Overall lifting construction method of large complex composite structure steel roof

A combined structure, overall improvement technology, applied in the direction of building structure, construction, building materials processing, etc., can solve the problems of high cost of measures, high safety risks, etc., achieve great promotion value, guarantee the construction period and control costs, and expand construction field effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

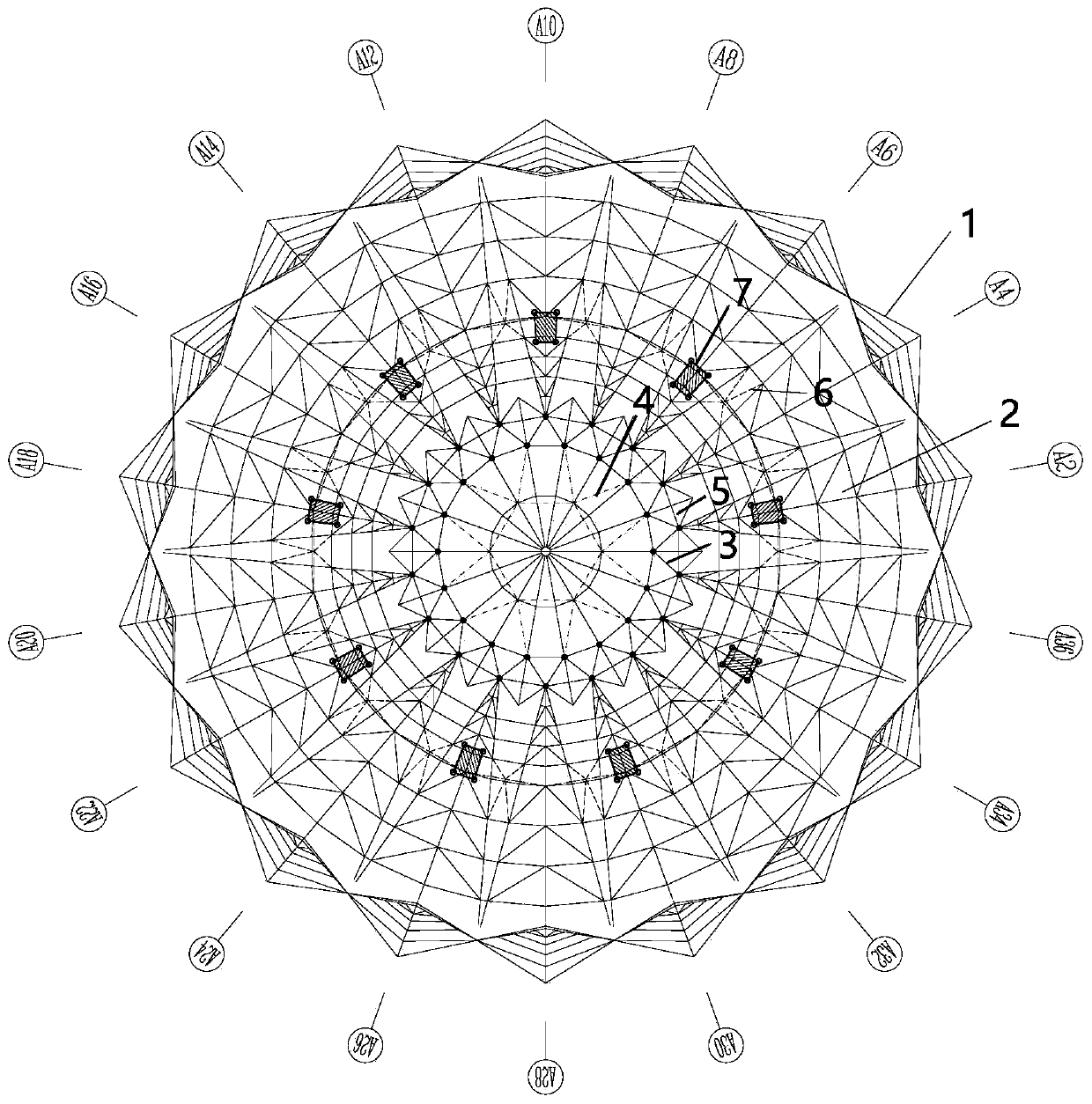

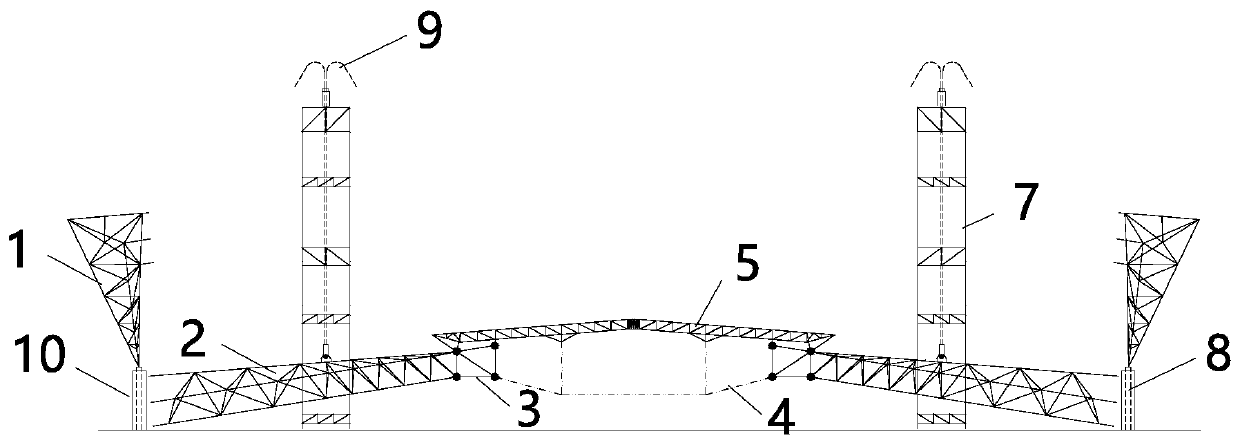

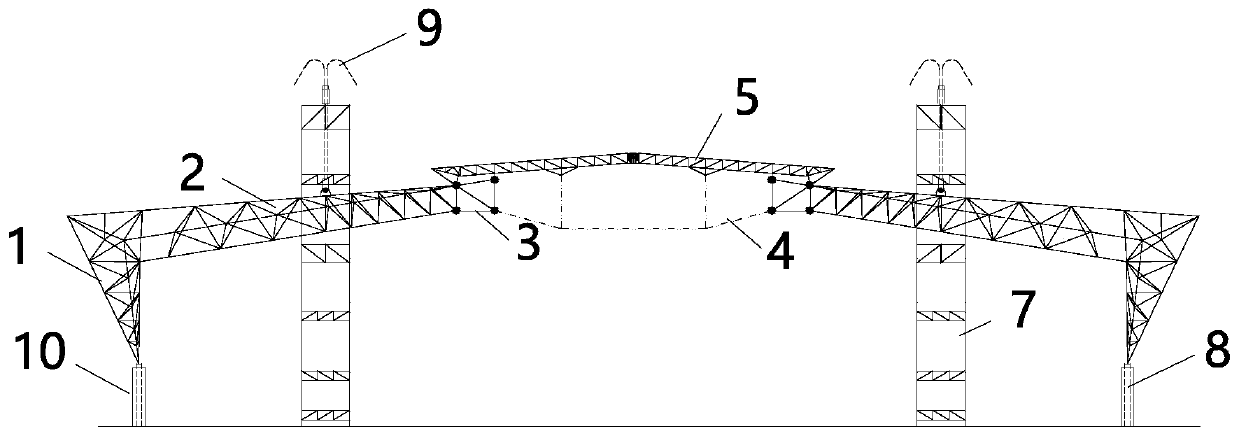

[0029] Refer to the attached drawing, a construction method for the overall lifting of a large-scale complex composite structure steel roof. A lifting bracket 7 is set in the hall, and an H-shaped stiff column 8 is added to the frame column 10 under the truss column support. The truss column 1 adopts the hall External hoisting, the truss beam 3, the ring grid 4, the cable 4 and the secondary roof truss 5 are assembled on the ground in the hall.

[0030] According to the calculation and analysis of the overall lifting conditions, the ring truss 6 must be installed at the lifting point, the lifting bracket 7 is located in the middle of the truss girder chord, and the horizontal connection and lateral support (arrangement of lifting equipment and improvement of the strength and rigidity of the lifting frame) are required during the lifting process. The horizontal support under the parallel and truss beams needs to be removed and replaced;

[0031] After the roof system has been assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com