A preparation method of quantum dot light-emitting diodes coupled with gold nanorods

A technology of quantum dot luminescence and gold nanorods, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, electrical components, etc. The effect of luminous intensity, short period and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

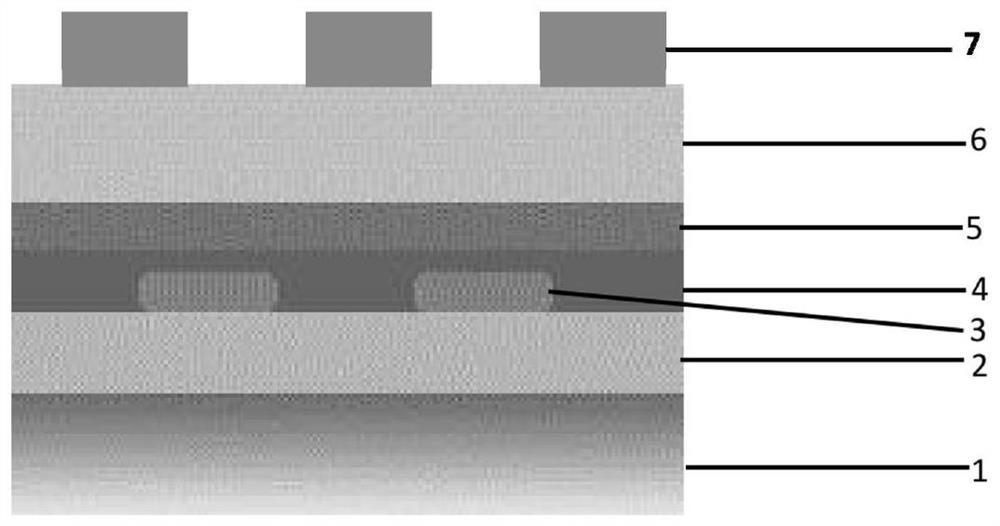

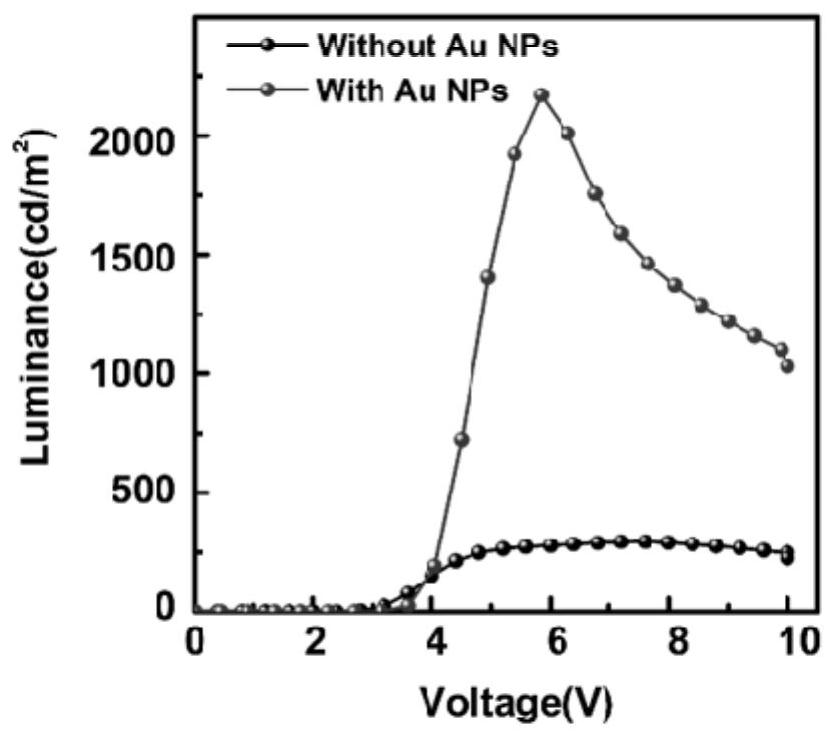

[0032] A method for preparing a quantum dot light-emitting diode coupled with gold nanorods, the method is specifically carried out according to the following steps:

