GeSn phototransistor based on III-V group material emitter region and manufacturing method thereof

A III-V, phototransistor technology, used in final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve problems such as low detection sensitivity, and achieve high sensitivity, large photocurrent magnification, and high optical gain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

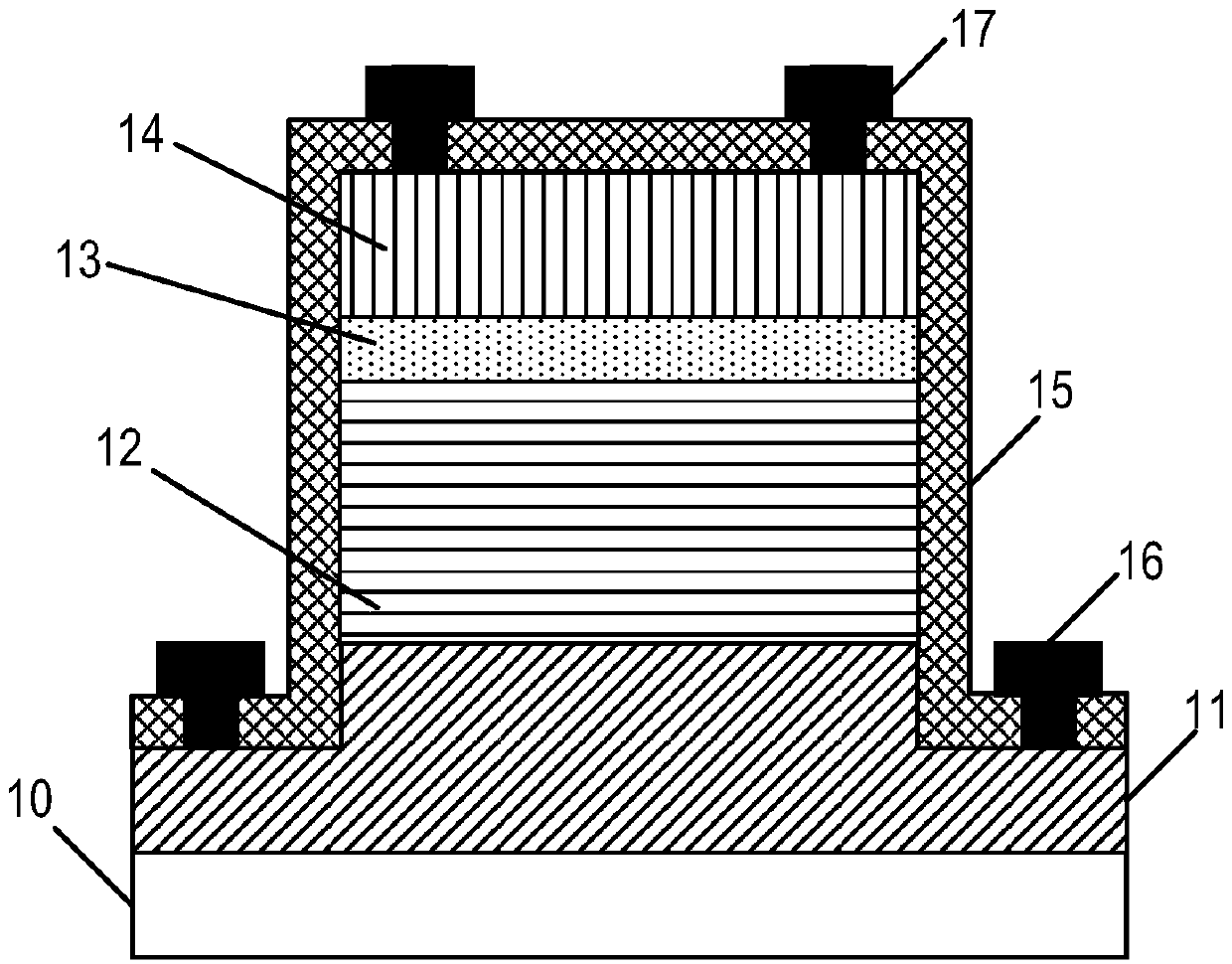

[0040] This specific embodiment provides a GeSn phototransistor based on the III-V group material emitter region, with figure 1 It is a structural schematic diagram of a GeSn phototransistor based on a III-V group material emitter region in the first embodiment of the present invention.

[0041] Such as figure 1 As shown, the GeSn phototransistor based on the emitter region of the III-V group material provided in this specific embodiment includes a substrate 10 and collectors stacked on the surface of the substrate 10 in sequence along a direction perpendicular to the substrate 10 Region 11, absorption layer 12, base region 13 and emitter region 14; the absorption layer 12 and the base region 13 use Ge 1-x sn x Composed of materials, wherein, 01-x sn x The lattice mismatch degree of the material is less than a preset value, and the energy bandgap of the III-V group material is larger than the Ge 1-x sn x Material.

[0042] In this specific embodiment, using Ge 1-x sn x...

no. 2 Embodiment approach

[0064] This specific embodiment provides a GeSn phototransistor based on the III-V group material emitter region, with Figure 4 It is a schematic structural diagram of a GeSn phototransistor based on a III-V group material emitter region in the second specific embodiment of the present invention. For the same parts as the first specific embodiment, this specific embodiment will not repeat it, and the differences from the first specific embodiment will be mainly described below.

[0065] Such as Figure 4 As shown, the GeSn phototransistor based on the emitter region of the III-V group material provided in this specific embodiment includes a substrate 40 and collectors sequentially stacked on the surface of the substrate 40 along a direction perpendicular to the substrate 40 Region 41, absorption layer 42, base region 43 and emitter region 44; the absorption layer 42 and the base region 43 use Ge 1-x sn x Composed of materials, wherein, 01-x sn x The lattice mismatch degre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com