Organic field effect transistor device and preparation method thereof

A transistor and organic field technology, applied in the field of organic field effect transistor devices and their preparation, can solve the problems of development limitations, low crystallinity of triazine covalent organic framework materials, etc., and achieve easy access, broadened application range, semiconductor performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] This embodiment provides a method for preparing an organic field effect transistor device, the preparation method comprising the following steps:

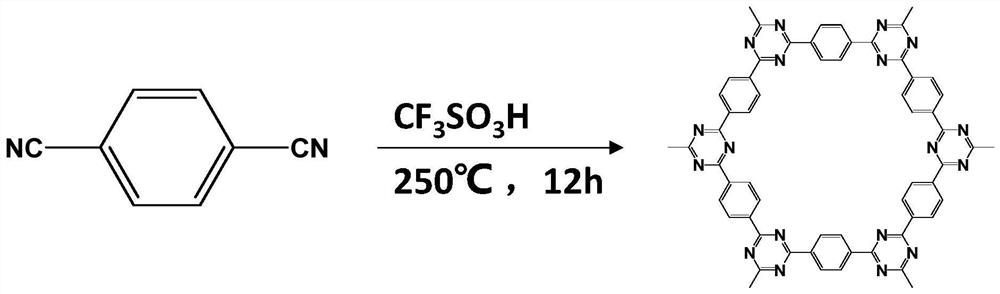

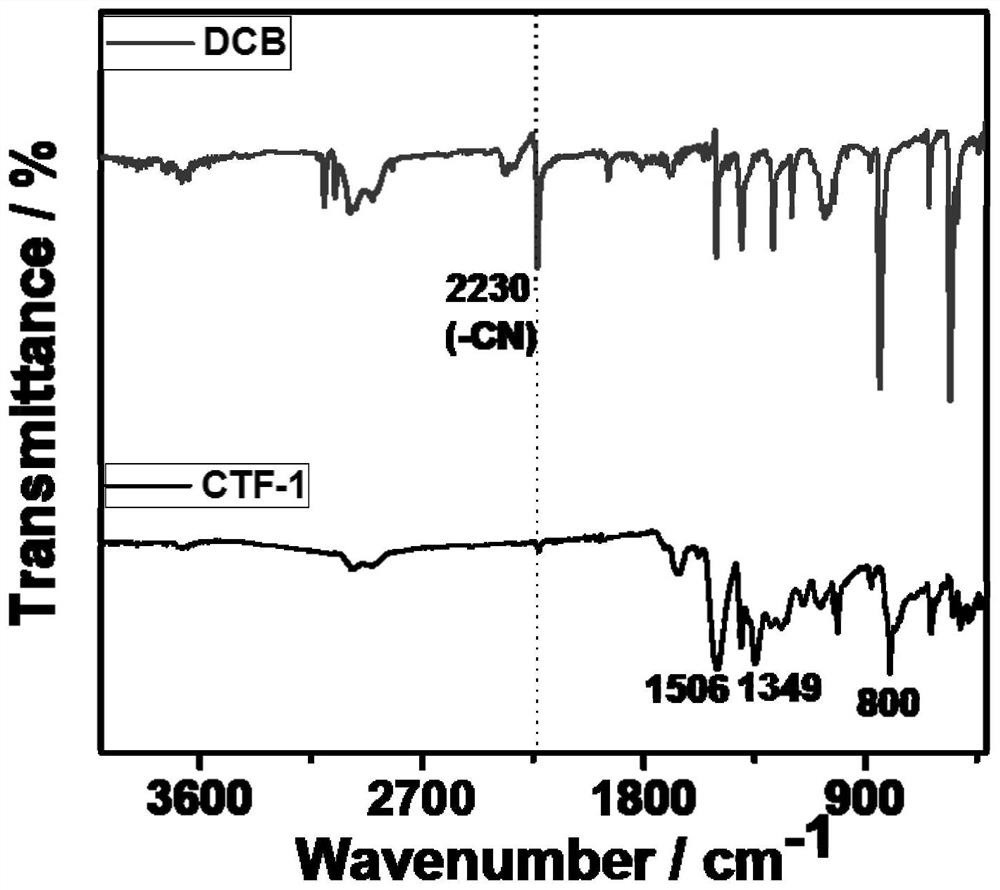

[0056] S1: Terephthalonitrile (2mmol, 0.256g) and trifluoromethanesulfonic acid (CF 3 SO 3 H, 1mmol, 0.15g) is put into the ampoule bottle; The ampoule bottle is carried out freezing, degassing and thawing treatment successively under liquid nitrogen; The ampoule bottle processed through thawing is sealed with flame, and the sealed ampoule bottle is put into Put it into a muffle furnace, heat up from room temperature to 250 °C at a rate of 5 °C / min, and keep it for 12 hours; after completion, cool the ampoule to room temperature and soak it in liquid nitrogen for 10 min; The processed sealed ampoules were opened in a fume hood, the solids were collected, ground into powder, and the powder was washed with water, N,N-dimethylformamide and ethanol in sequence, and the cleaned powder was heated at 100°C Vacuum drying for 12h, ...

Embodiment 2

[0064] This embodiment provides a method for preparing an organic field effect transistor device. The difference between the method of this embodiment and Example 1 is that terephthalonitrile (2mmol) and 1,4-dicyanotetrafluorobenzene (2mmol) ) into an ampoule bottle to prepare a fluorinated donor-acceptor type covalent triazine framework material, and then use the fluorinated donor-acceptor type covalent triazine framework material to prepare an organic field effect transistor device.

[0065] The structure of the organic field effect transistor device prepared according to the method of this embodiment includes Figure 9 The organic semiconductor layer, gate, source and drain are shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com