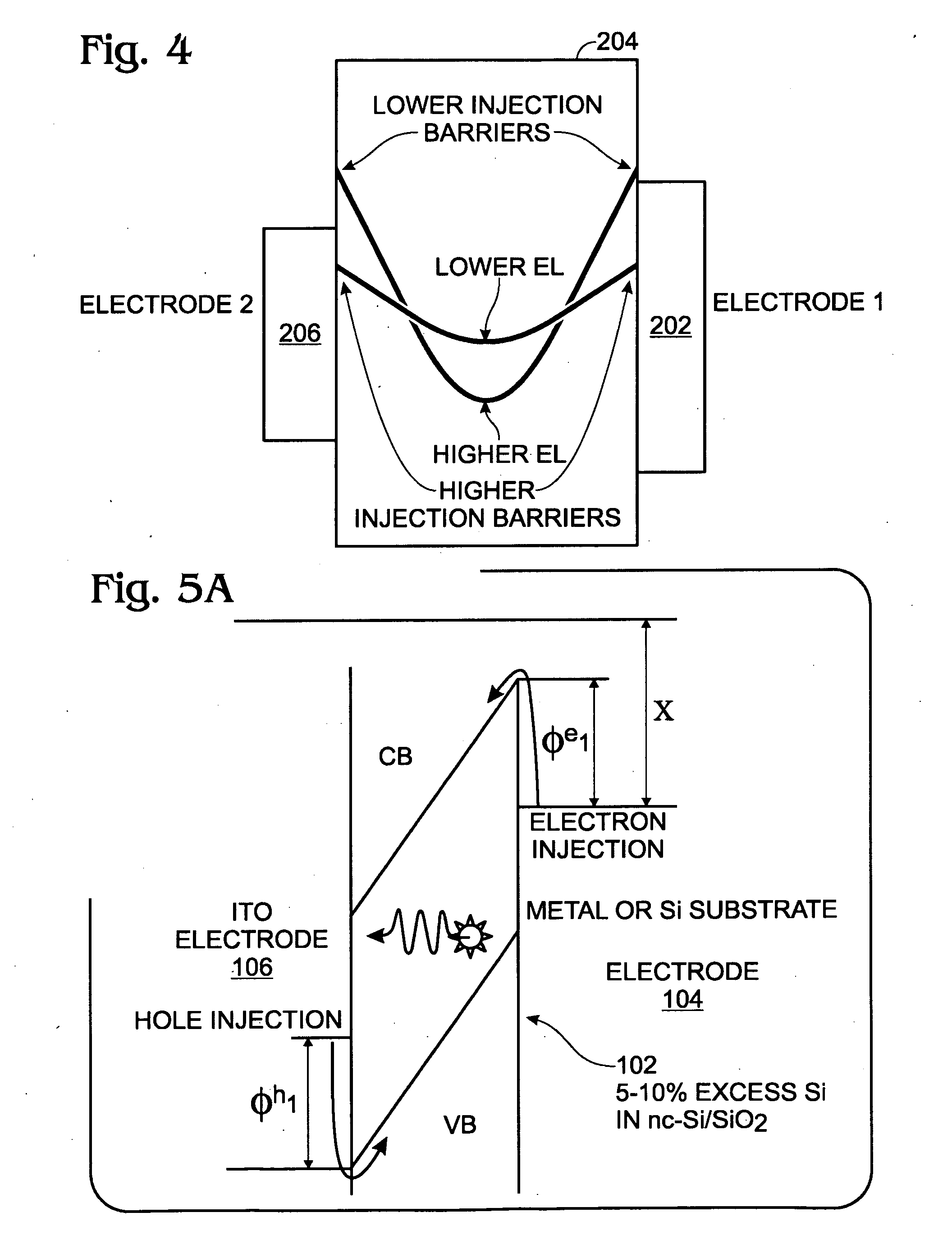

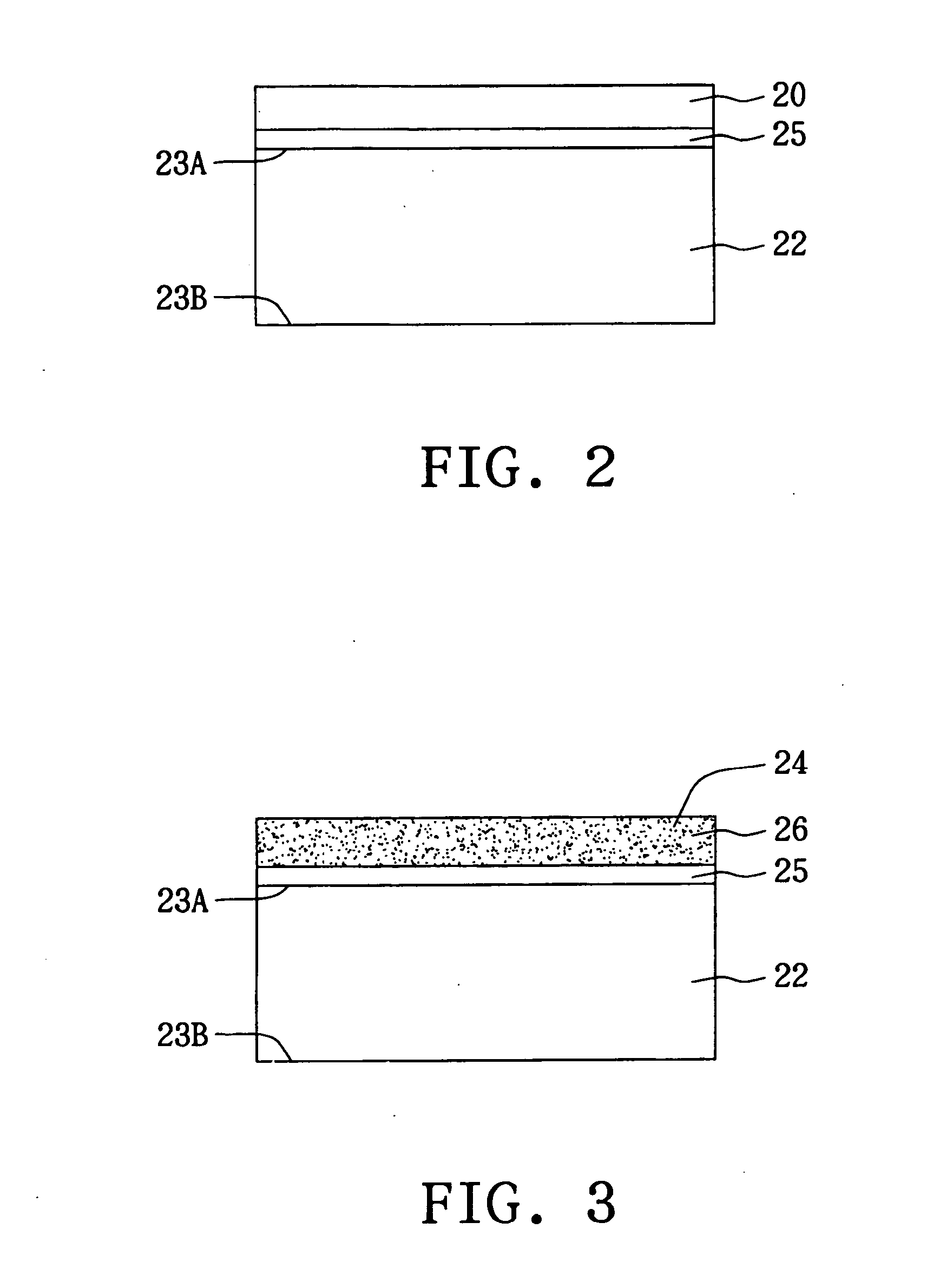

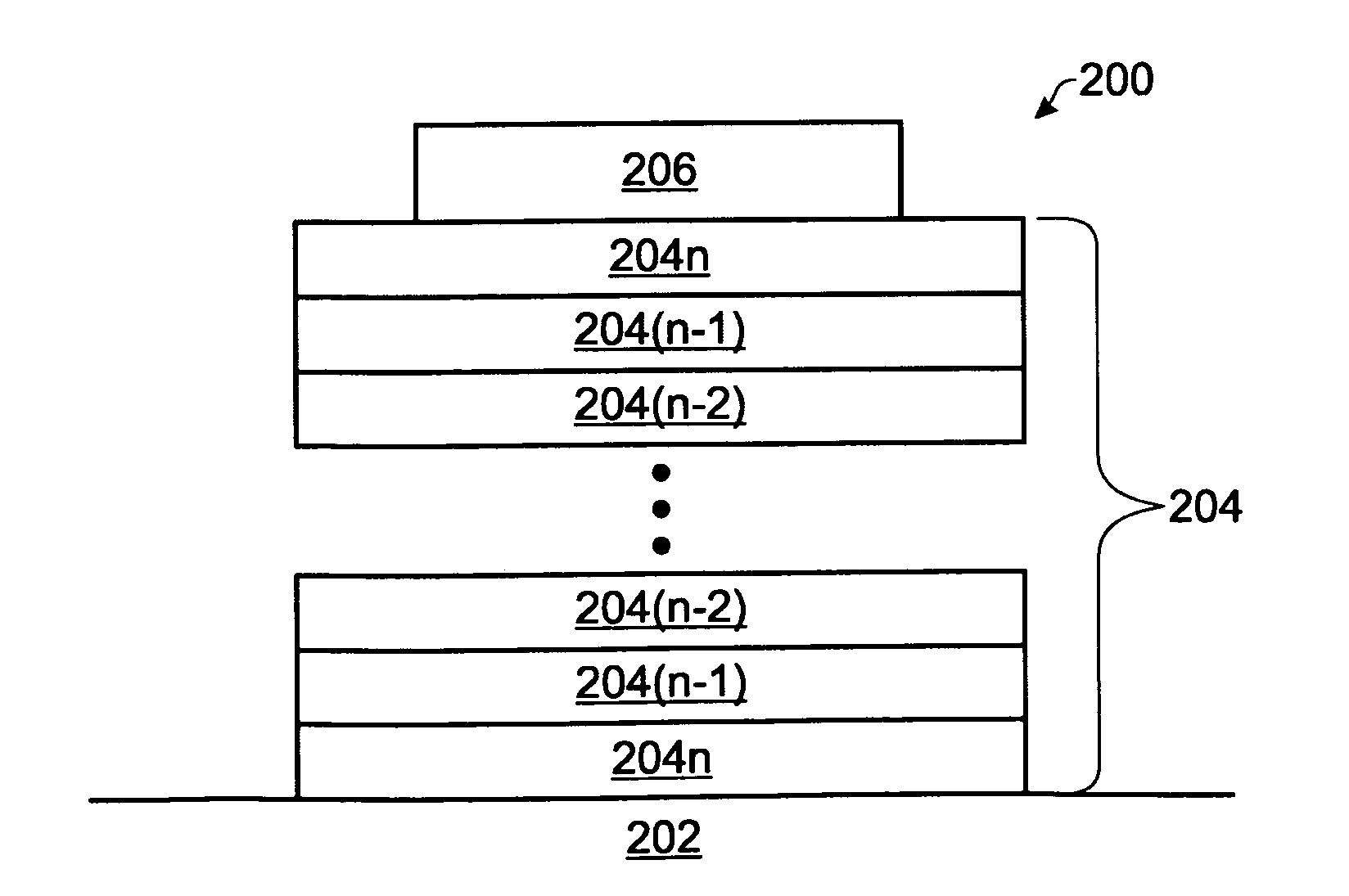

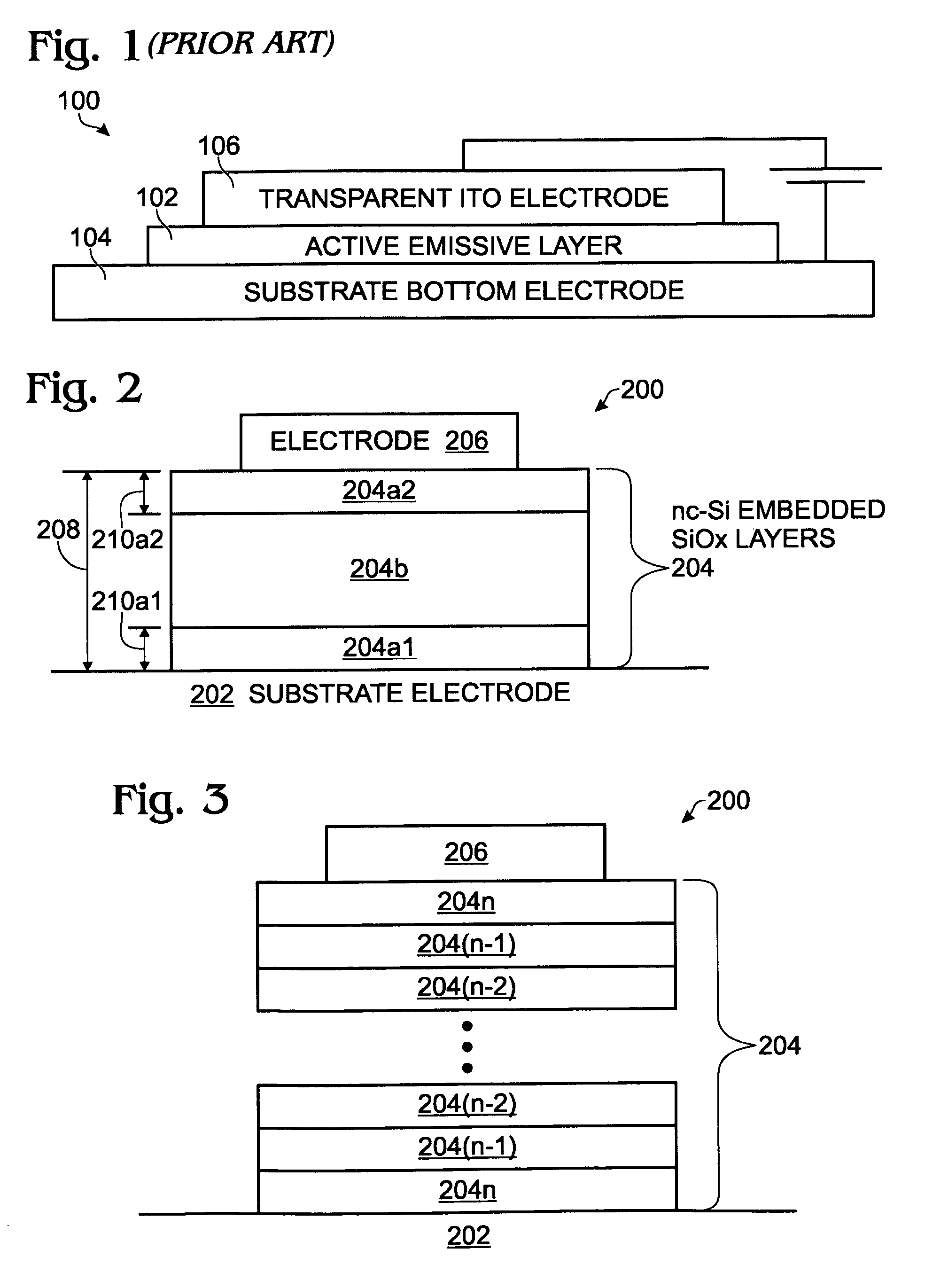

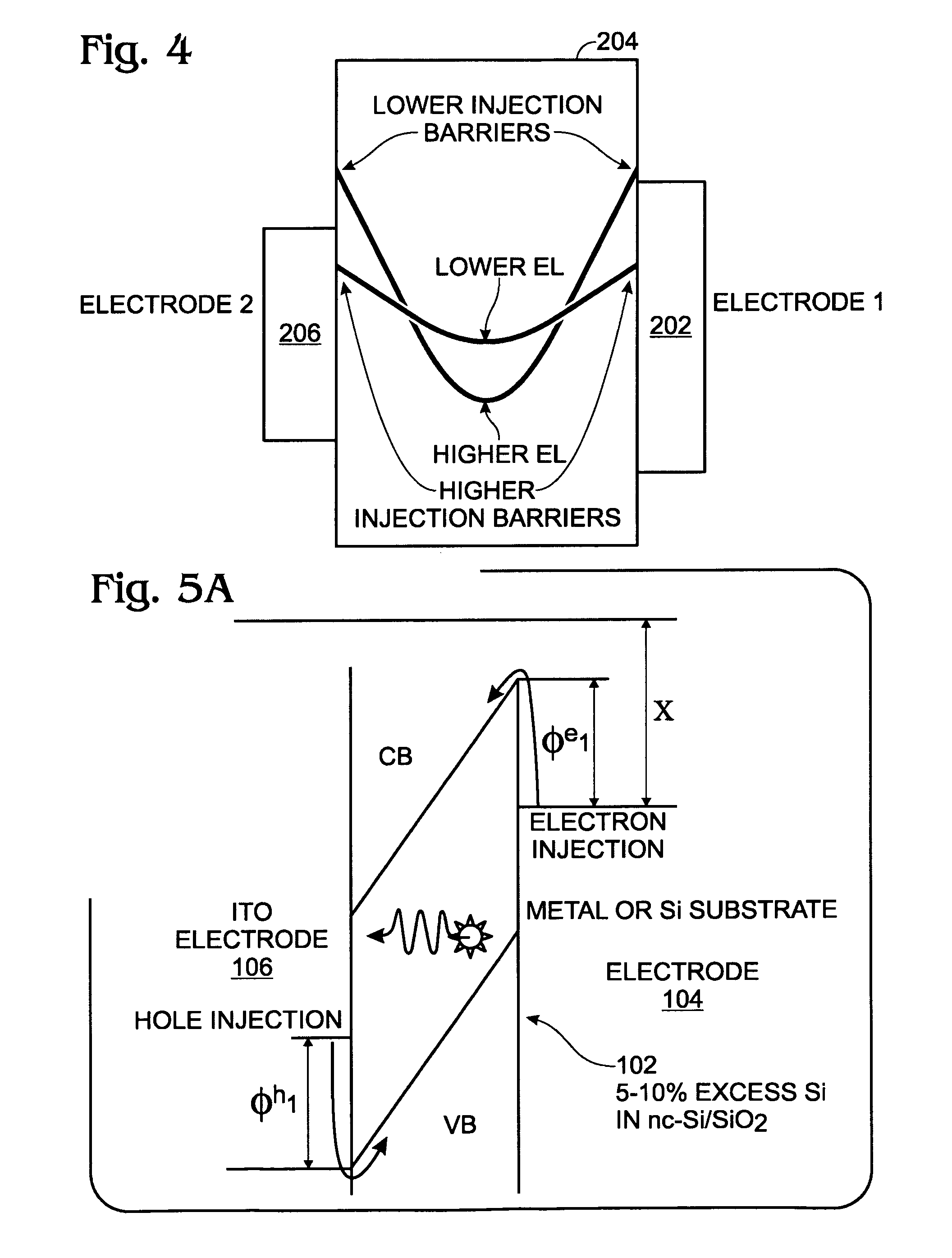

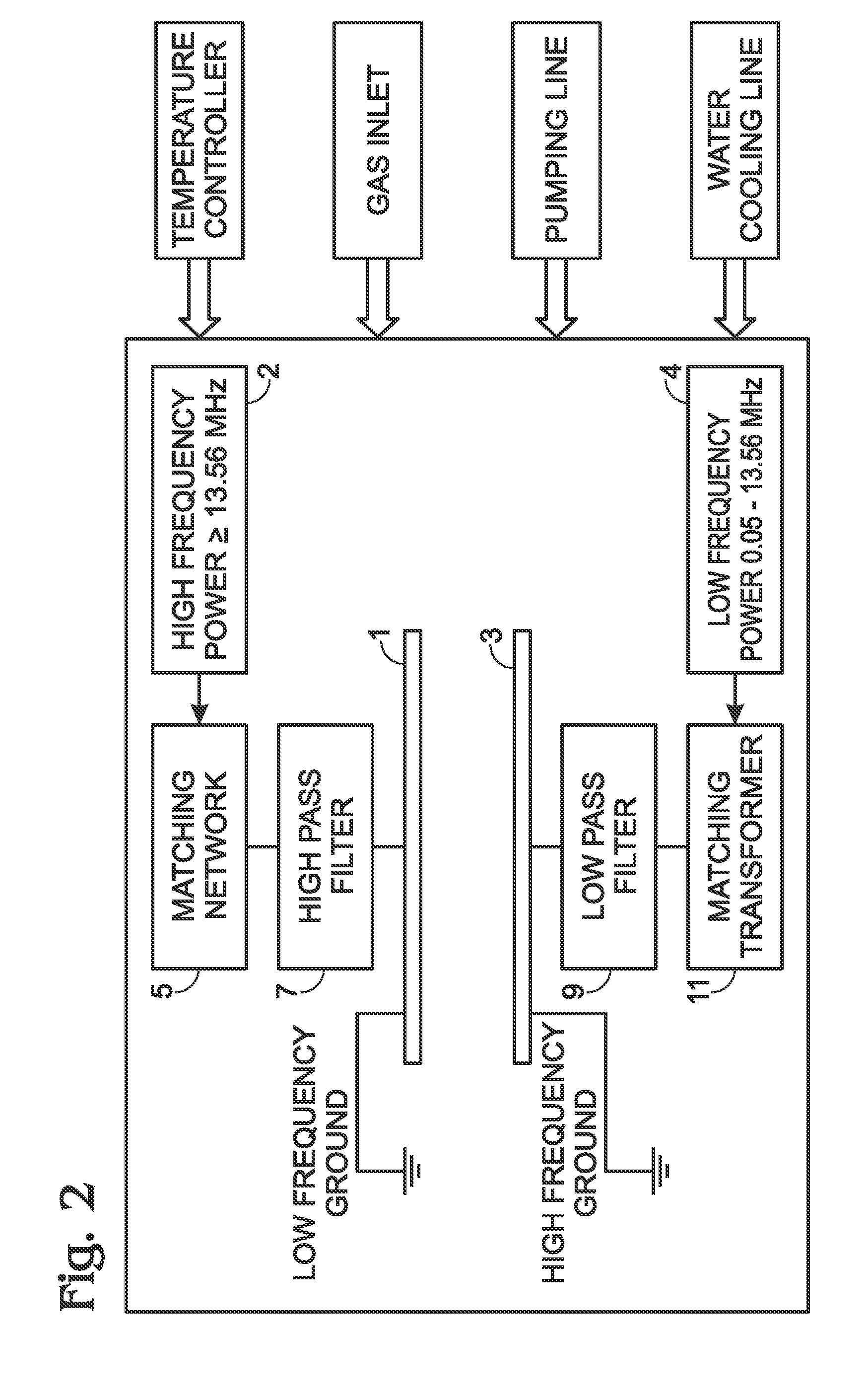

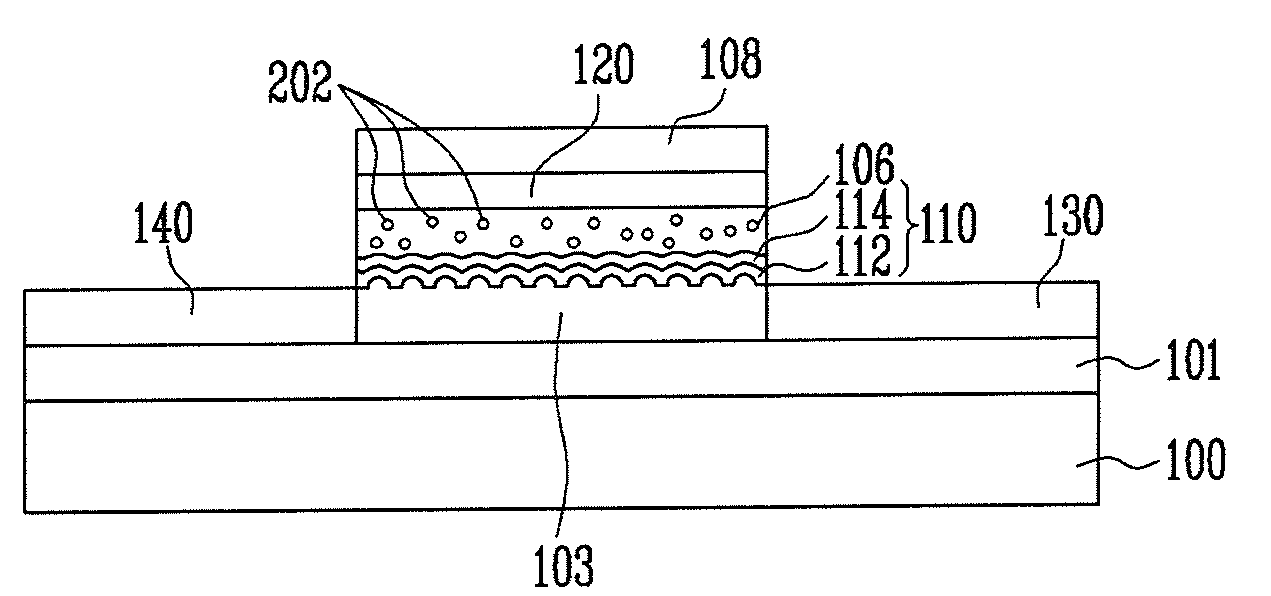

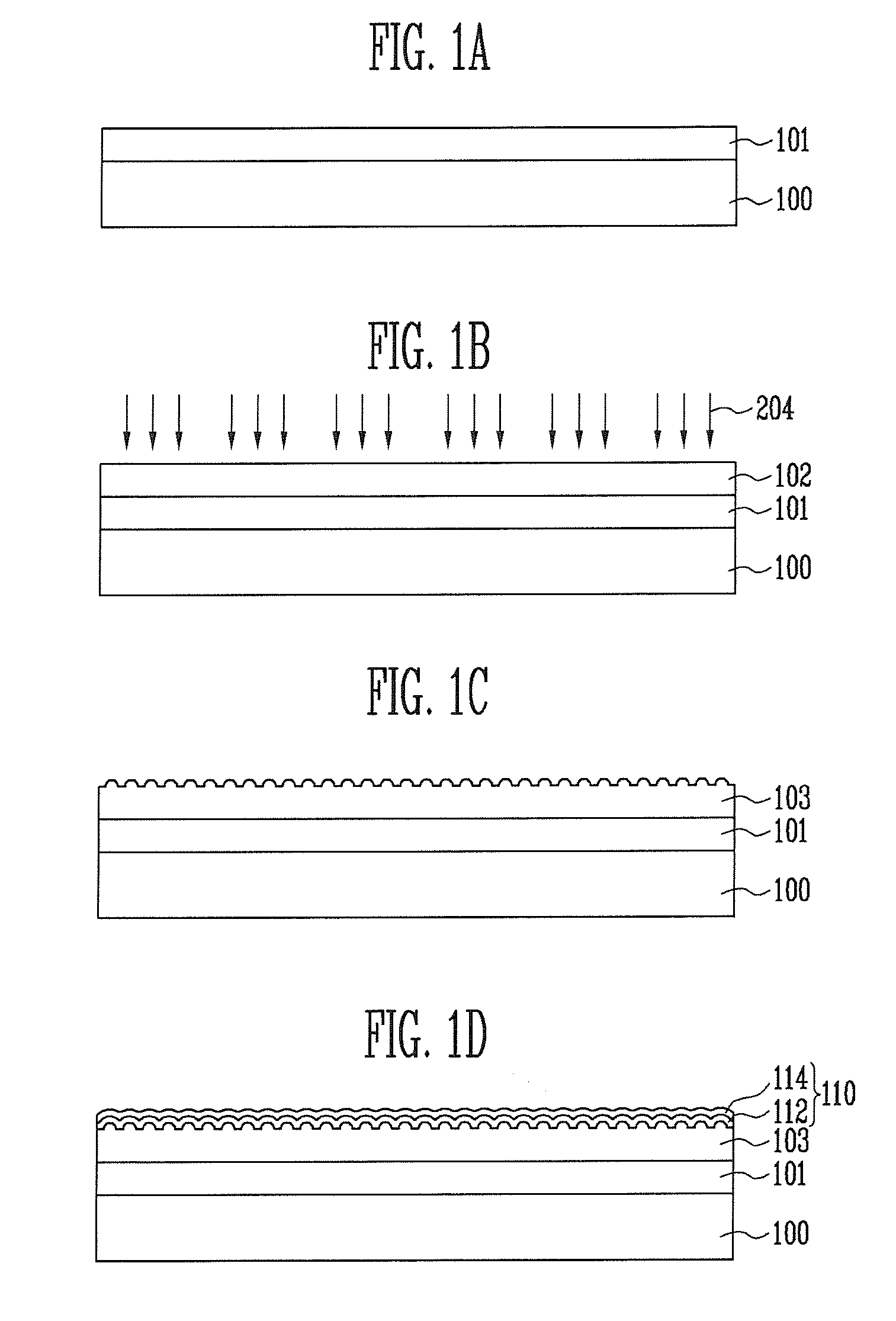

Graded Junction Silicon Nanocrystal Embedded Silicon Oxide Electroluminescence Device

A silicon (Si) nanocrystal embedded Si oxide electroluminescence (EL) device and associated fabrication process are presented. The method provides a substrate bottom electrode, and forms a plurality of Si nanocrystal embedded SiOx film layers overlying the bottom electrode, where X is less than 2. Each SiOx film layer has a Si excess concentration in a range of about 5 to 30%. The outside film layers sandwich an inner film layer having a lower concentration of Si nanocrystals. Alternately stated, the outside Si nanocrystal embedded SiOx film layers have a higher electrical conductivity than a sandwiched inner film layer. A transparent top electrode is formed over the plurality of Si nanocrystal embedded SiOx film layers. The plurality of Si nanocrystal embedded SiOx film layers are deposited using a high density plasma-enhanced chemical vapor deposition (HD PECVD) process. The HD PECVD process initially deposits SiOx film layers, which are subsequently annealed.

