Fluorescent material, and preparation method and application thereof

A fluorescent material and hydrosilylation reaction technology, applied in the field of fluorescent materials, can solve the problems of destroying the fluorescent properties of mesoporous materials, photofading, environmental pollution, etc., and achieve good biocompatibility, strong resistance to photofading, and photostability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

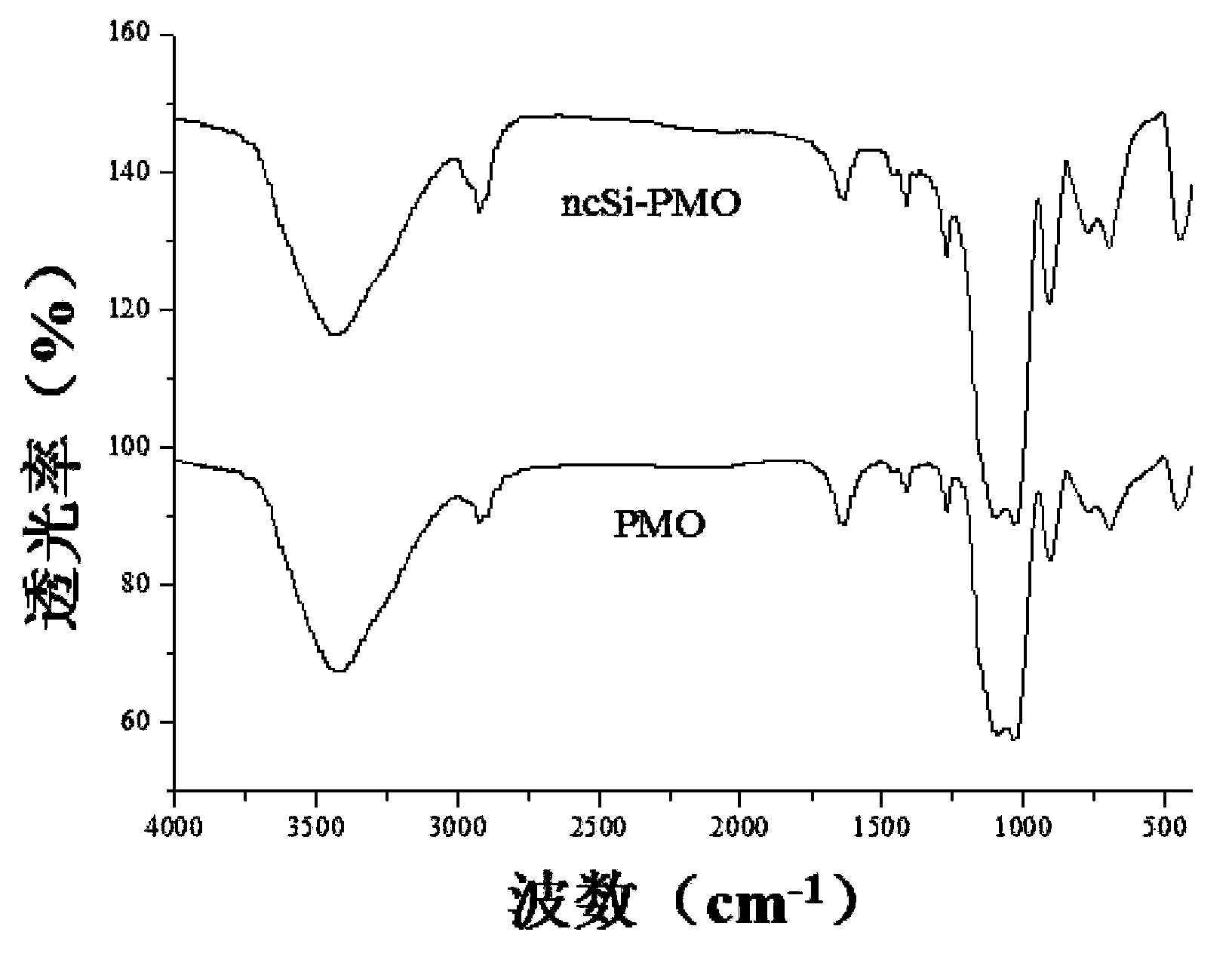

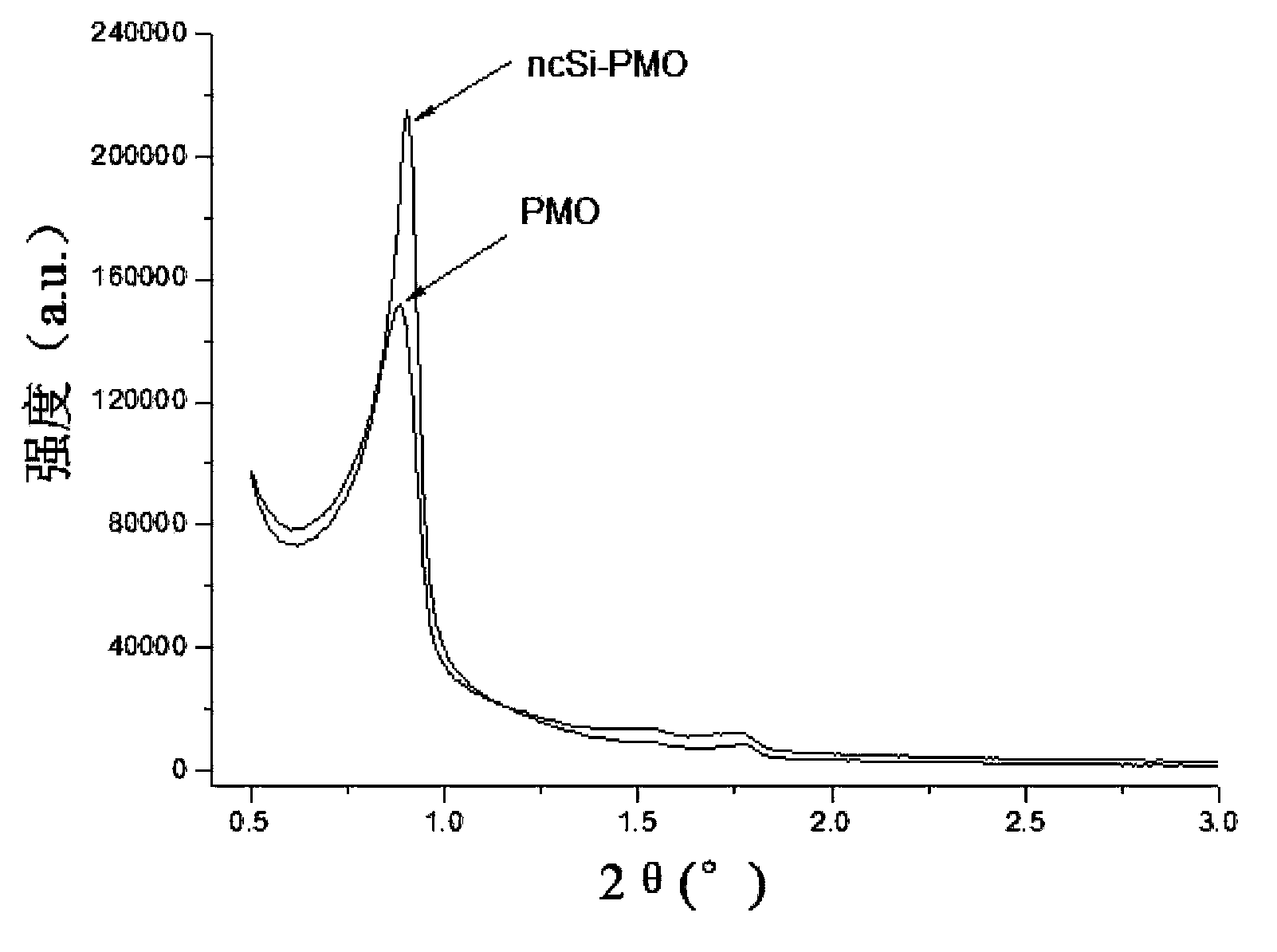

[0024] The ordered mesoporous organosilicon material is commercially available or can be prepared. The preparation of the ordered mesoporous organic silicon material can be carried out according to conventional methods in the art, for example, the preparation method of the ordered mesoporous organic silicon material can include: polyoxyethylene-polyoxypropylene-polyoxyethylene ( P123) was dissolved in an aqueous solution of potassium chloride, then added hydrochloric acid solution and 1,2-bistrimethoxysilylethane (BTME) in sequence, then stirred and mixed at 10-60°C for 1-30 minutes and placed for 5- 50 hours, and then react in an autoclave at 80-120° C. for 5-50 hours. After the reaction, the solid product is collected, and the ordered mesoporous organic silicon material is separated from the solid product.

[0025] In the above method for preparing ordered mesoporous silicone material, the weight ratio of the amount of P123 to the amount of BTME can be 100:80-200, preferably...

preparation example 1

[0044] Preparation of PMO materials

