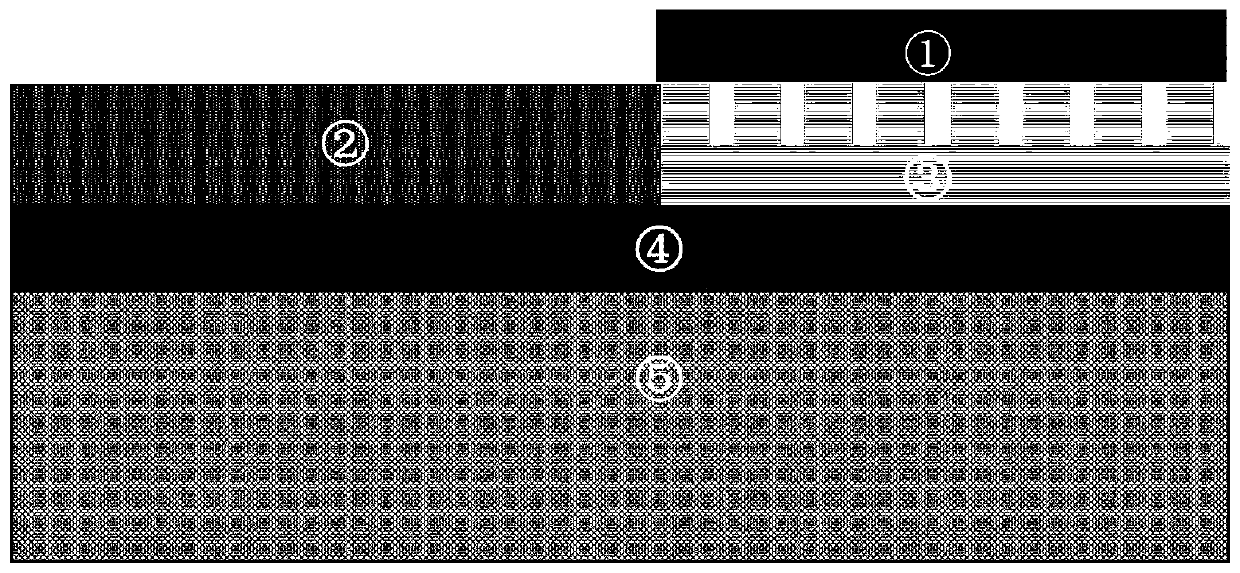

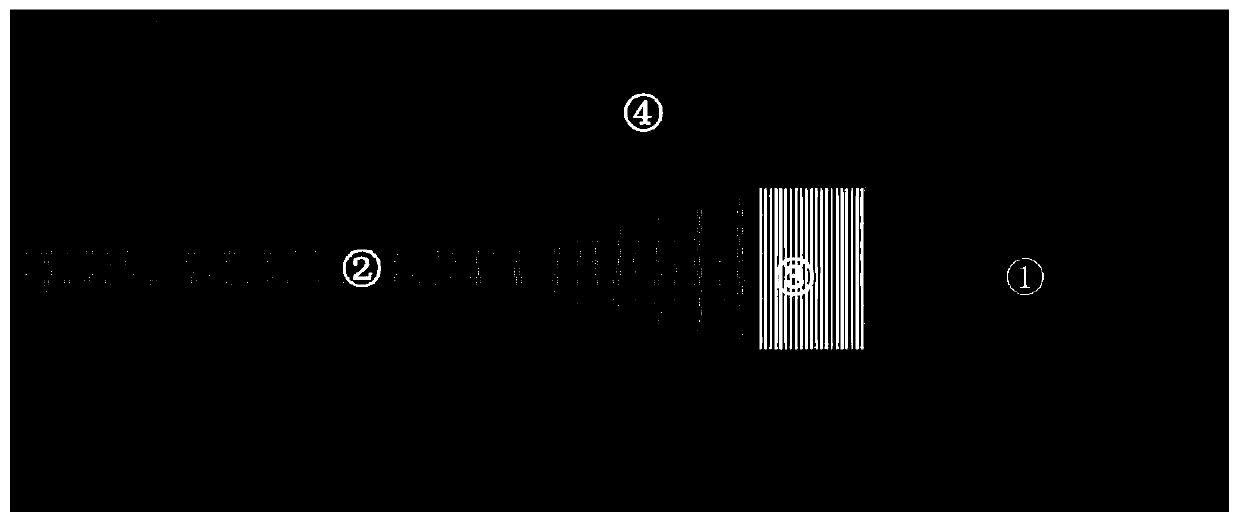

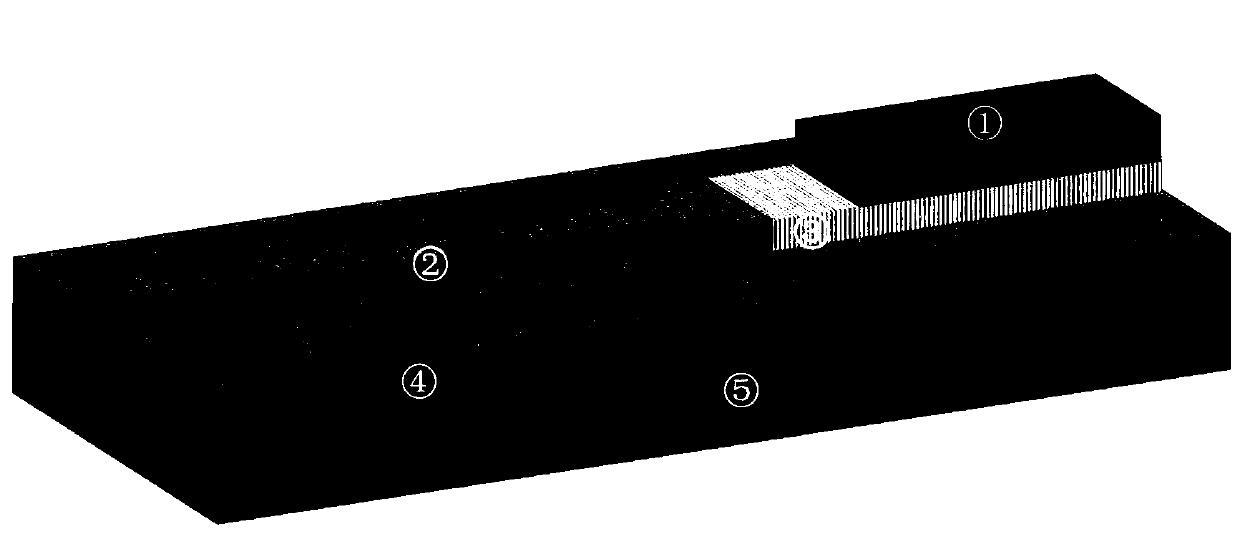

Distributed feedback laser of monolithic integrated silicon optical chip and preparation method thereof

A distributed feedback and silicon photonics chip technology, applied in the direction of lasers, laser components, semiconductor lasers, etc., can solve the problems of CMOS process incompatibility, low optical coupling efficiency, complex preparation process, etc., to achieve complete CMOS process compatibility, The effect of compact device structure and mature manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following examples are used to illustrate the present invention, but not to limit the present invention.

[0044] 1. Raw material and formula

[0045] Substrate: polished on both sides, volume is 20×20×0.2mm 3 SOI substrate;

[0046] Doping solvent: MIBK, Shanghai Aladdin Biochemical Technology Co., Ltd.;

[0047] Doping solute: ErI 3 , Shanghai Aladdin Biochemical Technology Co., Ltd.;

[0048] Gain Materials: Dow Corning FOx-1x and FOx-2x Flowable Oxides, Dow Corning Corporation;

[0049] Substrate cleaning solution: alcohol (analytical grade), acetone (analytical grade), Sinopharm Chemical Reagent Co., Ltd.;

[0050] Photoresist cleaning agent: phosphoric acid (analytical grade), hydrogen peroxide (analytical grade), concentrated sulfuric acid, Sinopharm Chemical Reagent Co., Ltd.

[0051] 2. Production device

[0052] Plasmalab System 120 Inductively Coupled Plasma Etcher, Oxford Instruments Ltd;

[0053] SK2-4-12 program-controlled tubular resistance fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com