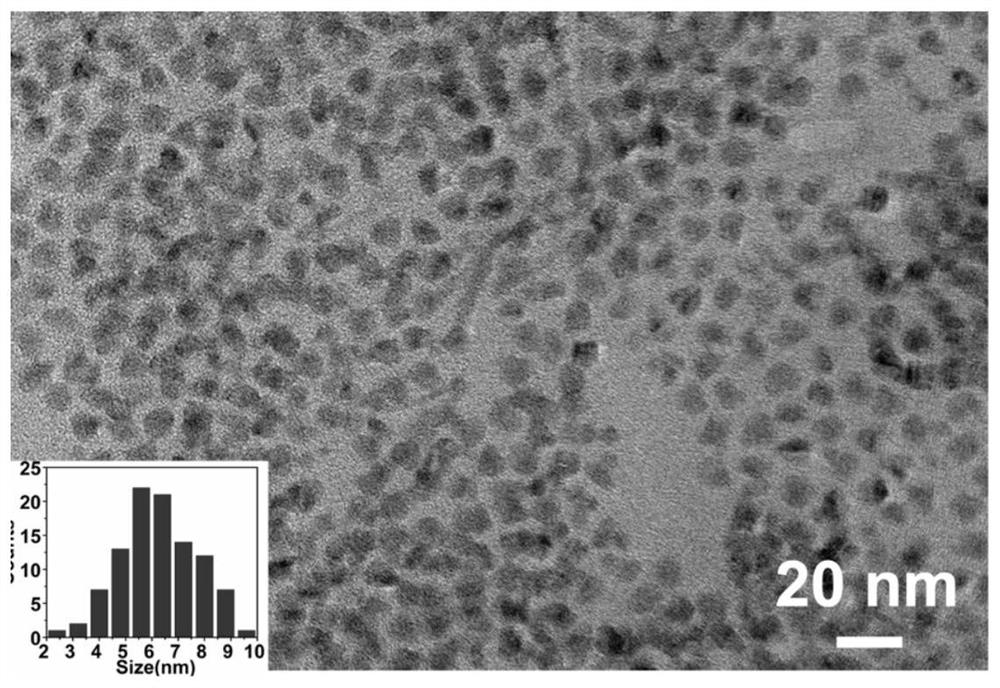

[0033] S1. Put cadmium stearate (0.1356g, 0.2mmol) and selenium powder (0.0079g, 0.1mmol) into a 25mL three-necked flask with 4mL 1-octadecene, stir and bubble with argon for 10 minutes , the flask was heated to 240°C at a heating rate of 40°C / min, and reacted for 40 minutes. After in-situ purification, a quantitative amount of cadmium-octane diethyldithiocarbamate was added, heated to 140°C, and reacted for 20 minutes. Then cool to 80°C, and then add a quantitative amount of cadmium-octane diethyldithiocarbamate solution for shell growth until the specified number of layers is reached, and the reaction is stopped to obtain a cadmium selenide / cadmium sulfide core-shell structure Quantum dots, the quantum dot particle size ≤ 10nm, average particle size 7nm, such as figure 2 Transmission electron microscope phot...

Embodiment 2

[0041] A method for preparing a quantum dot light-emitting diode coupled with gold nanorods, the method is specifically carried out according to the following steps:

[0042] S1. Put cadmium stearate (0.1356g, 0.2mmol) and selenium powder (0.0079g, 0.1mmol) into a 25mL three-necked flask with 4mL 1-octadecene, stir and bubble with argon for 10 minutes , the flask was heated to 240°C at a heating rate of 40°C / min, and reacted for 40 minutes. After in-situ purification, a quantitative amount of cadmium-octane diethyldithiocarbamate was added, heated to 140°C, and reacted for 20 minutes. Then cool to 80°C, and then add a quantitative amount of cadmium-octane diethyldithiocarbamate solution for shell growth until the specified number of layers is reached, and the reaction is stopped to obtain a cadmium selenide / cadmium sulfide core-shell structure Quantum dots, the quantum dot particle size ≤ 10nm, average particle size 7nm, such as figure 2 Transmission electron microscope photos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com