Autolifting type variable-shape diassembllable integrated lifting steel plateform system and construction method thereof

An overall lifting and steel platform technology, which is applied in the direction of formwork/formwork/working frame, building structure support, building structure support, etc., can solve problems such as no construction precedent, and achieve fully enclosed safety, good integrity, Guaranteed duration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

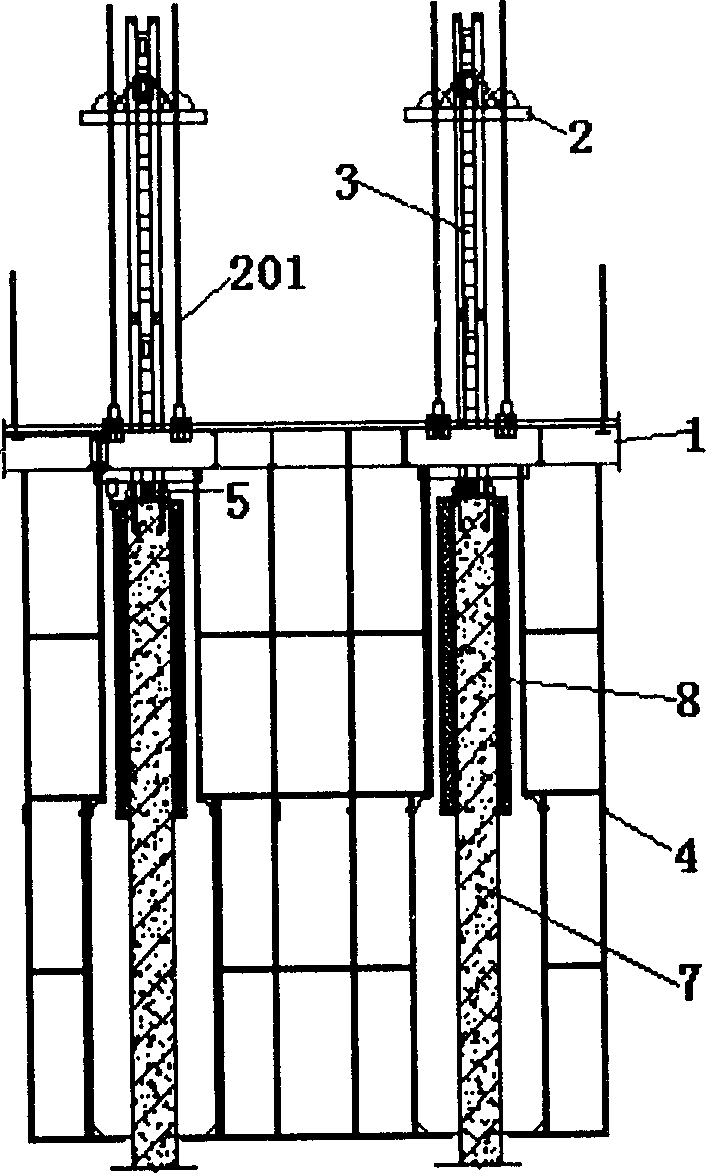

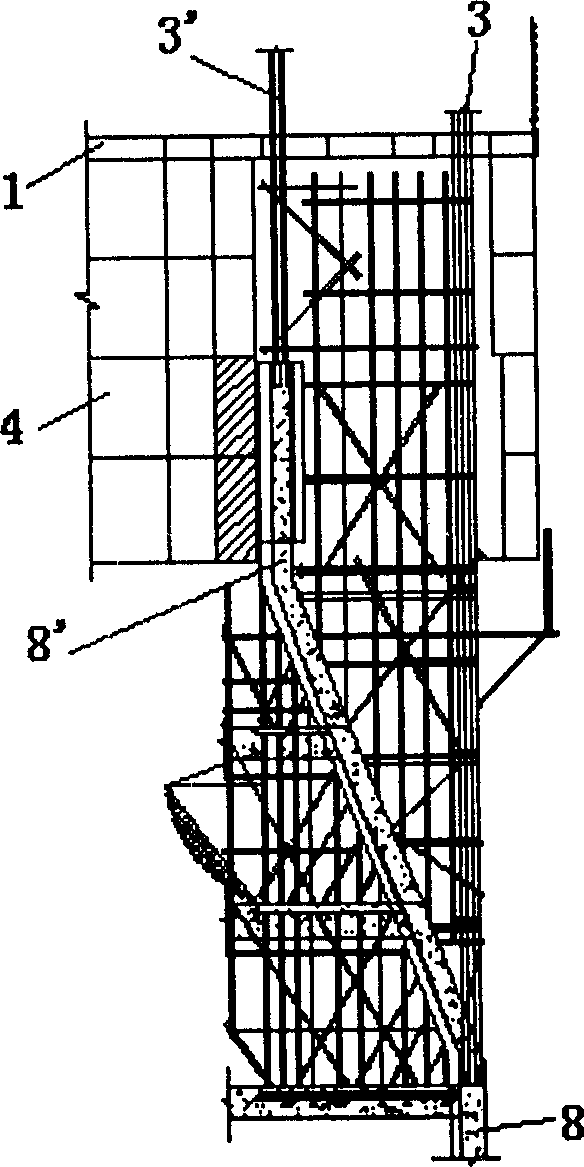

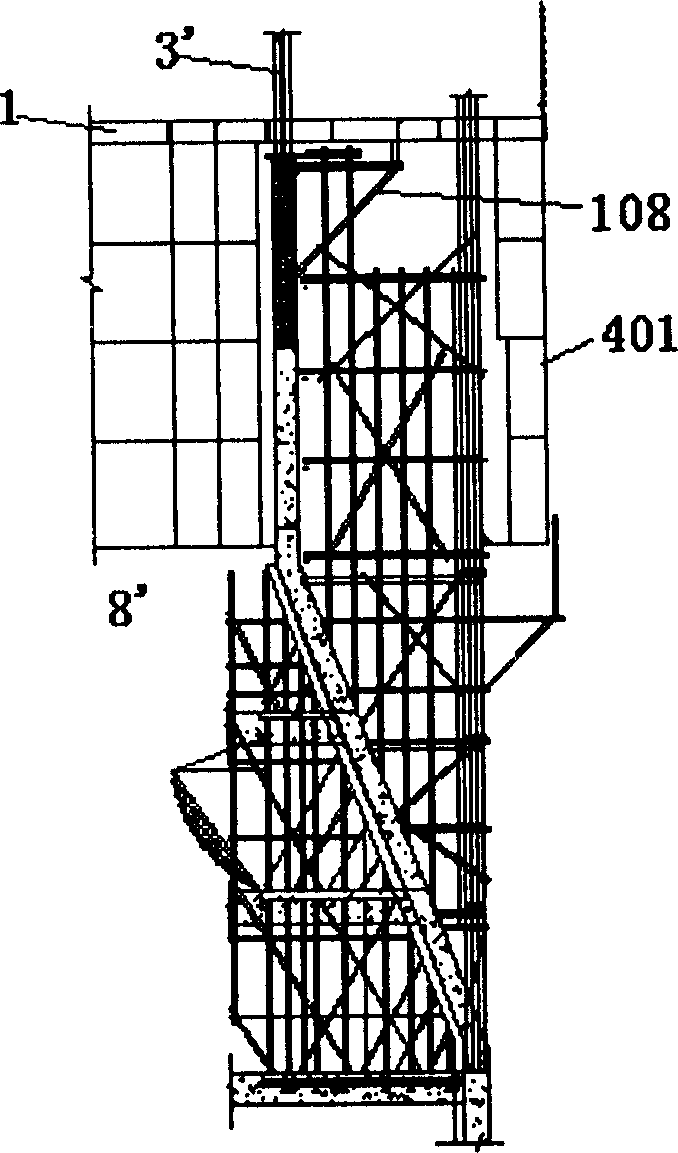

[0028] Such as figure 1 , Figure 8 and Figure 9 As shown, the self-elevating deformable and detachable overall lifting steel platform system of the present invention includes a steel platform 1, a lifting trigger 2, a rigid steel column 3, a suspension scaffold 4 and a load-bearing pin 5, and the suspension scaffold 4 is fixedly connected to the steel platform 1 , the steel platform 1 is a deformable steel platform, which includes a main beam 101 and a secondary beam 102, a rolling device 6 is provided at the connection node between the main beam 101 and the secondary beam 102, and the secondary beam 102 can pass through the rolling device 6 to form a main The beam 101 moves relative to the main beam on the track; the lifting trigger 2 is hung on the rigid steel column 3, and the lower end of the lifting screw 201 is fixedly connected with the steel platform 1; the rigid steel column 3 is a panel-style lattice column , the lower end of which is pre-embedded in the core tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com