Silicon-based LED and preparation method thereof

A silicon-based and silicon-substrate technology, applied in electrical components, nanotechnology, circuits, etc., can solve problems such as low luminous efficiency, and achieve the effects of increasing light output, increasing electroluminescent intensity, and increasing brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

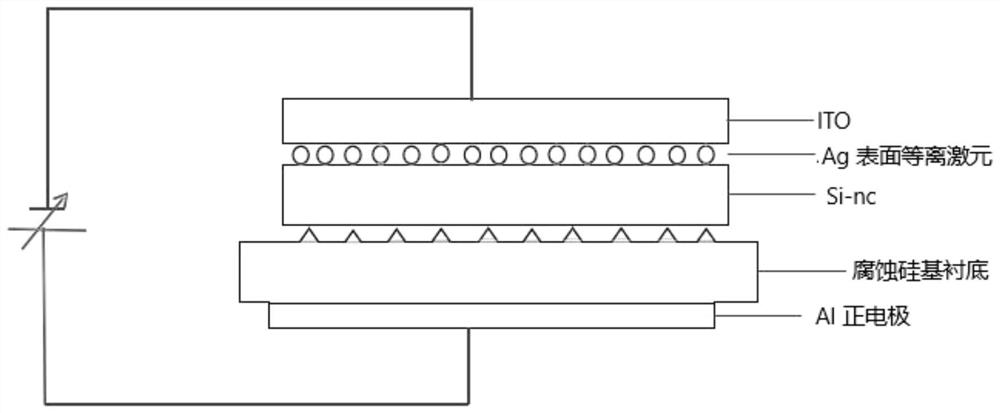

[0047] A method for preparing a silicon-based LED, comprising the following steps:

[0048] S1. Silver film evaporation: put Ag with a purity of 99.99% into a molybdenum boat, and place it in a vacuum of 4×10 -4 Evaporation is carried out in a Pa environment. In order to ensure the compactness of the evaporated silver film, the evaporation rate is: 0.04nm / s, and the thickness is 10nm. The silver film is evaporated on the p-type silicon substrate.

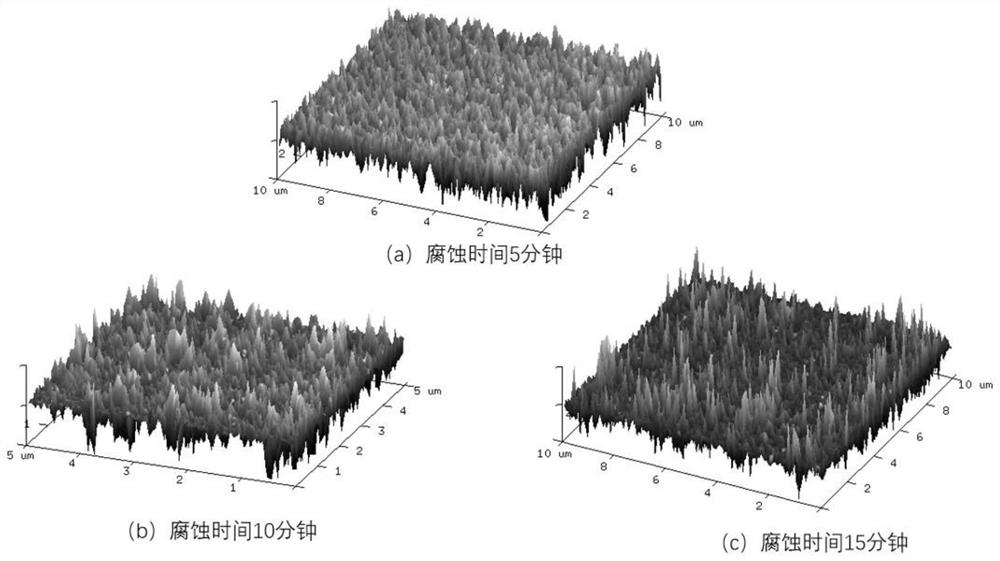

[0049] S2. Preparation of a rough silicon-based substrate: place the side of the silicon substrate with the silver film attached in H 2 O:H 2 o 2 : HF=8:4:1 mixed solution for etching, the etching time is 5 minutes, to obtain a silicon-based substrate with a rough surface, such as figure 2 shown.

