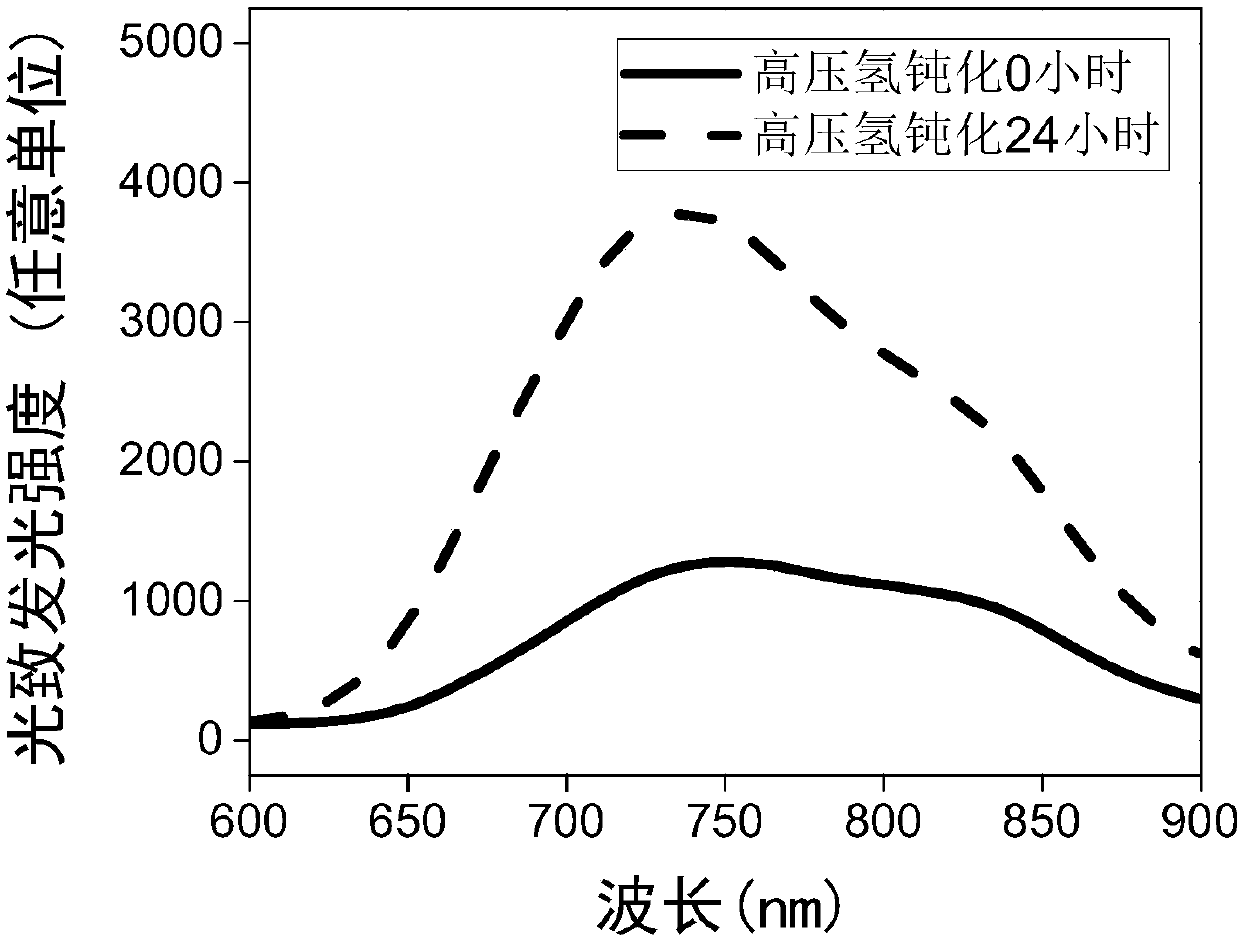

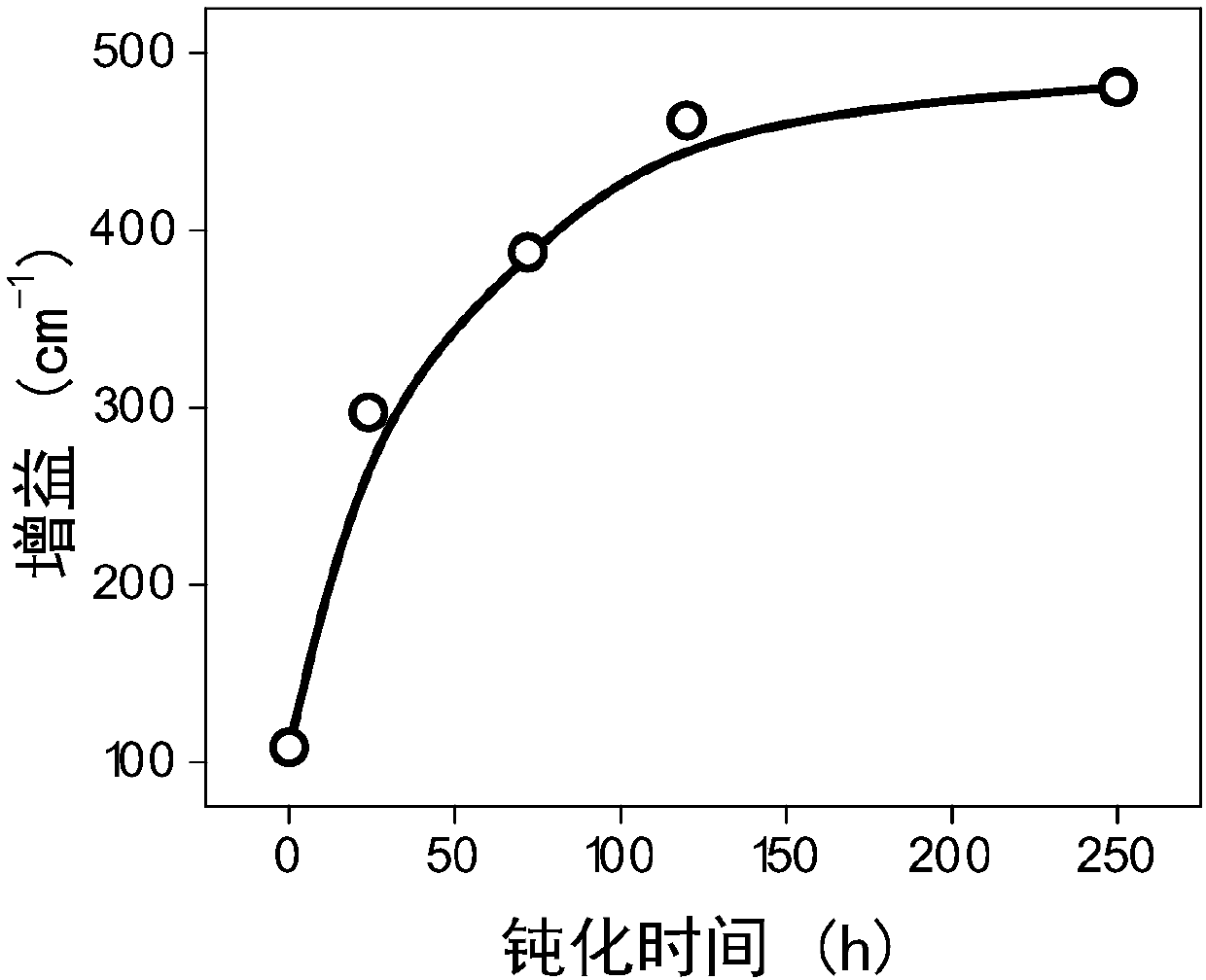

Method for preparing silicon nanocrystalline with optical gain which can be improved by high-pressure hydrogen passivation

A silicon nanocrystal, high-pressure hydrogen technology, applied in chemical instruments and methods, nanotechnology, inorganic chemistry, etc., can solve the problems of destroying the structure of the light-emitting layer, increasing the quenching center, structural defects, etc., to achieve the effect of improving light gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Raw material and formula

[0031] Substrate: polished on both sides, volume is 10×10×0.1mm 3 High temperature resistant quartz substrate;

[0032] Precursor material: Dow Corning FOx-1x and FOx-2x Flowable Oxides, Dow Corning Corporation;

[0033] Substrate cleaning solution: alcohol (analytical grade), Sinopharm Chemical Reagent Co., Ltd.;

[0034] 2. Process parameter setting

[0035] Film throwing conditions: room temperature, clean environment;

[0036] Annealing temperature: 1000°C;

[0037] Annealing time: 50 minutes

[0038] Subsequent cooling parameters: in-tube cooling after power failure, 1 hour

[0039] Passivation temperature: 100°C

