Steel reinforced concrete column type joint and construction method of underground diaphragm wall using same

A technology of underground diaphragm walls and concrete columns, which is applied in artificial islands, sheet pile walls, water conservancy projects, etc., can solve the problems of the overall rigidity and anti-seepage performance of the wall section connection structure not meeting the design requirements, and low construction efficiency. Achieve the effects of increasing the overall rigidity and anti-seepage performance, improving construction efficiency and shortening the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

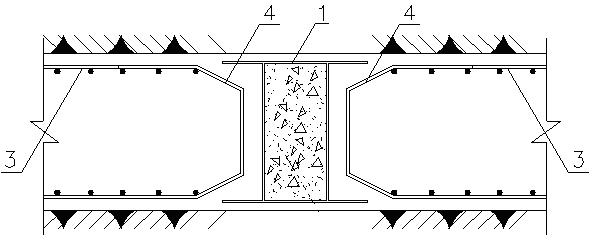

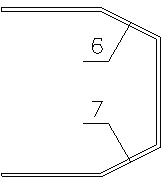

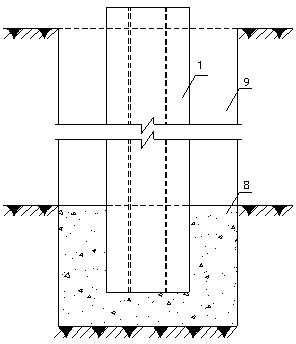

[0028] Such as Figures 1 to 3 As shown, a steel concrete column joint includes a Shaped section steel 1 and two late slot section steel cages 3, the two late slot section steel cages 3 are inserted into the In the flanges on both sides of shaped section steel 1, the Concrete is poured inside the shaped section steel 1, and the end of the reinforcement cage 3 of the trough section in the later stage is provided with a broken-line head reinforcement, and the Shaped section steel 1 is formed by cutting and blanking steel plates, assembling and welding, and its total height is greater than the depth of the groove section. Shaped section steel 1 is inserted into the bottom plane of the tank to a certain depth. After passing the test, the bottom of the bottom is poured with back-sealing concrete 8 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com