Composite pore molecular sieve and preparation method thereof

A molecular sieve and composite pore technology, applied in the direction of molecular sieves and alkali exchange compounds, chemical instruments and methods, crystalline aluminosilicate zeolites, etc. Poor adaptability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

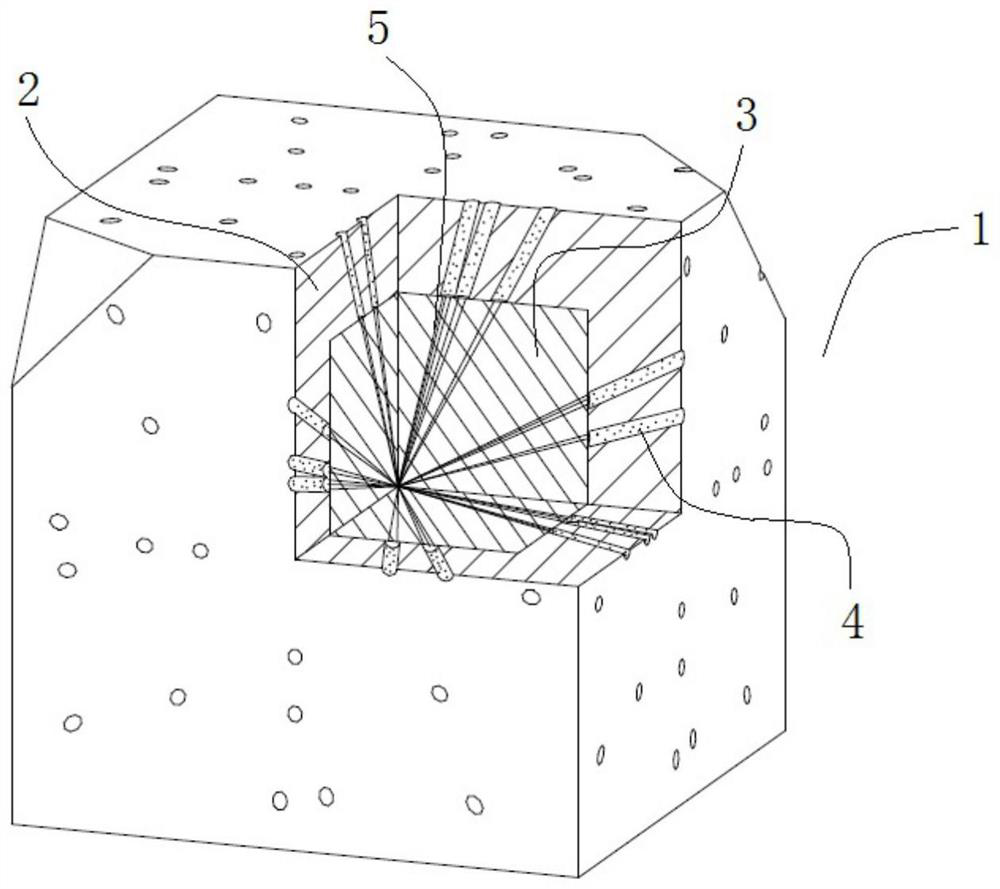

[0029] The composite pore molecular sieve of the present invention is a molecular sieve with mesoporous and microporous structures, and its preparation method includes the steps of pretreatment, primary lye treatment, secondary lye treatment and the like.

[0030] The molecular sieve is contacted with a reagent containing silicon tetrahalide or ammonium fluorosilicate to form a pretreated molecular sieve. During the contacting process, the molecular sieve reacts with silicon tetrahalide or ammonium fluorosilicate. The reaction temperature is 60-90°C, preferably 70-80°C. The contact time may be 1-3 h, preferably 1-2 h. According to one embodiment of the present invention, the molecular sieve is added into the reagent and fully stirred, and the pretreated molecular sieve is obtained after cooling, filtering, washing with water and drying. All of these can adopt conventional operations in the art, and will not be repeated here.

[0031] The molecular sieve of the present inven...

preparation example 1

[0047] The preparation of preparation example 1 Cu-SSZ-13 molecular sieve

[0048] 1) Al 2 o 3 , SiO 2 、Na 2 O and water are 1:50:30:1500 mixed evenly according to the mass ratio of substances to obtain a mixture, and then in the N,N,N-trimethyl-1-adamantyl ammonium hydroxide template (30wt% of the mixture mass) In the presence of the reaction at 40 ° C for 5 h.

[0049] 2) Transfer the product of step 1) to an autoclave, crystallize at 150° C. for 56 h, cool, filter to obtain the crystallized product, wash, dry and roast to obtain SSZ-13 molecular sieve.

[0050] 3) Disperse the SSZ-13 molecular sieve in step 2) in 0.5mol / L ammonium nitrate solution, stir at 80°C for 12h, cool, filter, wash, dry and roast to obtain H-SSZ13;

[0051] 4) Disperse H-SSZ13 in step 3) in 1mol / L copper nitrate solution, stir at 80°C for 12h, cool, filter, wash, dry and roast to obtain Cu-SSZ-13 molecular sieve.

