Positioning pile-driving guide frame and construction method thereof

A construction method and guide frame technology, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of inaccurate positioning of inclined piles, difficult construction, low efficiency, etc., so as to improve construction efficiency, high construction efficiency, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

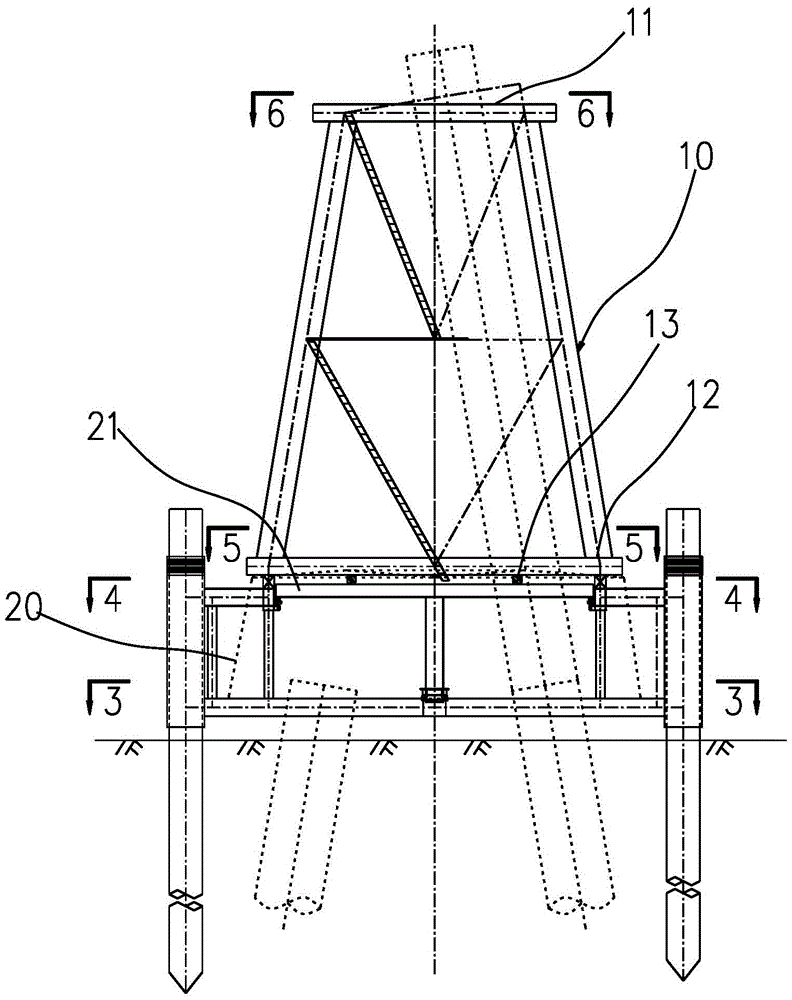

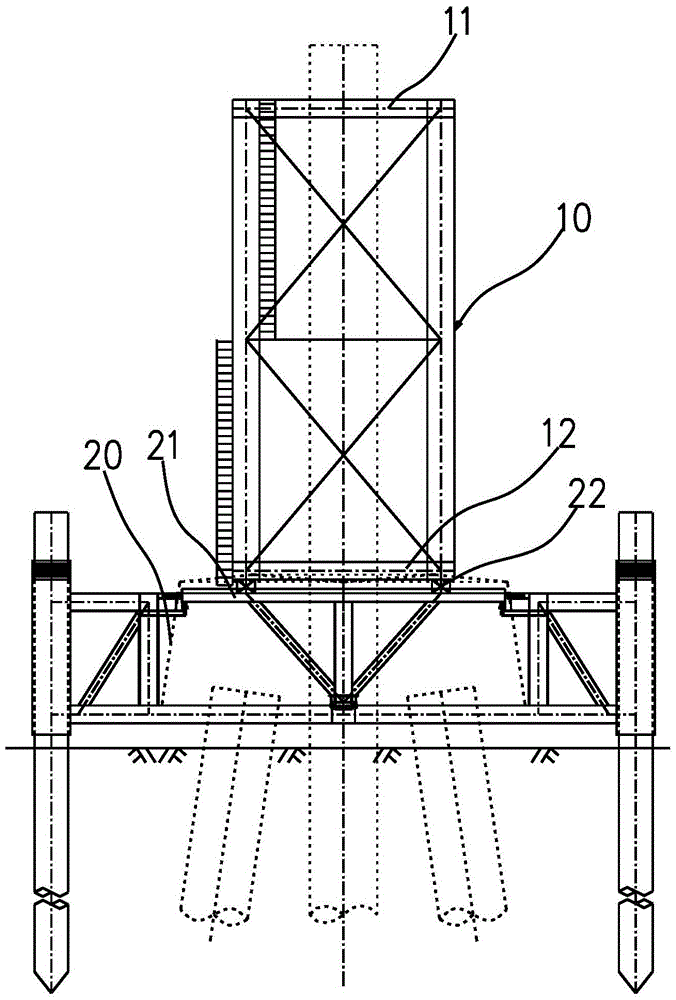

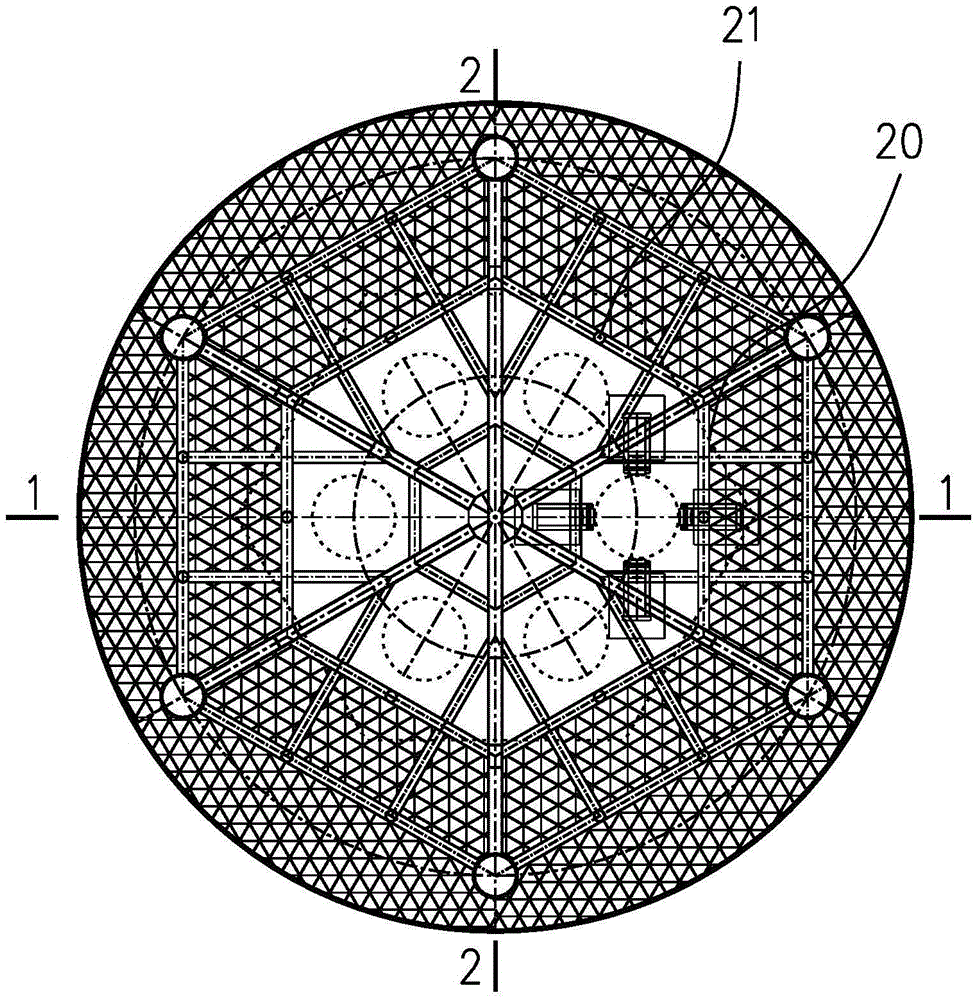

[0041] see Figures 1 to 8 As shown, the embodiment of the present invention provides a positioning piling guide frame, including a frame 10, a construction platform turntable 20 for driving the frame 10 to rotate, an upper platform 11 and a lower platform 12 are respectively arranged at the upper and lower ends of the frame 10 , the upper platform 11 and the lower platform 12 are provided with pile holders 14,

[0042] The pile holder 14 located on the upper platform 11, that is, the abdominal center of the upper pile holder coincides with the central axis of the frame 10 within a certain range, and is used for fixed-point hoisting of floating cranes;

[0043] The pile holding device 14 located on the lower platform 12, that is, a telescopic oil cylinder is arranged between the lower pile holding device and the lower platform 12, and the tel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com