Silicon nitride spray finishing method for quartz crucible for polysilicon solar battery casting ingot

A technology for solar cells and quartz crucibles, applied in the field of solar cells, can solve the problems of not paying attention to the requirement of cleanliness, not paying attention to the influence of the particle size of silicon nitride powder on the coating of the crucible, etc., to prevent the mixing of oxygen elements and impurity elements, Quality assurance, the effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

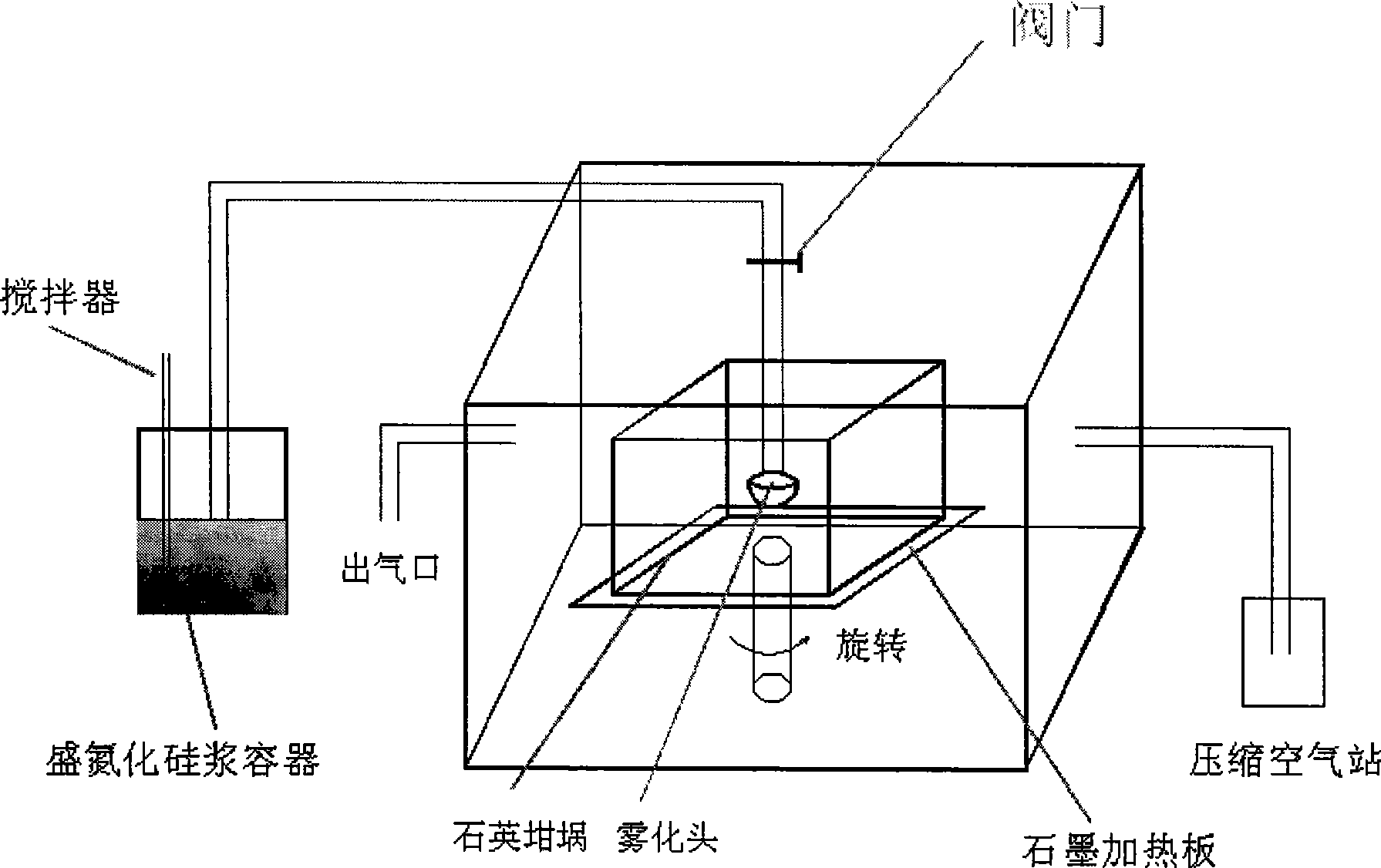

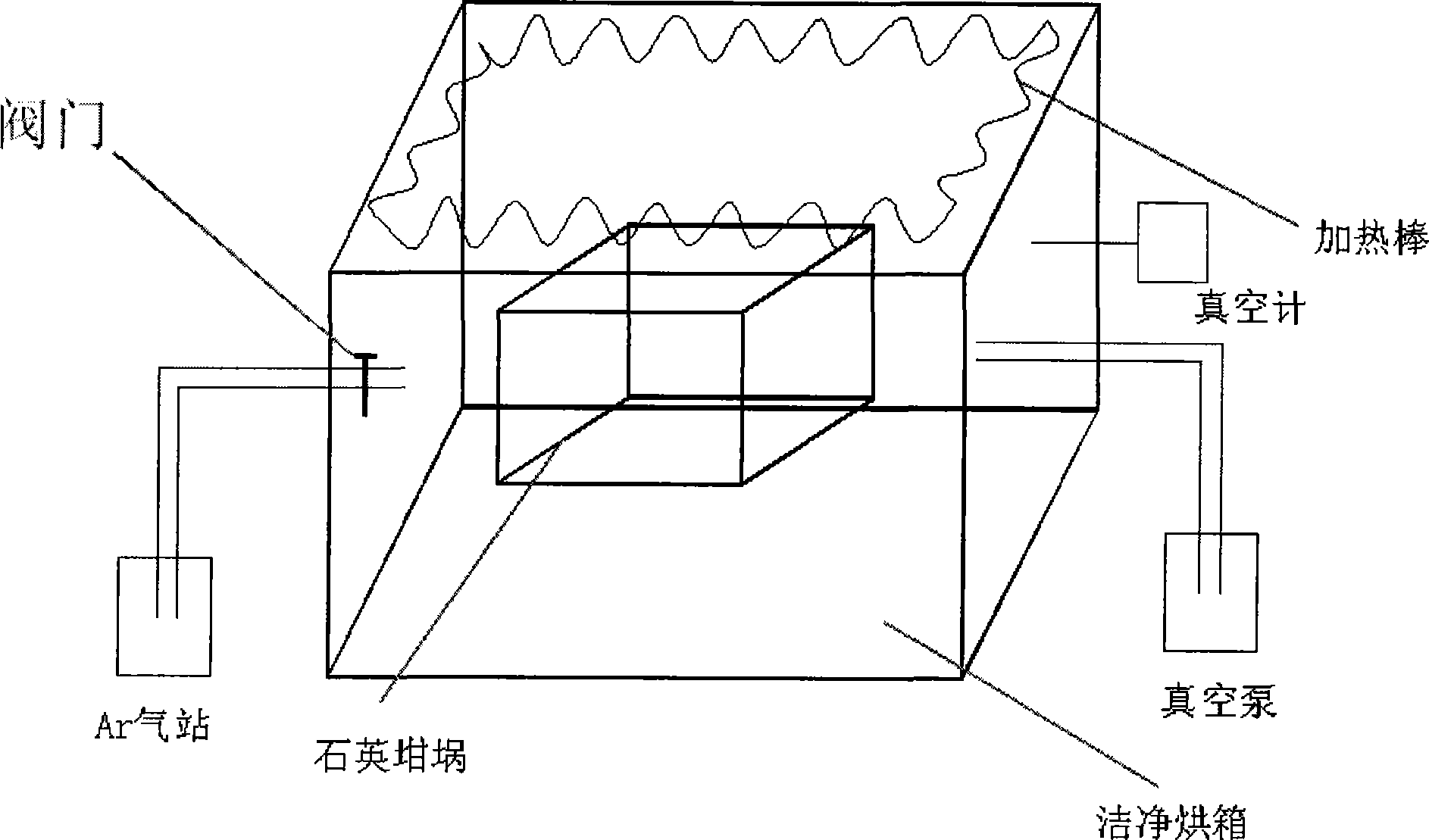

[0021] see Figure 1~3 , the present invention relates to a silicon nitride spraying method of a quartz crucible for ingot casting of polycrystalline silicon solar cells, which is to mix ultra-pure silicon nitride powder with a certain particle size and deionized water (DI water) in a certain amount, stir evenly, and then In the clean chamber, use a high-pressure gun to spray the inner wall of the quartz crucible that keeps the preheating temperature at all times (there is a graphite heating plate under the crucible). When spraying, keep the crucible rotating, and use the centrifugal force to spray more evenly on the crucible. After sintering in an oven under a certain program, a dense silicon nitride film spray coating is formed on the inner wall of the quartz crucible. During sintering, the oven is evacuated and Ar gas is introduced.

[0022] First, silicon nitride slurry must be prepared, that is, silicon nitride powder and deionized water (DI water, 18MΩ) are stirred and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com