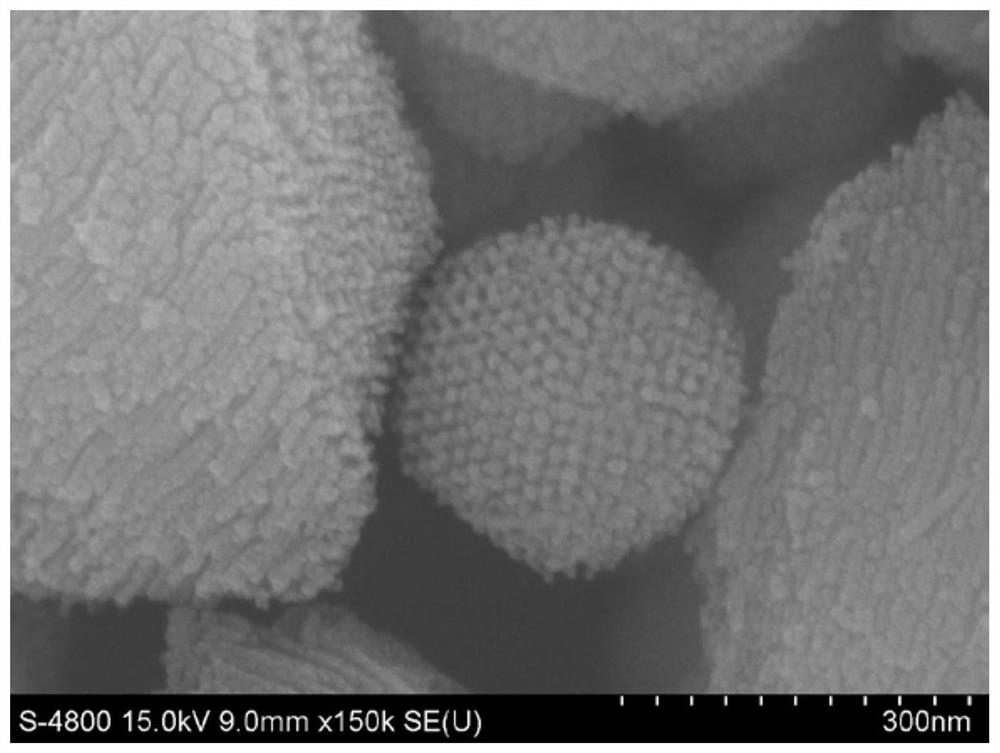

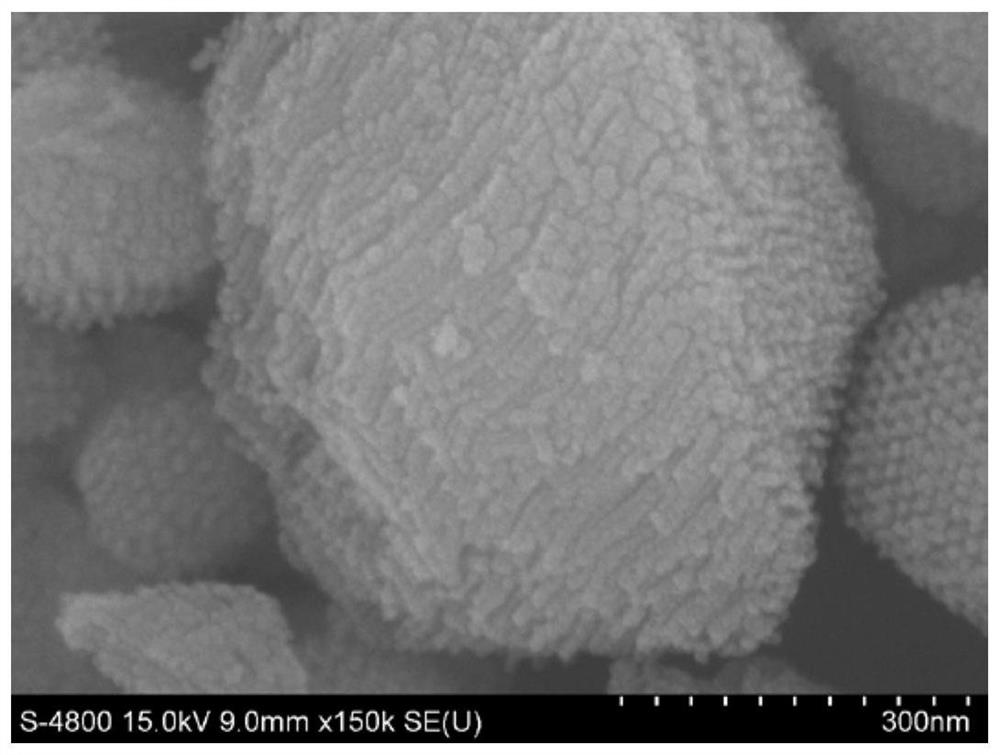

Embodiment 1

[0053] (1) Add 28.58g of Cu-SSZ-13 molecular sieve (preparation example 1) to SiCl with a mass ratio of 1:20 4 In a mixture with ethyl orthosilicate (250ml), SiCl 4 The mass ratio to molecular sieve was 1:20, stirred at 80°C for 2 hours, cooled to room temperature, filtered, and the filter residue was washed with water and dried to obtain a pretreated molecular sieve.

[0054] (2) Add the pretreated molecular sieve into an aqueous solution of 12wt% tetrapropylammonium hydroxide (TPAOH), stir at 100° C. for 10 h, cool to room temperature, filter, wash the filter residue with water and dry to obtain a primary treated molecular sieve.

[0055] (3) Add the primary treated molecular sieve into 0.1mol / L NaOH solution, stir at 70°C for 3h, cool to room temperature, filter, wash the filter residue with 0.1mol / L hydrochloric acid solution, then wash with water, and then roast at 550°C for 8h , Composite pore molecular sieve A was prepared.

[0056] The properties of the obtained comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com