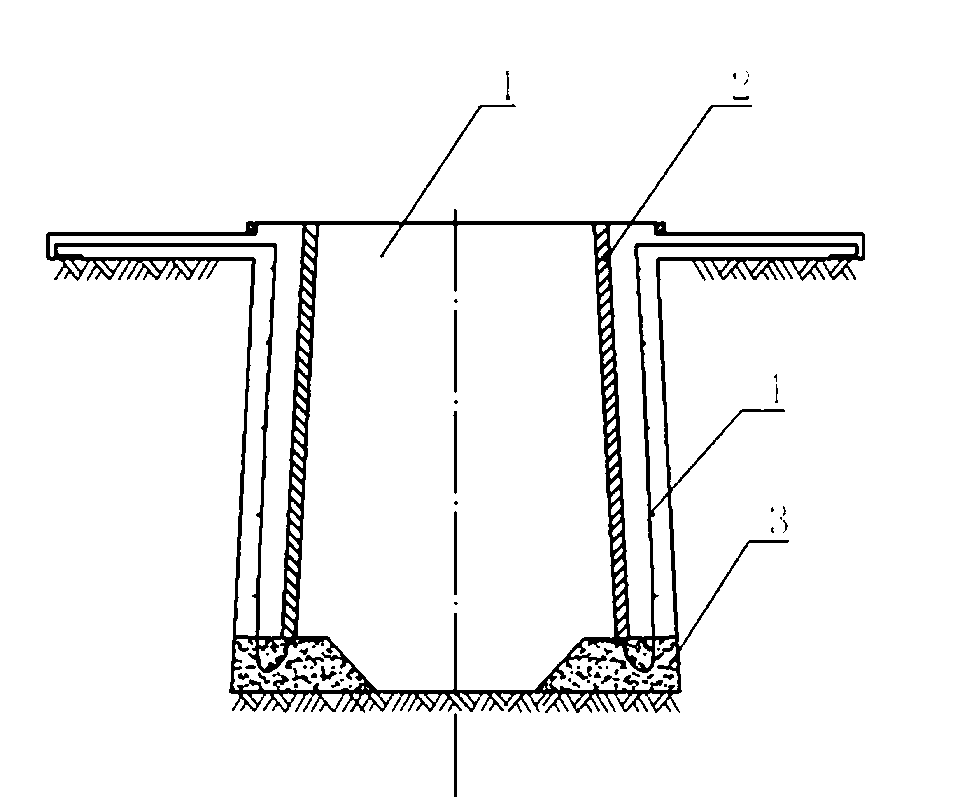

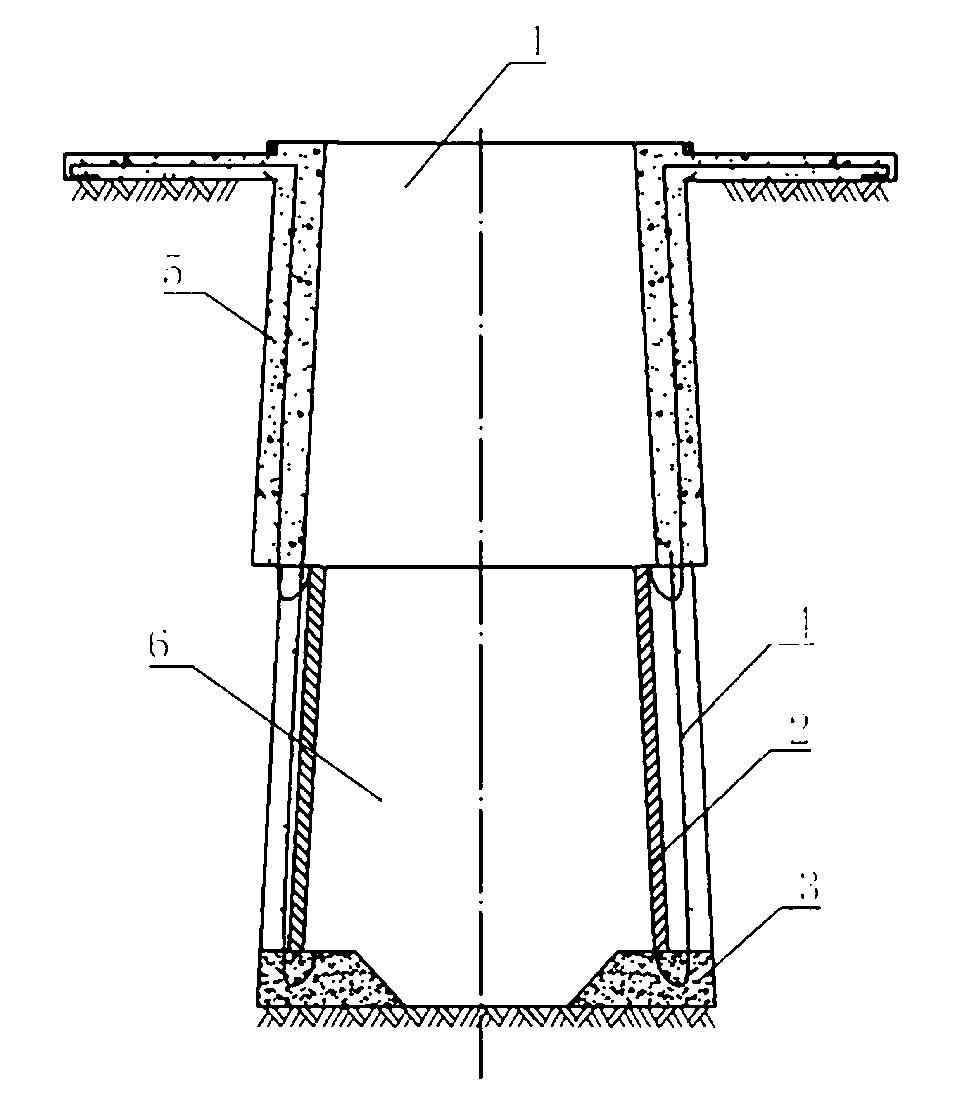

Foundation pit supporting method for manual dig-hole cement-soil steel pile

A technology of manual digging and cement soil, applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve the problems of short working space, unnecessary implementation, low implementation efficiency, etc., and achieve quality assurance, easy implementation, and guaranteed construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Project Overview

[0020] The proposed project is located in the yard of a certain unit on Yongdian Road, Haidian District, Beijing. This time it is mainly the foundation pit excavation and support plan for Building No. 76 (7 floors above ground and 2 floors below ground). The foundation depth is about 8.8m.

[0021] Engineering geological conditions

[0022] According to the "Geotechnical Engineering Survey Report of Radar and Optical Target Characteristic Laboratory Building and Large Target Characteristic Laboratory" provided by Beijing Aerospace Survey and Design Research Institute. The foundation of the original factory building has an independent underground concrete foundation with a buried depth of about 4.1m. ① The first layer of miscellaneous fill is mainly brick ash and slag.

[0023] ② layer of sandy silt, clayey silt, partly mixed pebble gravel, particle size 2~4cm. This layer is partially missing, and it can be seen that the layer thickness is 0.4~2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com