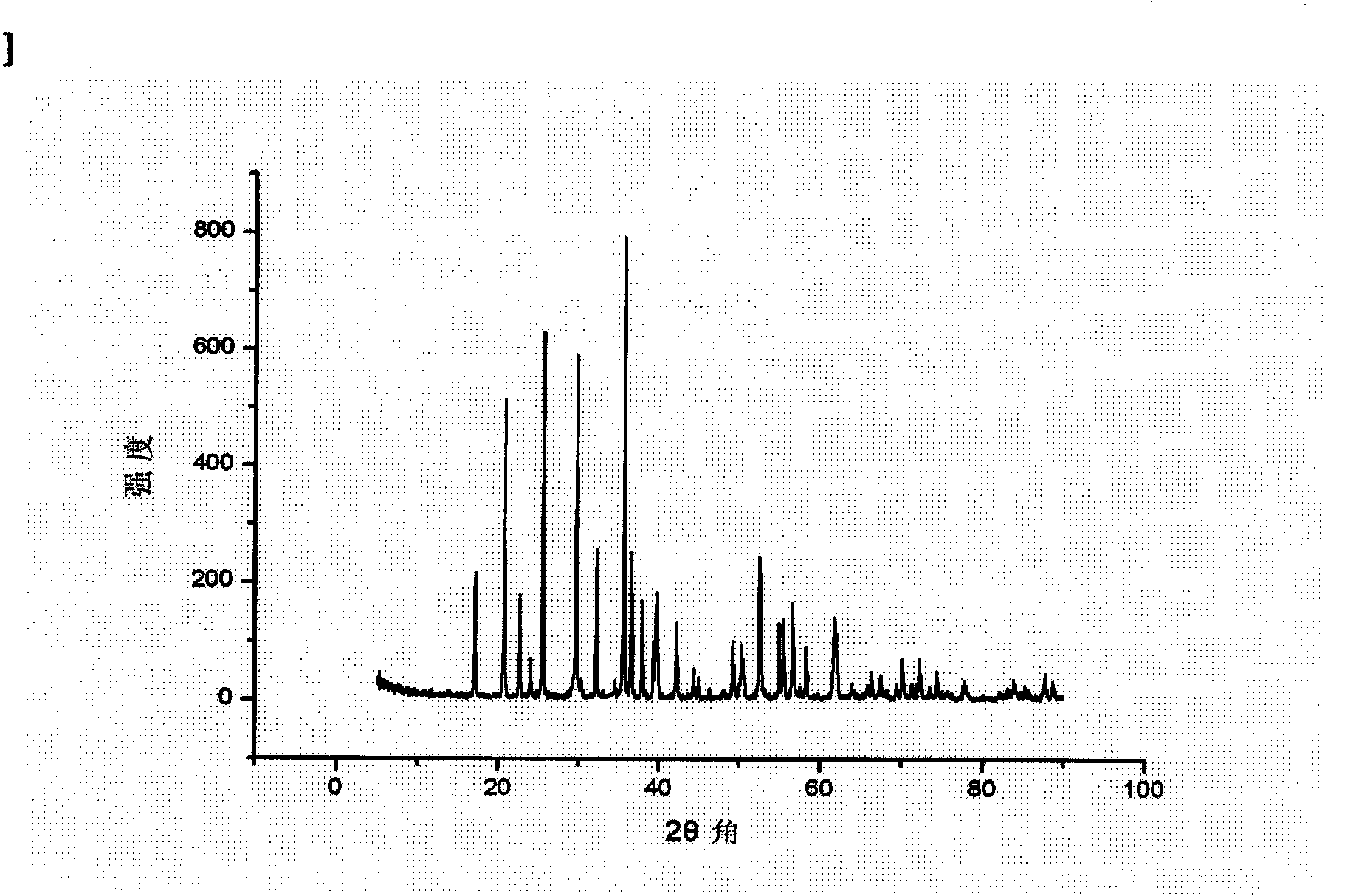

One-step preparation method of LiFePO4 powder coated with carbon

A carbon coating and powder technology, which is applied in the field of energy material preparation, can solve problems affecting material purity and tap density, difficulty in controlling product batch stability, and limiting material industrial production, etc., to improve electrochemical performance and morphology Uniform, short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

