Cabin top steel beam hydraulic hoisting and positioning apparatus of cylinder cabin structure building and construction method thereof

A technology of hydraulic lifting and construction methods, which is applied in the direction of buildings, building types, and large-capacity bulk material storage, etc., and can solve problems such as difficulty in positioning, high risk of operation, and low efficiency, so as to save construction costs and reduce construction costs , The effect of saving rental fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

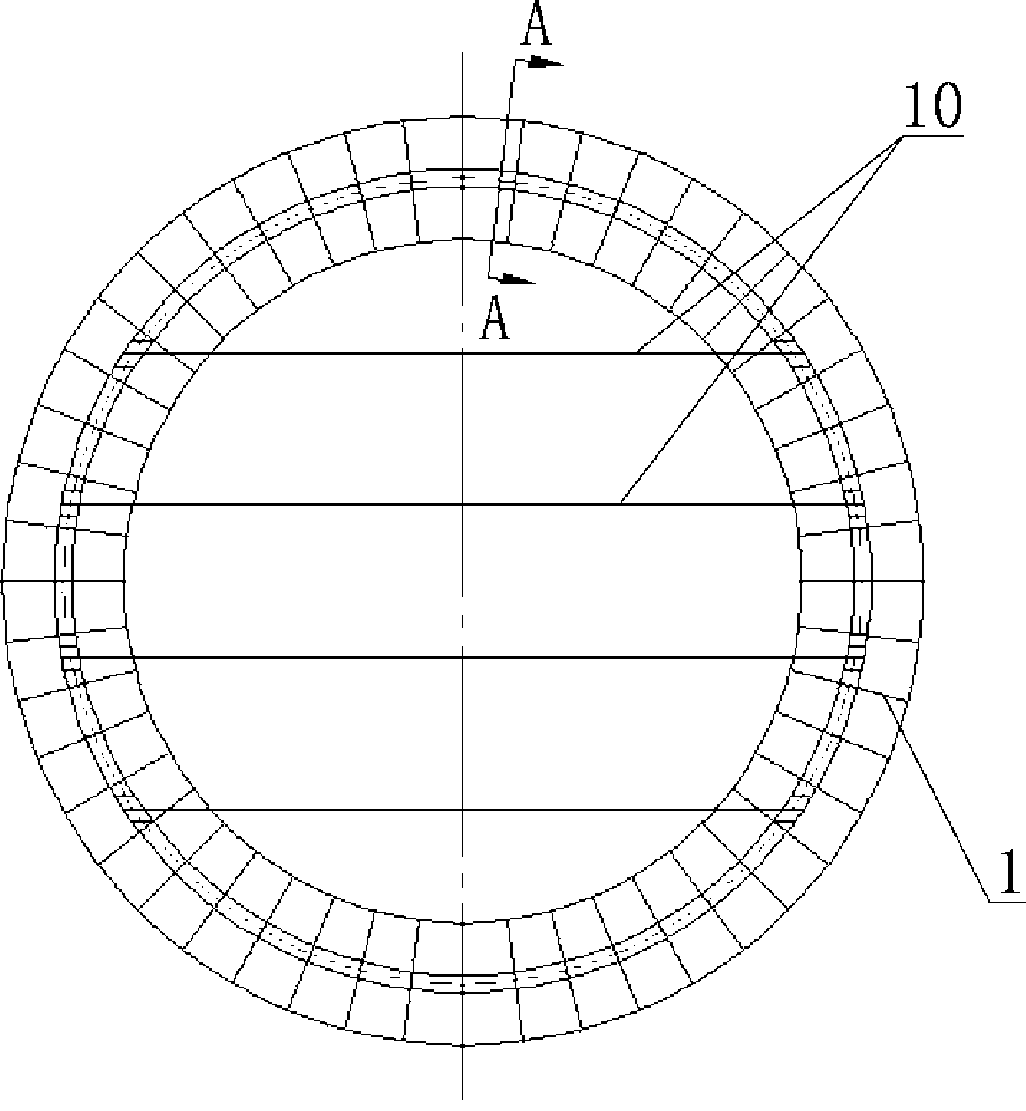

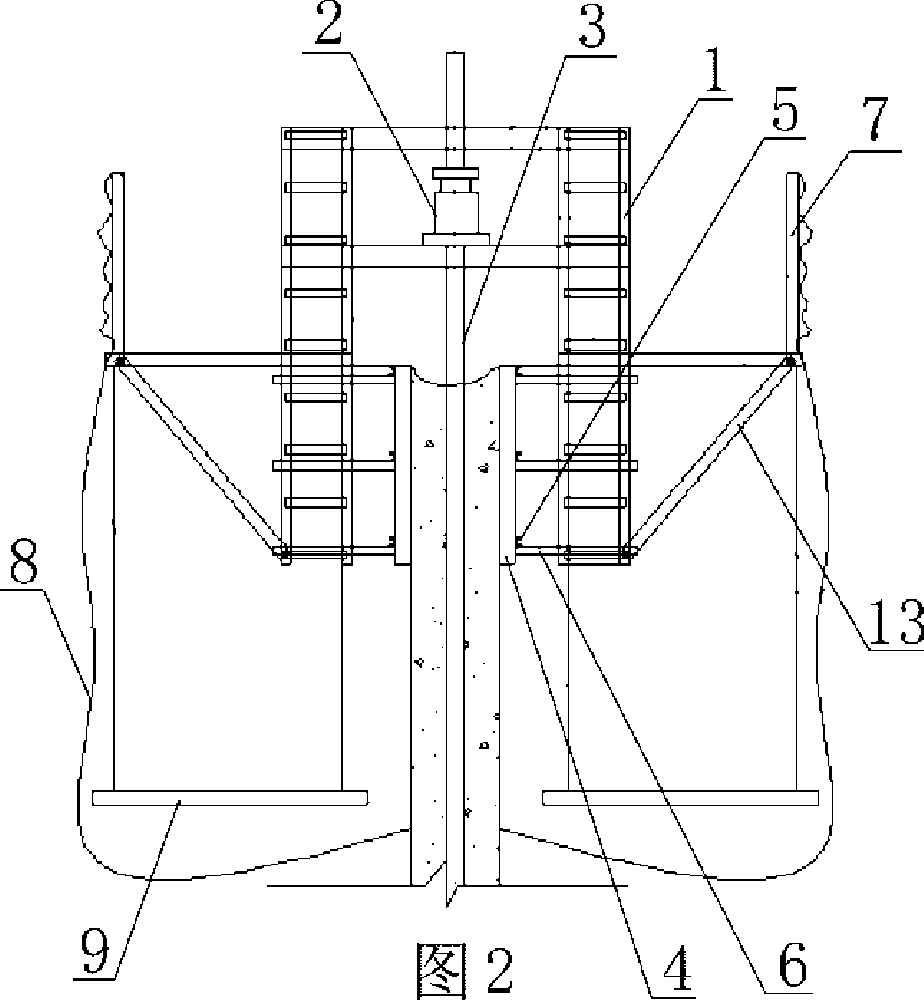

[0050] see figure 1 , as shown in Figure 2, this silo structure structure silo roof steel beam hydraulic lifting in place device, including sliding mode device and hydraulic lifting system, the sliding mode lifting frame 1 of the above-mentioned sliding mode device and the inner and outer formwork 4 and the operating platform Connection, scissor braces are connected between the two lifting frame columns, the sliding form lifting frame 1 is also connected with a steel beam support frame 11, the steel beam support frame 11 and the warehouse roof steel beam 10 are connected to form a lifting whole, and the hydraulic lifting system is used as the above-mentioned lifting whole. The lifting power system is composed of hydraulic jack 2, support rod 3, hydraulic console and oil circuit.

