A method for making soybean milk without false boiling and its soybean milk machine

A production method and technology for a soymilk machine, which are applied to dairy products, beverage preparation devices, kitchen utensils, etc., can solve the problems of high foam overflow risk, affecting the pulping cycle, and slow heating and curing process of the soymilk machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

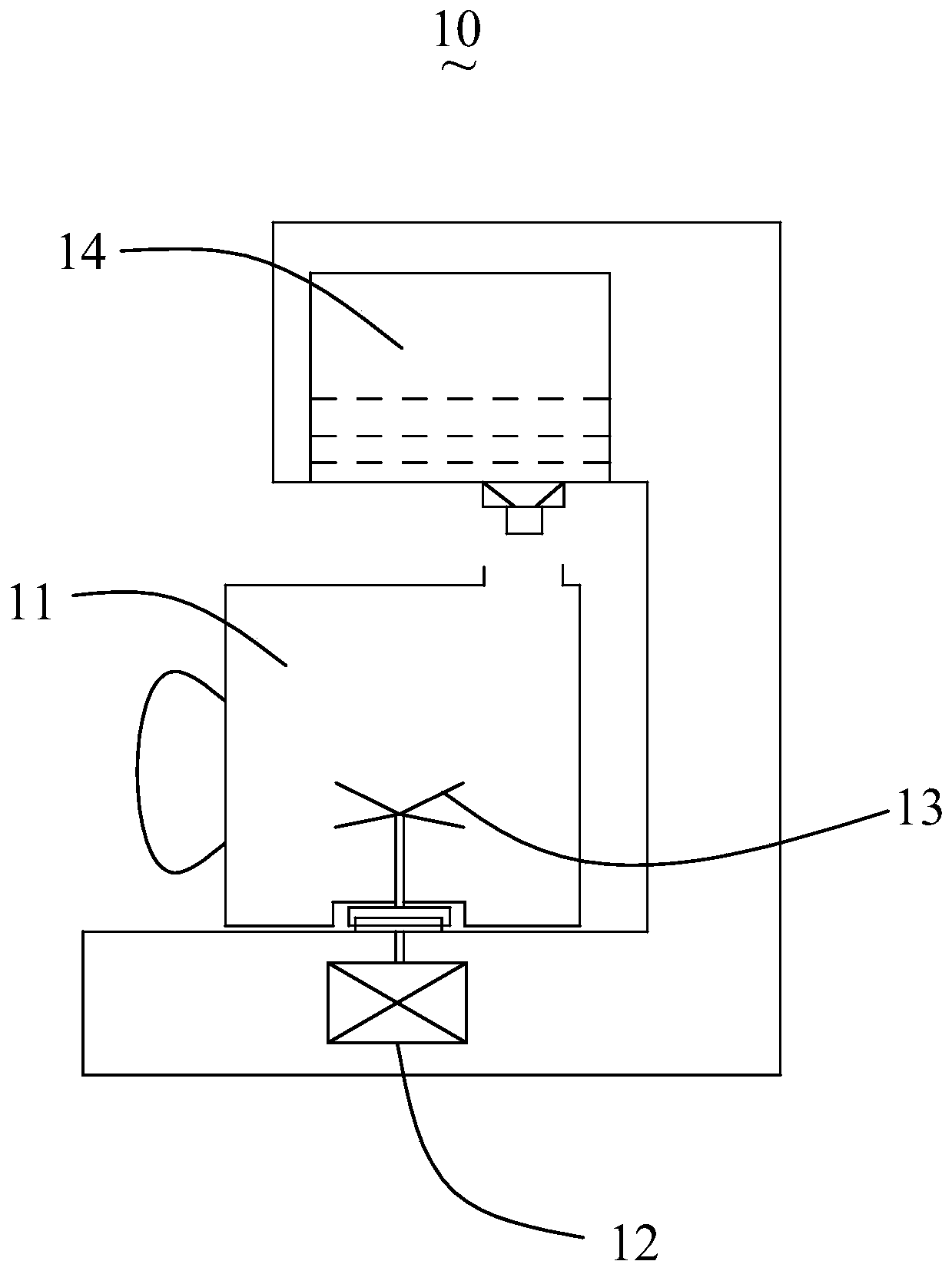

[0027] see figure 1 The schematic diagram of the non-false boiling soymilk machine used in the first preferred embodiment of the non-false boiling soymilk production method, the non-false boiling soymilk machine 10 includes a cup body 11, a heating device (not shown in the figure) ), motor 12, crushing tool 13, temperature detection device (not shown), water tank 14 and control device (not shown), the heating device, motor 12 and temperature detection device are electrically connected to the control device, and the motor 12 drives the pulverization The cutter 13 rotates, the temperature detection device detects the temperature of the liquid in the cup body 11, the heating device heats the cup body, and the control device controls the motor 12 to drive the pulverizing cutter 13 to rotate and pulverize at a first temperature to prepare slurry, and the first temperature is less than or equal to 70°C, and control the water tank 14 to quickly add water to the pulverized slurry in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com