Capacitor and manufacturing method thereof

A technology of capacitors and electrodes, which is applied in the field of semiconductor devices, can solve problems such as complex processes, and achieve the effect of simple processes and improved capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

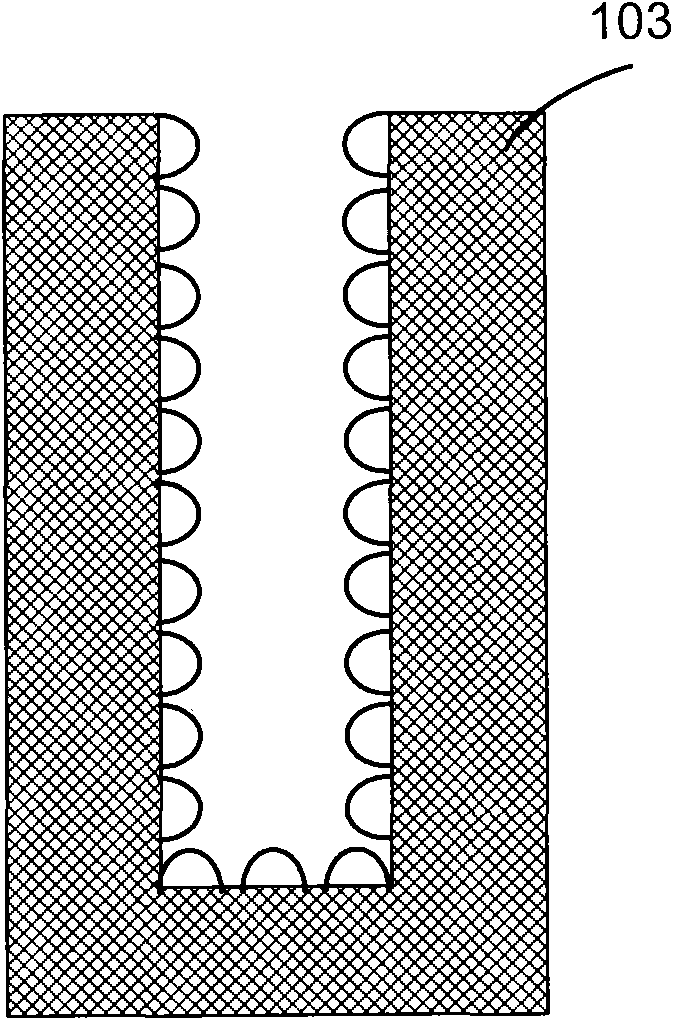

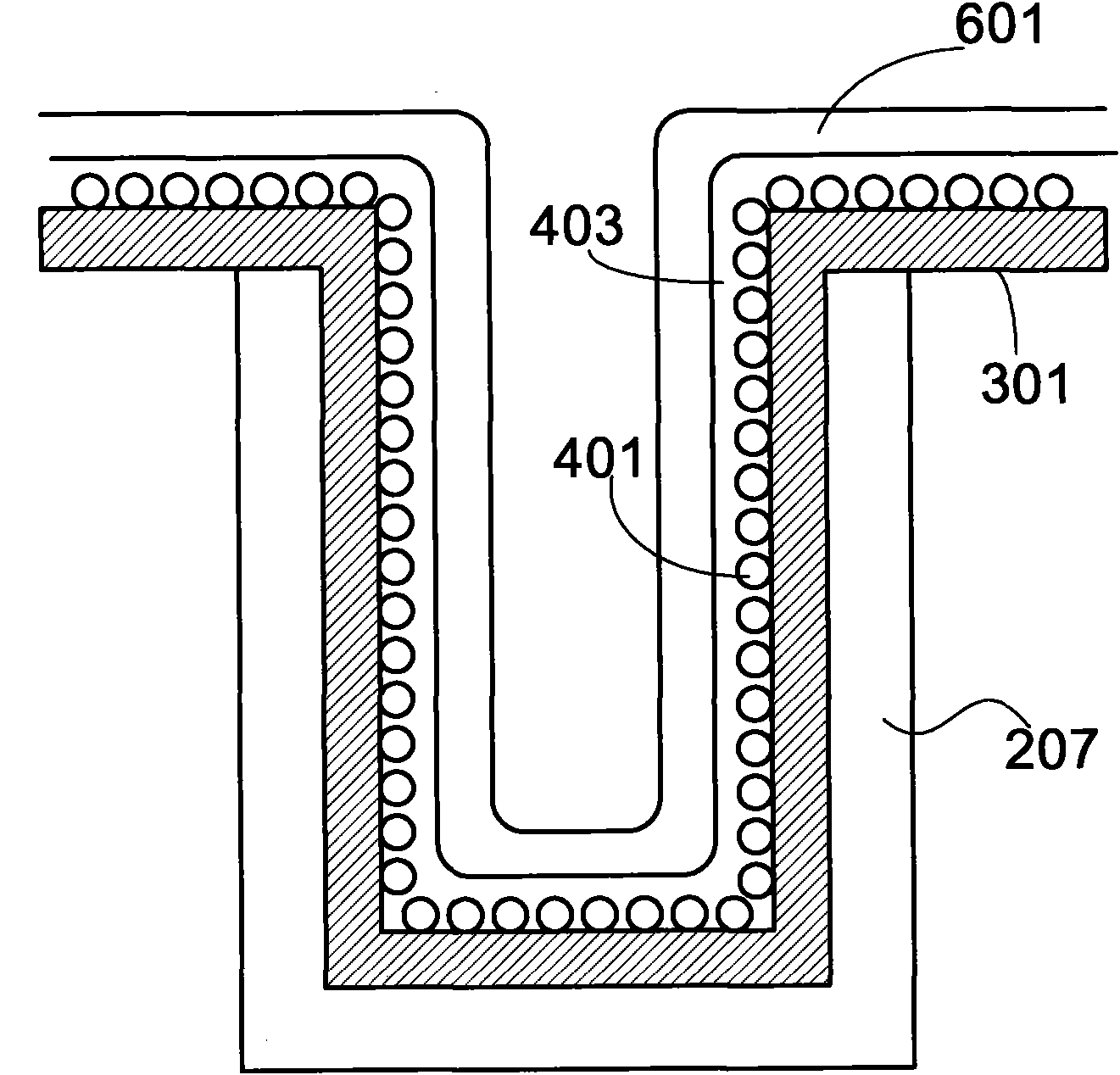

[0034] The present invention provides a capacitor, the capacitor includes a first electrode, a first dielectric layer on the first electrode, a silicon nanocrystal on the first dielectric layer, a silicon nanocrystal and the A second dielectric layer on the exposed portion of the first dielectric layer, a second electrode on the second dielectric