Method for strengthening silicon-based thin film electroluminescence

A silicon-based thin film and luminescence technology, which is applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of low electroluminescence efficiency of silicon-rich silicon nitride thin films, which are not enough for communication and data exchange, and achieve enhanced The effect of carrier injection efficiency, enhanced radiative recombination rate, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

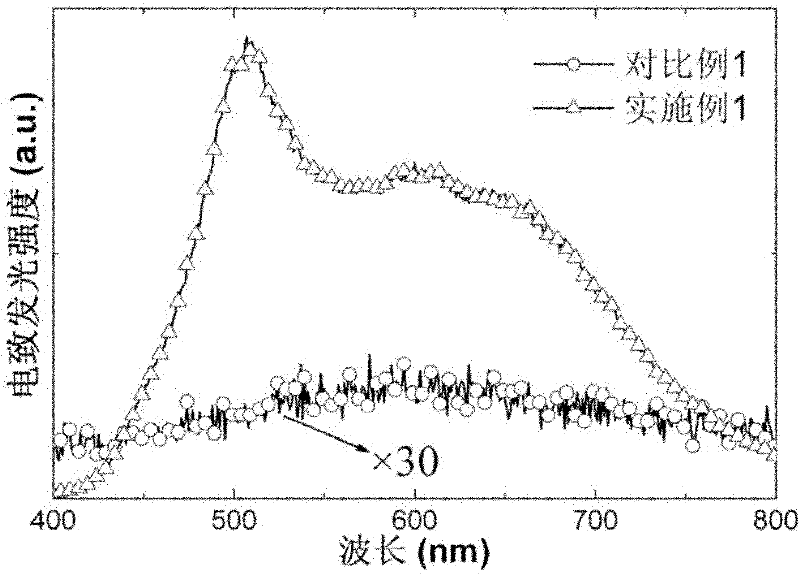

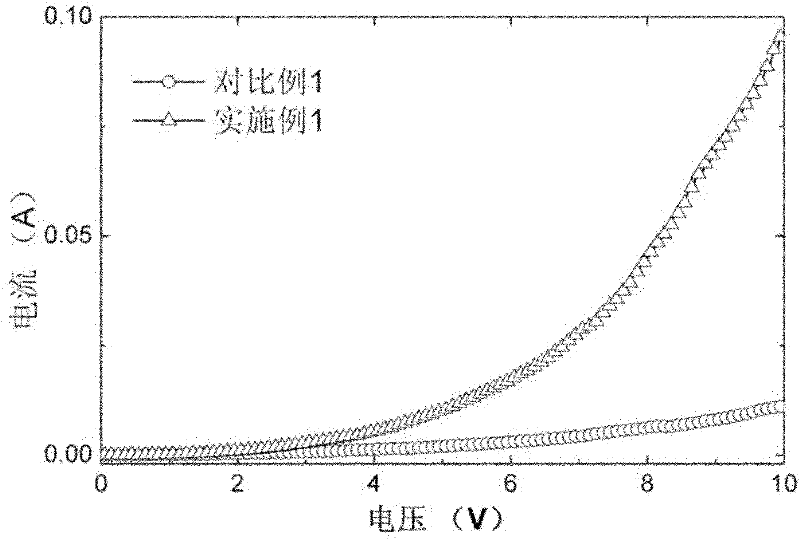

Embodiment 1

[0026] The P-type epitaxial silicon wafer (the substrate resistivity is less than 0.004Ω·cm, the epitaxial layer thickness is 11.4μm, and the resistivity is 2.5Ω·cm) is cleaned by standard RCA and the surface oxide layer is removed with hydrofluoric acid. The standard RCA cleaning steps are as follows: Put the P-type epitaxial silicon wafer into No. 1 cleaning solution (the volume ratio of ammonia water, hydrogen peroxide water and deionized water is 1:1:5), and put it in a water bath at about 80°C (80±5°C). Place it in the middle for 15 to 20 minutes; fully wash the P-type epitaxial silicon wafer with deionized water, put the cleaned P-type epitaxial silicon wafer into No. 2 cleaning solution (the volume ratio of hydrochloric acid, hydrogen peroxide and deionized water is 1:1: 6) Place it in a water bath at about 80°C (80±5°C) for 15-20 minutes, take it out and then wash it thoroughly with deionized water.

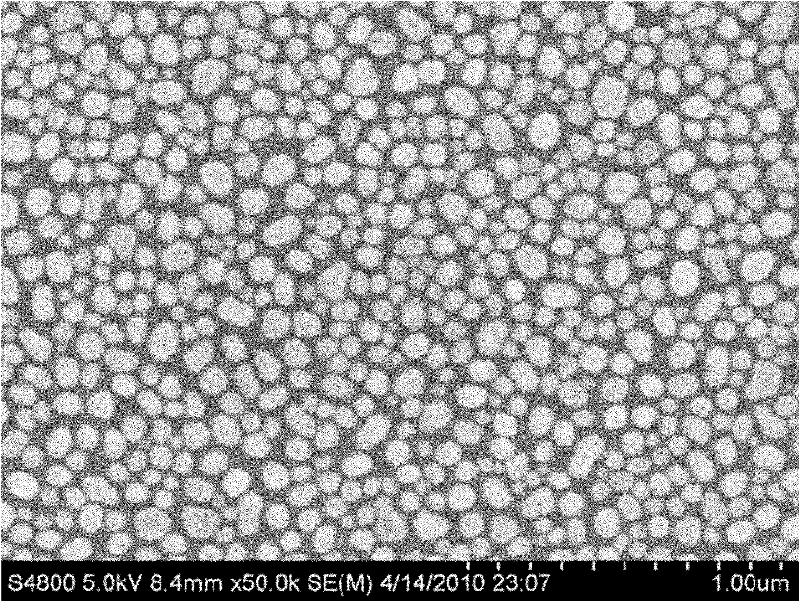

[0027] Then use electron beam evaporation (the size of the electron ...

Embodiment 2

[0037] The P-type epitaxial silicon wafer (the substrate resistivity is less than 0.004Ω·cm, the epitaxial layer thickness is 11.4μm, and the resistivity is 2.5Ω·cm) is cleaned by standard RCA and the surface oxide layer is removed with hydrofluoric acid. The standard RCA cleaning steps are as follows: Put the P-type epitaxial silicon wafer into No. 1 cleaning solution (the volume ratio of ammonia water, hydrogen peroxide water and deionized water is 1:1:5), and put it in a water bath at about 80°C (80±5°C). Place it in the middle for 15 to 20 minutes; fully wash the P-type epitaxial silicon wafer with deionized water, put the cleaned P-type epitaxial silicon wafer into No. 2 cleaning solution (the volume ratio of hydrochloric acid, hydrogen peroxide and deionized water is 1:1: 6) Place it in a water bath at about 80°C (80±5°C) for 15-20 minutes, take it out and then wash it thoroughly with deionized water.

[0038] Then use the method of DC magnetron sputtering (sputtering po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com