High-efficiency crucible for polycrystal ingot casting and preparation method thereof

A polycrystalline ingot, high-efficiency technology, applied in the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc., can solve the problems of poor uniformity of crystal nucleus, low photoelectric conversion efficiency, uneven distribution of silicon wafers, etc. Achieve the effect of improving conversion efficiency and avoiding scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

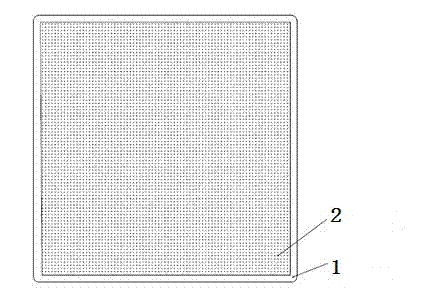

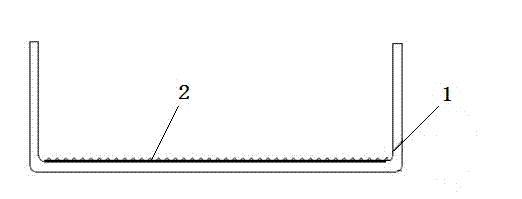

[0023] Such as figure 1 , 2 As shown, the high-efficiency crucible for polycrystalline ingot casting of the present invention includes a conventional quartz crucible 1, and the bottom of the quartz crucible 1 is uniformly inlaid with high-purity particles 2, and the high-purity particles 2 are silicon carbide particles with a particle size of 1.5 mm. The height of the high-purity particles 2 protruding from the bottom of the quartz crucible 1 is 1 mm, the distance between the high-purity particles 2 is 5 mm, and the high-purity particles 2 are arranged in a matrix.

[0024] The preparation method of the above-mentioned high-efficiency crucible for polycrystalline ingots includes the following steps: (1) making a quartz crucible 1 according to the existing technology; (2) selecting high-purity particles 2; (3) uniformly inlaying the high-purity particles 2 in the quartz In the quartz slurry at the bottom of the crucible 1; (4) The high-purity particles 2 are firmly fixed on th...

Embodiment 2

[0026] Such as figure 1 , 2 As shown, the high-efficiency crucible for polycrystalline ingot casting of the present invention includes a conventional quartz crucible 1, and the bottom of the quartz crucible 1 is uniformly inlaid with high-purity particles 2, and the high-purity particles 2 are quartz particles with a particle size of 2 mm. The height of the high-purity particles 2 protruding from the bottom of the quartz crucible 1 is 1 mm, the distance between the high-purity particles 2 is 5 mm, and the high-purity particles 2 are arranged in a matrix.

[0027] The preparation method of the above-mentioned high-efficiency crucible for polycrystalline ingots includes the following steps: (1) making a quartz crucible 1 according to the existing technology; (2) selecting high-purity particles 2; (3) uniformly inlaying the high-purity particles 2 in the quartz In the quartz slurry at the bottom of the crucible 1; (4) The high-purity particles 2 are firmly fixed on the bottom of...

Embodiment 3

[0029] Such as figure 1 , 2 As shown, the high-efficiency crucible for polycrystalline ingot casting of the present invention includes a conventional quartz crucible 1, and the bottom of the quartz crucible 1 is uniformly inlaid with high-purity particles 2, and the high-purity particles 2 are silicon particles with a particle size of 1.5 mm. The height of the high-purity particles 2 protruding from the bottom of the quartz crucible 1 is 1 mm, the distance between the high-purity particles 2 is 6 mm, and the high-purity particles 2 are arranged in a matrix.

[0030] The preparation method of the above-mentioned high-efficiency crucible for polycrystalline ingots includes the following steps: (1) making a quartz crucible 1 according to the existing technology; (2) selecting high-purity particles 2; (3) uniformly inlaying the high-purity particles 2 in the quartz In the quartz slurry at the bottom of the crucible 1; (4) The high-purity particles 2 are firmly fixed on the bottom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com