[0040] Passivation duration: 24, 72, 120, 240 hours;

[0041] 3. Production device

[0042] VD650 ultra-clean workbench, Suzhou Su Clean Equipment Co., Ltd.

[0043] SK2-4-12 program-controlled tubular resistance furnace, Shanghai Shiyan Electric Furnace Co., Ltd.

Embodiment 2

[0053] 1. Raw material and formula

[0054] Substrate: polished on both sides, volume is 20×20×0.2mm 3 High temperature resistant quartz substrate;

[0055] Precursor material: Dow Corning FOx-1x and FOx-2x Flowable Oxides, Dow Corning Corporation;

[0056] Substrate cleaning solution: alcohol (analytical grade), Sinopharm Chemical Reagent Co., Ltd.;

[0057] 2. Process parameter setting

[0058] Film throwing conditions: room temperature, clean environment;

[0059] Annealing temperature: 1150°C;

[0060] Annealing time: 90 minutes

[0061]Subsequent cooling parameters: in-tube cooling after power failure, 3 hours

[0062] Passivation temperature: 300°C

[0063] Passivation duration: 24, 72, 120, 240 hours;

[0064] 3. Production device

[0065] VD650 ultra-clean workbench, Suzhou Su Clean Equipment Co., Ltd.

[0066] SK2-4-12 program-controlled tubular resistance furnace, Shanghai Shiyan Electric Furnace Co., Ltd.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com