Ingot casting method for quasi-monocrystalline silicon

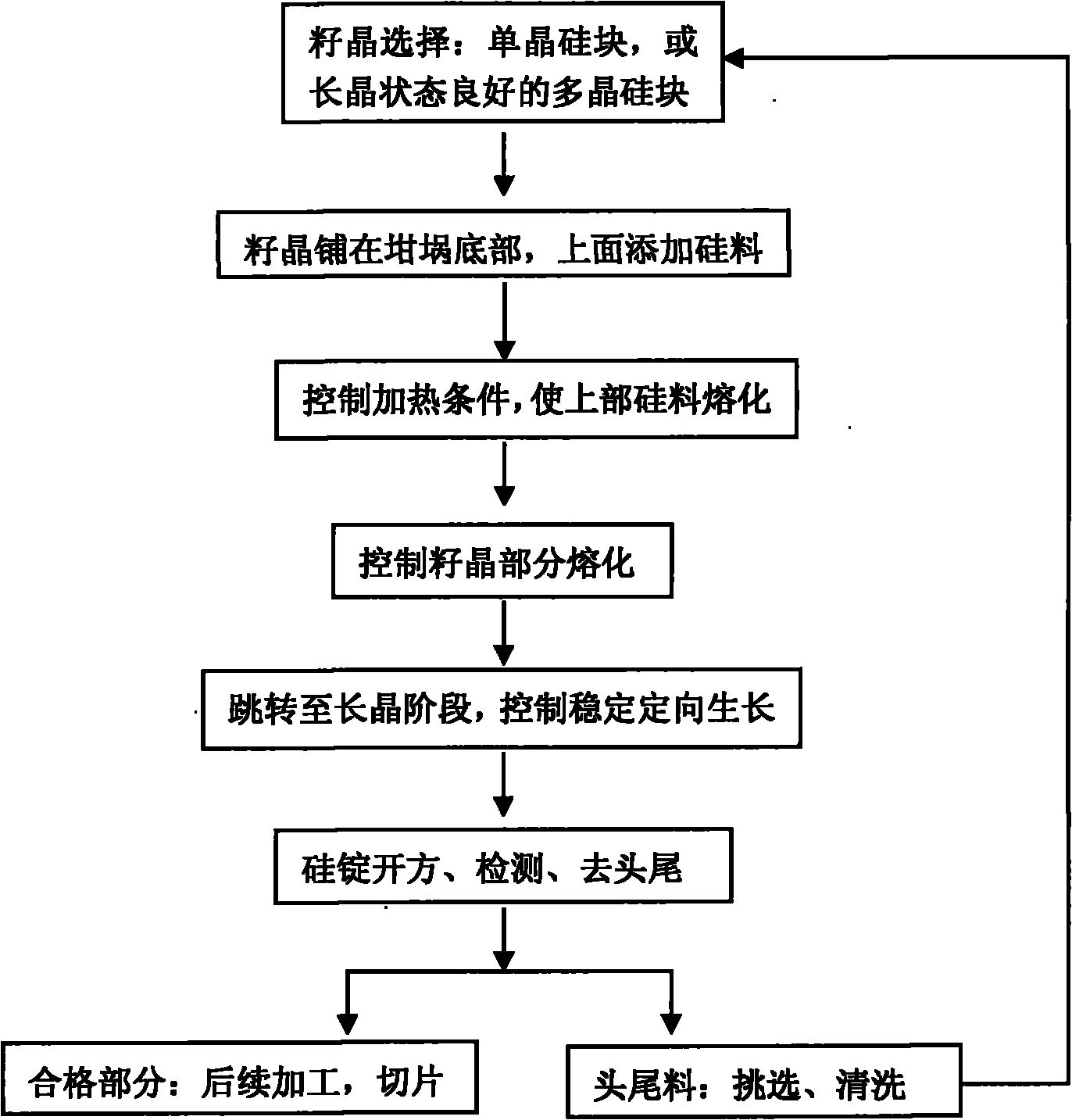

A quasi-single crystal silicon and seed crystal technology, applied in the field of quasi-mono-silicon ingots, can solve the problems of being unsuitable for large-scale production, increasing the cost of ingots, complicated processes, etc., achieving easy operation, easy industrialization, and low cost. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

