Relaxation GeSn infrared avalanche photodetector and manufacturing method thereof

A technology of avalanche optoelectronics and manufacturing methods, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problem of low sensitivity of GeSn infrared photodetectors, and achieve the effect of high sensitivity and large photocurrent magnification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation of the relaxation GeSn infrared avalanche photodetector and its manufacturing method provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

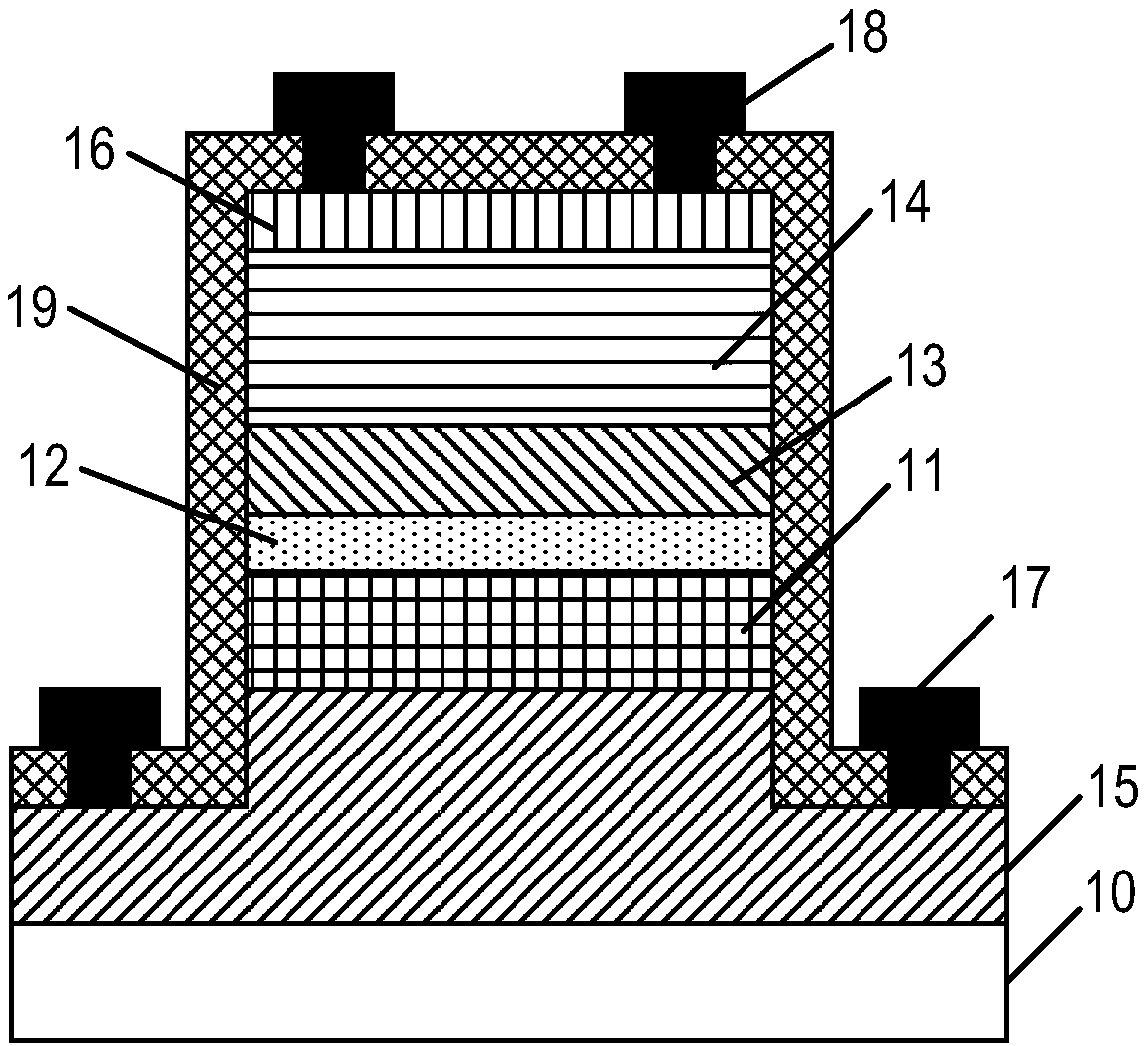

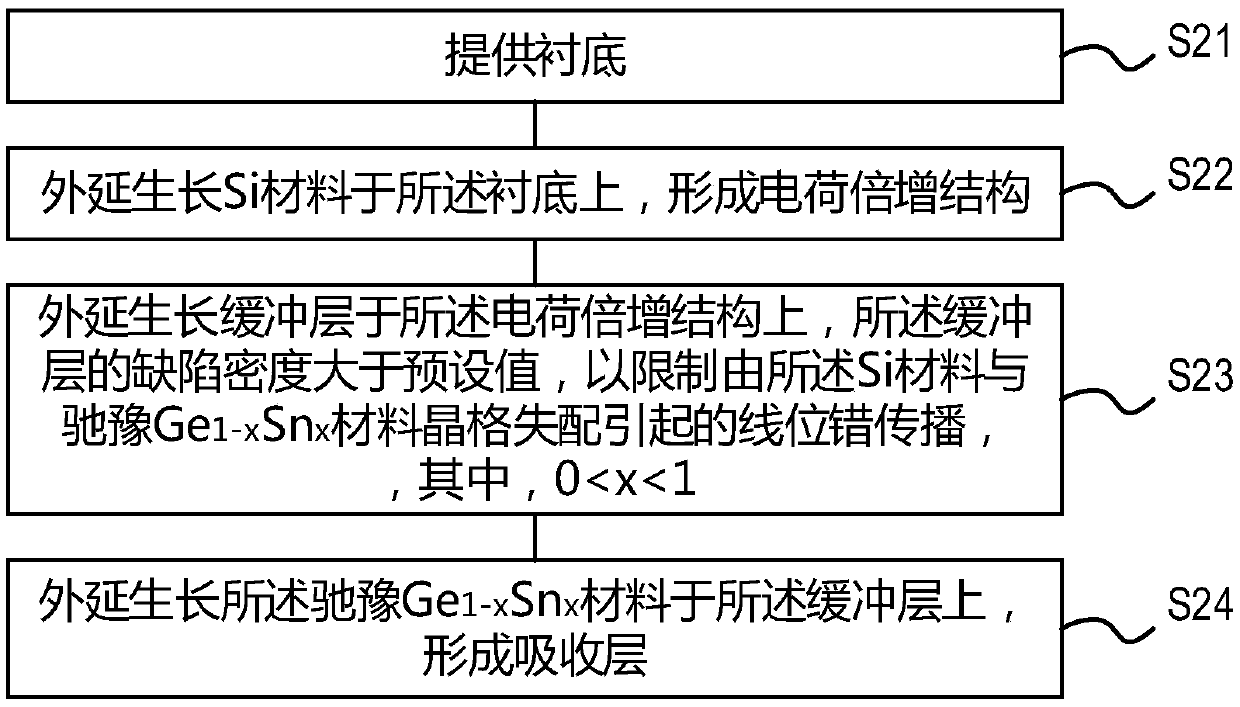

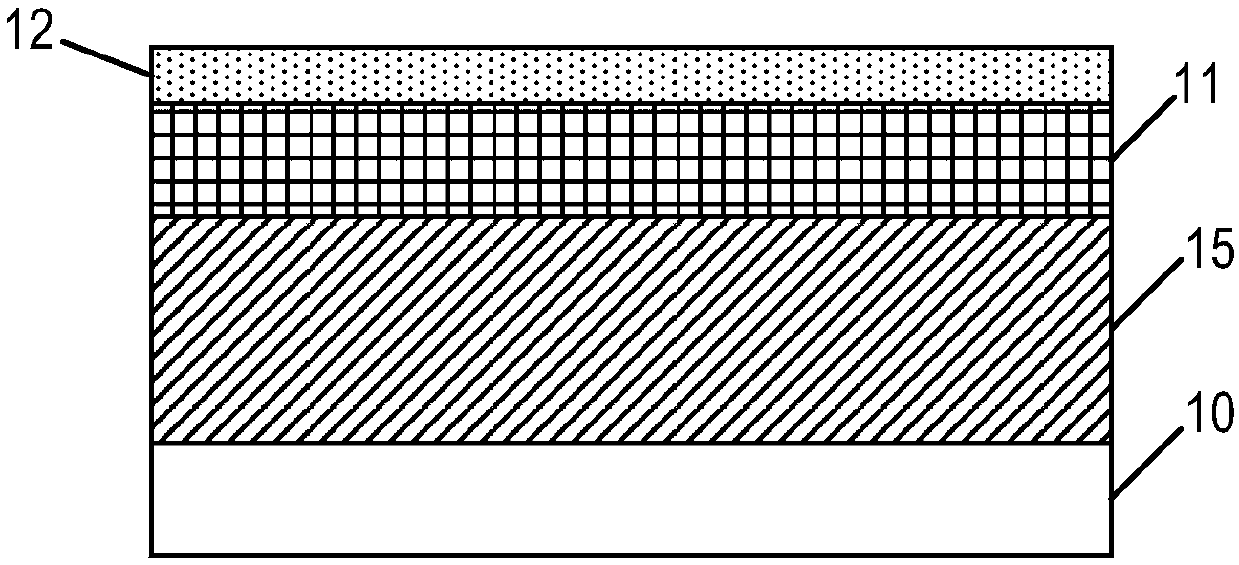

[0040] This specific embodiment provides a kind of relaxation GeSn infrared avalanche photodetector, with figure 1 It is a structural schematic diagram of a relaxed GeSn infrared avalanche photodetector in a specific embodiment of the present invention. Such as figure 1 As shown, the relaxed GeSn infrared avalanche photodetector provided in this specific embodiment includes a substrate 10 and a charge multiplication structure, a buffer layer 13 and an absorbing layer stacked on the substrate 10 in sequence along a direction perpendicular to the substrate 10. Layer 14; the charge multiplication structure is made of Si material; the absorption layer 14 is made of relaxed Ge 1-x sn x material, wherein, 01-x sn x Wire dislocation propagation du...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com