Nanotube-containing composite bodies, and methods for making same

a composite body and nanotube technology, applied in the field of nanotube-containing composite materials, can solve the problems of insufficient durability of low expansion polymer composite materials, deficiency of glasses, and difficult processing, and achieve the effect of maintaining other mechanical properties such as modulus and flexural strength and enhancing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example i

[0079] This Example, demonstrates, among other things, the successful incorporation of carbon nanotubes (CNTs) into a metal-ceramic composite material and in particular, the survivability of the CNTs during infiltration processing with the metal in a molten condition.

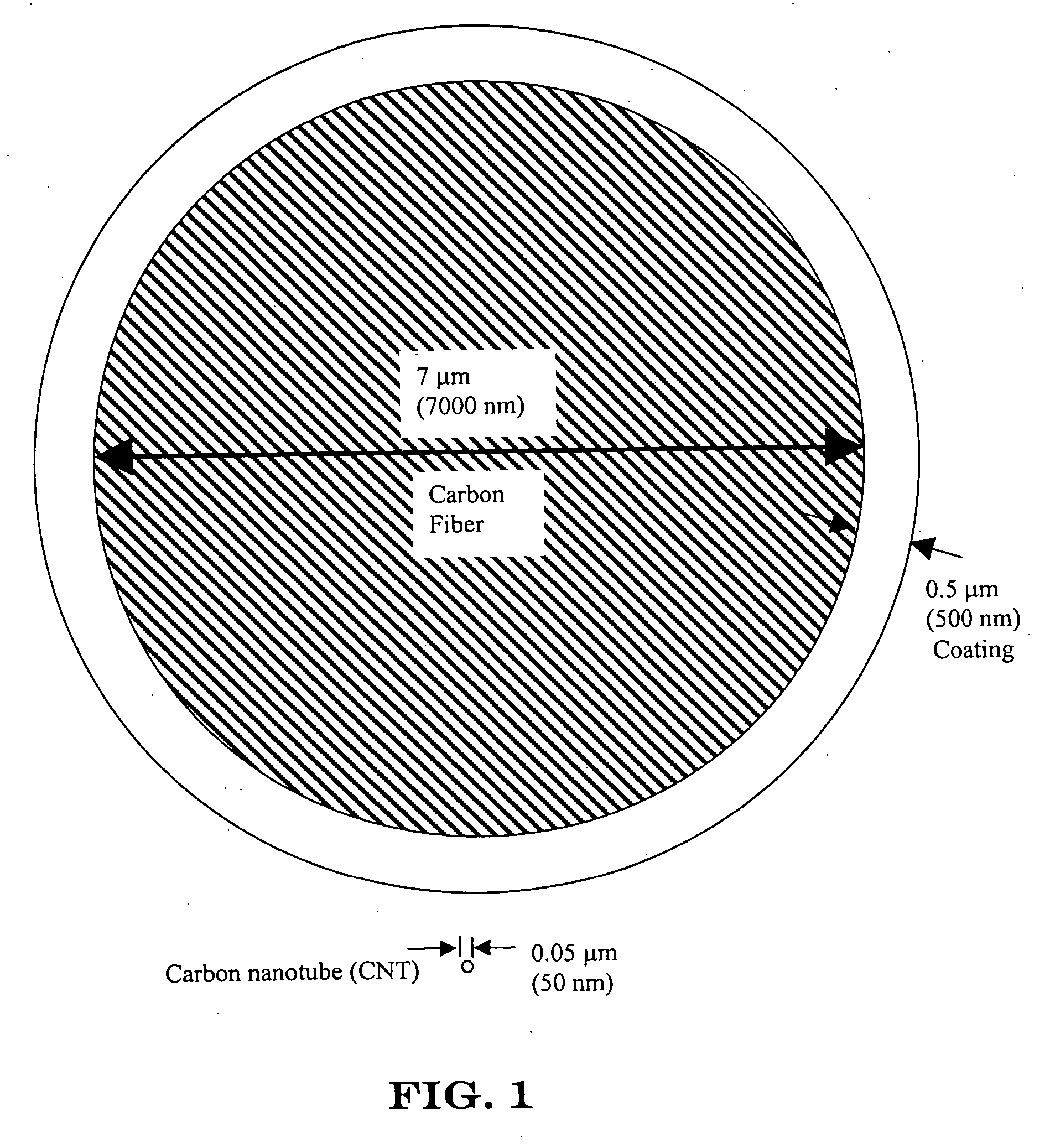

[0080] About 3.86 g of chemical vapor deposition (CVD) grown multi wall carbon nanotubes (Iljin Nanotech Co. Ltd., Seoul, Korea) were mixed with about 42.64 g of phenolic (SC1008 from Borden Chemical Inc., Louisville, Ky.) to make a mixture. The CNTs diameter ranged from about 10-50 nm.

[0081] The mixture was poured in a rubber mold with a cavity measuring about 5 by 5 by 1.3 cm. The rubber mold was placed on a vibrating table for about 12 hours. A thin TEFLON® sheet measuring about 5 cm square was placed on the mixture in the mold. A graphite block measuring about 5 by 5 by 2.5 cm (and having a mass of about 225 g) was placed on top of the TEFLON® sheet. The mold was then placed in a curing oven and heated to about 14...

example ii

[0086] This Example, demonstrates, among other things, the successful incorporation of carbon nanotubes (CNTs) into a metal-ceramic composite material also containing another filler or reinforcement material.

[0087] About 50 g of SiC powders consisting of a 70:30 weight ratio of 240 and 500 grit particulates (Saint Gobain / Norton Industrial Ceramics, Worcester, Mass.), 2 g CNTs, about 20.93 g phenolic and about 15.6 g THF (solvent) were hand mixed in a beaker to make a mixture. The mixture was poured in a rubber mold with a cavity measuring about 5 by 5 by 1.3 cm. The rubber mold was placed on a vibrating table for about 12 hours. A thin TEFLON® sheet measuring about 5 cm square was placed on the mixture. A graphite block measuring about 5 by 5 by 2.5 cm was placed on top of the TEFLON® sheet. The mold was then placed in a curing oven and heated to about 140° C. for about 3 hours and then cooled to room temperature. A cured, stand-alone preform was produced after demolding. This pref...

example iii

[0095] Examples III and IV through X demonstrate, among other things, various methods for blending and distributing carbon nanotubes throughout a mass of preform material.

[0096] To a plastic jar were added a 100 g mixture of 240 and 500-600 grit SiC (Saint Gobain Ceramics and Plastics, Inc. Worcester, Mass.) in a 60:40 weight ratio, about 5 g of CVD grown multi-walled carbon nanotubes (Iljin Nanotech, Soeul, South Korea), about 15.25 g of phenolic (SC1008 from Borden Chemical Inc., Louisville, Ky.), and about 40 g of Reagent Alcohol. The jar was sealed and placed on a rolling mill.

[0097] After roll mixing for about 12 hours, the mixture was poured out of the jar and into a rubber mold of nominal cavity size about 71 mm square by about 13 mm deep. The rubber mold was placed on a vibrating table for about 18 hours, during which time, the excess liquid pooled at the top, and it was periodically removed. The mold was placed in an oven and the temperature was raised to about 140° C. at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com