Preparation method of silicon carbide nanometer crystal whiskers

A technology of nano-whiskers and silicon carbide, which is applied in the field of preparation of silicon carbide nano-whiskers, can solve the problems of harsh reaction conditions, high toxicity and corrosion, and limited applications, and achieve the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

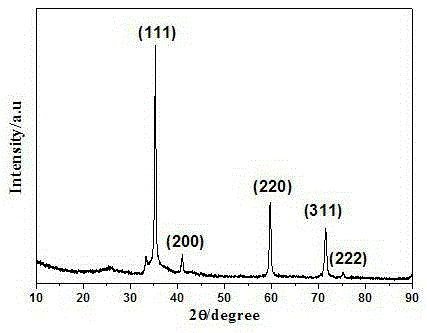

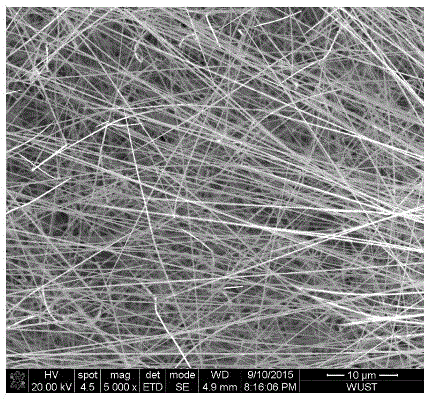

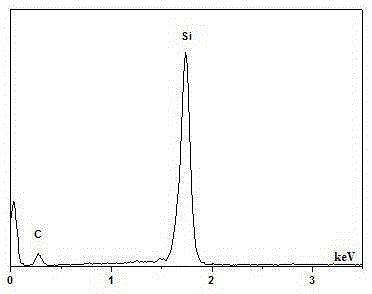

Image

Examples

Embodiment 1

[0033] Step 1. Preparation of silicon-doped pitch

[0034] According to the solid-liquid mass ratio of 1: (1~3), dissolve the pulverized asphalt in an organic solvent, let it stand for 6~8 hours, filter, and distill the filtered filtrate at 120~150°C to obtain asphalt Organic solvent soluble components.

[0035] Mix 10~20wt% organic silicon with 80~90wt% asphalt organic solvent soluble components to obtain asphalt mixture, and then dissolve the asphalt mixture in organic solvent according to the solid-liquid mass ratio of 1:(1~3) , and stirred for 2-3 hours to obtain a mixture of asphalt organic solvent-soluble components.

[0036] Move the mixture of asphalt organic solvent-soluble components to the reaction kettle, and raise the temperature to 250-300°C at a rate of 2-10°C / min under an inert atmosphere and stirring conditions, and keep it warm for 2-3 hours; then stop Stir and cool naturally in an inert atmosphere to obtain silicon-doped pitch.

[0037] Step 2. Preparatio...

Embodiment 2

[0044] Step 1. Preparation of silicon-doped pitch

[0045] According to the solid-liquid mass ratio of 1: (1~3), dissolve the pulverized asphalt in an organic solvent, let it stand for 6~8 hours, filter, and distill the filtered filtrate at 120~150°C to obtain asphalt Organic solvent soluble components.

[0046] Mix 20~30wt% organic silicon with 70~80wt% asphalt organic solvent soluble components to obtain asphalt mixture, and then dissolve the asphalt mixture in organic solvent according to the solid-liquid mass ratio of 1:(1~3) , and stirred for 2-3 hours to obtain a mixture of asphalt organic solvent-soluble components.

[0047]Move the mixture of asphalt organic solvent soluble components into the reaction kettle, raise the temperature to 300~350℃ at a rate of 2~10℃ / min under inert atmosphere and stirring condition, keep it warm for 3~4h; then stop Stir and cool naturally in an inert atmosphere to obtain silicon-doped pitch.

[0048] Step 2. Preparation of silicon-doped...

Embodiment 3

[0055] Step 1, preparation of silicon-doped resin

[0056] According to the solid-liquid mass ratio of 1: (1~3), dissolve the pulverized resin in an organic solvent, let it stand for 6~8 hours, filter, and distill the filtered filtrate at 120~150°C to obtain the resin Organic solvent soluble components.

[0057] Mix 30~40wt% silicone with 60~70wt% resin organic solvent soluble components to obtain a resin mixture, and then dissolve the resin mixture in an organic solvent according to the solid-to-liquid mass ratio of 1:(1~3) , and stirred for 2 to 3 hours to obtain a mixed solution of resin organic solvent soluble components.

[0058] Move the mixed liquid of the organic solvent-soluble components of the resin to the reaction kettle, raise the temperature to 350-400°C at a rate of 2-10°C / min under an inert atmosphere and stirring conditions, and keep it warm for 4-5h; then stop Stirring and natural cooling in an inert atmosphere yields a silicon-doped resin.

[0059] Step 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com