Preparing method of self-assembly forming-dimension-controllable silicon nanocrystal films

A technology of silicon nanocrystals and self-assembly, applied in semiconductor/solid-state device manufacturing, photovoltaic power generation, electrical components, etc., can solve problems such as random distribution of nanocrystals, narrow PL luminescence peak, and influence of crystal orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Self-assembly of the present invention forms a method for preparing a size-controllable silicon nanocrystal film, comprising the steps of:

[0029] 1) Choose glass or single crystal silicon wafer as the substrate, and pre-treat before coating;

[0030] The thickness of the substrate is 500 ~ 520um, and the surfactants cocoic acid monoethanolamide (CMEA), cocoic acid diethanolamide or commercially available white cat detergent, (flowing) deionized water, acetone, and absolute ethanol are successively passed through each Ultrasonic cleaning for 15-20min.

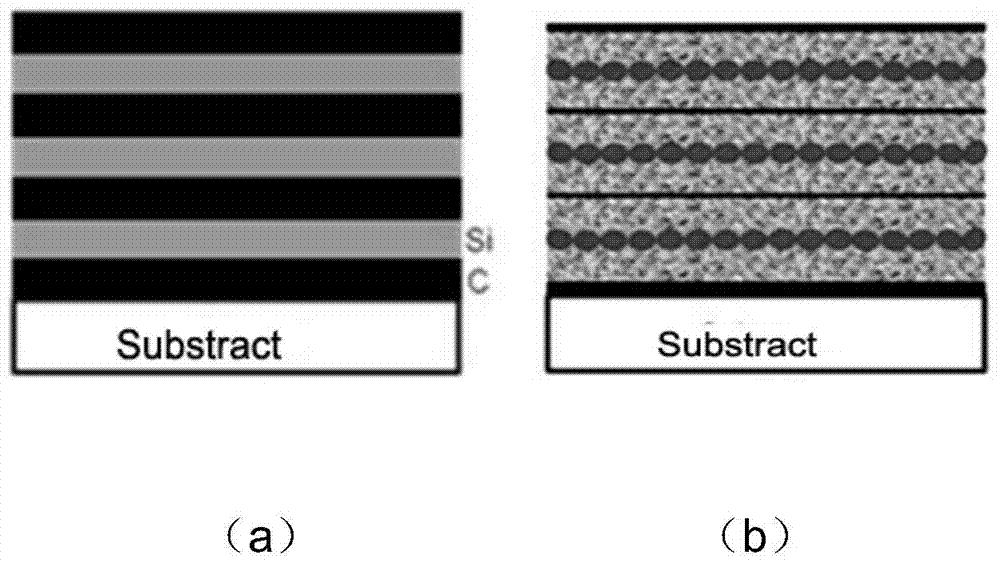

[0031] 2) Ar gas is used as the sputtering atmosphere. Under the condition of applying a bias voltage to the substrate, the silicon target and the carbon target are respectively subjected to magnetron co-sputtering by radio frequency and DC power, and amorphous silicon / silicon is alternately deposited on the glass or silicon substrate. Carbon superlattice structure multilayer film;

[0032] Among them, the method of a...

Embodiment 1

[0044] Glass is selected as the substrate and pre-treated before coating. The thickness of the substrate is 500um, and it is ultrasonically cleaned for 15 minutes by surfactant cocoic acid monoethanolamide (CMEA), (flowing) deionized water, acetone, and absolute ethanol.

[0045] Using argon as the sputtering gas, carry out magnetron co-sputtering on the silicon target and the carbon target, deposit the silicon layer and the carbon layer on the glass substrate, keep the thickness of the carbon layer at 10nm, change the thickness of the silicon layer, and make the modulation wavelength ratio 0.6 Superlattice Si / C multilayer thin film. Among them, the silicon target uses a 100W RF power supply, the carbon target uses a 100W DC power supply, and the substrate bias voltage is 80V; the sputtering Ar gas flow rate is 4 sccm; the deposition time is about 1.h, and the film thickness is about 120nm. The sample was annealed in stages under a nitrogen atmosphere: first, the temperature w...

Embodiment 2

[0049] A single crystal silicon wafer was selected as the substrate and pre-treated before coating. The thickness of the substrate was 520um, and it was ultrasonically cleaned for 20 minutes by the surfactant coconut acid diethanolamide, (flowing) deionized water, acetone, and absolute ethanol.

[0050] Using argon as the sputtering gas, carry out magnetron co-sputtering on the silicon target and the carbon target, deposit the silicon layer and the carbon layer on the single crystal silicon substrate, keep the thickness of the carbon layer at 10nm, change the thickness of the silicon layer, and make the modulated wavelength Superlattice Si / C multilayer films with a ratio of 0.7. Among them, the silicon target uses a 100W RF power supply, the carbon target uses a 100W DC power supply, and the substrate bias voltage is 80V; the sputtering Ar gas flow rate is 4 sccm; the deposition time is about 1.8h, and the film thickness is about 120nm. The sample was annealed in stages under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com