Owner:SHARP KK

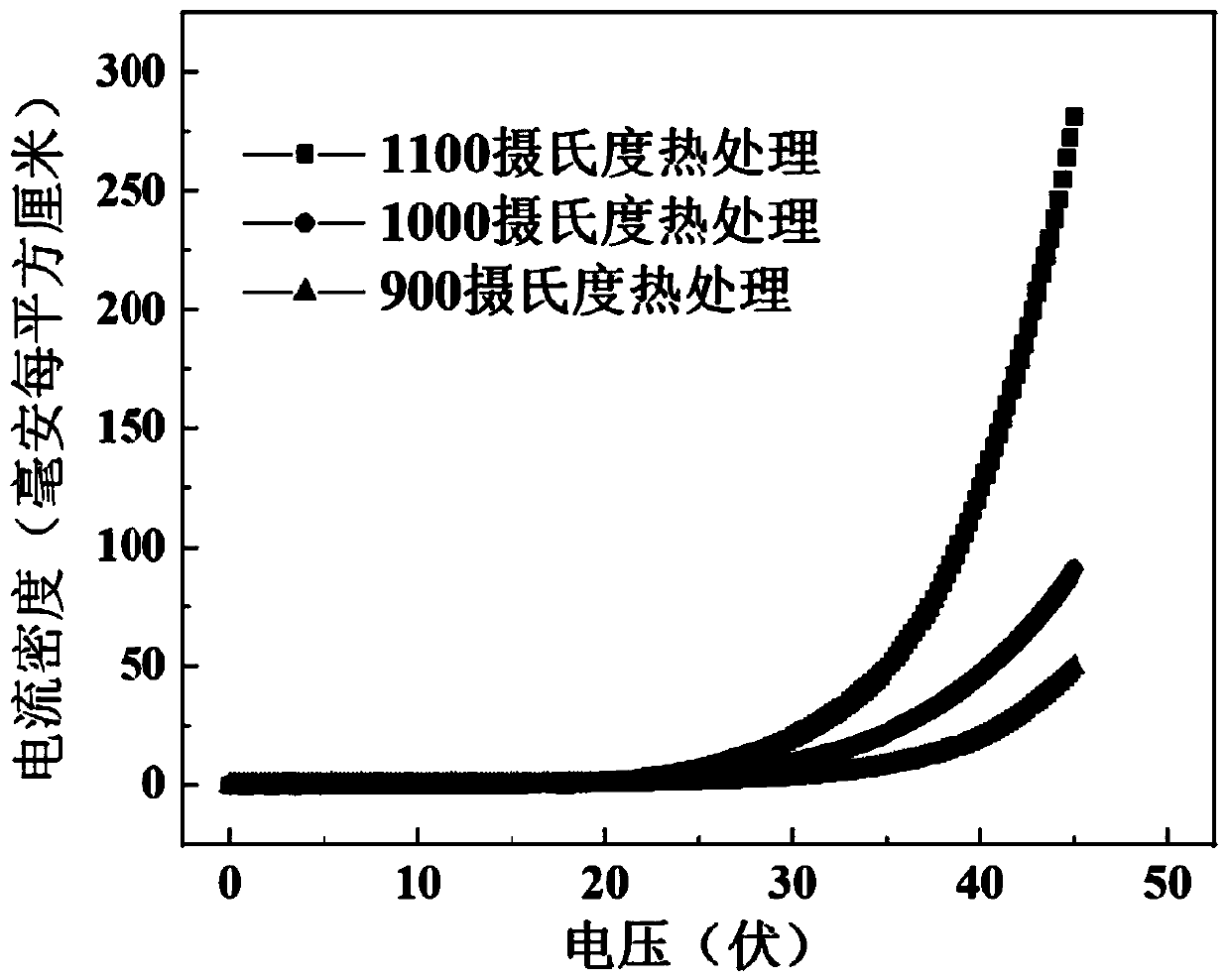

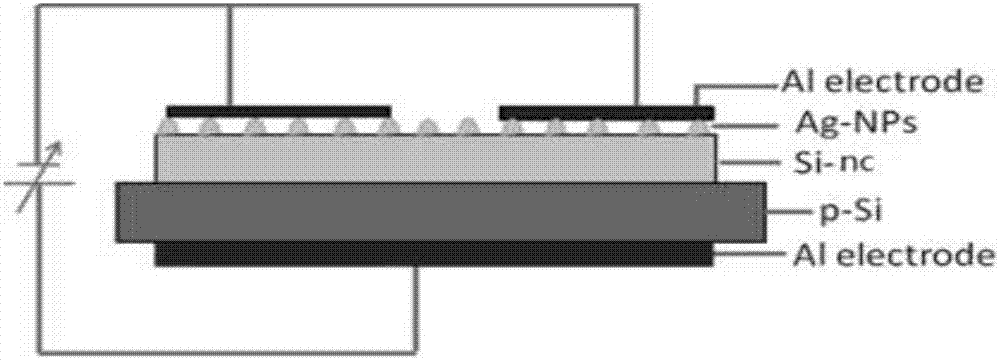

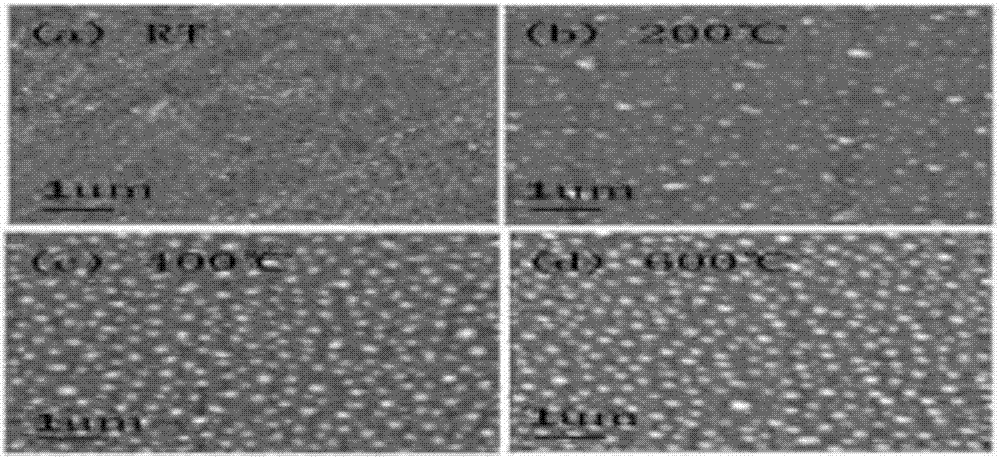

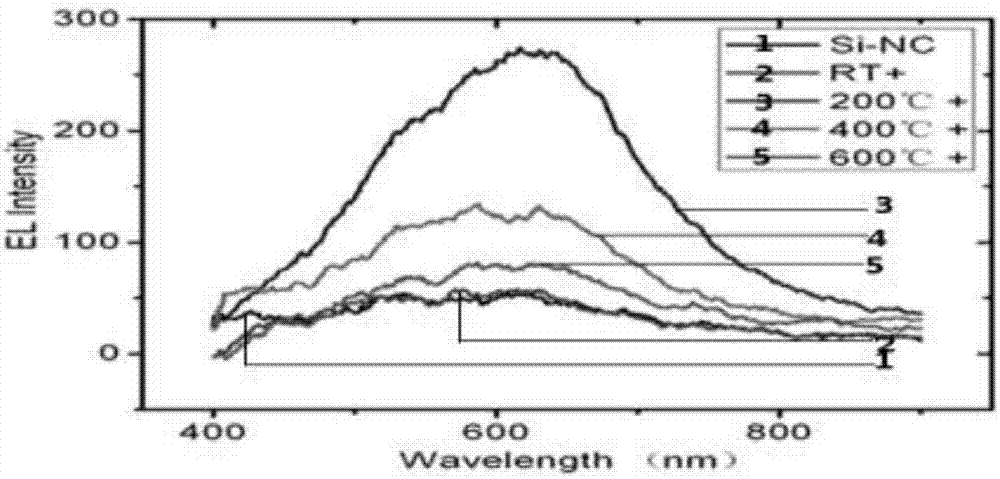

Preparation method and application of Ag surface plasmon-containing silicon-based LED

InactiveCN107464861AIncrease the intensity of electroluminescenceIncrease chance of compoundingSemiconductor devicesLuminous intensityNanoparticle

The invention belongs to the technical field of preparation of a silicon-based LED, and particularly relates to preparation method and application of an Ag surface plasmon-containing silicon-based LED. The preparation of the Ag surface plasmon-containing silicon-based LED is completed according to four steps of immersion, primary annealing, secondary annealing and third annealing, silver nitrate is decomposed to Ag nanoparticles by adjusting ultrasound and an annealing parameter, the Ag nanoparticles are used as silicon nanocrystal surface plasmon, so that the surface plasmon field of the silicon-based LED is further improved, and the light-emitting intensity of the silicon-based LED is improved; and optimal light-emitting intensity can be obtained by applying biases to two ends of the silicon-based LED and changing the sizes of the applied biases.

Owner:GUIZHOU MINZU UNIV

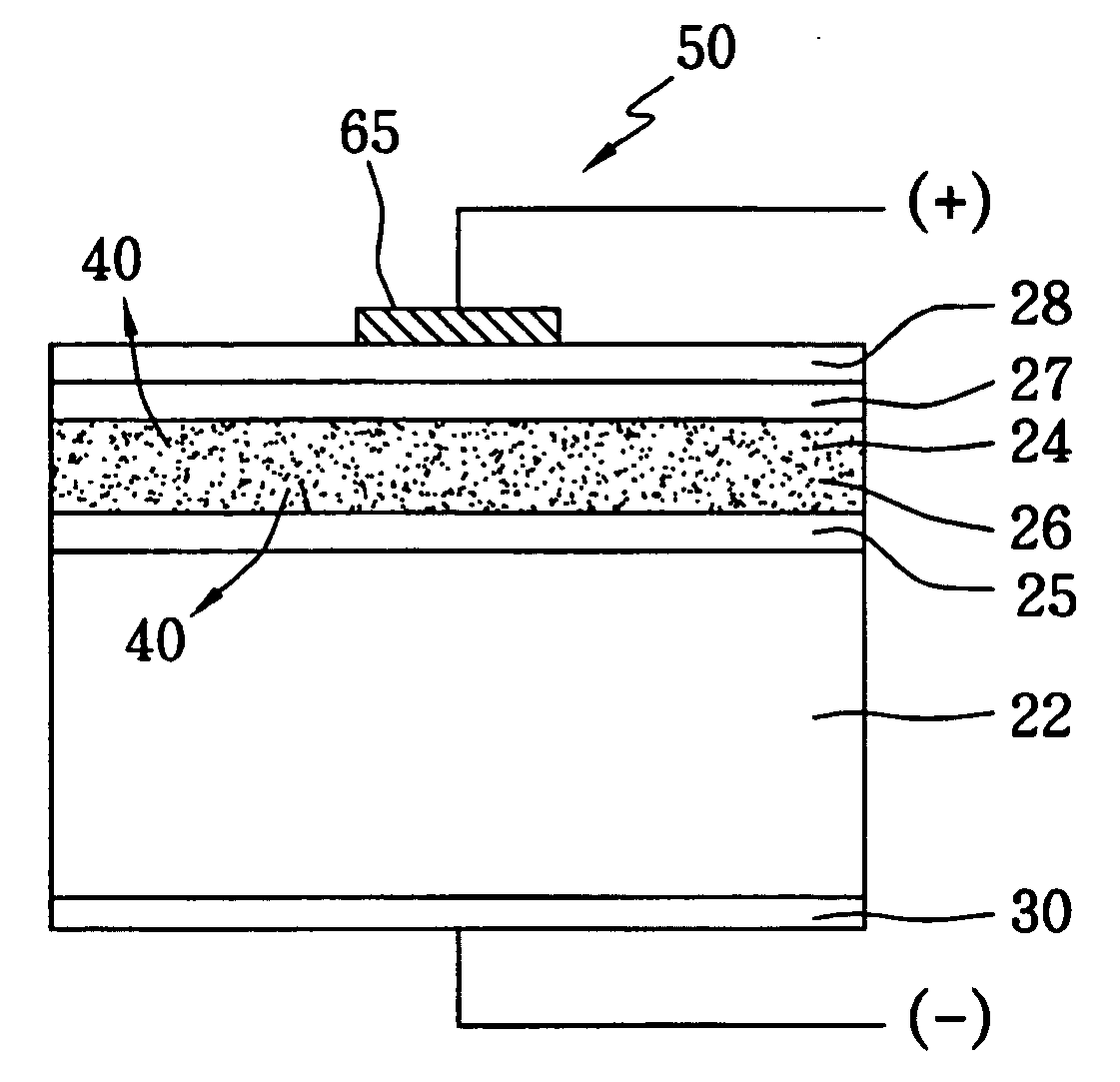

White light-emitting device and method for preparing the same

InactiveUS20060043884A1Discharge tube luminescnet screensElectroluminescent light sourcesPresent methodOhmic contact

