Single crystal manufacturing method and device

A manufacturing method and single crystal technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of different judgments, different, unable to reduce the occurrence frequency of single crystal dislocation, etc. dislocation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

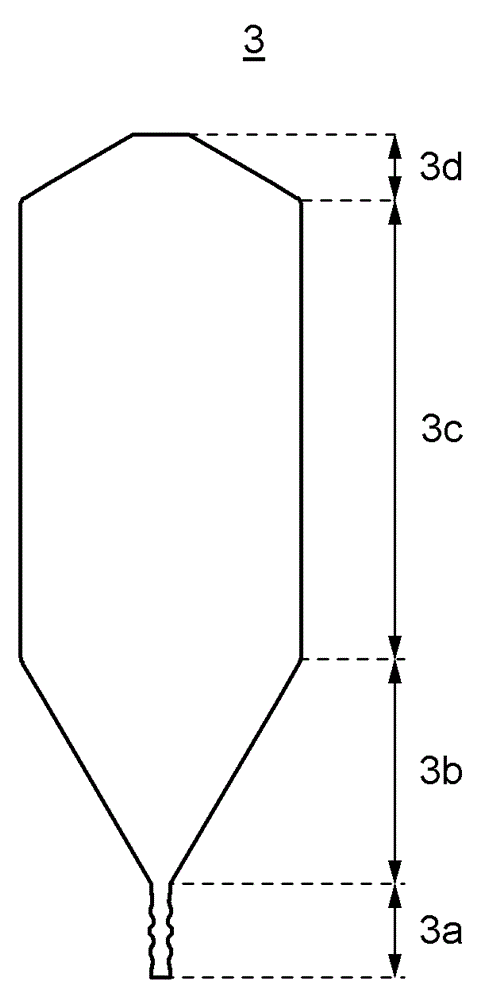

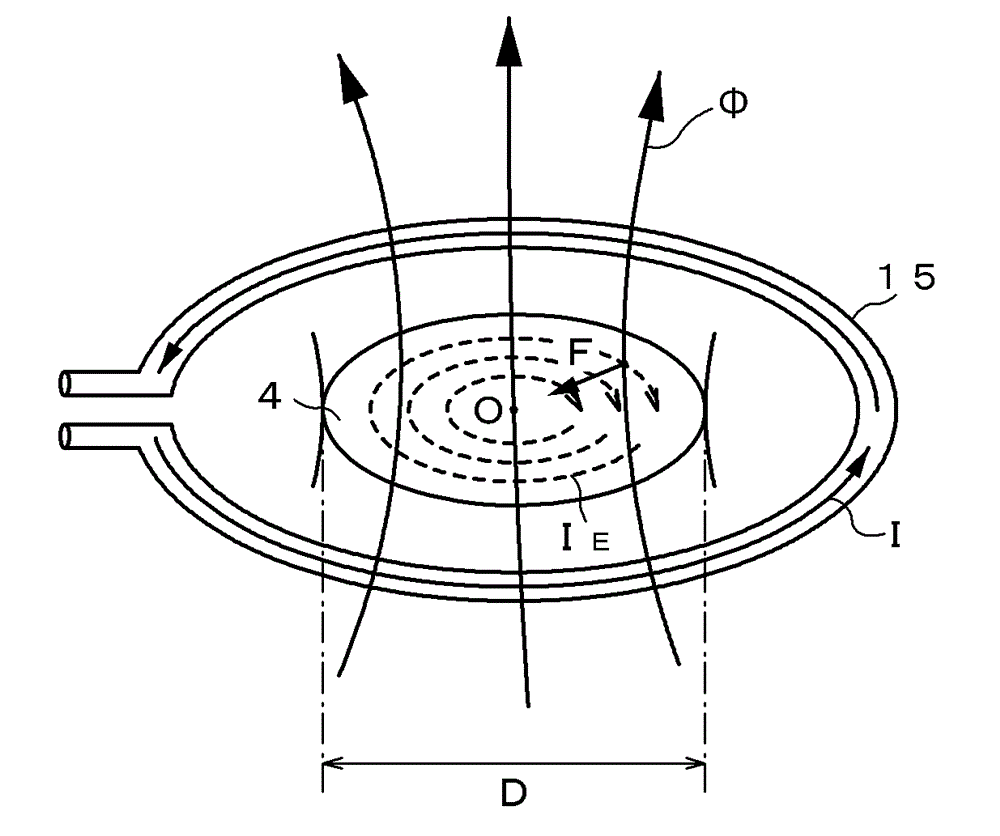

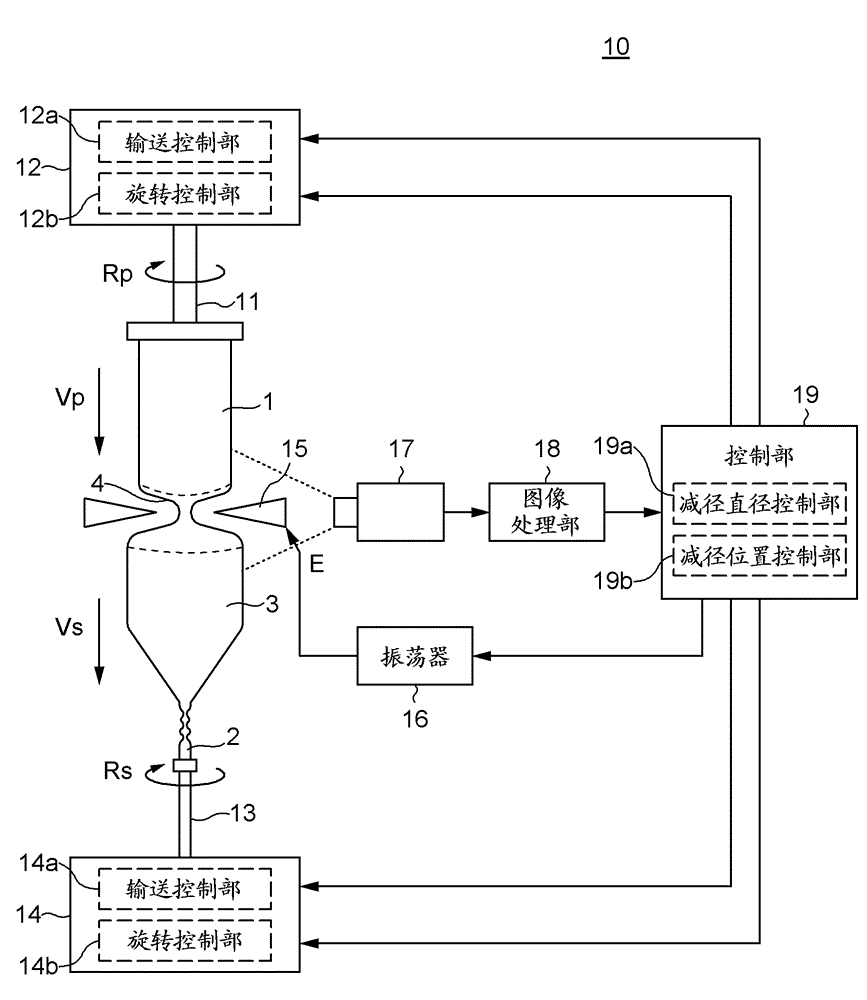

[0060] use figure 1 shown in the single crystal fabrication setup, additionally follow the Figure 5 The shown control block performs the diameter reduction process of the silicon single crystal by automatic control. In the automatic control of the reduction process, the reduction diameter and the reduction position are calculated based on the image data captured by the CCD camera, and the high-frequency current is operated based on the result to perform PID control on the reduction diameter, and the crystal transport speed is also controlled. Perform PID control on the reducing position. The above diameter reduction process was carried out three times to obtain three single crystal samples.

[0061] On the other hand, as a comparative example, the diameter reducing step of the silicon single crystal was performed by manual control. In the manual control of the diameter reduction process, the operator controls the diameter reduction by manipulating the output of the oscilla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com