Preparation method and application of Ag surface plasmon-containing silicon-based LED

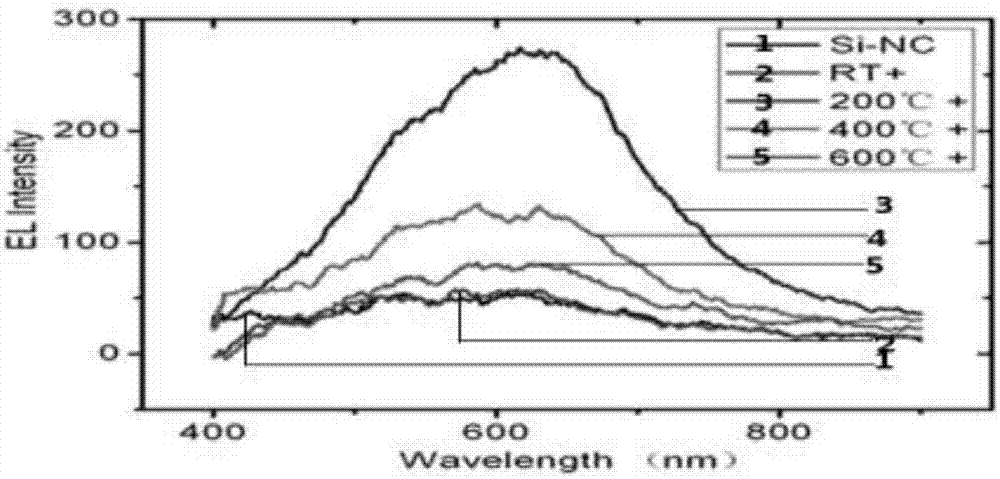

A surface plasmon, silicon-based technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of small amount of information, difficult integration, slow electron transmission speed, etc., to improve the intensity of electroluminescence, increase The Effect of Compounding Chances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

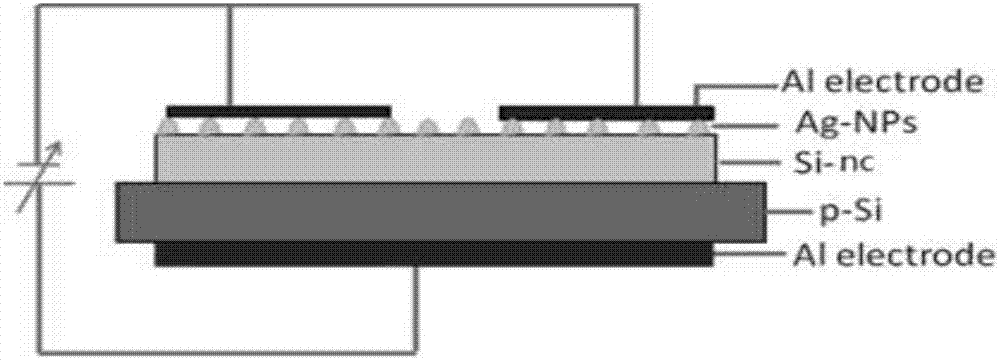

[0028] A method for preparing a silicon-based LED containing Ag surface plasmons, comprising the following steps:

[0029] (1) Soaking: put the silicon nanocrystalline film into the AgNO 3 solution, after ultrasonic treatment for 30min, take it out and dry it with nitrogen gas.

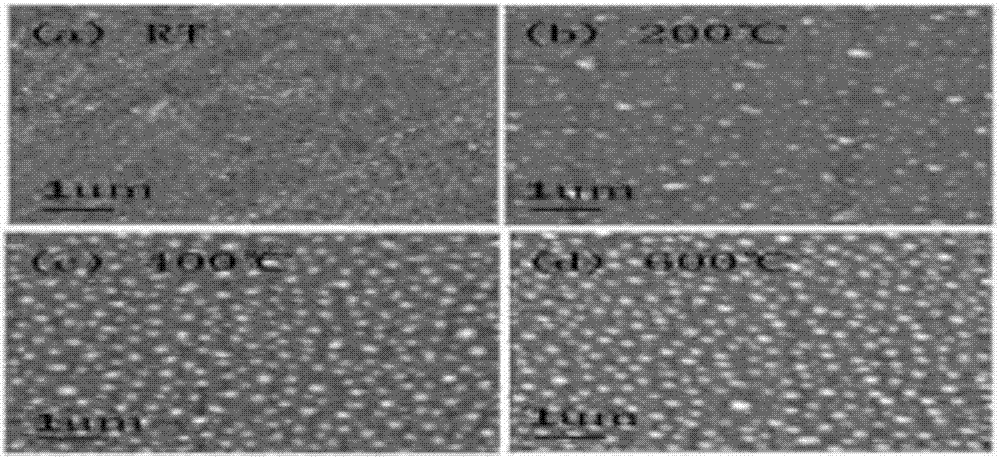

[0030] (2) Primary annealing: perform thermal annealing in a high-temperature annealing furnace, the annealing temperature is 200° C., and the annealing time is 30 minutes to obtain a Si-nc film containing Ag nanoparticles;

[0031] (3) Secondary annealing: evaporating 2 μm of Al on the back side of the film described in step (2) as a positive electrode, performing thermal annealing in a high-temperature annealing furnace, the annealing temperature is 480 ° C, and the annealing time is 10 min;

[0032] (4) Three times of annealing; after step (3), vapor-deposit a 700nm Al ring on the front side of the Si-nc film as a negative electrode, and perform thermal annealing in a high-temperature annealing fu...

Embodiment 2

[0040] A method for preparing a silicon-based LED containing Ag surface plasmons, comprising the following steps:

[0041] (1) Soaking: put silicon nanocrystals into AgNO 3 solution, after ultrasonic treatment for 30min, take it out and dry it with nitrogen gas.

[0042] (2) Primary annealing: perform thermal annealing in a high-temperature annealing furnace, the annealing temperature is 400° C., and the annealing time is 30 minutes to obtain a Si-nc film containing Ag nanoparticles;

[0043] (3) Secondary annealing: evaporating 2 μm of Al on the back side of the film described in step (2) as a positive electrode, performing thermal annealing in a high-temperature annealing furnace, the annealing temperature is 480 ° C, and the annealing time is 10 min;

[0044] (4) Three times of annealing; after step (3), vapor-deposit an 800nm Al ring on the front side of the Si-nc film as a negative electrode, and perform thermal annealing in a high-temperature annealing furnace with an...

Embodiment 3

[0052] A method for preparing a silicon-based LED containing Ag surface plasmons, comprising the following steps:

[0053] (1) Soaking: put the silicon nanocrystalline film into the AgNO 3 solution, after ultrasonic treatment for 30min, take it out and dry it with nitrogen gas.

[0054] (2) Primary annealing: perform thermal annealing in a high-temperature annealing furnace, the annealing temperature is 600° C., and the annealing time is 30 minutes to obtain a Si-nc film containing Ag nanoparticles;

[0055] (3) Secondary annealing: evaporating 2 μm of Al on the back side of the film described in step (2) as a positive electrode, performing thermal annealing in a high-temperature annealing furnace, the annealing temperature is 480 ° C, and the annealing time is 10 min;

[0056] (4) Three times of annealing; after step (3), a 900nm Al ring is vapor-deposited on the front side of the Si-nc film as a negative electrode, and thermal annealing is performed in a high-temperature an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com