The present white light-emitting device includes a substrate with first window layer, a trisilicon tetranitride layer positioned on the first window layer, a plurality of silicon nanocrystals distributed in the trisilicon tetranitride layer, a second window layer, a transparent conductive layer and a first ohmic contact electrode positioned in sequence on the trisilicon tetranitride layer, and a second ohmic contact electrode positioned on the bottom surface of the substrate. The present method first forms a sub-stoichiometric silicon nitride (SiNx) layer on a substrate, wherein the numerical ratio (x) of nitrogen atoms to silicon atoms is smaller than 4 / 3. A thermal treating process is then performed to transform the sub-stoichiometric SiNx layer into a trisilicon tetranitride layer with a plurality of silicon nanocrystals distributed therein. The thickness of the trisilicon tetranitride layer is between 1 and 10,000 nanometers, and the diameter of the silicon nanocrystal is between 1 and 10 nanometers.

Owner:INST NUCLEAR ENERGY RES ROCAEC

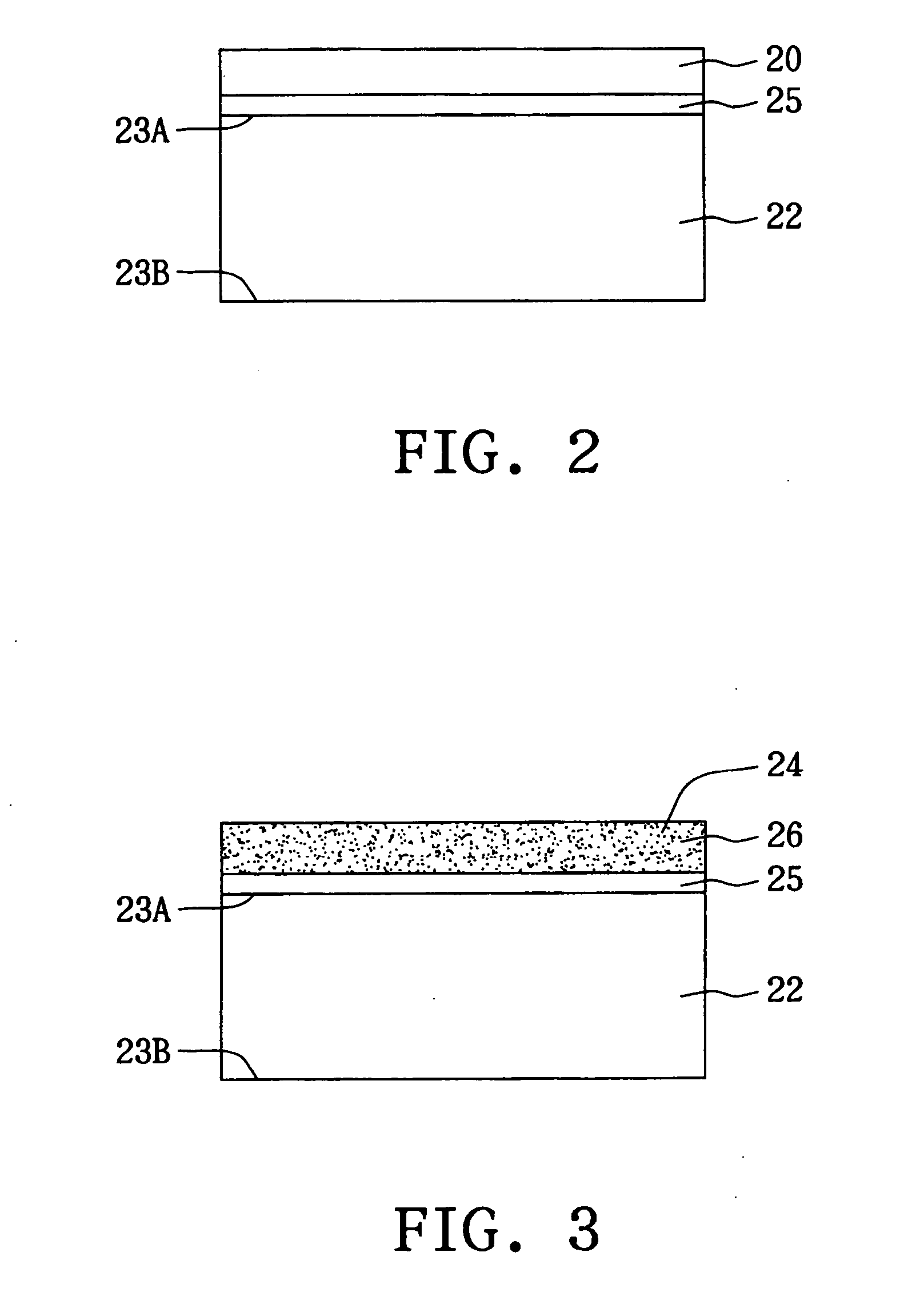

Red light-emitting device and method for preparing the same

InactiveUS20060043383A1Solid-state devicesSemiconductor/solid-state device manufacturingPresent methodOhmic contact

The present red light-emitting device includes a substrate with a first window layer, a silicon dioxide layer positioned on the first window layer, a plurality of silicon nanocrystals distributed in the silicon dioxide layer, a second window layer, a transparent conductive layer and a first ohmic contact electrode positioned in sequence on the silicon dioxide layer, and a second ohmic contact electrode positioned on the bottom surface of the substrate. The present method forms a sub-stoichiometric silica (SiOx) layer on a substrate, wherein the numerical ratio (x) of oxygen atoms to silicon atoms is smaller than 2. A thermal treating process is then performed in an oxygen atmosphere to transform the SiOx layer into a silicon dioxide layer with a plurality of silicon nanocrystals distributed therein. The thickness of the silicon dioxide layer is between 1 and 10,000 nanometers, and the diameter of the silicon nanocrystal is between 3 and 5 nanometers.

