Fluorescent material, and preparation method and application thereof

A technology of fluorescent materials and mesoporous materials, applied in the field of fluorescent materials, can solve the problems of destroying the fluorescence properties of mesoporous materials, poor chemical corrosion resistance, photofading, etc., and achieve good biocompatibility, strong resistance to photofading, The effect of good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] In one embodiment, the preparation method of ncSi may include: in the presence of an organic solvent, mixing silicon nanocrystals with the silane compound, cooling to -50°C to -100°C for freezing and degassing, and then raising the temperature to 150 -200°C, and react at this temperature for 8-16 hours (such as overnight reaction), and then carry out vacuum distillation to remove the unreacted silane compound and the organic solvent, thereby obtaining ncSi. The organic solvent is a solvent capable of dissolving the silicon nanocrystals, such as n-decane, ethanol, chloroform and the like.

[0026] The silicon nanocrystals can be obtained commercially, and can also be prepared according to conventional methods. For example, the preparation method can include: contacting and reacting trichlorosilane with excess deionized water at 0-78°C for 1-2 hours, and then filtering And collect the precipitate, burn the precipitate (such as burning at 800-1500°C for 0.5-3 hours), grind...

preparation example

[0039] Preparation of Modified Silicon Nanocrystals

[0040] At -75°C, mix 25ml of deionized water with 10ml of trichlorosilane, react for 1.5 hours to get a white precipitate, separate the white precipitate, and vacuum dry the white precipitate, then transfer it to a tube furnace, Burning at 1100° C. for 1 hour gave a brown complex. The compound was ground to a particle size below 1 mm, then 0.6 g of the ground compound was placed in a plastic beaker, 9 ml of deionized water, 18 ml of ethanol and 30 ml of hydrofluoric acid (48% by weight) were added thereto. After reacting for 3 hours, silicon nanocrystals with a particle size of about 3 nanometers were obtained, and then the silicon nanocrystals were extracted with n-decane to obtain a n-decane solution of silicon nanocrystals.

[0041] The n-decane solution of the silicon nanocrystals was transferred into a round bottom flask, and 9ml of vinyltriethoxysilane was added thereto; then frozen at -75°C, then decompressed and pu...

Embodiment 1

[0043] This example is used to illustrate the fluorescent material and its preparation method of the present invention.