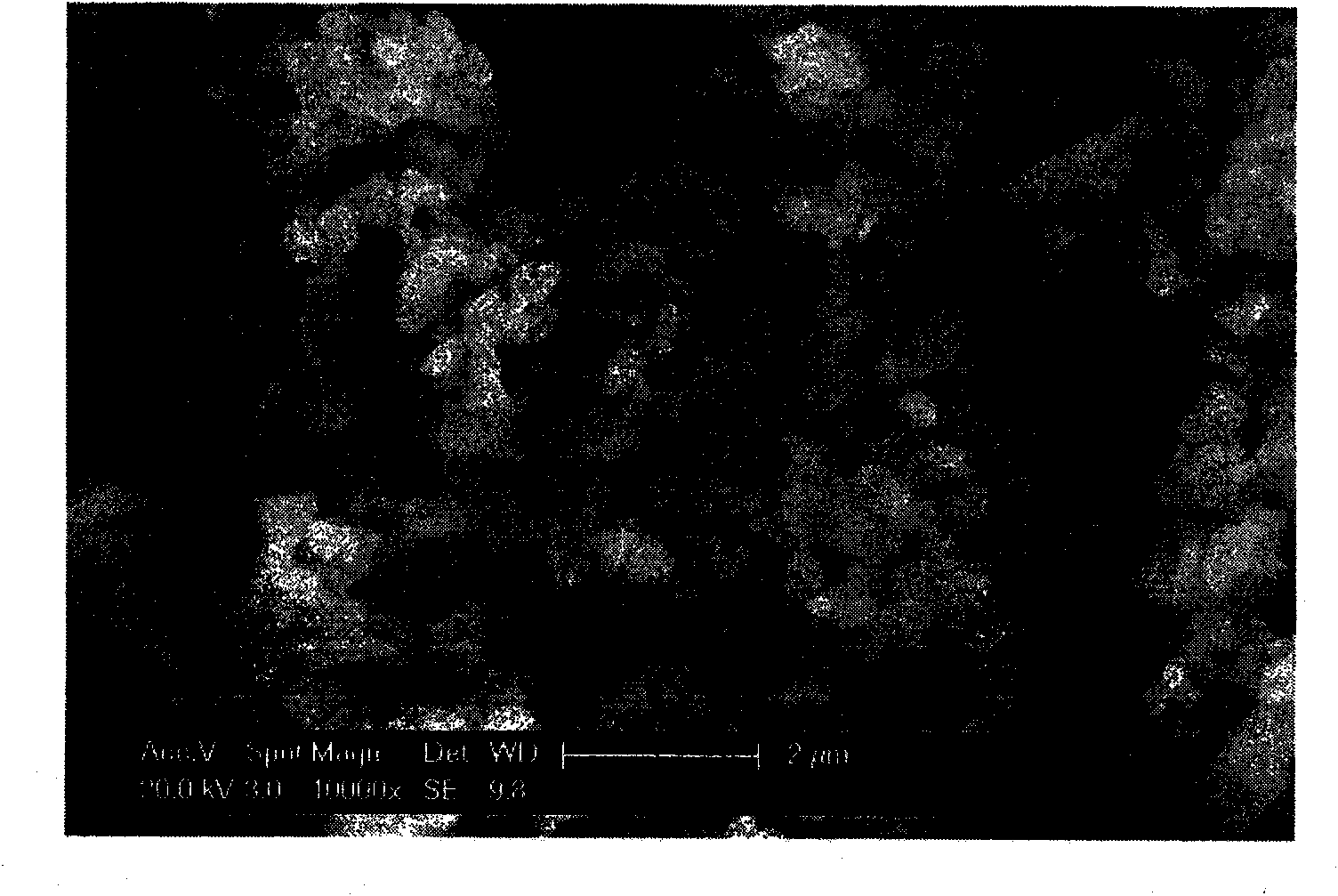

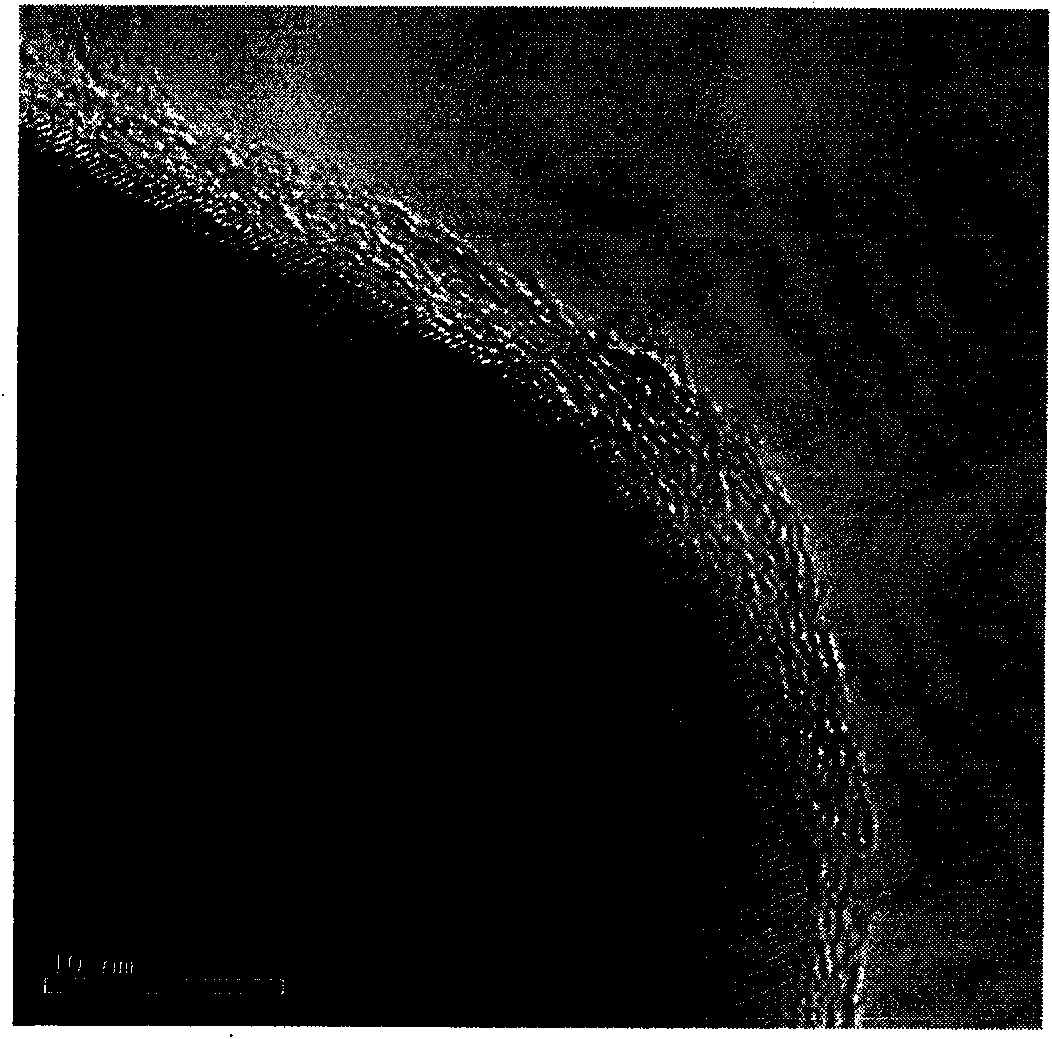

Embodiment 1

[0022] Using phosphoric acid, lithium hydroxide monohydrate, ferrous sulfate heptahydrate, gelatin and ascorbic acid as raw materials, according to the molar ratio of lithium hydroxide monohydrate, phosphoric acid and ferrous sulfate heptahydrate as 3:1:1, accurately weigh 2.224g Ferrous sulfate heptahydrate, 1.001g lithium hydroxide monohydrate, 0.55ml phosphoric acid (mass percentage is 85%), take by weighing 0.08g gelatin and 0.04g antioxidant ascorbic acid, the two account for 6% of the theoretically synthesized lithium ferrous phosphate quality respectively % and 3%. The above substances were prepared into phosphoric acid solution, lithium hydroxide monohydrate solution and ascorbic acid solution respectively, and dissolved in deionized water at 40° C. to obtain gelatin aqueous solution. The phosphoric acid solution and the lithium hydroxide monohydrate solution are uniformly mixed to obtain lithium phosphate precipitation, and the pH of the reaction process is controlled...

Embodiment 2

[0025]Using phosphoric acid, lithium hydroxide monohydrate, ferrous sulfate heptahydrate, gelatin and ascorbic acid as raw materials, according to the molar ratio of lithium hydroxide monohydrate, phosphoric acid and ferrous sulfate heptahydrate as 3:1:1, accurately weigh 2.224g Ferrous sulfate heptahydrate, 1.001g lithium hydroxide monohydrate, 0.55ml phosphoric acid (mass percentage is 85%), take by weighing 0.013g gelatin and 0.040g antioxidant ascorbic acid, the two