Owner:INST NUCLEAR ENERGY RES ROCAEC

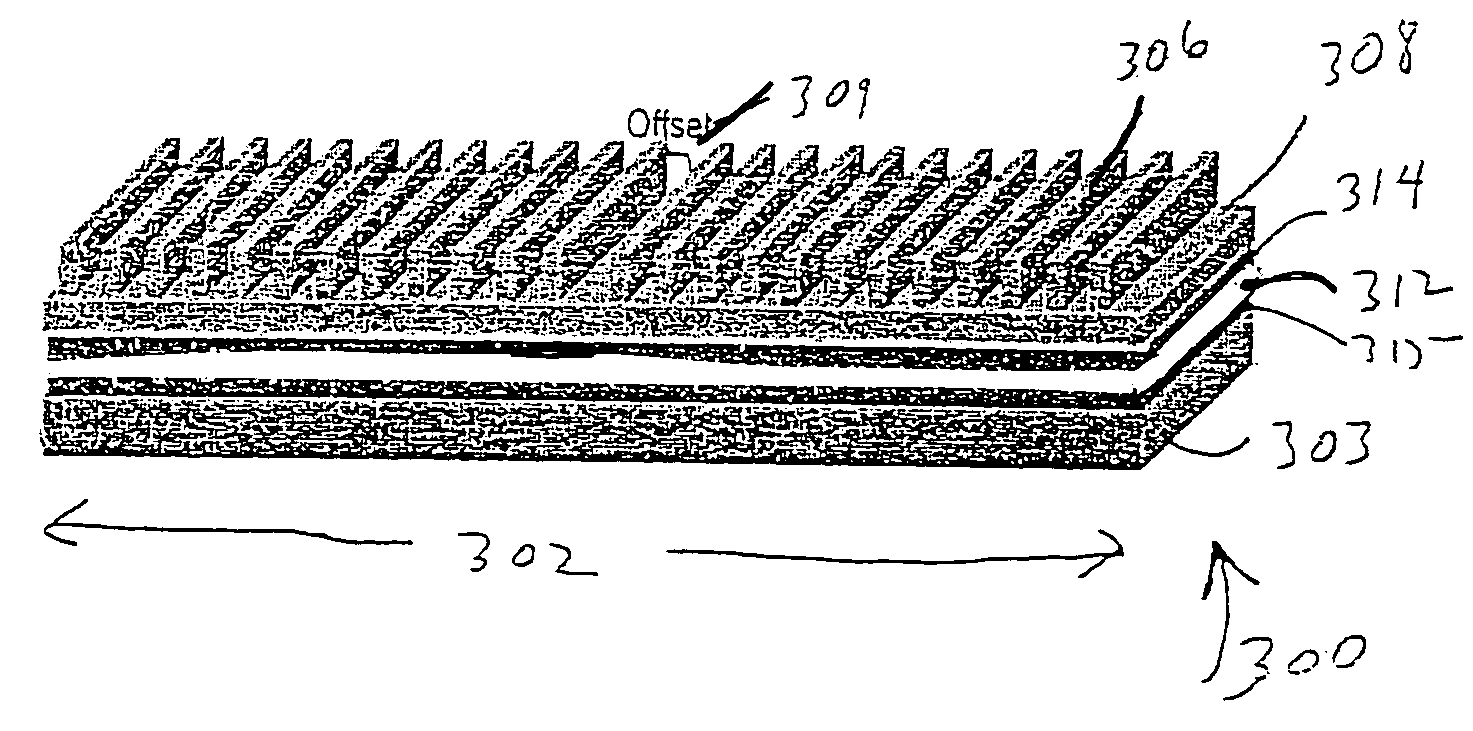

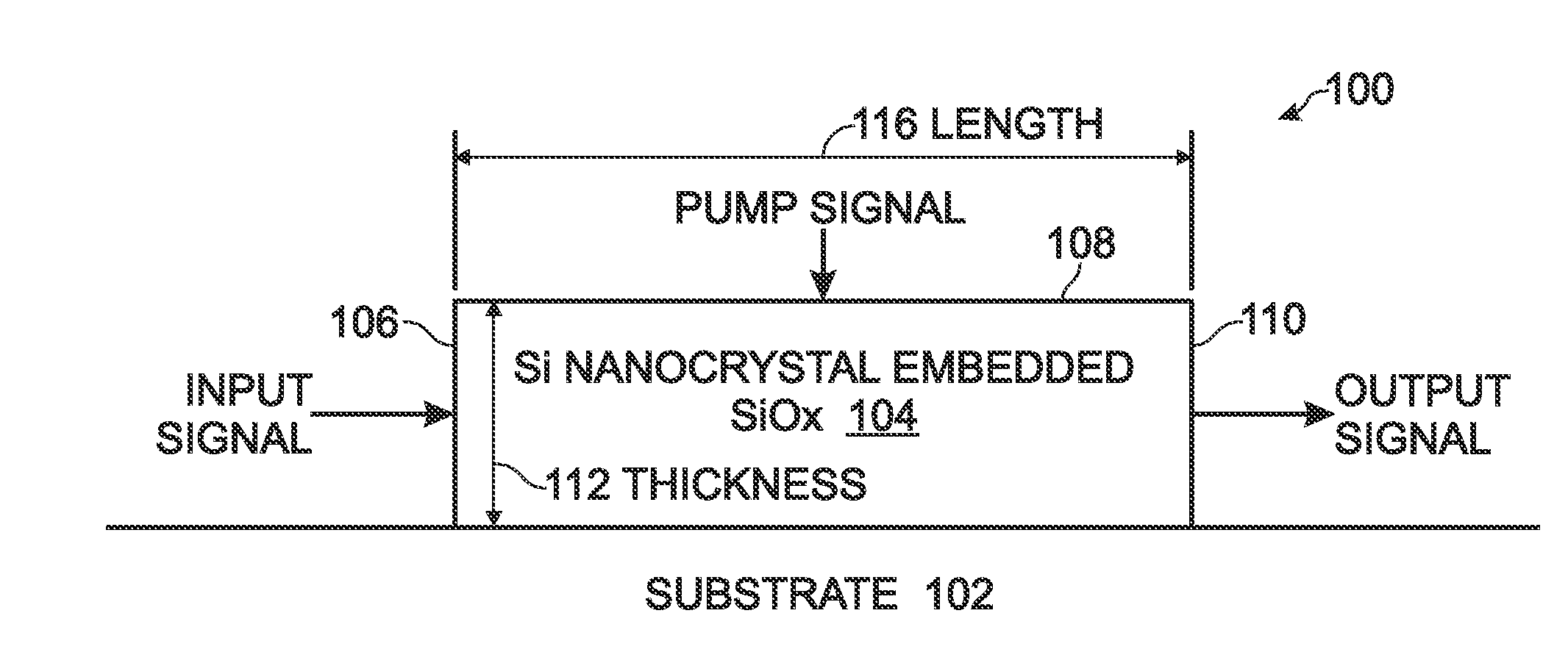

Optical Waveguide Amplifier Using High Quantum Efficiency Silicon Nanocrystal Embedded Silicon Oxide

ActiveUS20090040599A1Increase signal levelImprove overall senseLaser detailsSemiconductor/solid-state device manufacturingQuantum efficiencyAudio power amplifier

A method is provided for optical amplification using a silicon (Si) nanocrystal embedded silicon oxide (SiOx) waveguide. The method provides a Si nanocrystal embedded SiOx waveguide, where x is less than 2, having a quantum efficiency of greater than 10%. An optical input signal is supplied to the Si nanocrystal embedded SiOx waveguide, having a first power at a first wavelength in the range of 700 to 950 nm. The Si nanocrystal embedded SiOx waveguide is pumped with an optical source having a second power at a second wavelength in a range of 250 to 550 nm. As a result, an optical output signal having a third power is generated, greater than the first power, at the first wavelength. In one aspect, the third power increases in response to the length of the waveguide strip.

Owner:SHARP KK

Fluorescent material, and preparation method and application thereof

ActiveCN103666463AStrong resistance to photofadingAdjustable bandgapPharmaceutical non-active ingredientsLuminescent compositionsSilane compoundsOrganic solvent

The invention provides a fluorescent material which contains an ordered mesoporous material and a modified silicon nanocrystal. The modified silicon nanocrystal is prepared by performing silicon hydrogenation reaction on a silicon nanocrystal and silane compounds of which the general formula is R1Si(OR2)3. The invention also provides a preparation method of the fluorescent material, which comprises the following step: in the presence of an organic solvent, mixing and contacting the modified silicon nanocrystal and the ordered mesoporous material, wherein the modified silicon nanocrystal is prepared by performing silicon hydrogenation reaction on the silicon nanocrystal and silane compounds of which the general formula is R1Si(OR2)3. The invention also provides application of the fluorescent material as a drug conduction carrier. The fluorescent material has fluorescent characteristic, and has the advantages of high capacity for resisting photofading and better drug slow-release property.

Owner:CHINA PETROLEUM & CHEM CORP +1

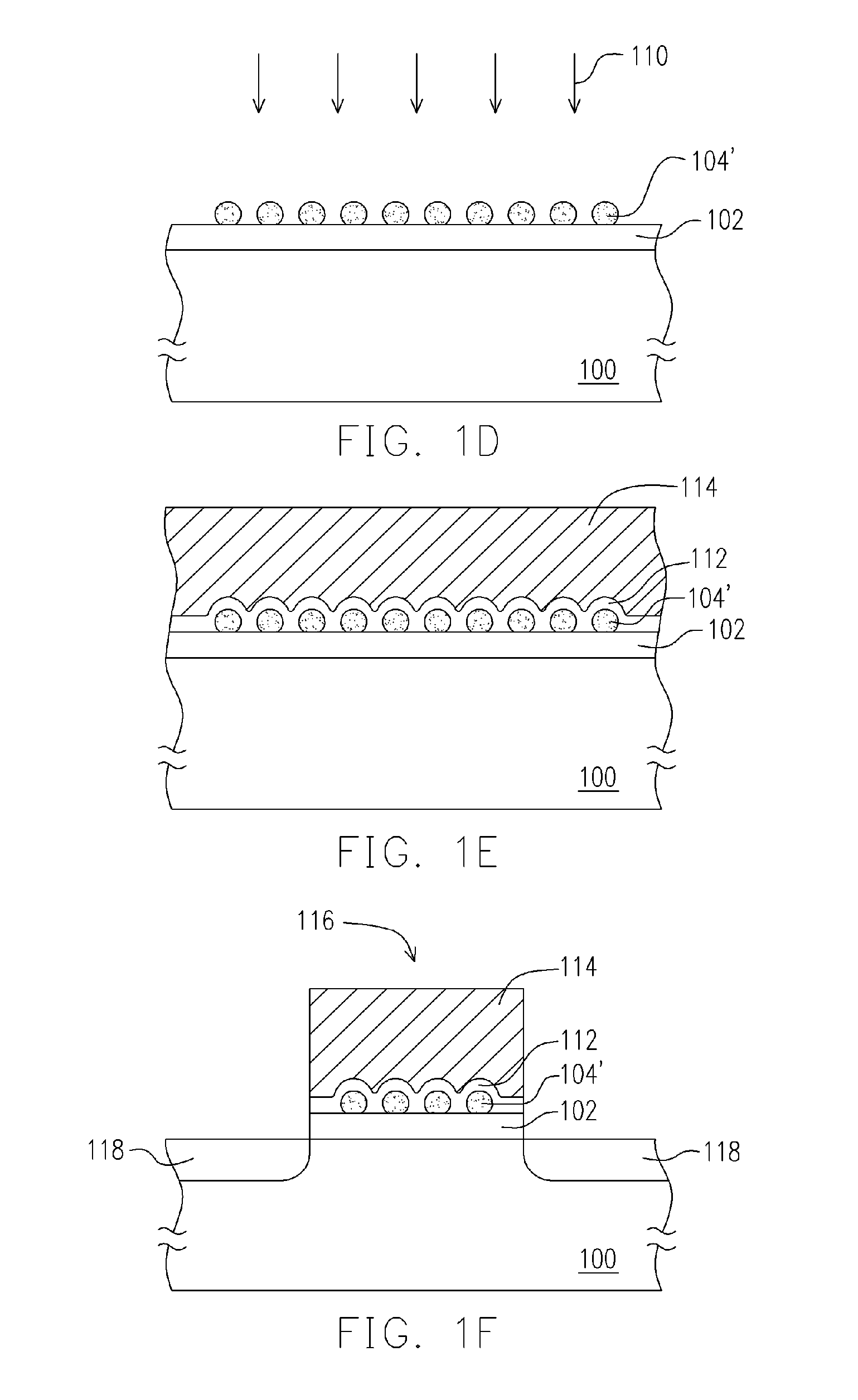

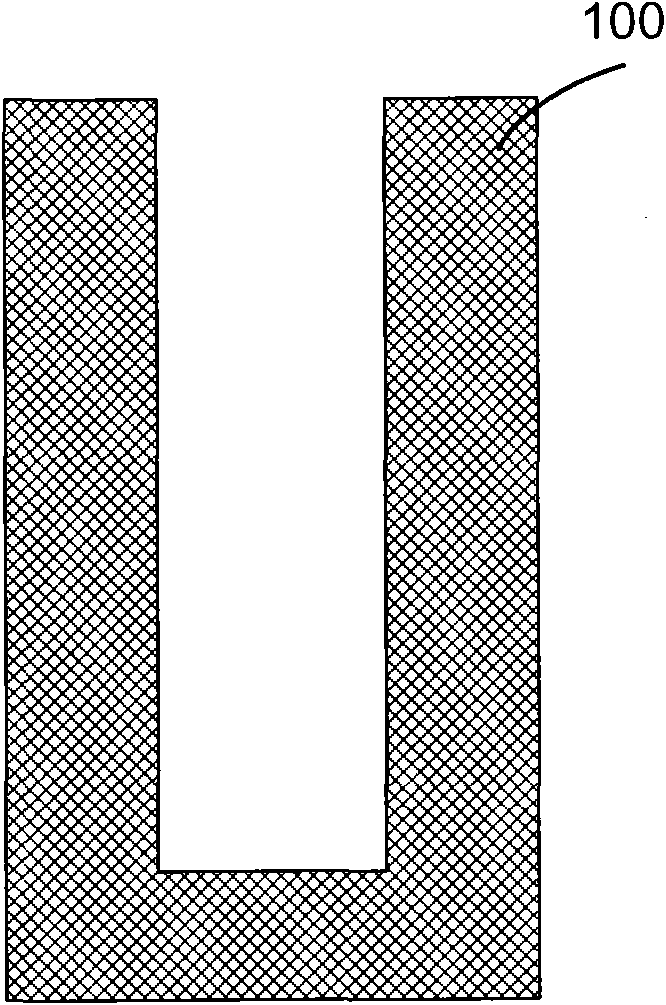

Capacitor and manufacturing method thereof

InactiveCN102044569AIncrease capacitanceIncrease interface areaNanoinformaticsSemiconductor/solid-state device manufacturingCapacitanceSilicon nanocrystal

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Nonvolatile memory cell, array thereof, fabrication methods thereof and device comprising the same

A nonvolatile memory cell is capable of reducing an excessive current leakage due to a rough surface of a polysilicon and of performing even at a low temperature process by forming the first oxide film including a silicon oxynitride (SiOxNy) layer using nitrous oxide plasma and by forming a plurality of silicon nanocrystals in a nitride film by implanting a silicon nanocrystal on the nitride film by an ion implantation method, and a fabricating method thereof and a memory apparatus including the nonvolatile memory cell.

