Preparation method for high-purity quartz sand

A technology of high-purity quartz sand and quartz material, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of impurity ion dissolution, low flotation efficiency, etc., to improve dissolution efficiency, improve purification efficiency and purity, obvious economic and The effect of practical application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

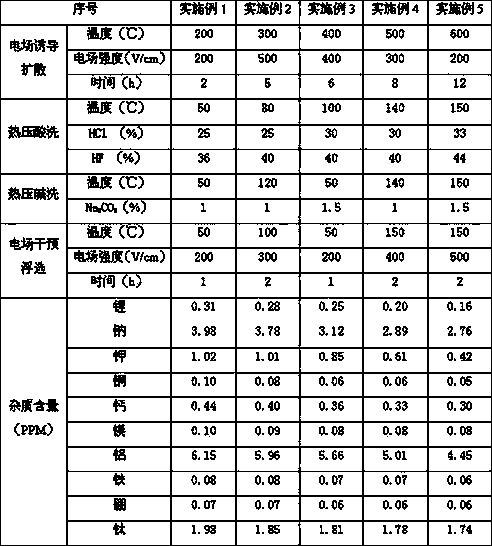

Embodiment 1

[0025] Select quartz stone with a purity of more than 99.95% as raw material, after rough washing, crushing, roasting, water quenching, crushing and grading, place it at 200°C and apply a DC electric field with a strength of 200V / cm for 2h to conduct electric field-induced diffusion . Then put it in a pressure-resistant reactor, add 25% hydrochloric acid and 36% hydrofluoric acid, and heat to 50°C for acid leaching for 48 h. Then put the crushed quartz material in a pressure-resistant reaction kettle, add a 1% sodium carbonate solution, and heat to 50°C for alkaline leaching for 1 hour. Place the pickled and alkali-washed quartz material at a temperature of 50°C, apply a DC electric field with an electric field strength of 200V / cm for 1h with a metal electrode, and then put it into a flotation machine for flotation, and then undergo chlorination treatment and sand baking , magnetic separation and other process steps to obtain high-purity quartz sand with the total amount of i...

Embodiment 2

[0028] Select quartz stone with a purity of more than 99.95% as the raw material, after rough washing, crushing, roasting, water quenching, crushing and grading, place it at 300°C and apply a DC electric field with a strength of 500V / cm for 5h to conduct electric field induced diffusion . Then place it in a pressure-resistant reactor, add 25% hydrochloric acid and 40% hydrofluoric acid, and heat to 80°C for acid leaching for 48 h. Then put the crushed quartz material in a pressure-resistant reaction kettle, add a 1% sodium carbonate solution, and heat to 120°C for alkaline leaching for 1 hour. Place the pickled and alkali-washed quartz material at a temperature of 100°C, apply a DC electric field with an electric field strength of 300V / cm for 2 hours with a metal electrode, and then put it into a flotation machine for flotation, and then undergo chlorination and sand baking. , magnetic separation and other process steps to obtain high-purity quartz sand with the total amount ...

Embodiment 3

[0031] Select quartz stone with a purity of more than 99.95% as the raw material, after rough washing, crushing, roasting, water quenching, crushing and grading, place it at 400°C and apply a DC electric field with a strength of 400V / cm for 6h to conduct electric field-induced diffusion . Then put it in a pressure-resistant reactor, add 30% hydrochloric acid and 40% hydrofluoric acid, and heat to 100 ° C for 48 h. Then put the crushed quartz material in a pressure-resistant reaction kettle, add a sodium carbonate solution with a concentration of 1.5%, and heat it to 50°C for alkali leaching for 2 hours. Place the pickled and alkali-washed quartz material at a temperature of 50°C, apply a DC electric field with an electric field strength of 200V / cm for 1h with a metal electrode, and then put it into a flotation machine for flotation, and then undergo chlorination treatment and sand baking , magnetic separation and other process steps to obtain high-purity quartz sand with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com