account for 1% of the theoretically synthesized lithium iron phosphate quality respectively % and 3%. The above substances were prepared into phosphoric acid solution, lithium hydroxide monohydrate solution and ascorbic acid solution respectively, and dissolved in deionized water at 40° C. to obtain gelatin aqueous solution. The phosphoric acid solution and the lithium hydroxide monohydrate solution are uniformly mixed to obtain lithium phosphate precipitation, and the pH of the reaction process is controlled a...

Embodiment 3

[0028] Using phosphoric acid, lithium hydroxide monohydrate, ferrous sulfate heptahydrate, gelatin and ascorbic acid as raw materials, according to the molar ratio of lithium hydroxide monohydrate, phosphoric acid and ferrous sulfate heptahydrate as 3:1:1, accurately weigh 2.224g Ferrous sulfate heptahydrate, 1.001g lithium hydroxide monohydrate, 0.55ml phosphoric acid (mass percentage is 85%), take by weighing 0.013g gelatin and 0.013g antioxidant ascorbic acid, both account for 1% of the theoretical synthesis lithium iron phosphate quality %. The above substances were prepared into phosphoric acid solution, lithium hydroxide monohydrate solution and ascorbic acid solution respectively, and dissolved in deionized water at 40° C. to obtain gelatin aqueous solution. The phosphoric acid solution and the lithium hydroxide monohydrate solution are uniformly mixed to obtain lithium phosphate precipitation, and the pH of the reaction process is controlled at 7-9. Dissolve ferrous s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com