Owner:SAMSUNG DISPLAY CO LTD

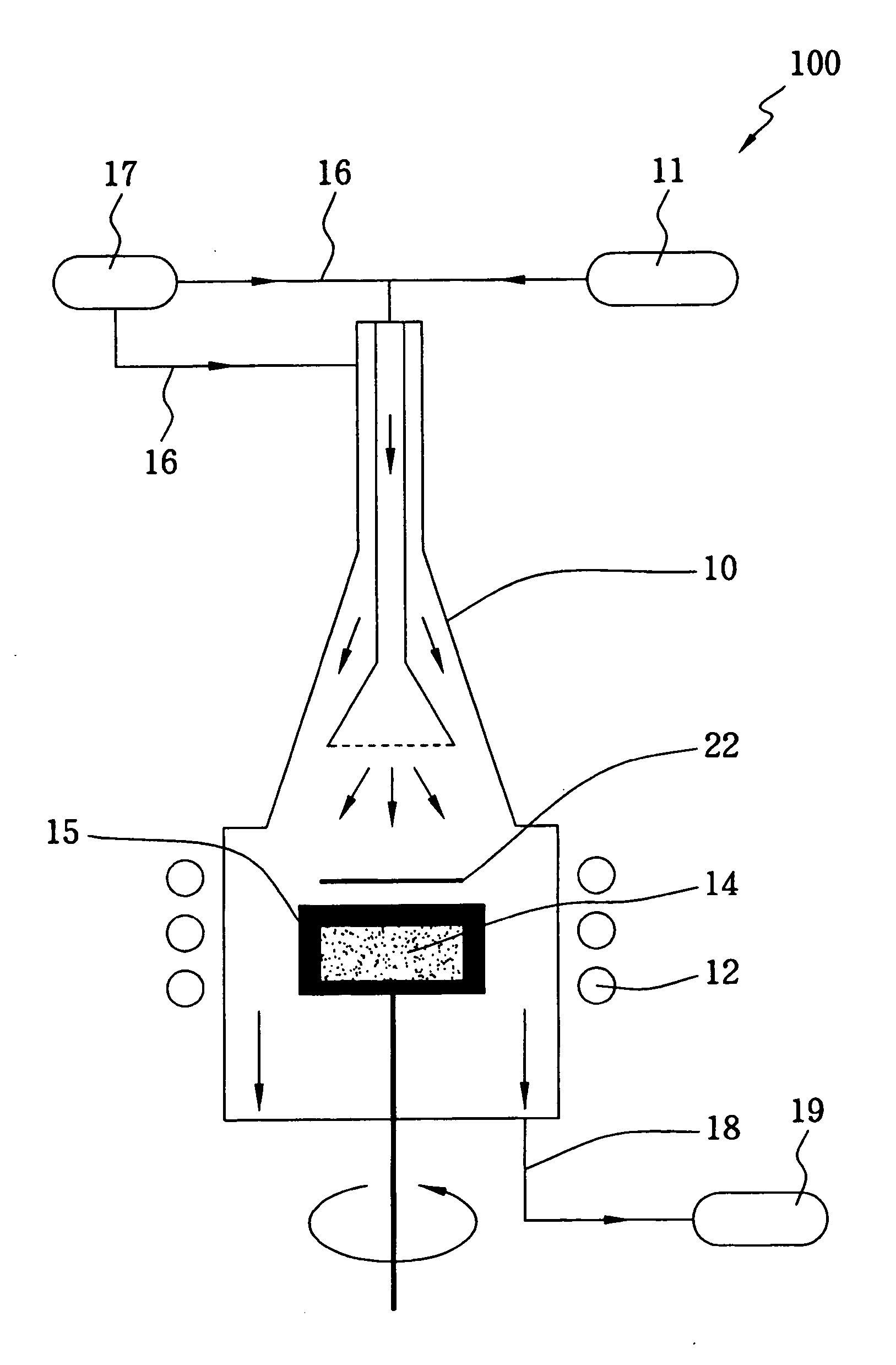

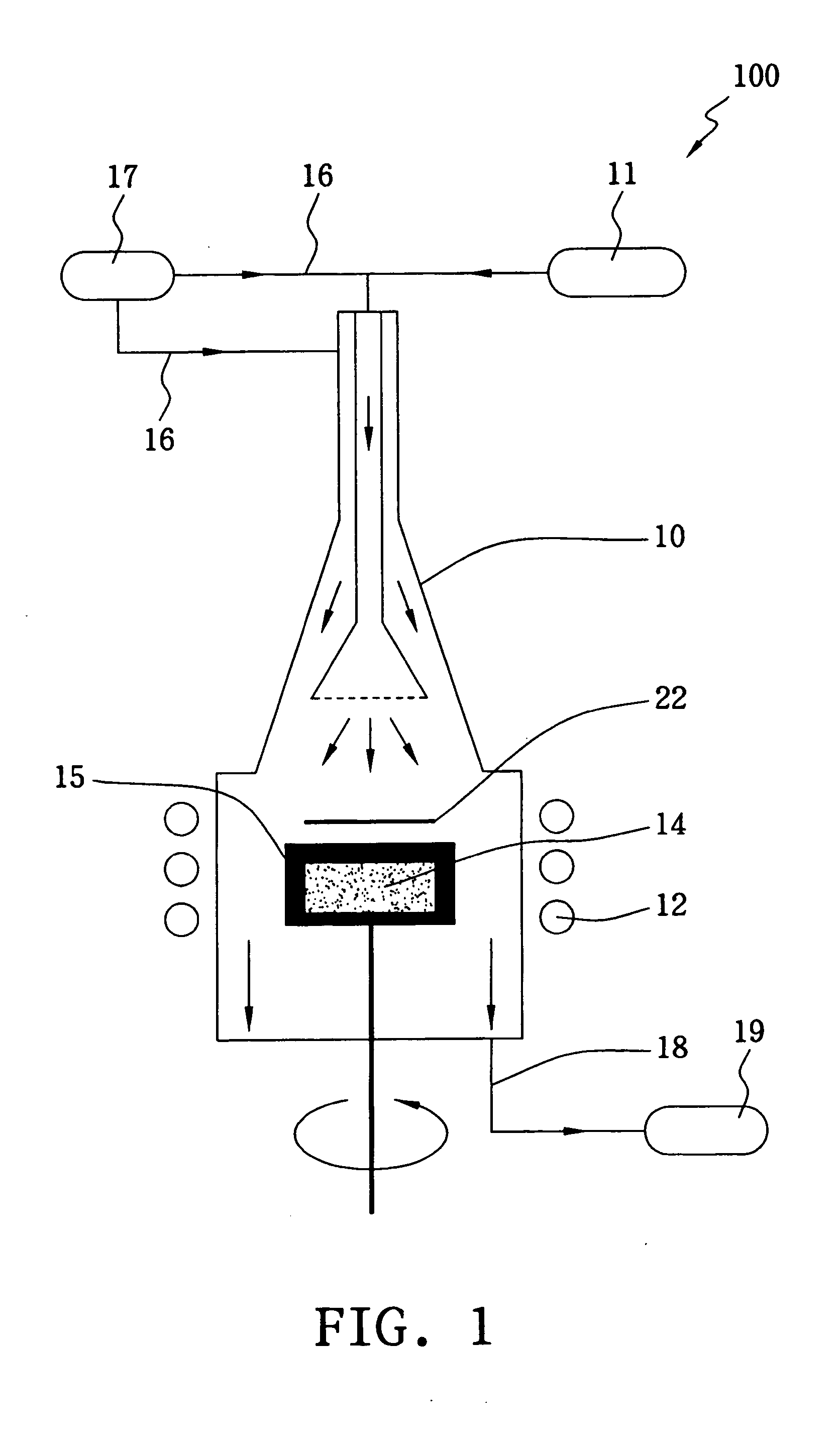

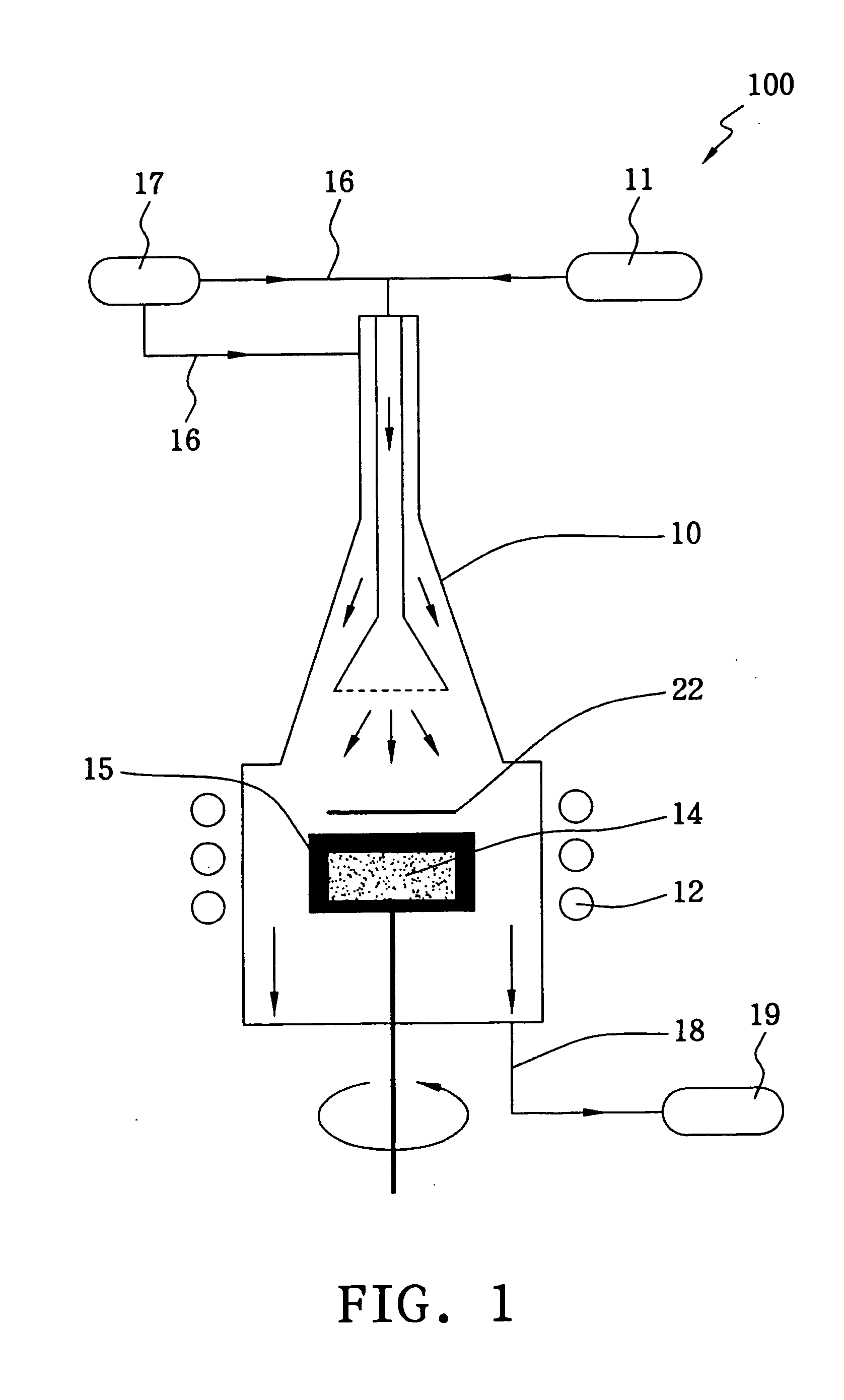

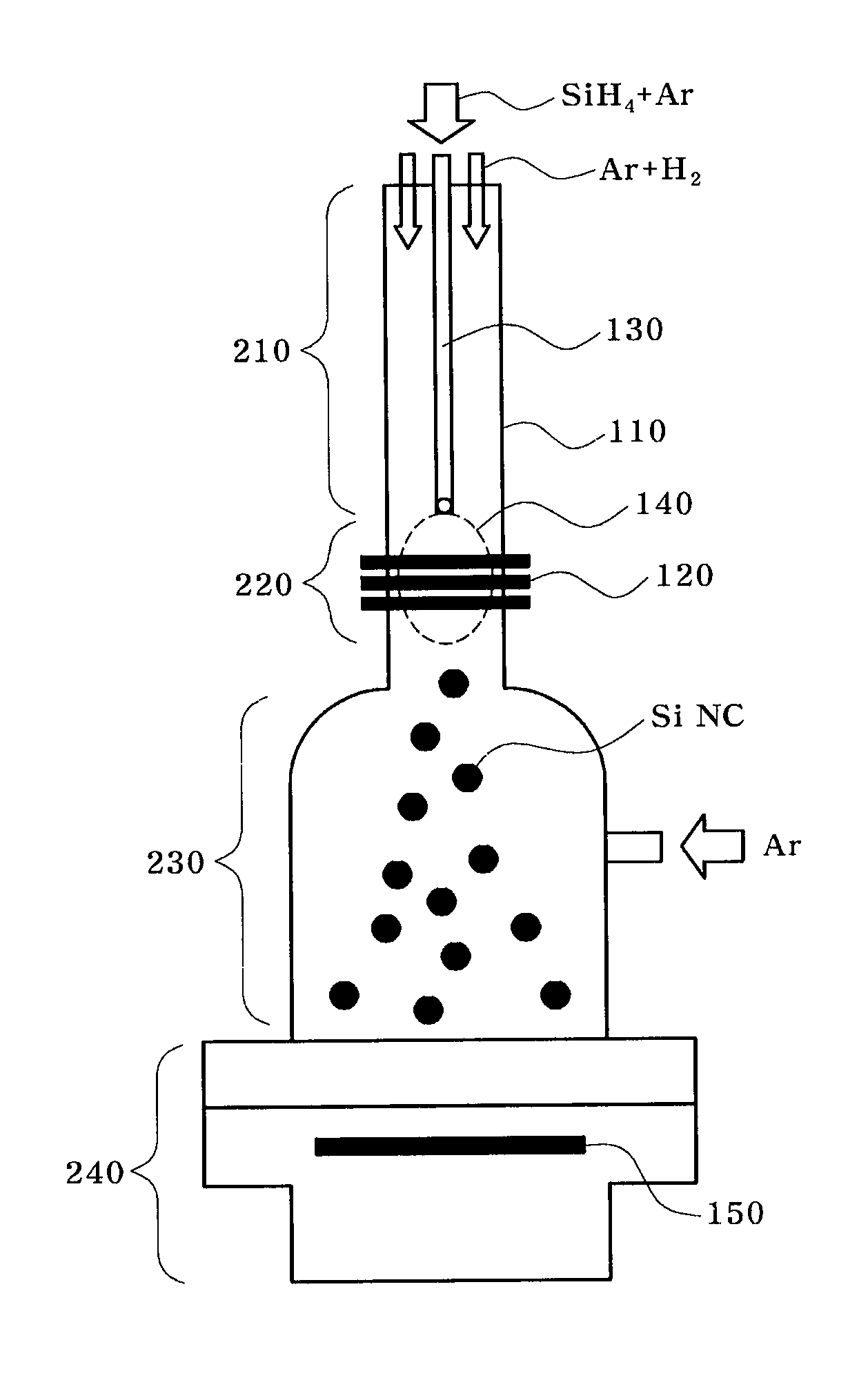

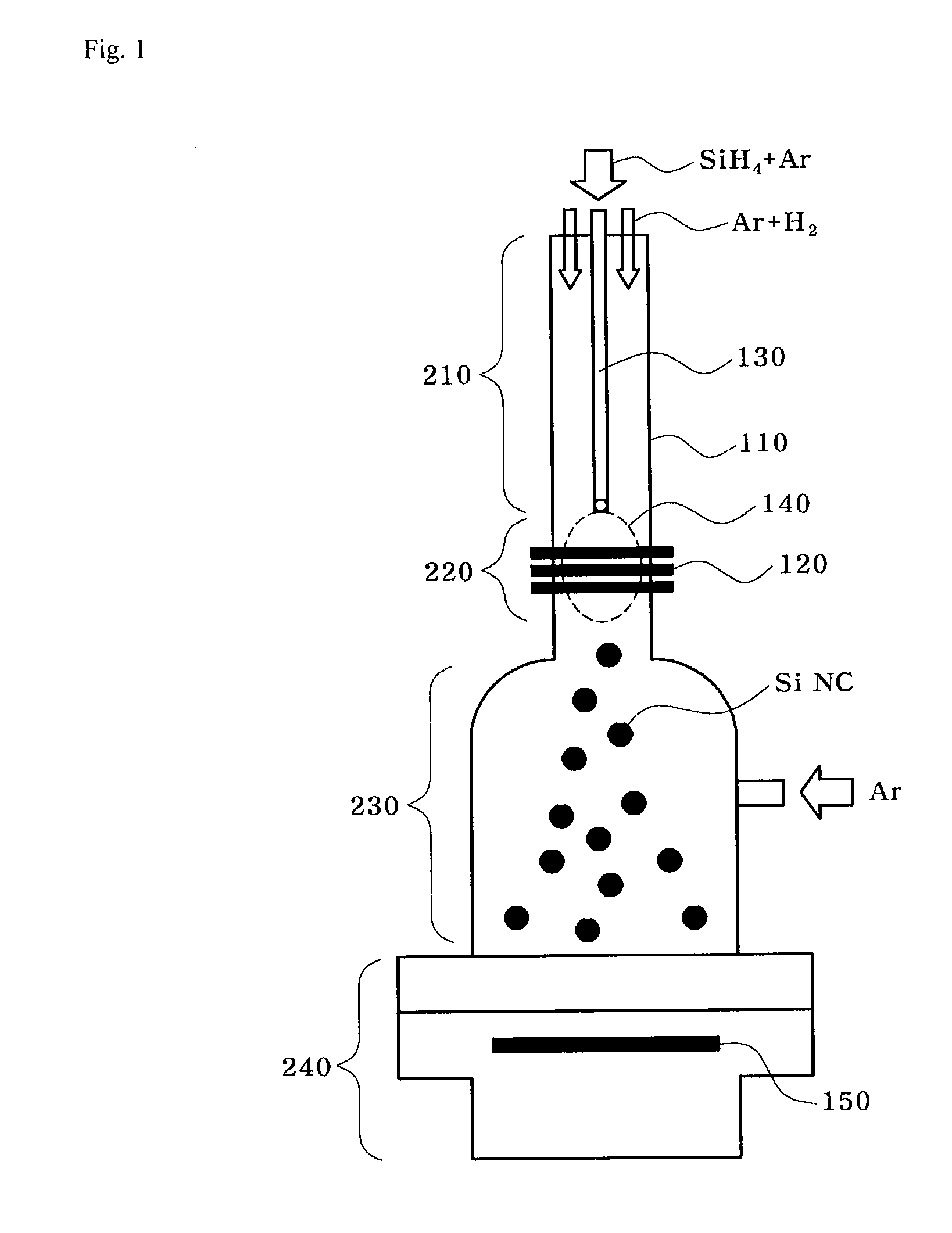

Apparatus for producing silicon nanocrystals using inductively coupled plasma

ActiveUS8377205B2Improving particle size characteristic and qualityMinimize diffusionMaterial nanotechnologyNanostructure manufactureSurface reactionPlasma diffusion

The present disclosure relates to an apparatus for producing silicon nanocrystals, which can minimize plasma diffusion by finely adjusting a plasma region created by an ICP coil. The apparatus includes a reactor having an ICP coil wound around an outer wall thereof and a tube inserted into the reactor, wherein a primary gas for forming silicon nanocrystals and a secondary gas for surface reaction of the silicon nanocrystals are separately supplied to the reactor through an inner side and an outer side of the tube, respectively.

Owner:EL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com