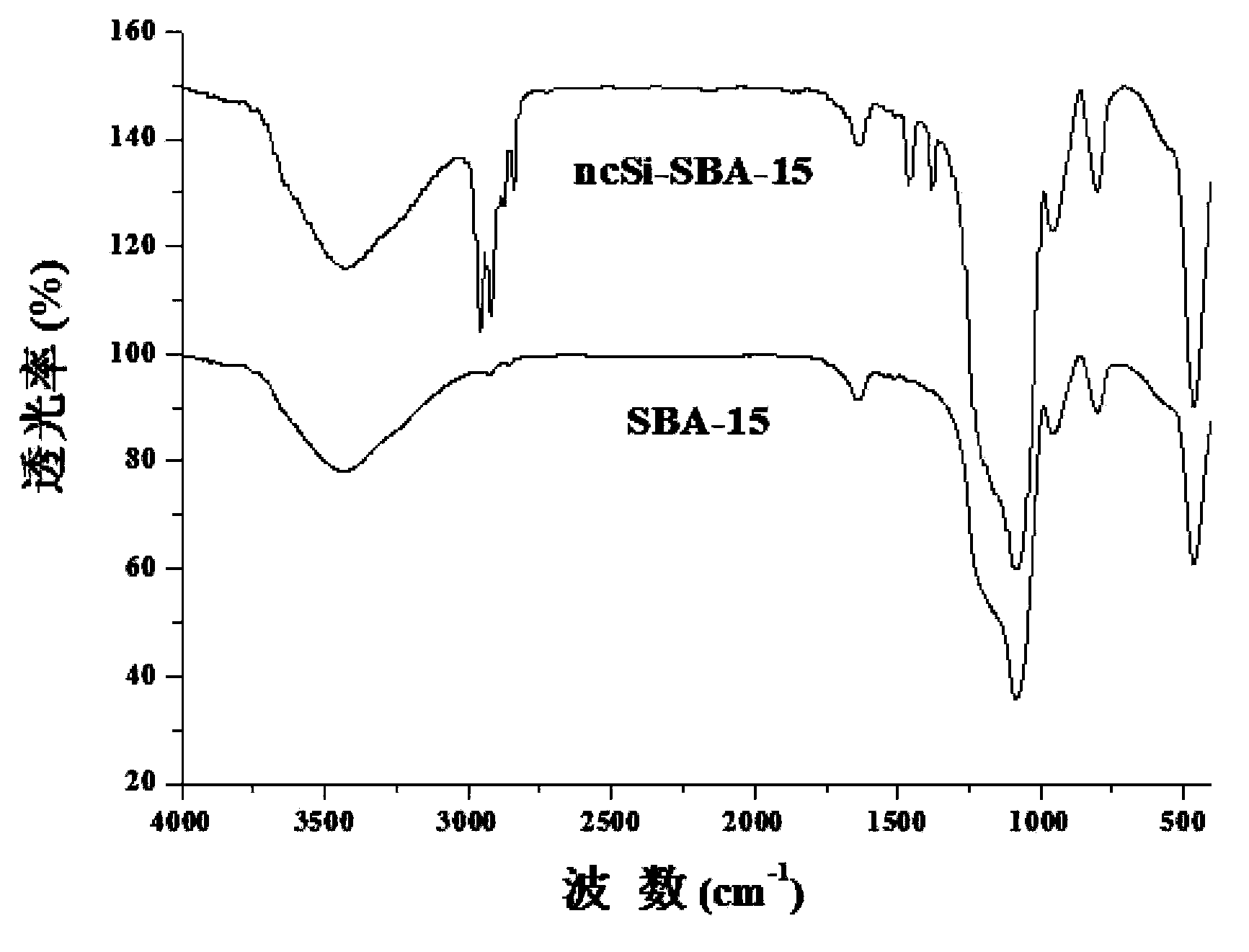

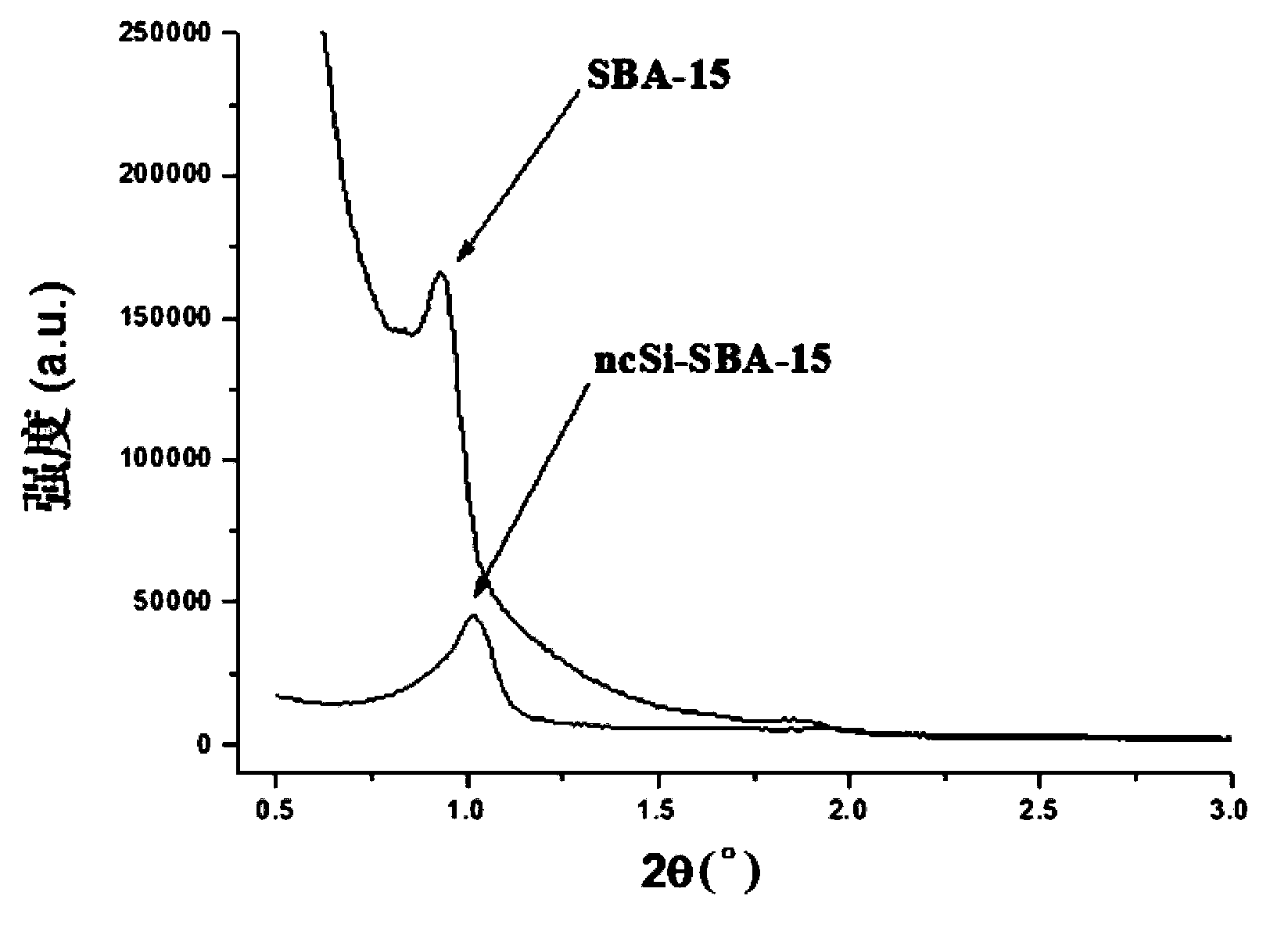

[0044] Dissolve 1.025 g of the modified silicon nanocrystal prepared in the above preparation example in 8.074 g of ethanol, stir to fully dissolve the modified silicon nanocrystal, take 0.36 g of the obtained solution, and then add 50 mg of mesoporous Material SBA-15 (purchased from Jilin University High-tech Co., Ltd.), uniformly dispersed under stirring, and then added 0.1mol L -1 HCl in ethanol, adjust the pH to 1.5, and stir the reaction at 25 °C for 24 hr. After the reaction, the solid product was collected by centrifugation, washed with ethanol, and finally vacuum-dried to obtain fluorescent material A1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com