Method for manufacturing crystalline silicon high-efficiency solar cell

A technology of solar cells and crystalline silicon, applied in circuits, electrical components, final product manufacturing, etc., can solve the problems of low conversion efficiency and high price, and achieve easy mass production and industrialization, large short-circuit current, and equipment. and the effect of fewer process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further set forth the technical means and effects that the present invention takes for reaching the intended purpose of the invention, the specific implementation is described, and the detailed description is as follows:

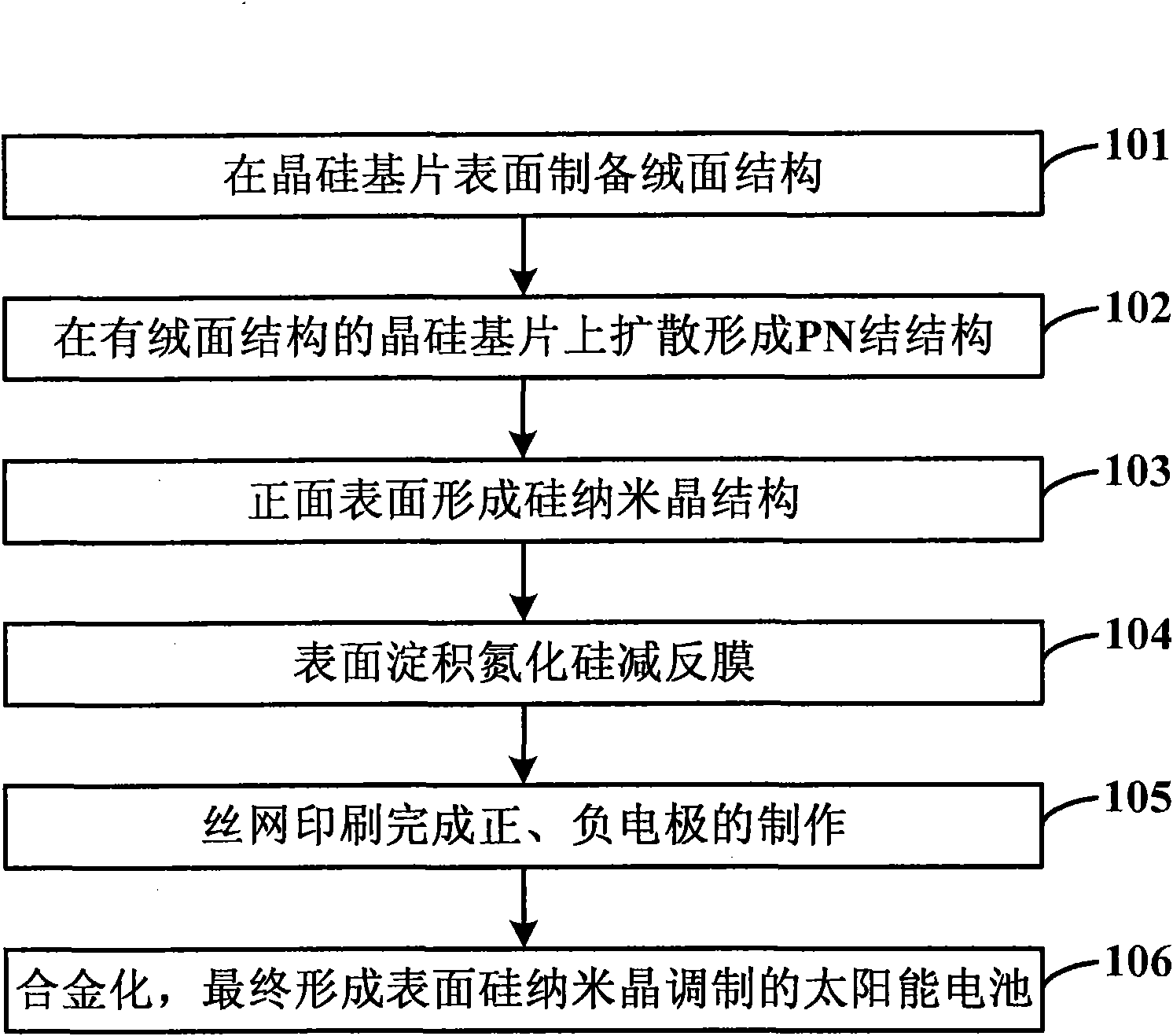

[0034] Such as figure 1 as shown, figure 1 A flow chart of a method for preparing a surface silicon nanocrystal modulated crystalline silicon high-efficiency solar cell provided by the present invention, the method includes the following steps:

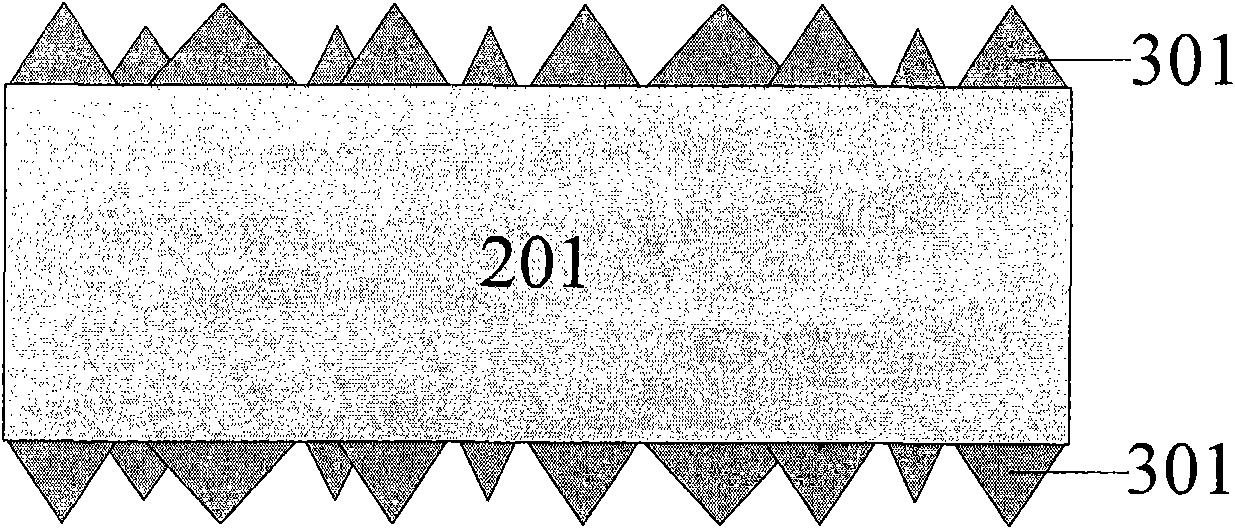

[0035] Step 101: preparing a textured structure on the surface of the crystalline silicon substrate;

[0036] Step 102: Diffusion on a crystalline silicon substrate with a textured structure to form a PN junction structure;

[0037] Step 103: forming a silicon nanocrystal structure on the front surface;

[0038] Step 104: Depositing a silicon nitride antireflection film on the surface;

[0039] Step 105: screen printing to complete the production of positive and negative electrodes;

[0040] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com