Construction method of digging and conveying earth of deep foundation pit through current scour

A construction method and deep foundation pit technology, which is applied in excavation, infrastructure engineering, construction, etc., can solve the problems of restricting the passage of large earth-moving vehicles, flying dust from large-scale earth-moving vehicles, and affecting the normal life of surrounding residents, so as to achieve safety, Resolving downtime issues and reducing impact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

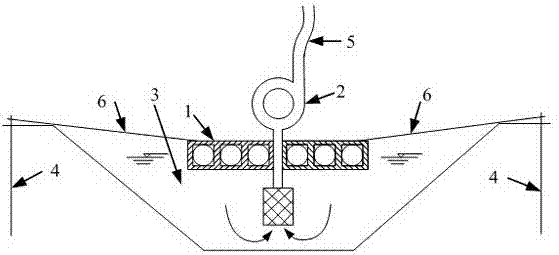

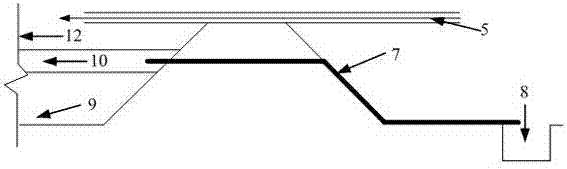

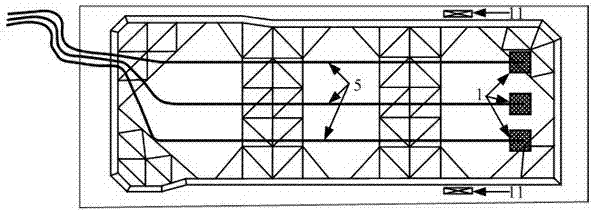

[0028] Below in conjunction with accompanying drawing, the present invention will be further described:

[0029] The principle of the present invention is an earthwork construction method that uses water flow to excavate and transport earth, that is, water flows through a high-pressure water pump and is sprayed out through a water gun to form a dense high-speed water column to cut and crush the soil to make it Wet and disintegrate to form a mixture of mud and mud, which is then transported to the spoil area by mud pumps and mud pipes, and settles in the spoil area, and the clear water after sedimentation is discharged or recycled.

[0030] The construction process of the present invention is: foundation pit support and division - excavation of mud suction tank - installation of mud pump - installation of high pressure water pump and water supply tank - excavation of spoil area - installation of mud pipe and intermediate pressurization equipment - water flushing The soil is fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com