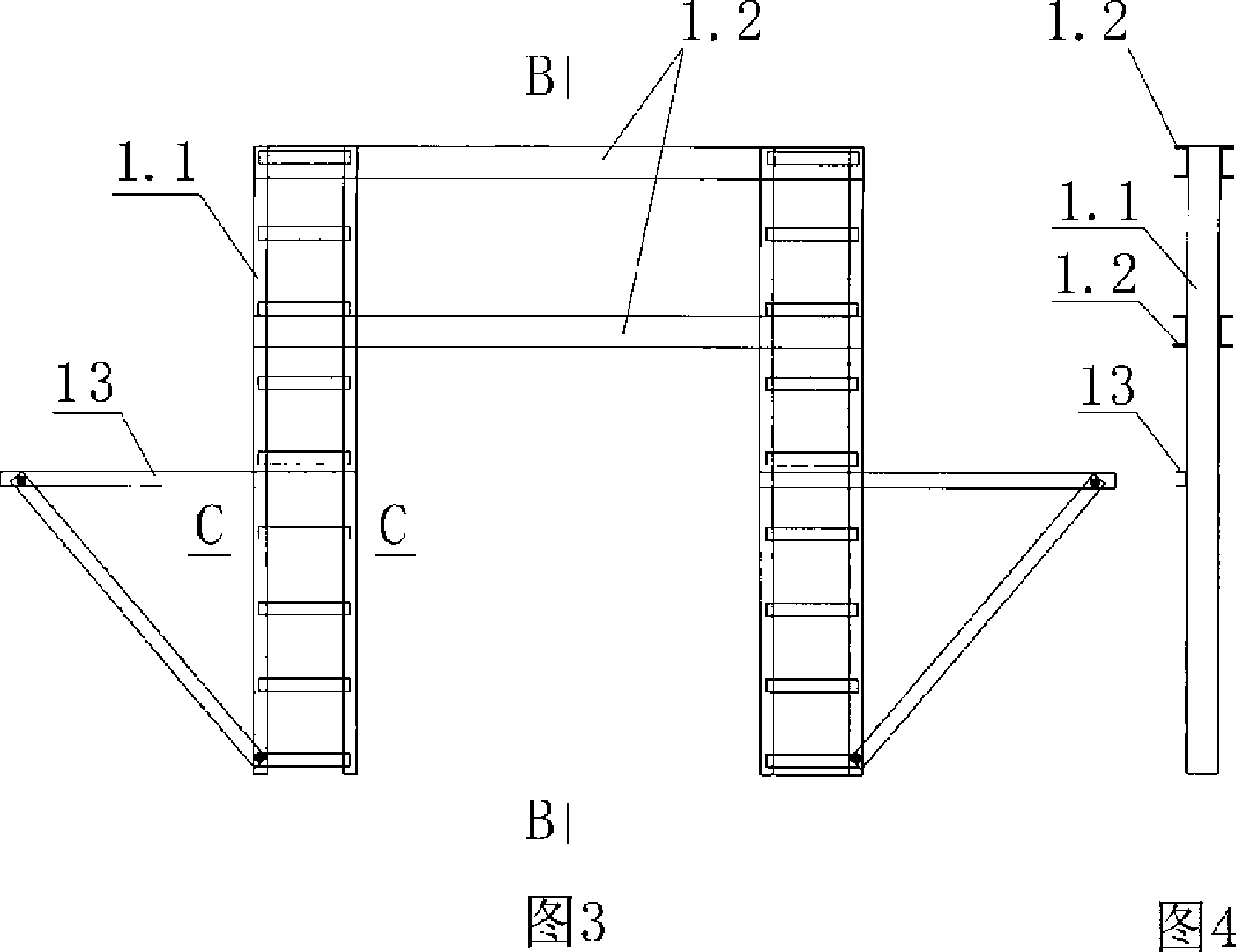

[0051]Referring to Figures 3-5, the sliding-form device is connected by two longitudinal columns 1.1 of lifting frame and two horizontal rows of lifting frame beams 1.2 to form an open-shaped sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com