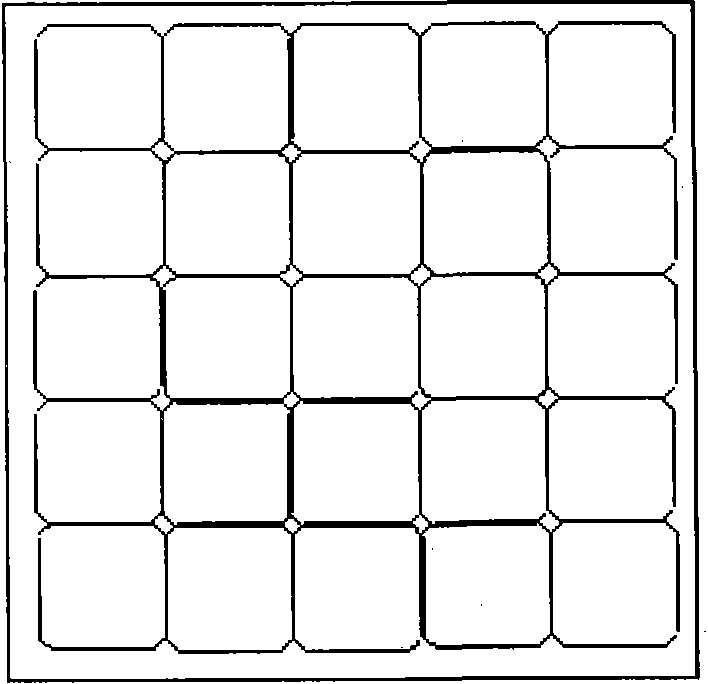

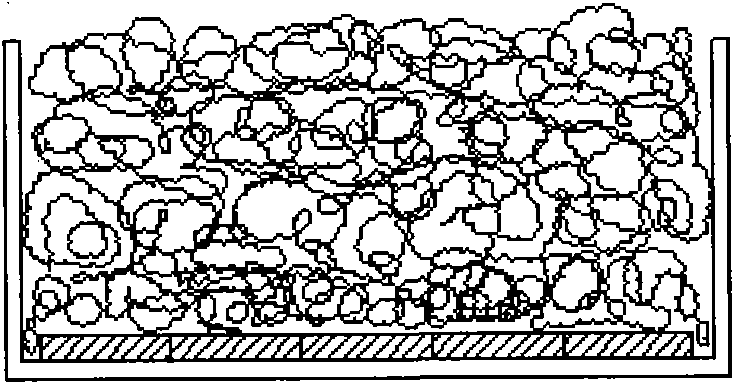

Embodiment 1

[0029] The (100) oriented single crystal rod obtained by the Czochralski method was squared to obtain a square column with a cross-sectional size of 156×156 mm, which was cut into 40-50 mm thick blocks as seed crystals. Choose a standard 450kg quartz crucible, that is, the internal size is 840×840×400mm, select 25 pieces of 156×156mm seed crystals according to the above standards, and spread them tightly on the bottom of the crucible in a 5×5 manner, and try to center the seed crystals when placing them. That is, the distance between the most edge surface of the peripheral seed crystal and the inner wall of the crucible is similar. The primary polycrystal is placed on top of the seed crystal, and a total of 430kg is loaded including the seed crystal. The specific arrangement of the seed crystal and the filling method of the seed crystal, silicon material and dopant are shown in the attached Figure 2a , 2b As shown, the dopant is boron, gallium or phosphorus, and the resistiv...

Embodiment 2

[0033] Square the (100) crystal orientation single crystal rod obtained by the Czochralski method to obtain a silicon rod with a cross-sectional size of 156×156mm and a length of about 160mm and 310mm, and then cut it along the radial direction to obtain a silicon rod with a size of 156×310×30mm , 156*160*30mm seed crystal. According to each row of 2 pieces of 310mm and 1 piece of monocrystalline silicon block of 160mm, they are closely arranged with a side of 156mm, and a total of 15 seed crystals are tiled in 5 rows in a quartz crucible of 840×840×400mm, and the seeds are placed as far as possible. The crystal is in the middle, that is, the edge surface of the peripheral seed crystal is close to the inner wall of the crucible. The primary polycrystal is placed on top of the seed crystal, and a total of 430kg is loaded including the seed crystal, and the target resistivity of doping is 1.5Ω.cm.

[0034] Vacuum after loading, control the power to heat to 1000-1400°C; after en...

Embodiment 3

[0037] As in Example 1, 13 (100) single-crystal seed crystals were obtained; in addition, the silicon ingots obtained by casting quasi-single-crystal silicon ingots were squared, detected, and cut with a band saw, and the cut bottom silicon blocks ( Mainly the remaining seed crystal) and the top large-grained silicon block are selected and processed, and the upper and lower impurity-enriched layers are removed and then cleaned, which is used as another part of the seed crystal. In this example, 6 remaining seed crystal silicon blocks recovered at the bottom and 6 large-grained silicon blocks at the top were each used as seed crystals, with a thickness of 2.5 to 3 cm. The 25 seed crystals obtained above were closely arranged in a 5×5 pattern and laid flat in a standard quartz crucible with an internal size of 840×840×400 mm, and were arranged in a symmetrical manner for different types of seed crystals for effect comparison. A total of 430kg of material is charged including the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com