layer. The silicon nanocrystals increase the interface area between the dielectric layer and the electrode, and when the capacitor is charged, more charges are attracted to the interface, thereby increasing the capacitance of the capacitor.

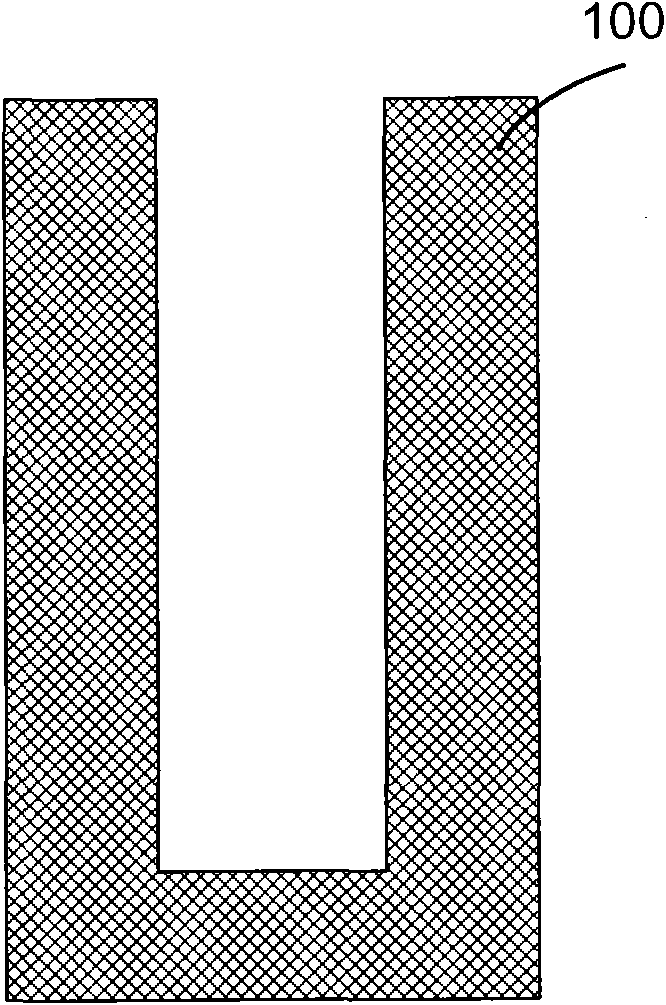

[0035] Specific examples reference figure 2 , figure 2 A schematic diagram of the structure of the capacitor according to the first embodiment of the present invention is given, and the capacitor includes a first electrode 207, and the first electrode is made of such as doped polysilicon, a compound of a conductive material, or a metal; the first electrode 207 has a first length and a first w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com