[0045] At 40°C, 1 g of P123 (purchased from sigma-Aldrich) was dissolved in 2.98 g of 1.0 mol L -1 In the KCl aqueous solution, add 40g concentration to it again and be 0.167mol L -1 hydrochloric acid solution, and then 1.40 g of BTME (purchased from sigma-Aldrich) was added to the mixed solution and stirred. Stirring was stopped after 10 minutes, and the reaction system was left standing at 40° C. for 1 day. Subsequently, the mixture was transferred to an autoclave, and reacted at 100° C. for 24 hours. After the reaction, the solid product was collected by filtration and dried at room temperature. Finally, the solid product was subjected to Soxhlet extraction with ethanol to obtain the PMO material.

preparation example 2

[0047] Preparation of Modified Silicon Nanocrystals

[0048] At -75°C, mix 25ml of deionized water with 10ml of trichlorosilane, react for 1.5 hours to get a white precipitate, separate the white precipitate, and vacuum dry the white precipitate, then transfer it to a tube furnace, Burning at 1100° C. for 1 hour gave a brown complex. The compound was ground to a particle size below 1 mm, then 0.6 g of the ground compound was placed in a plastic beaker, 9 ml of deionized water, 18 ml of ethanol and 30 ml of hydrofluoric acid (48% by weight) were added thereto. After reacting for 3 hours, silicon nanocrystals with a particle size of about 3 nanometers were obtained, and then the silicon nanocrystals were extracted with n-decane to obtain a n-decane solution of silicon nanocrystals.

[0049] The n-decane solution of the silicon nanocrystals was transferred into a round bottom flask, and 9ml of vinyltriethoxysilane was added thereto; then frozen at -75°C, then decompressed and pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com