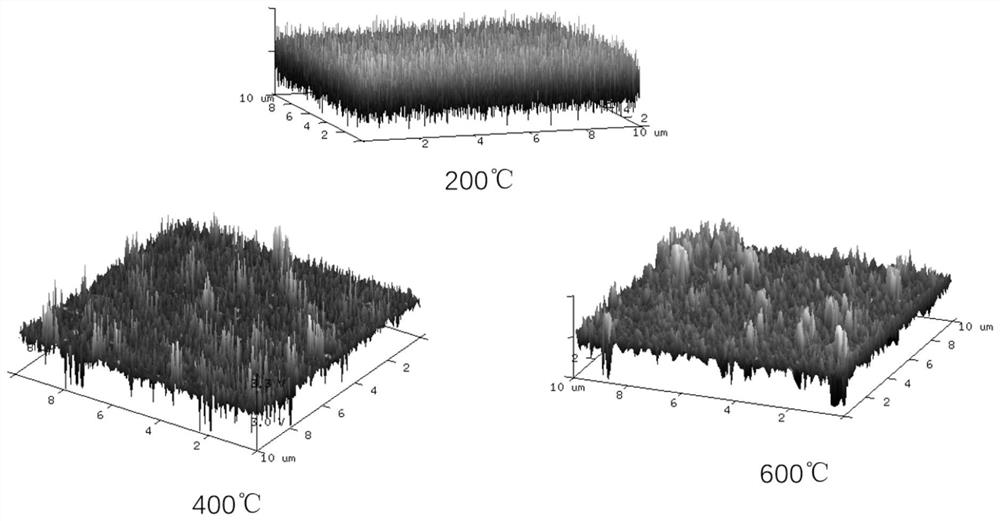

[0050] S3. Silicon nanocrystalline film: SiO and SiO with a purity of 99.99% 2 Put them into the molybdenum boat and molybdenum crucible respectively, and the vacuum degree is 4×10 -4 Under the Pa environment, thermal evaporation a...

Embodiment 2

[0057] S1. Silver film evaporation: put Ag with a purity of 99.99% into a molybdenum boat, and place it in a vacuum of 4×10 -4 Evaporation is carried out in a Pa environment. In order to ensure the compactness of the evaporated silver film, the evaporation rate is: 0.04nm / s, and the thickness is 10nm. The silver film is evaporated on the p-type silicon substrate.

[0058] S2. Preparation of a rough silicon-based substrate: place the side of the silicon substrate with the silver film attached in H 2 O:H 2 o 2 : HF=8:4:1 mixed solution for etching, and the etching time is 10 minutes to obtain a silicon-based substrate with a rough surface, such as figure 2 shown.

[0059] S3. Silicon nanocrystalline film: SiO and SiO with a purity of 99.99% 2 Put them into the molybdenum boat and molybdenum crucible respectively, and the vacuum degree is 4×10 -4 Under the Pa environment, thermal evaporation and electron beam heating are used for evaporation, and the evaporation rate is: 0....

Embodiment 3

[0066] S1. Silver film evaporation: put Ag with a purity of 99.99% into a molybdenum boat, and place it in a vacuum of 4×10 -4 Evaporation is carried out in a Pa environment. In order to ensure the compactness of the evaporated silver film, the evaporation rate is: 0.04nm / s, and the thickness is 10nm. The silver film is evaporated on the p-type silicon substrate.

[0067] S2. Preparation of a rough silicon-based substrate: place the side of the silicon substrate with the silver film attached in H 2 O:H 2 o 2 : HF=8:4:1 mixed solution for etching, the etching time is 15 minutes, to obtain a silicon-based substrate with a rough surface, such as figure 2 shown.

[0068] S3. Silicon nanocrystalline film: SiO and SiO with a purity of 99.99% 2 Put them into the molybdenum boat and molybdenum crucible respectively, and the vacuum degree is 4×10 -4 Under the Pa environment, thermal evaporation and electron beam heating are used for evaporation, and the evaporation rate is: 0.08n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com