Measurement control system for diameter of Czochralski grown monocrystalline germanium

A technology of control system and diameter measurement, which is applied in the directions of single crystal growth, crystal growth, self-melting liquid pulling method, etc., can solve the problem that the aperture signal of germanium solid-liquid interface cannot be detected, and the automatic control unit cannot grow germanium in equal diameter Automatic control and other issues to achieve the effect of reducing labor intensity, reducing the amount of data transmission, and avoiding repeated design and investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail through the embodiments below in conjunction with the accompanying drawings.

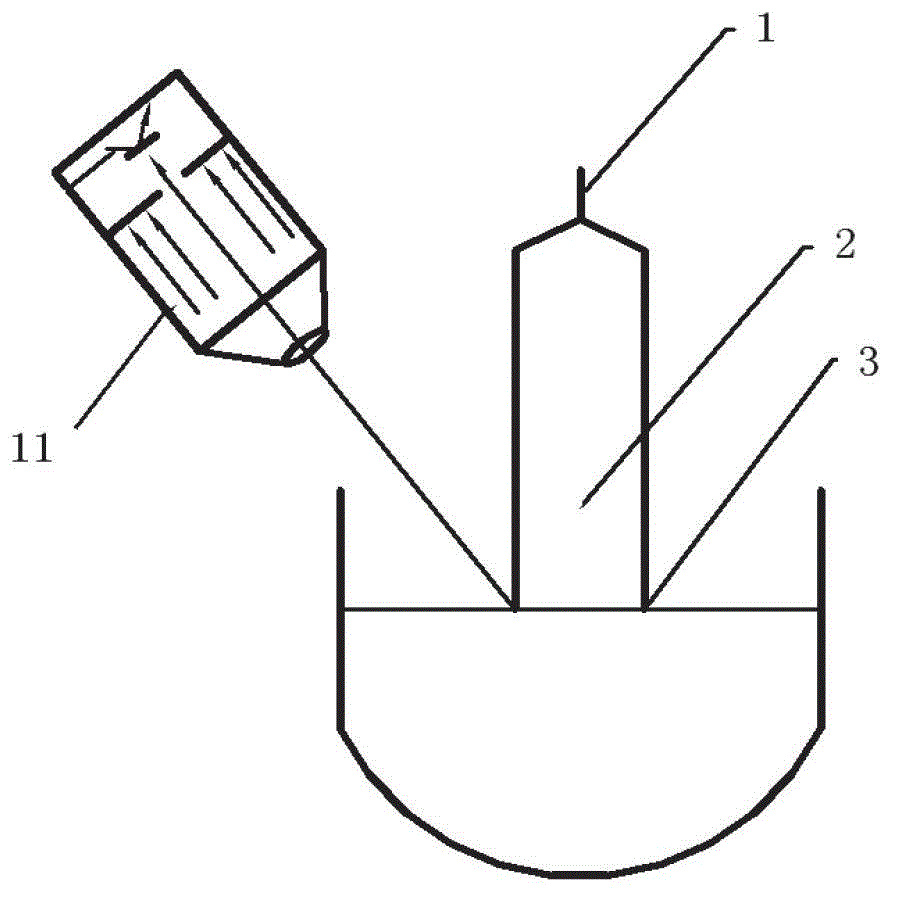

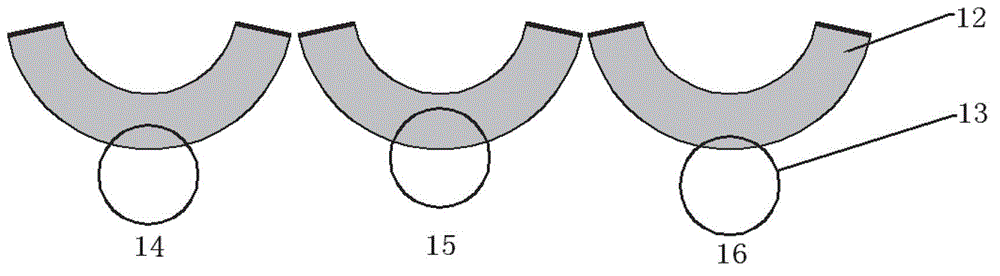

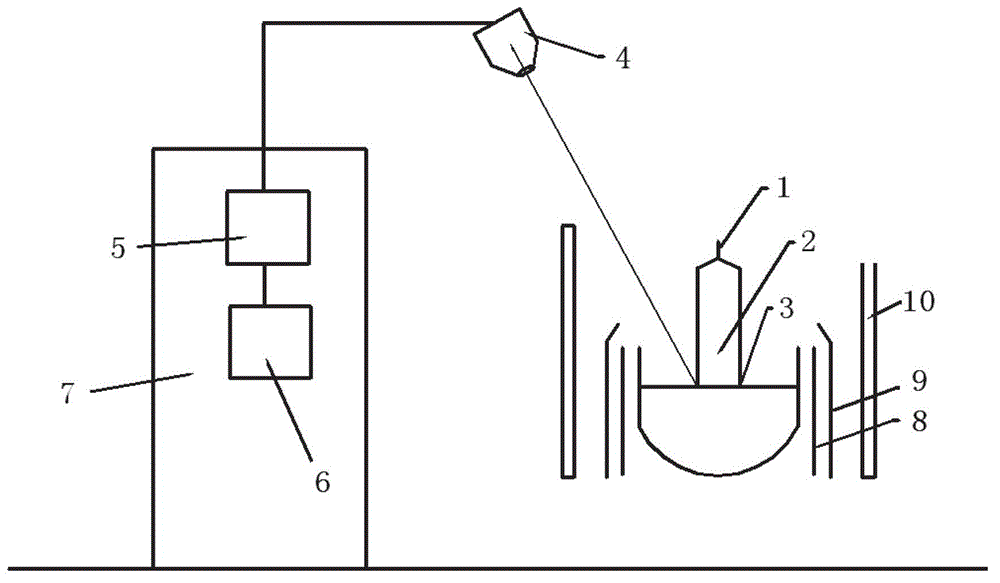

[0024] Czochralski germanium single crystal diameter measurement and control system described in the present invention (such as image 3 shown), the system has a CCD camera 4, an image processing device 5 and an automatic control unit 6. The CCD camera is placed at the position of the observation window of the single crystal furnace, and the position of the aperture 3 at the solid-liquid interface is found (such as Figure 4 shown), synchronously collect the image data of equal-diameter growth of germanium single crystal, and transmit the image data to the image processing device 5; the image processing device recognizes the image data of the solid-liquid interface aperture 17 detected by the CCD camera, and the aperture 17 is detected by the computer. intersects the three preset lines 18 (eg Figure 5 shown), save the position inform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com